OPERATOR’S MANUAL Form No.

909879

418T Wheel Loader

GEHL CONSTRUCTION WARRANTY

GEHL CONSTRUCTION DIVISION of the GEHL COMPANY, hereinafter referred to as Gehl, warrants new Gehl construction equipment to the Original Retail Purchaser to be free from defects in material and workmanship for a period of twelve (12) months from the Warranty

Start Date:

GEHL CONSTRUCTION WARRANTY INCLUDES:

Genuine Gehl parts and labor costs required to repair or replace equipment at the selling dealer’s business location.

GEHL MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED (INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE), EXCEPT AS EXPRESSLY STATED IN THIS WARRANTY STATEMENT.

GEHL WARRANTY SERVICE DOES NOT INCLUDE:

1.Transportation to selling dealer’s business location or, at the option of the Original Retail Purchaser, the cost of a service call.

2.Used equipment.

3.Components covered by their own non-Gehl warranties, such as tires, trade accessories and engines.

4.Normal maintenance service and expendable, high wear items.

5.Repairs or adjustments caused by: improper use; failure to follow recommended maintenance procedures; use of unauthorized attachments; accident or other casualty.

6.Liability for incidental or consequential damages of any type, including, but not limited to lost profits or expenses of acquiring replacement equipment.

No agent, employee or representative of Gehl has any authority to bind Gehl to any warranty except as specifically set forth herein. Any of these limitations excluded by local law shall be deemed deleted from this warranty; all other terms will continue to apply.

Thecompletedocumentationconsistsof:

Description

Partnumber

Operator’sManual909879

Operator’sManual(Engine)

Sparepartscatalogue909880

Legend

Edition Issued

ASeptember2002

©Copyright–2002GehlCompany

PrintedintheUnitedStatesofAmerica

Allrightsreserved

Nopartofthispublicationmaybereproduced,translatedorusedinanyformorbyanymeans–graphic,electronic ormechanicalincludingphotocopying,recording,tapingor informationstorageorretrievalsystems–withoutprior permissioninwriting.

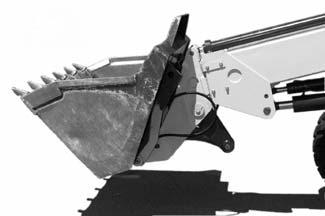

Thecoverfeaturesthemachinewithpossibleoptionalequipment.

GehlCompany

P.O.Box179

WestBend,WI53095U.S.A.

Document:909879

Partno.:909879

Edition:A

Tableofcontents

AP0902 I-1

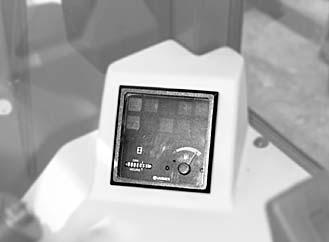

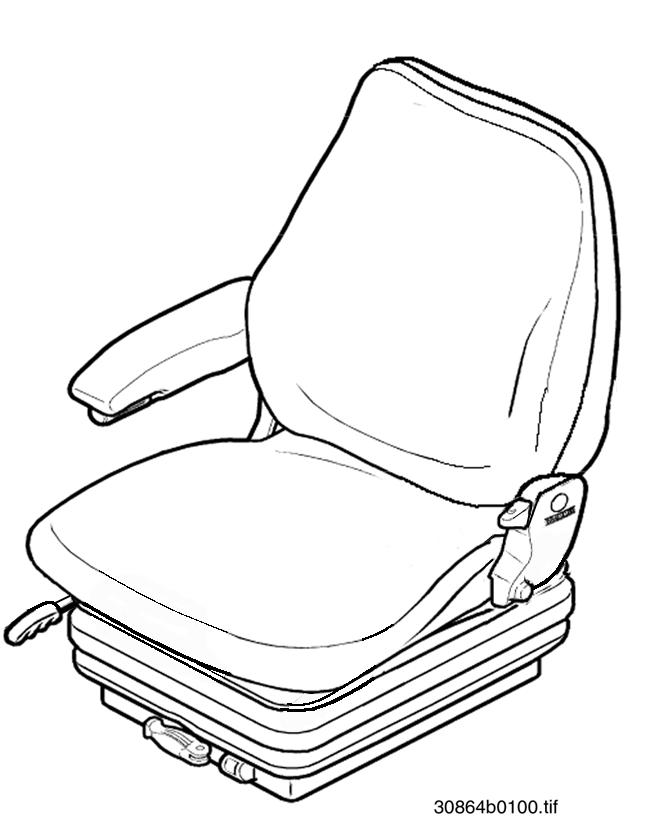

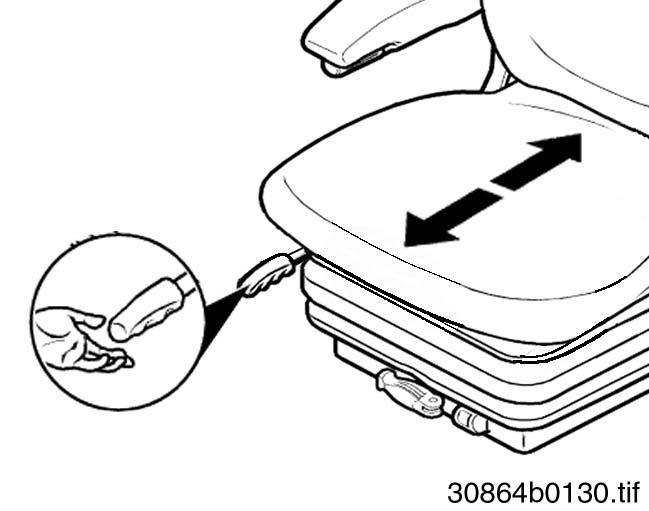

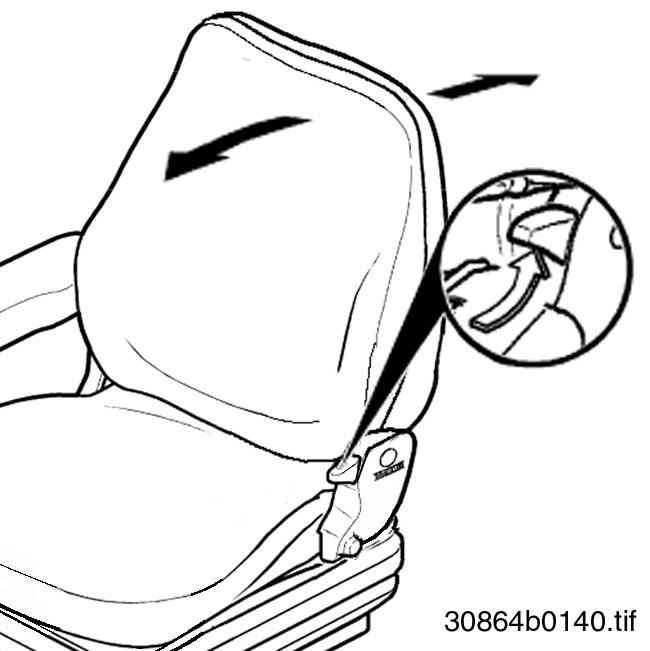

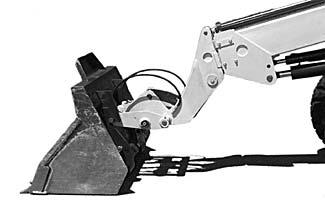

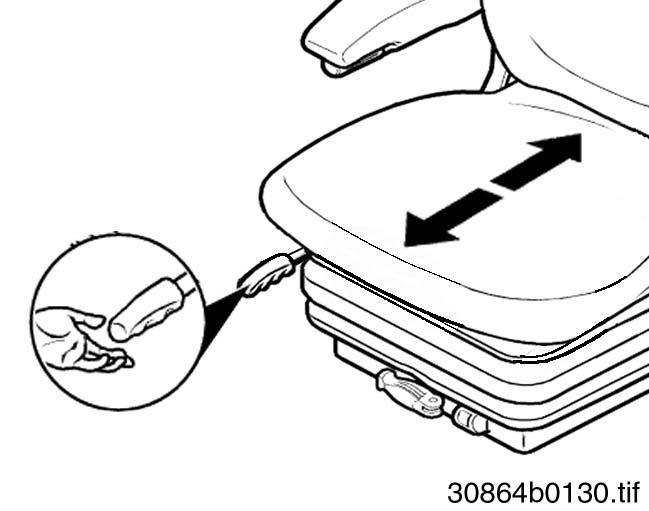

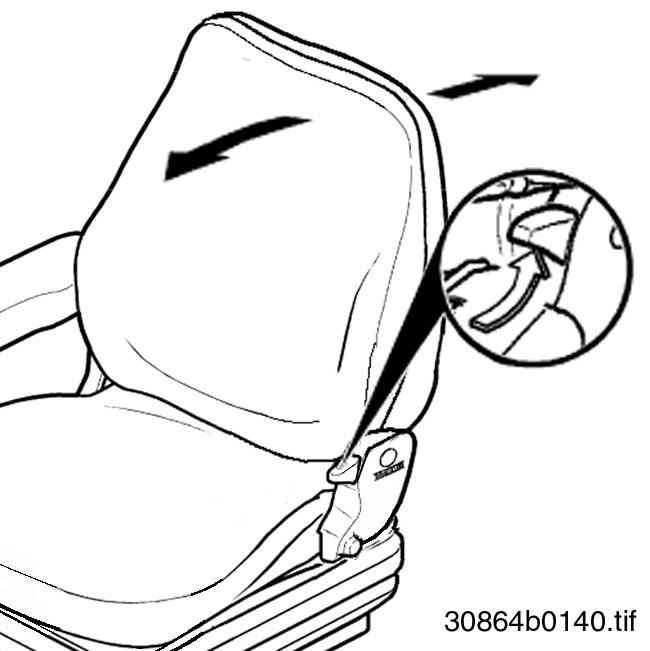

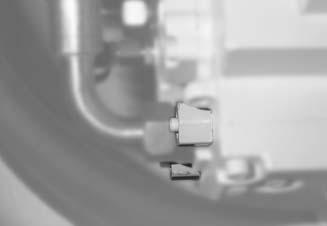

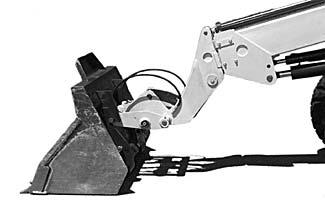

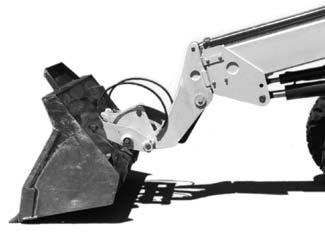

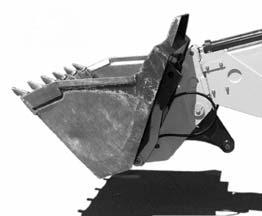

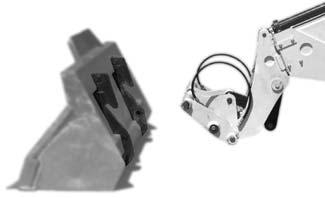

Introduction Introduction....................................................................................................................1-1 Notesonthisoperator’smanual.............................................................................1-1 Machine:Overview...................................................................................................1-2 Briefdescription........................................................................................................1-3 Applications..............................................................................................................1-4 Regulations...............................................................................................................1-5 Machinedata............................................................................................................1-6 Typelabelsandcomponentnumbers.......................................................................1-7 Safetysignsandsymbols.......................................................................................1-8 Safetyinstructions Safetyinstructions..........................................................................................................2-1 Identificationofwarningsanddangers...................................................................2-1 Designateduses.......................................................................................................2-2 Generalconductandsafetyinstructions...................................................................2-3 Safetyinstructionsregardingoperation....................................................................2-5 Safetyinstructionsforserviceandmaintenance......................................................2-9 Warningofspecialhazards...................................................................................2-11 Operation Operation.......................................................................................................................3-1 Overviewofcab.......................................................................................................3-2 Overview:Multifunctionalleverandconsoles.........................................................3-4 Placingintoservice..................................................................................................3-5 Safetyinstructions.............................................................................................3-5 Placingthemachineintoserviceforthefirsttime.............................................3-5 Checklists..........................................................................................................3-6 Drivingthemachine..................................................................................................3-8 Overviewofcontrols:........................................................................................3-8 WarningLights:overview................................................................................3-13 Beforestartingtheengine...............................................................................3-16 Startingtheengine..........................................................................................3-16 Beforedrivingthemachine...............................................................................3-20 Driving.............................................................................................................3-22 Driveranges.....................................................................................................3-23 Differentiallock.................................................................................................3-25 Stoppingthemachine......................................................................................3-25 Parkingthemachine.........................................................................................3-26 Lightsystem.....................................................................................................3-27 Signallingsystem..............................................................................................3-28 Cabheatingandventilation..............................................................................3-29 Windowwashsystem.......................................................................................3-30 Seatadjustment................................................................................................3-31 Seatbelt...........................................................................................................3-33 Driver'sdoorandsidewindow..........................................................................3-35 Othercontrols...................................................................................................3-38 Towingandtransportingthemachine..............................................................3-39 Workingwiththemachine......................................................................................3-42 Generalsafetyinstructions..............................................................................3-42 Loaddiagram...................................................................................................3-42 Safeloadindicator............................................................................................3-43 Controlvalveforthetelescopicunit:overview.................................................3-45 Tableofcontents

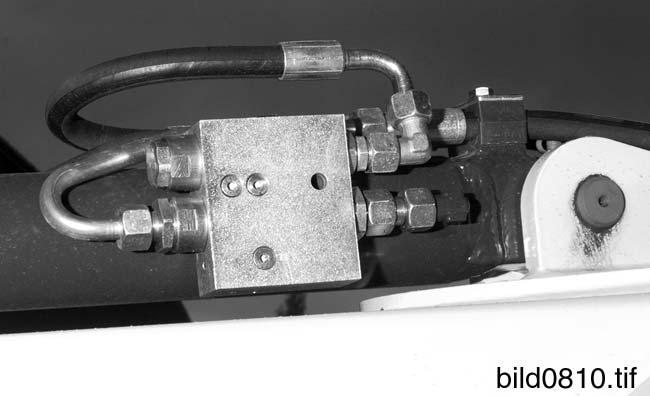

I-2 AP0902 Tableofcontents Loweringthetelescopicunitwiththeengineswitchedoff................................3-47 Relievingpressurethequickcouplersonthetelescopicunit.........................3-47 Installinganattachment...................................................................................3-48 Connectingpressurizedquickcouplers...........................................................3-51 Operationofthetelescopicunit........................................................................3-53 Safetydevice“Hoseburstvalve“......................................................................3-55 Workingwithstandardbucketandpalletforks.................................................3-58 Workingwithpalletforks...................................................................................3-66 Troubleshooting Troubleshooting.............................................................................................................4-1 Enginetrouble..........................................................................................................4-2 Possiblecausesformalfunctions.......................................................................4-3 Maintenance Maintenance...................................................................................................................5-1 Introduction..............................................................................................................5-1 Fuelsystem..............................................................................................................5-1 Specificsafetyinstructions................................................................................5-1 Refuelling............................................................................................................5-2 Cleaningthefueltank........................................................................................5-3 Changingthefuelfilter........................................................................................5-4 Cleaningthefuel/waterseparator.......................................................................5-5 Bleedingthefuelsystem.....................................................................................5-6 Enginelubricationsystem.........................................................................................5-7 Checkingtheengineoillevel.............................................................................5-7 Toppinguptheengineoil..................................................................................5-7 Changingtheengineoil......................................................................................5-8 Changingtheengineoilfiltercartridge...............................................................5-9 Engineandhydraulicscoolingsystem....................................................................5-10 Specificsafetyinstructions..............................................................................5-10 Checkingthecoolantlevel/toppingupthecoolantlevel..................................5-11 Cleaningthecoolingfins..................................................................................5-12 Airfilter...................................................................................................................5-13 V-belt.......................................................................................................................5-15 CheckingtheV-belttension.............................................................................5-15 Re-tensioningtheV-belt..................................................................................5-15 Hydraulicsystem.....................................................................................................5-16 Specificsafetyinstructions..............................................................................5-16 Checkingthehydraulicoillevel.......................................................................5-16 Toppingupthehydraulicoil..............................................................................5-17 Changingthehydraulicoil...............................................................................5-17 Hydraulicoilreturnfilter....................................................................................5-20 Replacingthebreatherfilter.............................................................................5-21 Hydraulicpressurelines..................................................................................5-21 Gearboxesandaxles.............................................................................................5-22 Rearaxletransfergearbox..............................................................................5-22 Frontandrearaxledifferentials........................................................................5-24 Frontandrearaxleplanetarydrives................................................................5-25 Lubricatingtherearaxleoscillation-typebearing.............................................5-26

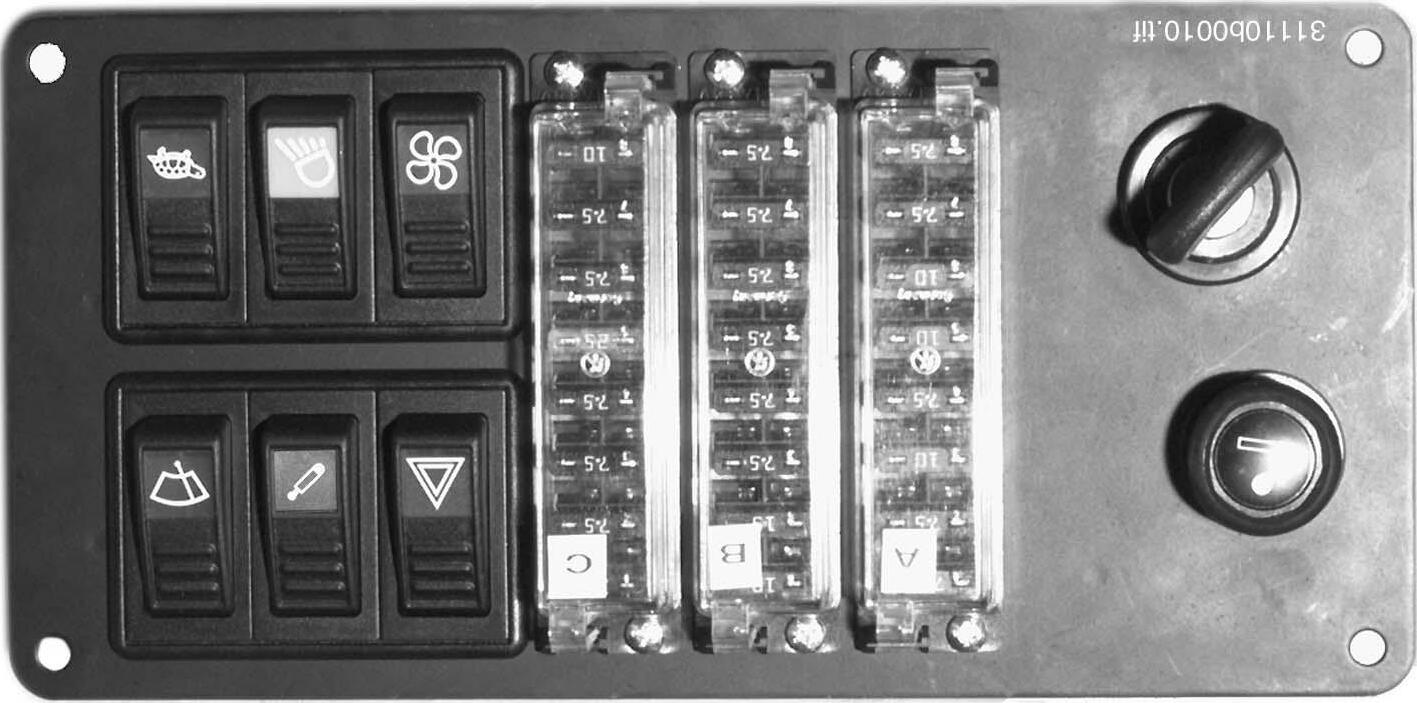

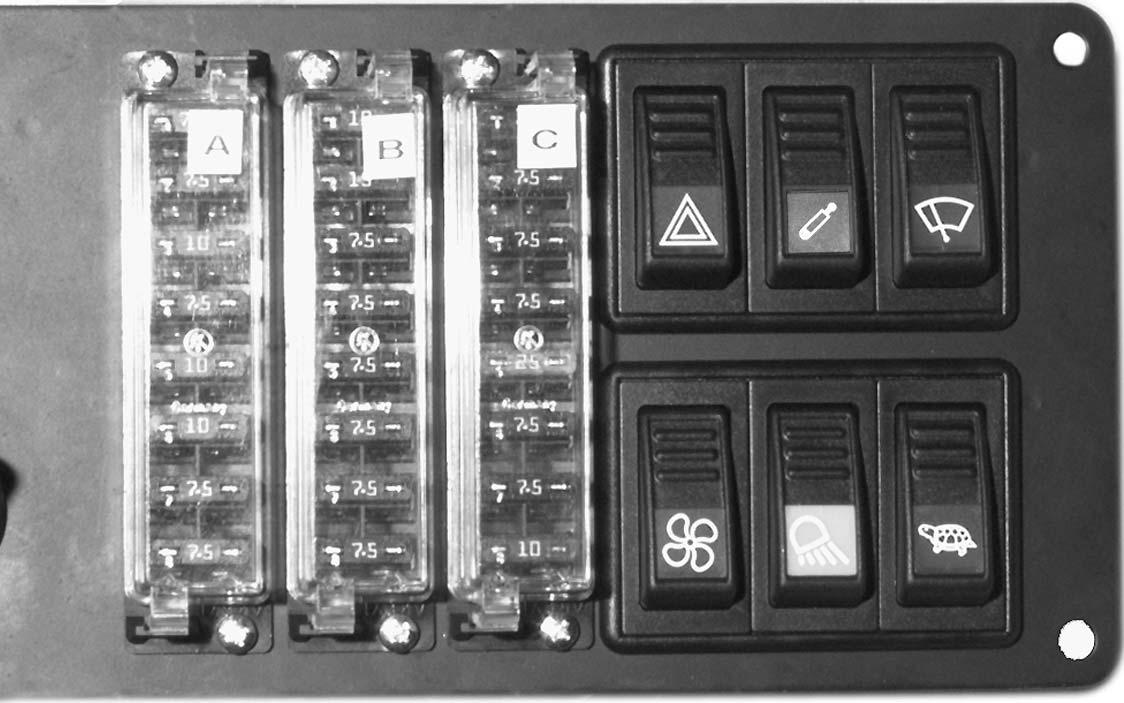

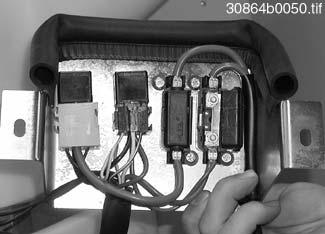

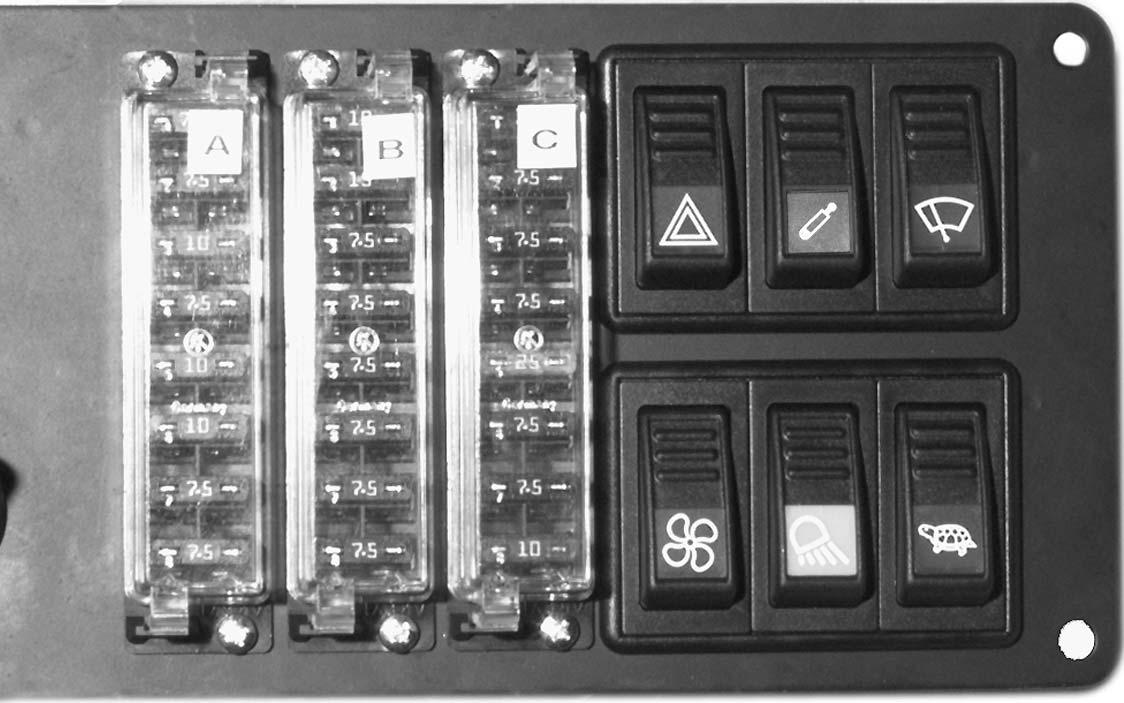

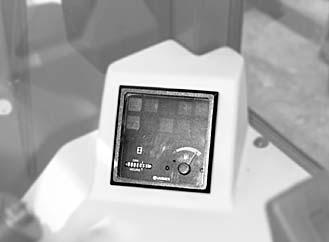

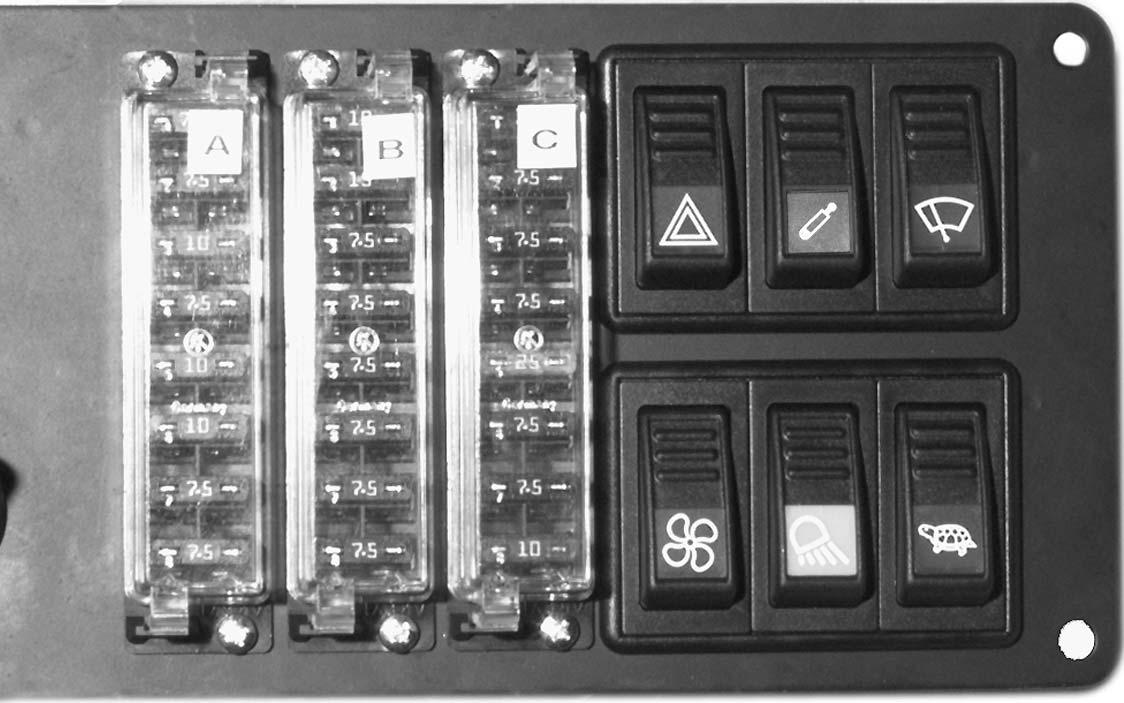

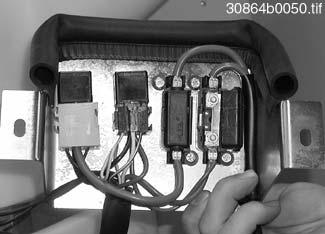

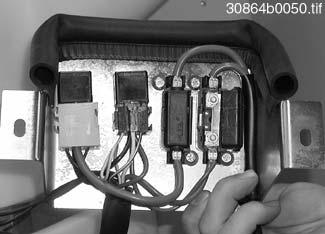

AP0902 I-3 Tableofcontents Maintenanceofthebrakesystem...........................................................................5-27 Specificsafetyinstructions..............................................................................5-27 Checking/toppingupbrakefluid......................................................................5-27 Telescopicunit........................................................................................................5-28 Lubricatingthepivotpointsofthetelescopicunit............................................5-28 Lubricatingthetelescopicunit.........................................................................5-28 Adjustingthewearpads...................................................................................5-29 Tirecare.................................................................................................................5-30 Inspectionwork................................................................................................5-30 Wheelchange...................................................................................................5-31 Heating...................................................................................................................5-32 Cleaningthedustfilteroftheheatingsystem..................................................5-32 Electricalsystem.....................................................................................................5-33 Specificsafetyinstructions..............................................................................5-33 Serviceandmaintenanceworkatregularintervals.........................................5-33 Instructionsconcerningspecificcomponents...................................................5-34 Generalmaintenancework.....................................................................................5-36 Cleaning..........................................................................................................5-36 Boltedconnections...........................................................................................5-38 Pivotsandhinges............................................................................................5-38 Enginefluidsandlubricants..................................................................................5-39 Maintenancekits....................................................................................................5-40 Helpfulinformationforusingtheservicepartslist Helpfulinformationforusingtheservicepartslist.........................................................6-1 Introduction..............................................................................................................6-1 Compositionofservicepartslist..............................................................................6-1 Groups...............................................................................................................6-1 Groupoverview..................................................................................................6-2 Figures................................................................................................................6-3 Numberindex....................................................................................................6-3 Symbolsandabbreviations......................................................................................6-4 Descriptionofsymbols......................................................................................6-4 Abbreviations......................................................................................................6-6 Machinedata...........................................................................................................6-6 Helpfulinformationfororderingserviceparts...........................................................6-7 Orderinformation...............................................................................................6-7 Addressforyourservicepartorder....................................................................6-8 Specifications Specifications................................................................................................................. 7-1 Frame......................................................................................................................7-1 Engine.....................................................................................................................7-1 Powertrain...............................................................................................................7-2 Axles.......................................................................................................................7-2 Brakes.....................................................................................................................7-3 Steering..................................................................................................................7-3 Workhydraulics......................................................................................................7-3 Telescopicunit........................................................................................................7-4 Electricalsystem......................................................................................................7-5 Fuseboxesinsideconsole...............................................................................7-5 Mainfusesinenginecompartment....................................................................7-6 Relays................................................................................................................7-6 Tires.......................................................................................................................... 7-7

I-4 AP0902 Tableofcontents Weights...................................................................................................................7-7 Noiselevels.............................................................................................................7-7 Vibration...................................................................................................................7-8 Dimensions.............................................................................................................7-8 Coolanttable.............................................................................................................7-9 Tighteningtorques...................................................................................................7-9 Generaltighteningtorques................................................................................7-9 Specifictighteningtorques................................................................................7-9 Conversiontables..................................................................................................7-10 Conversionfactors...........................................................................................7-10 Specificconvertedvalues................................................................................7-11 Annex Proofsofmaintenance..................................................................................................A-1 Maintenanceplanmodel418T(overview)....................................................................A-3 Maintenanceplanmodel 418T(maintenancelabel).............................................................................................A-5 Explanationofsymbolsusedinmaintenanceplan..................................................A-5 Legendforhydraulicsdiagram, model418T ❙➜ 418T0001.....................................................................................A-6 Hydraulicsdiagrammodel418T...................................................................................A-7 Electricaldiagram418T................................................................................................A-9

Fuelsystem....................................................................................5-1

Gearboxesandaxles...................................................................5-22

Generalmaintenancework..........................................................5-36

Heating.........................................................................................5-32

Hydraulicoilreturnfilter................................................................5-20

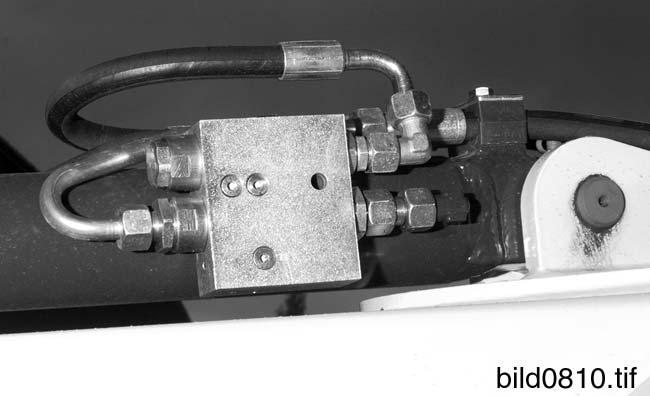

Hydraulicpressurelines...............................................................5-21

Hydraulicsystem..........................................................................5-16

Instructionsconcerningspecificcomponents...............................5-34

Lubricatingtheoscillation-typebearing........................................5-26

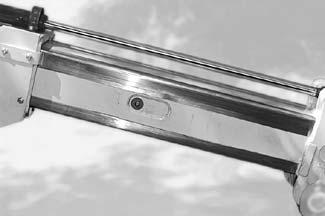

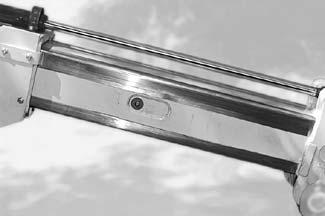

Lubricatingthetelescopicunit......................................................5-28

Maintenanceplan...........................................................................A-3 Pivotsandhinges.........................................................................5-38

Planetarydrives............................................................................5-25

Proofsofmaintenance...................................................................A-1

Replacingthefillerandbreatherfiltersonthehydraulicoiltank..5-21

Screwconnections.......................................................................5-38

Serviceandmaintenanceworkatregularintervals......................5-33 Telescopicunit.............................................................................5-28

Toppingupthe

Coolantlevel......................................................................5-11

Engineoil.............................................................................5-7

Hydraulicoil.......................................................................5-17

Transfergearbox..........................................................................5-22

Tirecare.......................................................................................5-30

V-belt............................................................................................5-15

Wheelchange..............................................................................5-31

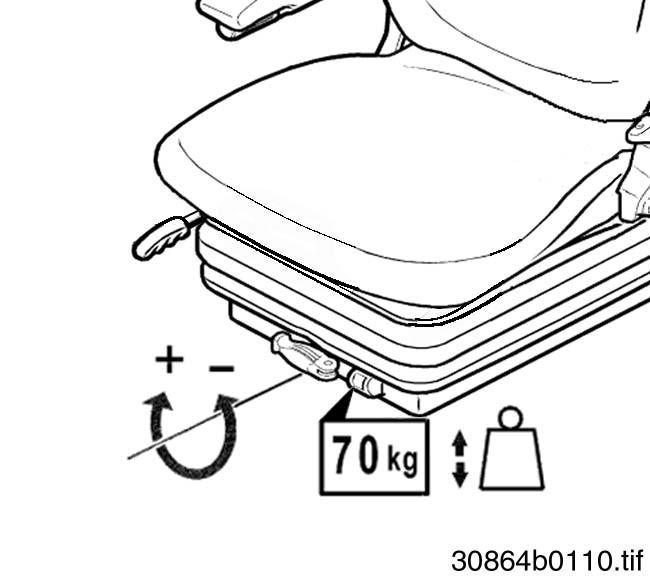

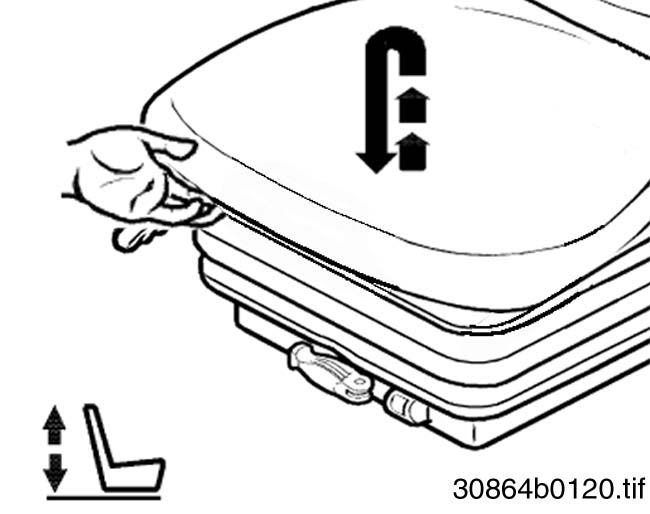

AP0902 I-5 Index A Abbreviations.........................................................................................1-1 Acceleratorpedal...................................................................................3-9 Applications Attachments....................................................................................1-4 B Backupwarningsystem(option)..........................................................3-24 Biodegradableoil.................................................................................5-19 Brakeinchingpedal...............................................................................3-9 Brakesystem.......................................................................................5-27 Brakefluid.....................................................................................5-27 Safetyinstructions.........................................................................5-27 C Changingdirection...............................................................................3-24 Changingdirection,Tipswitchfor........................................................3-24 Checklists..............................................................................................3-6 Controlelements....................................................................................3-8 Controlleverforattachmentsand3rdcontrolcircuit...........................3-46 Conversionfactors...............................................................................7-10 Convertedvalues.................................................................................7-11 D Designateduseandexemptionfromliability.........................................2-2 Differentiallock....................................................................................3-25 Documents.............................................................................................1-5 Drivingdirectionselectorswitch............................................................3-8 Drivinglicence.......................................................................................1-5 Drivingonpublicroads........................................................................3-20 Drivingthemachine...............................................................................3-8 Dustfilter..............................................................................................5-32 E Electricaldiagram.................................................................................A-9 Enginecoolantpreheater(option).......................................................3-18 Enginepreheater(option)....................................................................3-18 Equipmentofthemachine.....................................................................1-5 F Fieldsofapplication Possibleattachments......................................................................1-4 Fuellevelindicator...............................................................................3-15 Fuelpreheater(option)........................................................................3-18 G Generalconduct....................................................................................2-3 H Hazardwarningsystem.......................................................................3-28 Heating................................................................................................3-29 Highbeam...........................................................................................3-27 Hydraulicoilpreheater(option)............................................................3-18 J Jump-startingtheengine.....................................................................3-19 L Lightsystem.........................................................................................3-27 Loaddiagram.............................................................................1-12,3-42 Loaderunit Checkingthetiltpositionofthebucket.........................................3-58 Lockfordrivingonpublicroads...........................................................3-46 Loweringthetelescopicunitwiththeengineswitchedoff...................3-47 M Machine Briefdescription..............................................................................1-3 Data................................................................................................1-7 Fieldsofapplication........................................................................1-4 Overview........................................................................................1-2 Machineinspections..............................................................................1-5 Maintenance Airfilter.........................................................................................5-13 Biodegradableoil..........................................................................5-19 Bleedingthefuelsystem................................................................5-6 Brakesystem................................................................................5-27 Changingthe Engineoil.............................................................................5-8 Engineoilfiltercartridge......................................................5-9 Fuelfilter..............................................................................5-4 Hydraulicoil.......................................................................5-17 Checkingthe Coolantlevel......................................................................5-11 Engineoillevel.....................................................................5-7 Hydraulicoillevel...............................................................5-16 Cleaning.......................................................................................5-36 Cleaningthe Fueltank..............................................................................5-3 Cleaningthecoolingribs..............................................................5-12 Cleaningthefuel/waterseparator..................................................5-5 Differentials..................................................................................5-24 Electricaldiagram...........................................................................A-9 Electricalsystem..........................................................................5-33 Engineandhydraulicscoolingsystem.........................................5-10 Enginelubricationsystem..............................................................5-7

Index I

I-6 AP0902 Index

Multifunctionallever.............................................................................3-11 O Operation...............................................................................................3-1

Beforemovingoff..........................................................................3-20 Beforestartingtheengine.............................................................3-16 Changingdirection........................................................................3-24 Driveranges.................................................................................3-23

Parkingthemachine.....................................................................3-26

Startingtheengine........................................................................3-16 Stoppingthemachine...................................................................3-25 Operationmanual Notes..............................................................................................1-1 P Palletforks...........................................................................................3-66 Approachingthematerial..............................................................3-66 Loadingthematerial.....................................................................3-67 Safetyinstructions........................................................................3-66 Settingdownthematerial.............................................................3-68 Parkingbrake.......................................................................................3-10 Preheatingstartswitch..........................................................................3-8 R Refuelling...............................................................................................5-2 Regulations............................................................................................1-5 Rotatingbeacon(option).....................................................................3-28 Running-inperiod..................................................................................3-5 S Safeloadindicator...............................................................................3-43 Adjustingsignalvolume................................................................3-44 Overview.......................................................................................3-43 Whattodoif.................................................................................3-44 Safetyinstructions.................................................................................2-1 Identification....................................................................................2-1 Operation........................................................................................2-6 Specialhazards............................................................................2-13 Seatadjustment...................................................................................3-31 Armrestsetting..............................................................................3-32 Backrestsetting............................................................................3-32 Heightsetting................................................................................3-31 Longitudinalsetting.......................................................................3-32 Weightsetting...............................................................................3-31 Seatbelt...............................................................................................3-33 Servicebrake.......................................................................................3-22 Signallingsystem.................................................................................3-28 Signsandsymbols.................................................................................1-9 Specifications.........................................................................................7-1 Axles...............................................................................................7-2 Brakes.............................................................................................7-3 Conversionfactors........................................................................7-10 Coolantcompoundtable.................................................................7-9 Dimensions.....................................................................................7-8 Electricalsystem.............................................................................7-5 Engine.............................................................................................7-1 Frame.............................................................................................7-1 Noiselevels....................................................................................7-7 Powertrain.....................................................................................7-2 Specificconvertedvalues.............................................................7-11 Steering..........................................................................................7-3 Telescopicunit...............................................................................7-4 Tighteningtorques..........................................................................7-9 Tires...............................................................................................7-7 Vibration.........................................................................................7-8 Weights..........................................................................................7-7 Workhydraulics..............................................................................7-3 Startingwithstartingaid......................................................................3-24 Steering...............................................................................................3-21 Symbols................................................................................................1-1 T Takingintoservice................................................................................3-5 Checklists.......................................................................................3-6 Overviewofthecontrolelements...................................................3-8 Safetyinstructions..........................................................................3-5 Takingthemachineintoserviceforthefirsttime...........................3-5 Telescopicunit Checkingthetransportpositionofthebucket..............................3-58 Depressurizingthequickcouplersonthetelescopicunit.............3-47 Loweringthetelescopicunitwiththeengineswitchedoff............3-47 Lubrication....................................................................................5-28 Re-equippingthetelescopicunit..................................................3-48 WarningLights....................................................................................3-13 Towingandtransportingthemachine.................................................3-39 Transportingwithafullbucket............................................................3-59 Turnindicators....................................................................................3-28 Typelabelsandcomponentnumbers...................................................1-8 Tirecare..............................................................................................5-30 Tireinflationpressuretable.................................................................1-11 Tires......................................................................................................7-7 V Ventilation...........................................................................................3-29 Ventilation,freshair......................................................................3-29 W Warningidentification(option)...............................................................1-5 Warranty................................................................................................2-1 Washerpump......................................................................................3-30 Washersystem Tank.............................................................................................3-30 Wheelchange.....................................................................................5-31 Wheelsynchronizationposition...........................................................3-21 Windowwashsystem..........................................................................3-30 Wipers.................................................................................................3-30 Working ...withpalletforks.........................................................................3-66 Approachingthematerial.............................................................3-66 Loadingthematerial.....................................................................3-67 Safetydevice"Hoseburstvalve".................................................3-55 Settingdownthematerial.............................................................3-68 Workinglight(option)..........................................................................3-27 Workingwiththemachine Freeingthemachine.....................................................................3-65 Grading.........................................................................................3-65 Loadingheapedmaterial..............................................................3-64 Loadingloosematerial.................................................................3-60 Practicalhints...............................................................................3-65 Removingmaterial/digginginhardsoil........................................3-63 Removingmaterial/digginginsoftsoil..........................................3-62

Maintenancekits..................................................................................5-40

Backupwarningsystem(option)...................................................3-24

Movingoff.....................................................................................3-22 Overviewofcab..............................................................................3-2 Overviewofinstrumentpanel,multifunctionalanddrivelever........3-4

Selectingdriverange....................................................................3-23

1

Section1 Introduction

1.1Notesonthisoperator’smanual

Thisoperator’smanualcontainsimportantinformationonhowtoworksafely,correctlyand economicallywiththewheelloadermodel418T.Therefore,itaimsnotonlyatnewoperators,butitisalsoareferenceforexperienced ones.Ithelpstoavoiddangeroussituations, andreducerepaircostsanddowntimes.Furthermore,thereliabilityandtheservicelifeof themachinewillbeincreasedbyfollowingtheinstructionsintheoperator’smanual.Thisis whytheoperator’smanual must alwaysbekeptinthemachine.

Yourownsafety,aswellasthesafetyofothers,dependstoagreatextentonhowthe machineismovedandoperated.Therefore,carefullyreadandunderstandthisoperator’s manualpriortothefirstuse.Thisoperator’smanualwillhelptofamiliarizeyourselfmore easilywiththemachine,therebyenablingyoutouseitmoresafelyandefficiently.

GeneralsafetyinstructionsaregiveninPart2ofthisoperator’smanual.Carefullyread andunderstandthempriortothefirstdrive.Asarule,keepthefollowinginmind: Carefulandprudentworkingisthebestwaytoavoidaccidents!

Specialsafetyinstructionswithdirectreferencetoservice,functionandoperator’softhe machinearegivenbeforetheproceduretofollowintherespectivechapters.Thesesafety instructionsmustalwaysbeobservedandfollowed.

Operationalsafetyandreadinessofthemachinedonotonlydependonyourskill,butalso onmaintenanceandserviceofthemachine.Thisiswhyregularmaintenanceandservice workisabsolutelynecessary.Extensivemaintenanceandrepairworkshouldalwaysbe carriedoutbyanexpertwithappropriatetraining.Insistonusingoriginalserviceparts whenperformingmaintenanceandrepairwork.Thisensuresoperationalsafetyandreadinessofyourmachine,andmaintainsitsvalue.

Yourdealerwillbepleasedtoansweranyfurtherquestionsregardingthemachineorthe operator’smanual.

Abbreviations/symbols

• Thissymbolstandsforalist

• Thissymbolstandsforthesubdivisionofanenumerationoranactivity.Followthe stepsintherecommendedsequence.

☞ Thissymbolrequiresyoutocarryouttheactivitydescribed.

➥ Descriptionoftheeffectsorresultsofanactivity.

n.s.=notshown

SO=option

Statedwhenevercontrolsorothercomponentsofthemachineareinstalledasanoption.

Thissymbolshowsthedirectionoftravel–forbetterorientationinfiguresand graphics.

AP0902 1–1 1 1Introduction

Introduction

1–2 AP0902 Introduction 1.2Machine:Overview

308b0070.eps 308b0060.eps

31100b0190.eps

1 Workinglight(option) 2 Dangerlabel 3 Fronteyehooks–liftingandstrappingdownthemachine 4 Wheelchock 5 Horn 6 Mark–telescopicunitpositionforlong-haultravel 7 Accesshandle 8 ProtectiveFOPSscreen 9 Noiseemissionlabel 10 ECsign 11 Maximumdrivingspeedlabel 12 Fuelfillerinlet 13 Drawbarpin 14 Reareyehooks–liftingandstrappingdownthemachine 15 Step 16 Workinglight(option) 17 Turnindicator 18 Headlights 19 Enginecoverlock 20 Label–“Donotopenenginecoverbeforeengineisata standstill!” Donottouchanymovingorturningparts! 21 Brakelight,rearlight,turnindicator 22 Rearviewmirror 2 20 6 8 9 4 5 10 11 13 14 21 21 2 20 11 1 16 22 17 18 17 18 7 15 19 12 22 3 20 14 !

Fig.1:Machineoutsideviews

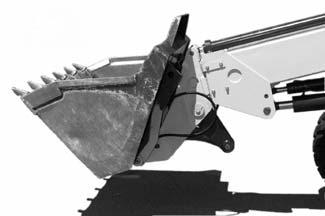

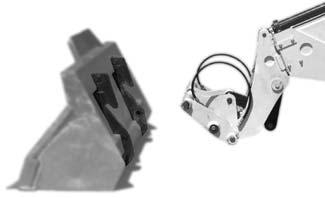

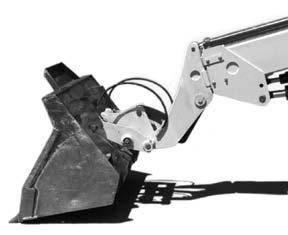

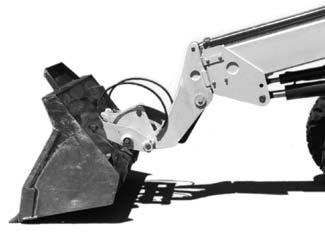

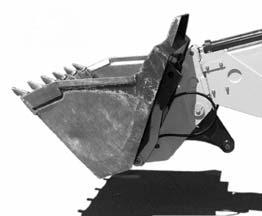

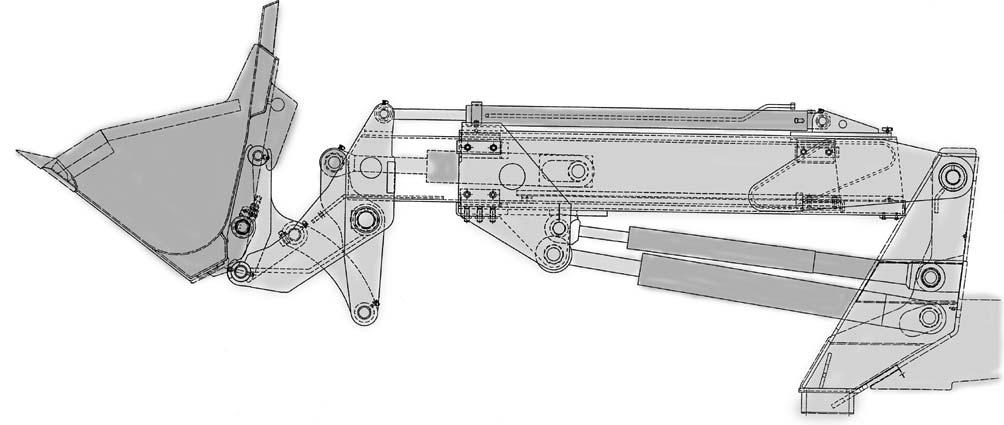

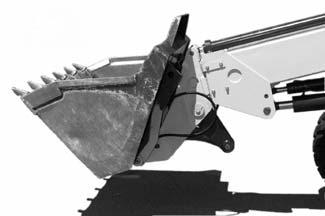

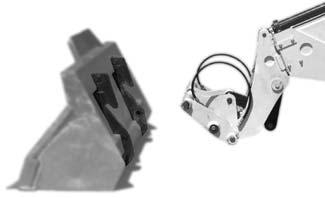

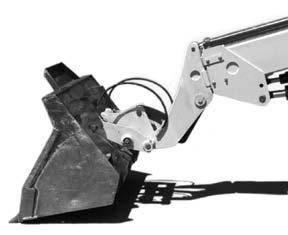

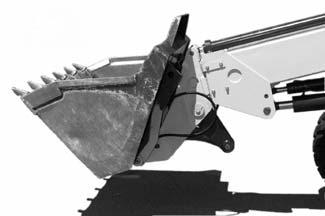

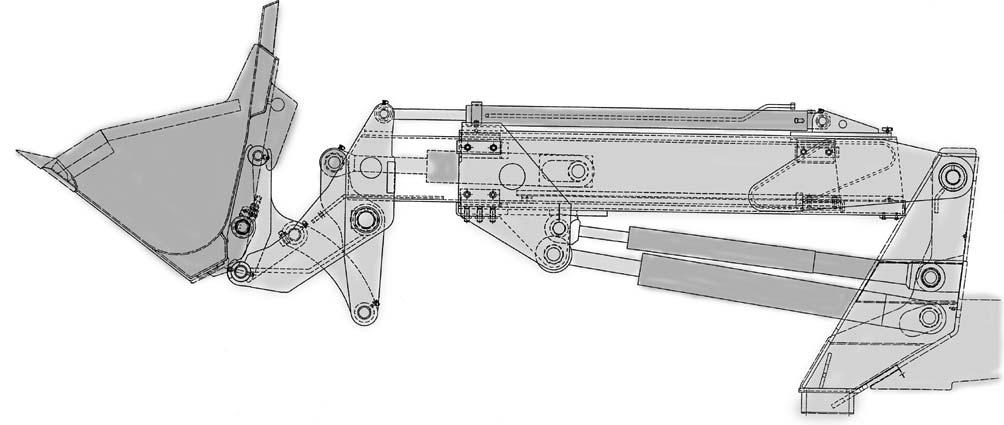

1.3Briefdescription

Thewheelloadermodel418Tisaself-propelledworkmachine. Thismachineisaversatileandpowerfulhelperformovingearth,gravelanddebrisonconstructionsitesandelsewhere.Thewiderangeofattachmentsaccountsforthenumerous applicationsofthemachine:asaforklift,asnowplow,aspreaderforsand,saltetc.,a sweeperoratreereplanter.Seepart 1.4Applications forfurtherapplications.Fitthe machinewiththerespectivesafetydeviceswhenusingitasaliftingmachine(see“Applicationswithliftingaccessories”inPart2SafetyInstructions).

Themaincomponentsofthewheelloadermodel418Tare:

• ROPStestedoperator’scab

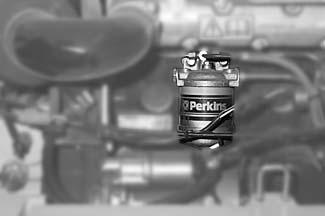

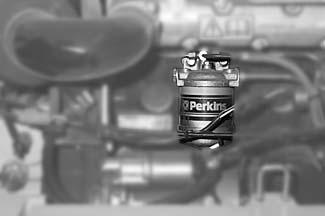

• Water-cooledfourcylinderPERKINSdieselengine,58hp(43.1kW)at2400rpm(as perDINISO9249)

• Sturdysteelsheetframeintorsion-resistantbox-typedesign

• Hydrostaticdrivewithelectroniccontrol,inching;12mph(20km/h)max.speed

• Hydrostaticfour-wheelsteeringwithemergencysteeringfeatures

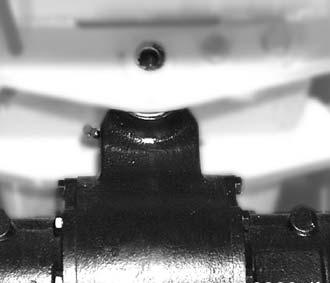

• Frontandrearplanetaryaxles,rearaxlewithoscillation

• Servicebrake(mechanicalorhydrostatic),mechanicaldisk-typeparkingbrake

• Telescopicunitwithsafeloadindicator

Hydrostaticdrive

Thedieselenginedrivesahydraulicpump,whoseoilflowissenttoahydraulicmotorconnectedtotherearaxle.Theforceofthehydraulicmotoristransmittedtotherearaxlevia thetransfergearbox.Atthesametime,thefrontaxleisdrivenbythecardanshaft,ensuringpermanentfourwheeldrive.

Workhydraulicsandhydrostaticfourwheelsteering

Thedieselenginealsodrivesthejointgearpumpforworkhydraulicsandhydrostaticfourwheelsteering.Theoilflowofthispumpdependsonthedieselenginespeedonly.

Whenthemachineisinoperation,theentiredieselengineoutputcanbetransmittedtothe gearpumpforworkhydraulicsandsteering.Thisismadepossiblebytheso-calledinching whichrespondsassoonastheinchingbrakeisused,reducingorcuttingoffpowerinputof thedrive.Therefore,engineoutputisfullyavailableforthetelescopicunitbypressingthe acceleratorpedalandtheinchingbrakepedalatthesametime.

Coolingsystem

Acombinedoil/watercooler(forthedieselengineandthehydraulicoil)islocatedatthe rearofthemachine.Thewarninglightsintheinstrumentpanel 17 ensureconstantmonitoringofthecoolantandhydraulicoiltemperature.Inaddition,anaudiblesignalsoundsin themachinecabassoonasthereisdangerofcoolantorhydraulicoiloverheatingandin caseoflowengineoilpressure.

AP0902 1–3 Introduction

Introduction 1.4Applications

Theattachmentswilldeterminewhereandhowthemachinecanbeused. Thefollowingtablegivesanoverviewofthepossibleattachments.

1–4 AP0902

DescriptionandModel ModelNo. Use Standardbucketw/teeth –normalmaterial 418T 810136Loosening,pickingup,transportingandloadinglooseor solidmaterial(materialdensity ≤ 2700lbs/yd³(18kg/m³)) Palletforks 418T 810135Pickingupandtransportingpalletsperloaddiagram

1.5Regulations

Drivinglicense

Earthmovingmachineryshouldbedrivenonpublicroadsonlyifthedriverhasadrivers license.

Getinformedonandfollowthelegalregulationsofyourcountry.

Equipment

Thehighwayregulationsofyourstate/provincemayrequireyoutoequipyourmachine with:

• Slow-MovingVehicle(SMV)emblem

• warninglights

Becomeinformedonandfollowthelocalhighwayregulations.

GehlwillsendyoutheoriginalcopyofthisDeclarationofManufactureratyourrequest. Pleasestatenameofproduct,modelandidentificationnumber(seetypelabelofthe attachment).

AP0902 1–5 Introduction

Introduction

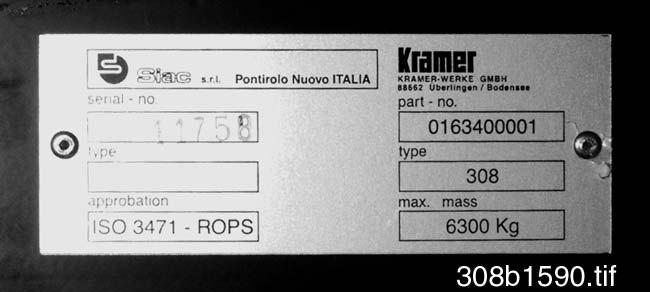

1.6Machinedata

Thefollowingdataprovideadetaileddescriptionofyourmachine.Pleasesupplyyour dealerwiththesedataforallcorrespondenceortelephoneinquiries.

Pleasereadthedatavalidforyourmachineofftheserialnumberplates,andenterthis datainthelist.Theywillimmediatelybeathandforallinquiriesorservicepartsorders.

Machinemodel:

Dateofregistration:

Servicehours/kilometerreading: ......................................................................................................................................

Serialnumber:

Cabnumber:

Engineno.: ......................................................................................................................................

Variabledisplacementpumpmodel–identificationno.:

Variabledisplacementmotormodel–identificationno.:

Frontaxleno.:

Rearaxleno.: ......................................................................................................................................

Cabno.:

Optionalattachments:

Yourlocaldealer:

• Address:

• Telephone:

1–6 AP0902

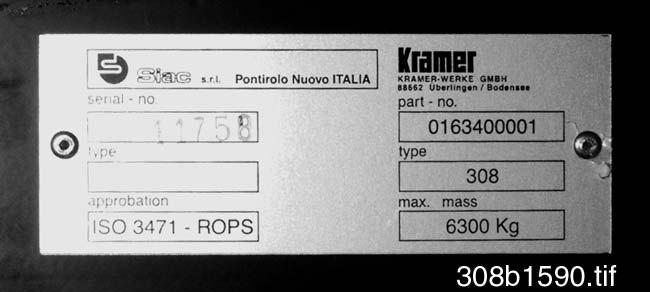

1.7Typelabelsandcomponentnumbers

Typelabel

Thetypelabel(Fig.3)islocatedatthefrontrightofthemachineframe(Fig.2 /1)

Serialnumber

Theserialnumberisstampedonthemachineframe(Fig.2/2).Itisalsostampedonthe typelabel(Fig.3)

Exampleforwheelloadermodel418T: 418T0005

Enginenumber

Theenginenumberislocatedonthelabelatthefrontoftheengineblock(arrow,Fig.4)

Example: 073305

Numberofhydraulicpump

Thetypelabel(arrow,Fig.5)islocatedonthepump,belowtheairfilter

Hydraulicmotornumber

Thetypelabel(arrow,Fig.6)islocatedonthelowersideofthehydraulicmotor,abovethe cardanshaft

AP0902 1–7

Introduction

Fhzg-Typ Model Modèle 308 311 10 311 10 0003 2001 Typ Ausf. Version Version Fg.-Nr. Serial no. No. de série Baujahr Model year Anné e fabr. Zul. Achslast vorn Front GAWR PNBE AV Zul. Achslast hinten Rear GAWR PNBE AR Zul. Ges. Gew. GWR PTAC Leistung Output Performance [ kg ] [ kg ] [ kg ] [ kW ] 3750 3750 6000 43,5 31100b0230.eps

Fig.2:Typelabel:location

1 2

Fig.3:Typelabelmodel418T

Fig.4:Dieselenginenumber

Fig.5:Hydraulicpump:typelabel

Fig.6:Hydraulicmotor:typelabel

Front/rearaxlenumber

Theaxlenumberislocatedonthetypelabel,ontherightsideofeachaxle(arrow,Fig.7)

1.8Safetysignsandsymbols

Thefollowingexplainssignsandsymbolsthatdonotcontainexplanatorytext.

...ontheoutsideofthemachine

Meaning

Generalindicationofdanger:

Thissign(Fig.9)warnspersonsstandingorworkingnearthemachineofincreaseddangeraroundthemachine.

Location

Frontleftandrightofmachineframe,andatrearofmachine(Fig.8/3)

Meaning

Eyehooks/limit(Fig.10)stopsonthemachine. Theeyehooksareusedforliftingorstrappingdownthemachine.

Location

Attherearofthecounterweight(Fig.8/2),aswellas atthefrontabovethefrontaxle,leftandrightontheframe

Meaning

1(Fig.11)Donotopenenginecoverbeforeengineisstopped!

2(Fig.11)Donottouchanymovingorturningparts!

Location

Attherearontheenginecover(Fig.8/1),aswellasontheengineblock.

1–8 AP0902 Introduction

Fig.7:Typelabelonthefrontaxle

3 3 2

Fig.8:Decalsattherear

308b0360.eps

Fig.9:Dangersign

308b0680.eps

Fig.10:Decal:eyehooks

Fig.11:Prohibitorysign

Meaning

Readandobservetheoperator’smanualbeforecarryingoutmaintenancework!

Location

Ontheengineblock(Fig.12)

AP0902 1–9 Introduction

Fig.12:Pleaserefertooperator’smanual

Introduction

...insidetheoperator’scompartment

Meaning

Cabtypelabel(Fig.13)

Location

OnleftsideofB-column

Meaning

Reifenluftdrucktabelle

Tire pressure

Pression pneumatiques

Tireinflationpressuretable (Fig.14)

Listofauthorizedtypesoftireswithprescribedtireinflationpressure

Tires Pneumatiques

Reifenbezeichnung vorn (bar) front (bar) AV (bar)

hinten (bar) rear (bar) AR (bar)

Bei Stapelbetrieb Luftdruck vorne um 0,5bar erhöhen! Increase tire pressure by 0,5 bar during pallet forks operation! Augmenter la pression pneumatique de 0,5bar en service porte-palette!

Location

Insidethecab,onleftsideoffrontwindow

Meaning

Loaddiagram (Fig.15foroperationwithpalletforks(forkarms):

Theframednumbersindicatethemaximumauthorizedloadontheforkarmsforindustrial (S=1.25)andoff-road(S=1.67)applicationsrespectively.Themaximumloadvaries accordingtothehorizontalandverticaldistanceoftheloadcenter,inthediagramdepicted ontheforkarmswithadistanceof500mmtotherearoftheforkarms.Thetelescopicunit withforkarmsmoveswithinthedottedrange.

Readingexampleforattachmentno.810135:

Off-roadapplication ➝ safetyfactorS=1.67

Distanceofloadtorearofforkarms=20inches(500mm)

Heightofforkarmabovetirecontactarea=61inches(1.56m)

Distancetotirefront=132inches(3.36m)

Maximumloadis2061lbs(935kg)!

1–10 AP0902

Fig.13:Cabinspectionlabel

31100b0010.eps

Fig.14:Tyreinflationpressuretablemodel31100

Fig.15:Loaddiagram

S=1,25/ 1100 kg S=1,67/ 820 kg S=1,25/ 1270 kg S=1,67/ 950 kg S=1,25/ 1500 kg S=1,67/ 1120 kg S=1,25/ 1800 kg S=1,67/ 1345 kg 311-00 311-10

charges Gültig

Anbaugerät

for attachment Valable pour équipement Nr. 10103-00 Nr. 10149-00 Nr. 10162-00 Nr. 10165-00

31100b0210.eps

Traglastdiagramm Load diagram Diagramme de

für

Valid

Section2

Safetyinstructions 2

2Safetyinstructions

2.1Identificationofwarningsanddangers

Importantindicationsregardingthesafetyoftheoperatingpersonnelandthemachineare indicatedinthisoperator’smanualwiththefollowingtermsandsymbols:

DANGER!/WARNING!/CAUTION!

Failuretoobservetheinstructionsidentifiedbythissymbolmayresultin personalinjuryordeathfortheoperatororotherpersons.

☞ Measuresforavoidingdanger

IMPORTANT

Failuretoobservetheinstructionsidentifiedbythissymbolmayresultin damagetothemachine.

☞ Measuresforavoidingdangerforthemachine

NOTE:

Thissymbolidentifiesinstructionsforamoreefficientandeconomicaluseofthe machine.

Environment!

Failuretoobservetheinstructionsidentifiedbythissymbolmayresultindamagetothe environment. Theenvironmentisindangerifenvironmentallyhazardousmaterial(e.g.wasteoil)isnot subjecttoproperuseordisposal.

AP0902 2–1 2

Safetyinstructions

Safetyinstructions

2.2Designateduses

• Themachineisintendedfor:

• Movingearth,gravel,coarsegravelorballastandrubbleaswellas

• Workingwiththeattachmentmentionedinthepresentoperator’smanual Everyotherapplicationisregardedasnotdesignatedfortheuseofthemachine.Gehl willnotbeliablefordamageresultingfromuseotherthanmentionedabove.Theuser alonewillbeartherisk.

Designatedusealsoincludesobservingtheinstructionsintheoperator’smanualand observingtheconditionsofmaintenanceandservice

• Observethepertinentregulationsrelevanttoaccidentprevention,othergenerally acknowledgedregulationsregardingsafetyandoccupationalmedicine,aswellasthe regulationsandstandardsrelevanttomotormachinesandtraffic.Themanufactureris notliablefordamageresultingfromthefailuretoobservetheseregulations

• Thesafetyofthemachinecanbenegativelyaffectedbycarryingoutmachinemodificationswithoutproperauthorityandbyusingspareparts,equipment,attachmentsand optionalequipmentwhichhavenotbeencheckedandapprovedbythemanufacturer. Themanufacturerwillnotbeliablefordamageresultingfromthis

• Themanufacturerwillnotbeliableforpersonalinjuryand/ordamagetoproperty causedbyfailuretoobservethesafetyinstructionsandtheoperator’smanual,andby thefailuretoexerciseduecarewhen:

• Handling

• Operating

• Servicingandcarryingoutmaintenancework

• Repairing themachine.Thisisalsoapplicableinthosecasesinwhichspecialattentionhasnot beendrawntothedutytoexerciseduecare,inthesafetyinstructionsaswellasinthe operator’sandmaintenancemanuals(machine/engine).

Readandunderstandtheoperator’smanualbeforestarting,servicingorrepairingthe machine.Observethesafetyinstructions!

• Themachinemaynotbeusedfortransportjobsonpublicroads

• Inapplicationswithliftingaccessories,themachineistobeusedaccordingtoitsdesignateduseonlyiftherequiredsafetydevicesareinstalledandfunctional

2–2 AP0902

2.3Generalconductandsafetyinstructions

Organizationalmeasures

• Themachinehasbeendesignedandbuiltinaccordancewithcurrentstandardsand therecognizedsafetyregulations.Nevertheless,itsusemayconstitutearisktolifeand limboftheuserorofthirdparties,orcausedamagetothemachineandtoother materialpropertyifitisnotusedproperly.

• Themachinemustonlybeusedinmechanicallygoodconditioninaccordancewithits designateduse(s)andtheinstructionssetoutintheoperator’smanual,andonlyby safety-consciouspersonswhoarefullyawareoftherisksinvolvedinoperatingthe machine.Anymalfunctions,especiallythoseaffectingthesafetyofthemachine,must thereforebecorrectedimmediately!

Basicrule:

Beforestartingthemachine,inspectthemachineforsafetyinworkandroadoperation!

• Carefulandprudentoperationisthebestwaytoavoidaccidents!

• Theoperatinginstructionsmustalwaysbeavailable,andmustthereforebekeptinthe storagecompartmentprovidedforinthecab.

Immediatelycompleteorreplaceanincompleteorillegibleoperator’smanual.

• Inadditiontotheoperatinginstructions,observeandinstructtheoperatorinallapplicablelegalandmandatoryregulationsrelevanttoaccidentpreventionandenvironmentalprotection.

Thesecompulsoryregulationsmayalsodealwiththehandlingofhazardous substances,issuingand/orwearingofpersonalprotectiveequipment,ortrafficregulations.

• Withregardtospecificoperationalfeatures,e.g.thoserelevanttojoborganization, worksequencesorthepersonsdoingthework,supplementtheoperator’smanualby correspondinginstructions,includingthoserelevanttosupervisingandreportingduties.

• Personswhowithworkonthemachinemusthavereadandunderstoodtheoperator’s manualandinparticular,Section2“SafetyInstructions”beforebeginningwork.This appliesespeciallytopersonsworkingonlyoccasionallyonthemachine,e.g.set-upor maintenance.

• Theuser/ownermustcheck–atleastfromtimetotime–whetherthepersonsdoing operationormaintenanceofthemachineareworkingincompliancewiththeoperator’s manualandareawareofrisksandsafetyfactors.

• Theuser/ownercommitshimselftooperateandkeepthemachineinagoodoperating condition,and,ifnecessaryorrequiredbylaw,torequiretheoperatingorservicing personstowearprotectiveclothingetc.

• Intheeventofsafety-relevantmodificationsorchangesonthemachineorofits behavior,stopthemachineimmediatelyandreportthemalfunctiontothecompetent authority/person. Safety-relateddamageormalfunctionsofthemachinemustbecorrectedimmediately.

• Nevermakeanymodifications,additionsor conversionstothemachineanditssuperstructure(cab,telescopicunitetc.),aswellastotheattachments,whichmightaffect safetywithouttheapprovalofthemanuufacturer!Thisalsoappliestotheinstallation andtheadjustmentofsafetydevicesandvalves,aswellastoweldingworkonloadbearingelements.

• Servicepartsmustcomplywiththetechnicalrequirementsspecifiedbythemanuufacturer.Originalservicepartsfromthemanuufacturercanbereliedtodoso.

• Replacehydraulichoseswithinstipulatedandappropriateintervalsevenifnosafetyrelateddefectshavebeendetected.

AP0902 2–3

Safetyinstructions

Safetyinstructions

• Beforeworkingonorwiththemachine,take offjewelry,suchasrings,wristwatches, bracelets,etc.,andtiebacklonghair,and donotwearloose-fittinggarments,suchas unbuttonedorunzippedjackets,tiesorscarves. Injurymayresultfrombeingcaughtupinthemachineryorfromringscatchingon movingparts!

• Keepthemachineclean.Thisreduces:

• Firehazard,e.g.duetooil-soakedragslyingaround

• Dangerofinjury,e.g.duetodirtordebrisonthesteps,and

• Dangerofaccidente.g.duetodirtordebrisonthebrakeoracceleratorpedal!

• Observeallsafety,warningandinformationsignsanddecalsonthemachine.

• Adheretoprescribedintervalsorthosespecifiedintheoperator’smanualforroutine checks/inspectionsandmaintenancework!

• Forservice,inspection,maintenanceorrepairwork,toolsandworkshopequipment adaptedtothetaskinvolvedareabsolutelyindispensable.

Selectionandqualificationofpersonnel,basicresponsibilities

• Anyworkonorwiththemachinemustbeperformedbyreliablepersonnelonly.Donot letunauthorizedpersonsdriveorworkwiththemachine!Observestatutoryminimum agelimits!

• Employonlytrainedorinstructedstaffonthemachine,andsetoutclearlyandunequivocallytheindividualresponsibilitiesofthepersonnelforoperation,set-up,maintenance andrepair!

• Definethemachineoperator'sresponsibilities –includingobservingtrafficregulations. Givetheoperatortheauthoritytorefuseinstructionsbythirdpartiesthatarecontraryto safety.

• Donotallowpersonstobetrainedorinstructed,orpersonstakingpartinageneral trainingcourse,toworkonorwiththemachinewithoutbeingsupervisedbyanexperiencedperson!

• Workontheelectricalsystemandequipment,onthechassisandonthesteeringand brakesystemsmaybecarriedoutonlybyskilledpersonnelwhohasbeenspecially trainedforsuchwork.

Workonthehydraulicsystemofthemachinemustbecarriedoutonlybypersonnel withspecialknowledgeandexperienceofhydraulicequipment!

• Sealofftheareaofdangershoulditnotbepossibletokeepasafedistance. Stopworkifpersonsdonotleavetheareaofdangerinspiteofwarning!Keepoutof theareaofdanger!

Areaofdanger : Theareaofdangeristheareainwhichpersonsareindangerduetothemovementsof the

• Machine

• Workequipment

• Additionalequipment,or

• Material

Thisalsoincludestheareaaffectedbyfallingmaterial,equipment,orbypartsthatare thrown.

2–4 AP0902

2.4Safetyinstructionsregardingoperation

Normaloperation

• Beforebeginningwork,familiarizeyourselfwiththesurroundingsandcircumstancesof theworksite.Theseare,e.g.,obstaclesintheworkingandtravellingarea,thesoil bearingcapacityandanynecessarybarriersseparatingtheworksitefrompublicroads.

• Takethenecessaryprecautionstoensurethatthemachineisusedonlywheninasafe andreliablecondition!

• Operatethemachineonlyifallprotectiveandsafety-relateddevices,e.g.,removable safety-devices,soundproofingelementsandmufflersetc.,areinplaceandfully functional!

• Checkthemachineatleastoncedaily/perworkingshiftforvisibledamageanddefects. Reportanychanges(suchaschangesinthemachine’sworkingbehavior)tothe competentorganization/personimmediately!Ifnecessary,stopthemachineimmediatelyandlockit!

• Intheeventofmalfunctions,stopthemachineimmediatelyandlockit!Haveany defectscorrectedimmediately!

• Startandoperatethemachinefromtheoperator’sseatonly!

• Carryoutstart-upandshut-downproceduresinaccordancewiththeoperator’smanual, andobservethewarninglights!

• Beforeputtingthemachine/attachmentintooperation(start-up/moving),makesure nobodyisatrisk!

• Beforedrivingthemachine,andalsoafterstoppingwork,checkwhetherthebrakes, steering,signallingandlightsystemsarefunctional!

• Beforemovingthemachinealwayscheckwhetherthesupplementaryequipmentand theattachmentshavebeensafelystowedawayorattached!

• Whendrivingonpublicroads,observethetrafficregulationsand,ifnecessary,make surebeforehandthatthemachineisincompliancewiththeseregulations!

• Inconditionsofpoorvisibilityandafterdarkalwaysswitchonthelights!

• Nolifting,loweringorcarryingofpersonsinthe workequipment/attachments!

• Nomountingofamanbasketorpersonalworkplatform!

• Whencrossingunderpasses,bridgesandtunnels,orwhenpassingunderoverhead lines,alwaysmakesurethereissufficientclearance!

• Alwayskeepatasafedistancefromtheedgesofexcavationsandslopes!

• Whenworkinginbuildingsorinenclosedareas,lookoutforthe

• Heightoftheceiling/clearances

• Widthoftheentrancesand

• Maximumloadofceilingsandfloors Provideforsufficientroomventilation–dangerofpoisoning!

AP0902 2–5

Safetyinstructions

Safetyinstructions

• Avoidanyoperationthatmightbearisktostability!

• Duringoperationonslopes,driveorworkuphillordownhill.Ifdrivingacrossaslope cannotbeavoided,bearinmindthestabilitylimitofthemachine! Alwayskeeptheattachments/worktoolclosetotheground.Thisalsoapplieswhen drivingdownhill!

Whendrivingorworkingacrossaslope,theloadmustbeontheuphillsideofthe machine.

• Onslopingterrainalwaysadaptyourdrivingspeedtotheprevailinggroundconditions. Neverchangetoalowergearonaslope,butalwaysbeforereachingit!

• Beforeleavingthemachine

• Lowertheworktool/attachmentstotheground

• Beforeleavingtheoperatorseat,alwayssecurethemachineagainstinadvertent movementandunauthorizeduse!

• Beforestartingwork,checkwhether

• Allsafetydevicesareproperlyinstalledandfunctional

• SlowMovingVehicle(SMV)embleminstalledasneeded

• Warninglightsinstalledasneeded,and

• AFirst-aidkitisonhand

• Beforemovingthemachineorbeforestartingwork:

• Makesurevisibilityissufficient(donotforgetrearviewmirrors!)

• Adjustcorrectseatposition(brakepedalmustbedepressedtothelimit). Neveradjusttheoperatorseatwhendrivingorworking!

• Fastenyourseatbelt

• Inspecttheimmediatearea(children!).Intheworkareatheoperatorisresponsible forthirdparties!

• Cautionwhenhandlingfuel–increaseddangeroffire!

Makesurefueldoesnotcomeintocontactwithhotparts!Stoptheengineduringrefuelling!Donotsmokeduringrefuelling,andavoidfireandsparks!

• Nevergetonoroffamovingmachine!Neverjumpoffthemachine!

• Ifthelightsofthemachinearenotsufficientforthesafeexecutionofcertainwork processes,provideadditionallightingoftheworkarea.

• Installedrearworklightsmustnotbeswitchedonfortravelonpublicroads.Theycan beswitchedoninworkoperationifusersofpublicroadsarenotdazzled.

• Hydrostaticfour-wheelsteeringtakestimegettingusedto.Therefore,adjustthedriving speedtoyourabilitiesandthecircumstances.Selectionandchangesteeringmodeof machineatstandstillonly!

WARNING!

Exposuretocrystallinesilica(foundinsand,soilandrocks)hasbeen associatedwithsilicosis,adebilitatingandoftenfatallungdisease.A HazardReview(Pub.No.2002-129)bytheU.S.NationalInstitutefor OccupationalSafetyandHealth(NIOSH)indicatesasignificantrisk(at least1in100)ofchronicsilicosisforworkersexposedtoinhaledcrystallinesilicaoveraworkinglifetime.NIOSHrecommendsanexposurelimit of0.05mg/m3 asatime-weightedaverageforuptoa10-hrworkdayduringa40-hrworkweek.NIOSHalsorecommendssubstitutinglesshazardousmaterialswhenfeasible,usingrespiratoryprotection,andregular medicalexaminationsforexposedworkers.

2–6 AP0902

Safetyinstructions

ApplicationswithliftingaccessoriesDefinition:

Applicationswithliftingaccessoriesareunderstoodasproceduresinvolvingthelifting, transportingandloweringofloadswithhelpofslingsandload-securingdevices(e.g. ropes,chains).Indoingso,thehelpofpersonsisnecessaryforsecuringanddetaching theload.Thisapplies,forexample,toliftingandloweringofpipes,shaftringsorcontainers.

• Themachinemaybeusedforapplicationswith liftingaccessoriesonlyiftheprescribed safetydevicesareinplaceandfunctional. Theseare,e.g.:

• Accessoriesforslingingandsecuringaliftingattachment(loadhook)

• Loaddiagrams

• Theloadmustbesecuredsoastopreventitfromfallingorslipping.

• Personsguidingtheloadorsecuringitmuststayinvisualcontactwiththemachine operator.

• Themachineoperatormustguidetheloadasnearaspossibletotheground,andavoid anyoscillatingorswingingmovements.

• Themachinemaybemovedwitharaisedloadonlyifthepathofthemachineislevel.

• Thepersonsattachingorsecuringloadsmayapproachtheboomfromthesideonly, andonlyafterthemachineoperatorhasgivenpermission.Themachineoperatormay givehispermissiononlyafterthemachineisatastandstillandthetool/attachmentis notmoving.

• Donotuseanydamagedliftingattachmentsorsuchliftingaccessories(ropes,chains) thatarenotsufficientlysized.Alwayswearprotectivegloveswhenworkingwithlifting accessories.

AP0902 2–7

Safetyinstructions

Trailersandattachments

• Itisnotpermittedtouseatrailerwiththetowingdeviceofthemachine!

• Attachmentsandcounterweightsaffecthandling,aswellasthesteeringandbrake capabilityofthemachine!

• Fittheattachmentswiththespeciallyrequireddevicesonly!

• Beforeuncouplingorcouplinghydrauliclines(hydraulicquickcouplers):

• Turnofftheengine,and

• Relievetheoilpressureinthehydraulicsystembymovingthecontrolleversofthe hydrauliccontrolunitsbackandforthacoupletimes.

• Couplingofattachmentsrequiresspecialcare!

• Securetheattachmentsagainstinadvertentmovement!

• Operatethemachineonlyifallsafetydevicesareinstalledandarefunctional,andifall brake,lightandhydraulicconnectionsareconnected!

• Ifoptionalequipmentisinstalled,alladditionallyrequiredlightinstallations,warning lights,etc.,mustbeprovidedforandfunctional.

• Mounttheattachmentsonlyiftheengineisstoppedandthedrivesystemisswitched off.

• Relievepressureinthehydraulicsystembeforeconnectingordisconnectinghydraulic lines.

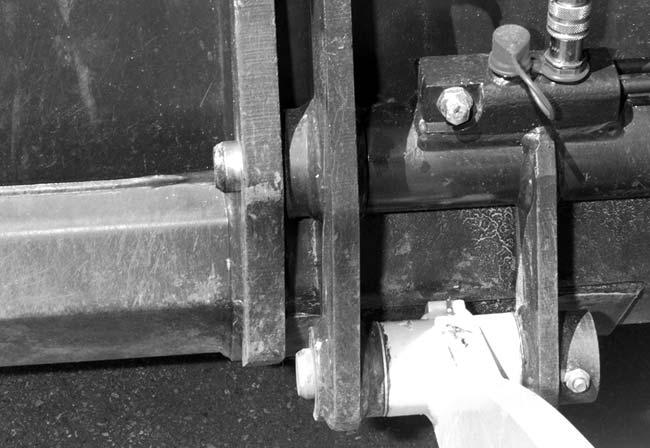

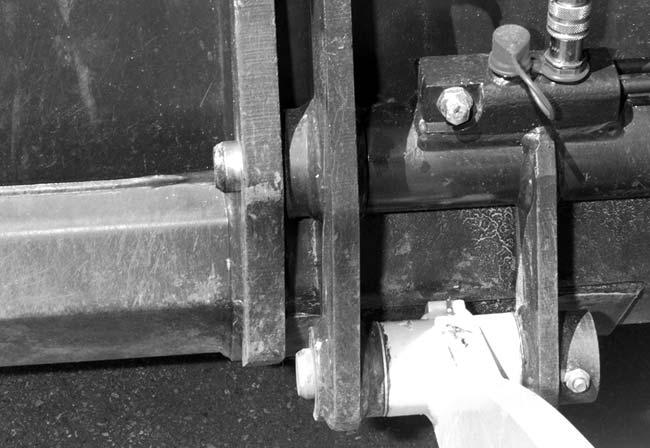

• Especiallywhendrivingorworkingwithmachineswithaquickhitchfacilityforthe attachments,besurethattheattachmentissecurelylockedinthequickhitchfacility. Thelockpinmustbevisibleonbothsidesoftheboresontheattachment.Check beforestartingwork.

• Priortoconnectingattachmentstotheloader,securethecontrolleverofthehydraulic controlagainstunintentionalmovement.

• Becarefulwhenconnectingattachmentstotheloadert:becauseofthedangerof personalinjuryduetocrushingandshearing.Besurenobodyisbetweenthemachine andtheequipmentwithoutsecuringthemachineandtheattachmentagainst movement. Transport

• Themachinemustbetowed,loadedandtransportedonlyinaccordancewiththe operator’smanual!

• Fortowingthemachineobservetheprescribedtransportposition,speedand procedure.

• Useonlyappropriatemeansoftransport,anduseliftinggearofadequatecapacity!

• Safelysecurethemachineonthetransportmachine!Usesuitablemountingpointsand load-securingdevices.

• Thestartupproceduremustbestrictlyinaccordancewiththeoperator’smanual!

2–8 AP0902

2.5Safetyinstructionsforserviceandmaintenance

• Avoidanyunsafeoperationalmode!

• Observetheadjusting,maintenanceandinspectionactivitiesandserviceintervalsset outintheoperator’smanual,includinginformationonthereplacementofparts/partial equipment.

Theseactivitiesmaybeperformedbyskilledpersonnelonly.

• Themachinemaynotbeserviced,repairedortest-drivenbyunauthorizedpersonnel.

• Informoperatingpersonnelbeforebeginningspecialoperationsandmaintenancework! Appointapersontosupervisetheactivities!

• Inanyworkconcerningtheoperation,conversionoradjustmentofthemachineandits safetydevices,oranyworkrelatedtomaintenance,inspectionandrepair,observethe start-upandshut-downproceduressetoutintheoperator’smanual,andtheinformationonmaintenancework.

• Ifrequired,securethemaintenanceareaappropriately!

• Priortoperformingservice,maintenanceandrepairwork,attachawarninglabel,such as“Repairwork–donotstartmachine!”,totheignitionlock/steeringwheelortothe controlelements.

Removetheignitionkey!

• Performservice,maintenanceandrepairworkonlyif:

• machineispositionedonfirmandlevelground

• Transmissioncontrolleverisinneutralposition

• Parkingbrakeisapplied

• Allhydraulicallymovableattachmentsandworkingequipmenthavebeenloweredto theground

• Engineisstopped

• Ignitionkeyisremoved,and

• machinehasbeensecuredagainstunintentionalmovement

• Ifmaintenanceorrepairisrequiredwiththeenginerunning:

• Onlyworkingroupsoftwo

• Bothpersonsmustbeauthorizedtooperatethemachine

• Onepersonmustbeseatedontheoperatorseatandmaintainvisualcontactwiththe otherperson

• Observethespecificsafetyinstructionsintherespectiveworkmanual

• Keepasafedistancefromallrotatingandmovingparts,e.g.fanblades,V-belt drives,PTOshaftdrives,fans,etc.

• Priortoperformingassemblyworkonthemachine,besurenomovablepartswillroll awayorstartmoving.

• Toavoidtheriskofaccidents,individualpartsandlargeassembliesbeingmovedfor replacementpurposesmustbecarefullyattachedandsecuredtoliftingtackle. Useonlysuitableliftinggearandsuspensionsystemsinagoodconditionwith adequateliftingcapacity!

Neverworkorstandundersuspendedloads!

AP0902 2–9

Safetyinstructions

Safetyinstructions

• Thefasteningofloadsandtheinstructingofliftoperatorsmustbedonebyexperienced personsonly!

Thepersongivingtheinstructionstotheoperatormustbewithinsightorsoundofhim.

• Foroverheadassemblywork,alwaysusespeciallydesignedorotherwisesafetyorientedladdersandworkplatforms.

Neverusemachinepartsorattachments/superstructuresasaclimbingaid! Wearasafetyharnesswhencarryingoutmaintenanceworkatgreaterheights! Keepallhandles,steps,handrails,platforms,landingsandladdersfreefromdirt,snow andice!

• Cleanthemachine,especiallyconnectionsandthreadedunions,ofanytracesofoil, fuelorpreservativesbeforecarryingoutmaintenance/repairwork! Donotuseaggressivedetergents!

Uselint-freecleaningrags!

• Beforecleaningthemachinewithwater,steamcleaning(high-pressurecleaning)or usingdetergents,coverortapeupallopeningsthat–forsafetyandfunctionalreasons –mustbeprotectedagainstwater,steamordetergents.Specialcaremustbetaken withtheelectricalsystem.

• Aftercleaning,removeallcoversandtapesappliedforthatpurpose!

• Aftercleaning,examineallfuel,lubricantandhydraulicoillinesforleaks,chafemarks anddamage!

Anydefectsfoundmustbecorrectedwithoutdelay!

• Tightenanyscrewconnectionsthathavebeenloosenedduringmaintenanceand repair!

• Anysafetydevicesremovedforset-up,maintenanceorrepairpurposesmustbe refittedandcheckeduponcompletionofthemaintenanceandrepairwork.

• Ensurethatallfluidsandreplacedpartsaredisposedofsafelyandwithminimum environmentalimpact!

• Donotusetheworktoolsasliftingplatformsforpersons!

• Beforeworkingonamachineparts/attachmentsmoveandcauseinjury(bruising, cutting),alwaysensuresafeblocking/supportofthesecomponents.

• Performmaintenanceandrepairworkbeneatharaisedmachine,worktool/attachmentsoradditionalequipmentonlyifasafeandsecuresupporthasbeenprovided (Theuseofhydrauliccylinders,jacks,etc.doesnotsufficientlysecureraisedmachines orequipment/attachments).

• Avoidcontactwithhotparts,suchastheengineblockortheexhaustsystemduringthe operationofthemachineandforsometimeafterwards–dangerofburns!

• Retainerpinscanflyoutorsplinterwhenstruckwithforce–becarefultoavoid personalinjury!

• Donotusestartingfluid(ether)!Thisespeciallyappliestothosecasesinwhicha heaterplug(intake-airpreheating)isusedatthesametime–becauseofthedangerof explosions!

• Usespecialcarewhenworkingonthefuelsystem–becauseoftheincreaseddanger offire!

2–10 AP0902

2.6Warningofspecialhazards

Electricalhazards

• Useonlyoriginalfuseswiththespecifiedcurrentrating! Turnoffthemachineimmediatelyandcorrectthemalfunctioniftroubleoccursinthe electricalsystem!

• Whenworkingwiththemachine,maintainasafedistancefromoverheadelectriclines! Ifworkistobecarriedoutclosetooverheadlines,theequipment/attachmentsmustbe keptwellawayfromthem.Learntheprescribedsafetydistances!

• Ifyourmachinecomesintocontactwithanelectricalwire:

• Donotleavethemachine

• Drivethemachineoutoftheareaofdanger,ifpossible

• Warnothersagainstapproachingandtouchingthemachine

• Havetheelectrifiedwirede-energized

• Donotleavethemachineuntiltheelectrifiedwirehasbeensafelyde-energized!

• Workontheelectricalsystemmayonlybeperformedbyaskilledtechnician,inaccordancewiththeapplicableelectricalsystemrepairprocedures.

• Inspectandchecktheelectricalsystemofthemachineatregularintervals.Defects suchaslooseconnectionsorburnedcablesmustbecorrectedimmediately.

• Observetheoperatingvoltageofthemachine!

• Alwaysremovethegroundstrapfromthebatterywhenworkingontheelectricalsystem orwhenperformingweldingwork!

• Startingwithabatteryjumpcablecanbedangerousifperformedimproperly.Observe thesafetyinstructionsregardingthebattery!

• Operatethemachineonlyinadequatelyventilatedlocations!Beforestartinginternal combustionenginesinenclosedlocations,makesurethatthereissufficientventilation!

• Carryoutwelding,flame-cuttingandgrindingworkonthemachineonlyifithasbeen expresslyauthorized,becausetheremaybeariskofexplosionorfire.

• Beforecarryingoutwelding,flame-cutting andgrindingwork,cleanthemachineandits surroundingsfromdustandotherflammablesubstances,andbesurethatthe premisesareadequatelyventilated–becauseofthedangerofexplosions!

AP0902 2–11

Safetyinstructions

Gas,dust,steam,smoke

Safetyinstructions

Hydraulicequipment

• Workonthehydraulicequipmentofthemachinemaybedoneonlybypersonshaving knowledgeandexperienceinhydraulicsystems!

• Checkalllines,hosesandconnections regularlyforleaksanddamage!Repairany damageandleaksimmediately!Leakingoilmaycauseinjuryandfire.

• Inaccordancewiththeoperator’smanual/instructionsfortheassembly,relievethe pressureinallsystemsectionsandpressurepipes(hydraulicsystem,)tobeopened beforedoinganyrepairwork!

• Hydrauliclinesmustberoutedandfittedproperly.Ensurethatnoconnectionsareinterchanged.Thefittings,lengthsandqualityofthehosesmustcomplywiththedesign specifications.

Noise

Oil,greaseandotherchemicalsubstances

• Wearhearingprotectionifnecessary!

• Whenhandlingoil,greaseandotherchemicalsubstances(e.g.,batteryelectrolyte— sulfuricacid),observetheproduct-relatedsafetyregulations(materialsafetydatasheet MSDS)!

• Becarefulwhenhandlingfluids,becauseoftheriskofburningorscalding!

Battery Whenhandlingthebattery,observethespecificsafetyinstructionstoavoidinjury.Batteriescontainsulfuricacid.

• Especiallywhenchargingbatteries,aswellasduringnormaloperation,ahydrogen-air mixtureisformedinthecellswhichhasadangerofexplosion!

• Inthecaseofafrozenbatteryorofaninsufficientelectrolytelevel,donottrystart-up withjumpercables.Thebatterycanburstorexplode.

Tires

• Repairworkontiresandrimsmaybecarriedoutbyskilledpersonalorbyanauthorizedworkshoponly!

• Damagedtiresand/orwrongtirepressurereducetheoperationalsafetyofthe machine.Thereforeconductregularchecksofthetiresfor

• Prescribedtirepressureand

• Damage

• Donotinflatetireswithinflammablegas–dangerofexplosion!

• Conductregularchecksofthewheelnutsfortightness,atleastevery600service hours.Afterchangingtirescheckthewheelnutsafter10servicehours–tightenif necessary!

2–12 AP0902

Section3 Operation

3Operation

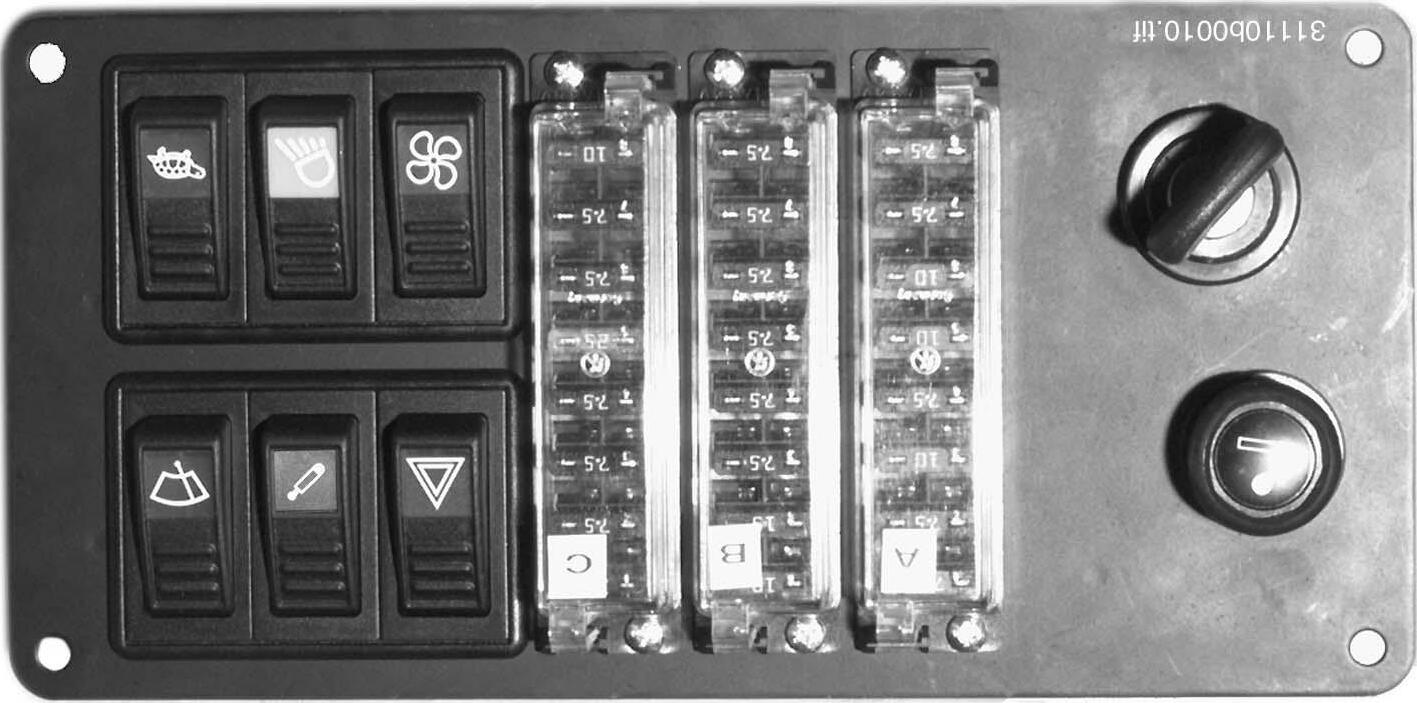

Thischapterdescribingthecontrolscontainsinformationonthefunctionandtheuseoftheindividualwarninglightsandcontrolsinthe operatorcab.

Thepageslistedinthetablerefertothedescriptionofthecorrespondingcontrols. Theidentificationofthecontrolswithacombinationofdigitsoracombinationofdigitsandletters,e.g.40/18 or40/A,means:Figureno. 40/controlelementno.18orposition A infigureno.40. Afigurecarriesnonumberwhenitisplacedtotheleftofthetext.

Unfoldpages3-2and3-4forabetteroverview.

Thesymbolsusedinthedescriptionhavethefollowingmeanings:

• Thissymbolstandsforalist

• Thissymbolstandsforthesubdivisionofanenumerationoranactivity.Followthestepsintherecommendedsequence

☞ Thissymbolrequiresyoutocarryouttheactivitydescribed

➥ Descriptionoftheeffectsorresultsofanactivity

n.s.=notshown

SO=option

Statedwhenevercontrolsorothercomponentsofthemachineareinstalledasanoption.

AP0902 3-1

3

Overview:seeoverleaf

3.1Overviewofcab

31110b0062.eps 308b0950.eps 308b0960.eps Operation 3-2 AP0902 1 2 3 19 21 22 6 8 9 10 25 7 Fig.16:Cab:overview