3 minute read

CHAPTER 8 LUBRICATION ACAUTION

NEVER attempt to lubricate the machine when any part of the unit Is In motion. ALWAYS BE SURE to exercise the MANDATORY SAFETY SHUTDOWN PROCEDURE (page 8) BEFORE proceeding to lubricate this machine.

It is well to remember that a sufficient amount of oil or grease will prevent excessive part wear and early failure.

Transmissions

Periodically check the oil level in each Transmission using the Dipstick, where provided. In the Beater Drive Transmission, replenish the oil, as necessary, with SAE #90 gear oil. For the Apron Drive Transmission, use only special GEHL Gear Lube (Part Number 090685). Special GEHL Gear Lube MUST be used to promote long life and avoid component breakdown and early failure.

Oiling

Lubricate all Drive Chains every 10 hours of operation using a good grade of foaming aerosol lubricant. The recommended method is to spray the entire length of Chain on the center of the Rollers. It is better to lubricate Chains when they are warm (after use, rather than before).

In addition to the Roller Chains, apply oil or foaming aerosol lubricant to the Telescoping PTO Drive Guard and the Upper Beater Drive Chain (where provided).

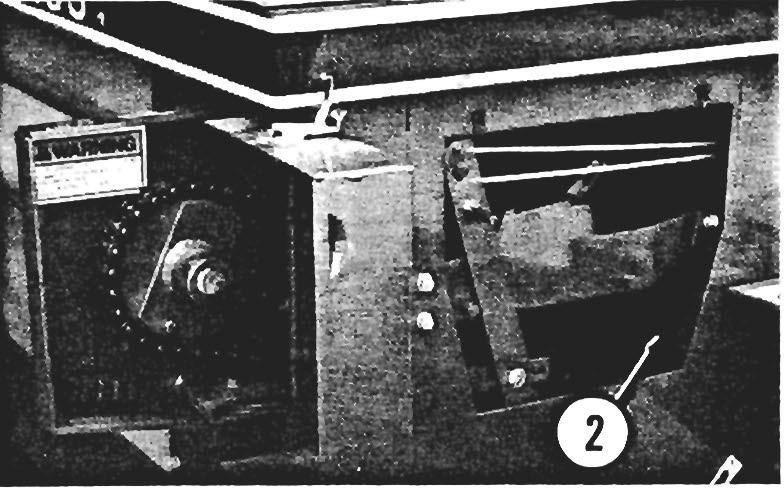

GREASING (Fig. 8-1)

Wipe dirt from the Fittings before greasing to prevent any dirt from being forced into the Bearings or pivots. Replace any missing Fittings, when noted. To minimize dirt build-up, avoid excessive greasing.

NOTE: In addition to the Fittings, inspect and repack the Wheel Bearings at least once a year.

Grease Fitting Locations

NOTE: For the first week of operation, lubricate al/ Fittings (and Cam surfaces) daily or after every three loads to insure proper break-in of the Drive components. Thereafter, lubricate al/ Fittings (and the Cam surfaces) at the prescribed inteNa/s of operation listed. Use a good grade of lithium-based grease.

Grease Every 15 Loads (or Weekly)

1. PTO Shaft Cross (3 Places)

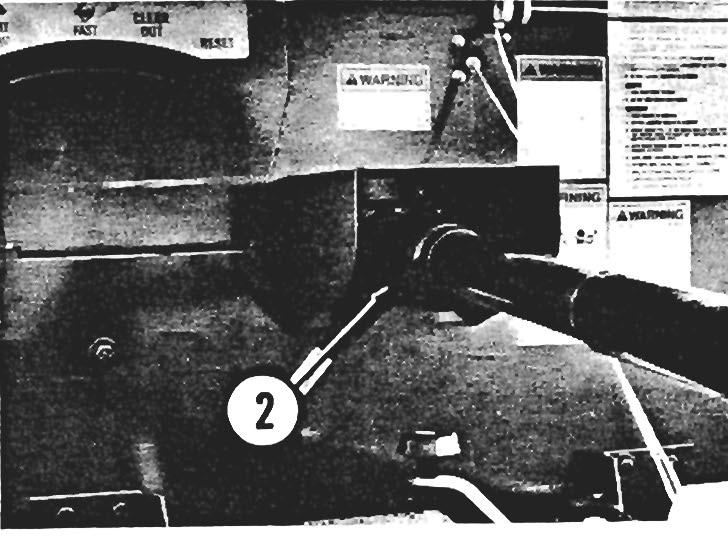

2. Jackshaft Bearings (2 Places)

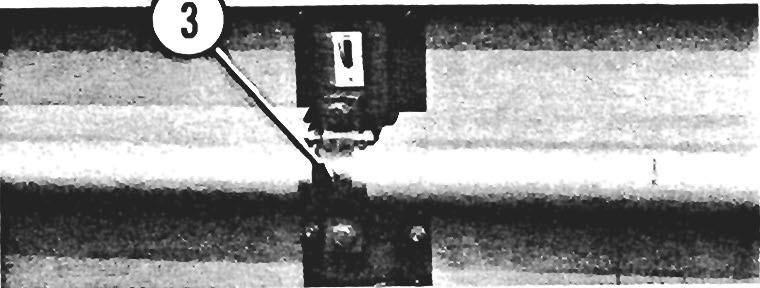

3. Drive Shaft Bearing

4. Left End of Apron Shaft

5. Beater Bearing

6. Clutch Yoke (2 Places)

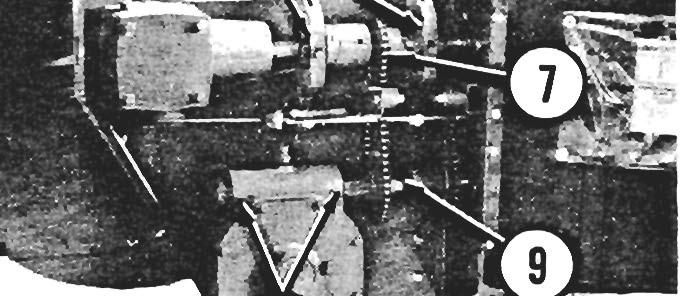

7. 2-Speed Sprocket

8. Apron Transmission Shaft (2 Places)

9. Overrunning Clutch

Grease Every 50 Hours

10. Telescoping Drive Tube

11. CV Joint Housing (2 Places)

Weasler TelescopIng PTO DrIve wIth Metal-shIelded Tubes

A Caution

BEFORE proceeding to perform all Service routines on this unit, exercise the MANDATORY SAFETY SHUTDOWN PROCEDURE (page 8).

TIRES & WHEELS A CAUTION

The GEHL Company does NOT sell replacement Tlres.!n addition, Tire mounting, repair and replacements should ONLY be attempted by a qualified tire manufacturer's representative or by properly trained personnel following the tire manufacturer's Instruction. If you do NOT have such Instructions, contact your tire dealer or the GEHL Company.

NOTE: A Spreader with Used or Recapped Truck Tires that have Inner Tubes with long Valve Stems MUST be mounted with the Valve Stems facing the outside of the Spreader to prevent breaking off the Valve Stems.

Check the Spreader Tire pressure after every 50 hours of operation. Tires should be inflated to the appropriate pressure listed in the Table. Wheel Lug torque should be checked after every 50 hours of operation and tightened to 125 ft-lb (170 Nm) torque.

Awarning

Inflating or servicing tires can be dangerous. Whenever possible, trained personnel should be called to service and/or mount tires. In addition, do NOT place fingers on tire bead during Inflation; serious Injury or amputation could resultl In any event, to avoid possible fatal or serious Injury, follow the safety precautions below:

• BE SURE the Rim Is clean and free of rust. Lubricate both the tire beads and rim flanges with a soap solution. Do NOT use 011 or grease.

• Use a Clip-on tire chuck with a remote hose and gauge which allows you to stand clear of the tire while Inflating It.

• NEVER Inflate beyond 35 PSI (240 kPa) to seat the beads. If beads have NOT seated by the time the pressure reaches 35 PSI, deflate the assembly, reposition the tire on the rim, relubrlcate both parts and reInflate It. Inflation pressure beyond 35 PSI with unseated beads may break the bead or rim with explosive force sufficient to cause fatal or serious Injury.

• After seating the beads, adjust the Infla c tlon pressure to the recommended operatIng pressure listed.

• Do NOT weld, braze, or otherwise attempt to repair and use a damaged rim.