1 minute read

2.5 O peration of the machine

2.5.15 Hopper

The hopper is equipped with a cover (1) which prevents material from falling on the engine bonnet or to the area of the engine during loading of the material.

Procedure for the hopper cover operation:

• Before loading the machine with material open the hopper cover (1) by tilting it over in the machine travel direction so that the locking pin (2) fits into the counter-piece (3).

• After loading the machine with material, close the hopper cover (1).

Before loading material to the machine always open and lock the hopper cover (1).

During machine travel the hopper cover (1) must be in the closed position.

Load the material to the machine according to Chapter 2.6.9.

It is prohibited to load the material during machine operation; the machine must be parked on a flat and solid surface with the engine off.

In case of mounting the material hopper extension, observe the mounting and safety instructions stated in the Mounting Manual.

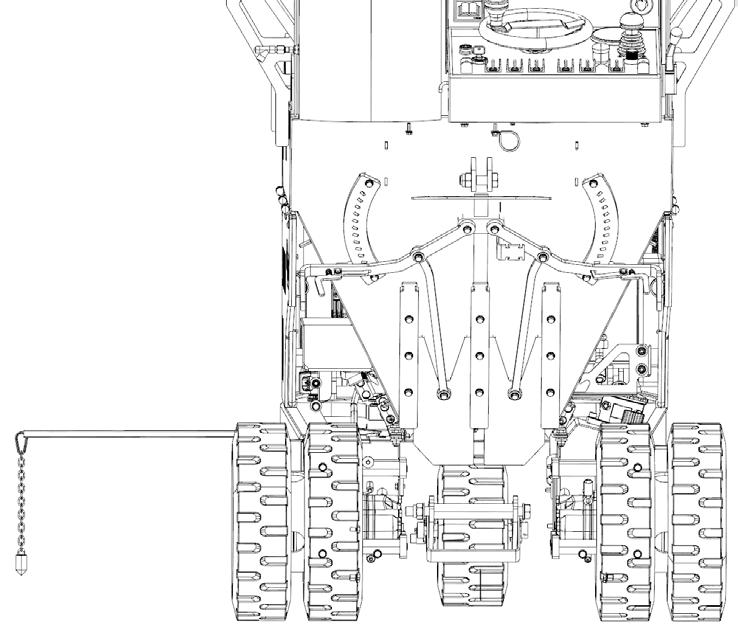

2.5.16 Material outlet

It serves for controlling the flow of the material to augers. For efficient transport of material over the entire width of the screed, it is recommended to keep the augers half immersed in the asphalt mixture throughout the paving.

Adjustment process:

• Control the flow rate of the material to augers as required on the left or right side by setting the lever (1) to the required position.

• By setting the lever (1) to the required position, you can control the flow rate of the delivered material to augers by changing the position of the material outlet (2).

During the operation of the machine pay higher attention when adjusting the material outlet with regard to the safety of the operator and machine operation.