4 minute read

3.6 Lubrication and maintenance operations

3.6.29 Hydraulic oil and hydraulic oil filter replacement

Change the hydraulic oil when the machine is parked on a flat and solid surface, the engine and the battery disconnector are off and the gas bottle is closed.

Hydraulic oil change and ventilation filter replacement procedure:

• Open the right material hopper side cover (1).

• Remove the ventilation filter (2).

• Place a vessel with a volume of at least 21 l (5.5 gal US) under the hydraulic oil drain plug (3).

• Remove the drain plug (3) from the hydraulic tank.

• Drain the oil into the prepared container.

• Mount the drain plug (3) onto the hydraulic tank and tighten.

• Fill in new oil to the hydraulic tank through the hole (4).

• The prescribed oil volume is 20 l (5.3 gal US).

• Check the oil level on the oil gauge (5).

• The hydraulic oil level must be between the MIN and MAX marks.

• Apply oil on the sealing O-Ring (6) on the ventilation filter (2).

• Mount a new ventilation filter (2).

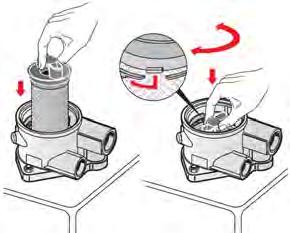

Hydraulic oil filter element replacement:

• Remove filter cap (1).

• Unlock the filter element (2).

• Pull out the filter element from the filter housing (3).

• Insert a new filter element (4).

• Turn the filter element clockwise up to the stop (4.1).

• Lock the filter element (5).

• Apply oil on the sealing O-Ring on the filter cap (7).

• Mount the cap onto the filter (8) and tighten it using the torque spanner; the maximum tightening torque value is 20 Nm (14.75 lb ft).

Change the hydraulic oil when the machine is parked on a flat and solid surface, the engine and the battery disconnector are off and the gas bottle is closed.

Wear the prescribed protective equipment when replacing the hydraulic oil and hydraulic oil filters.

Carry out the oil change when the oil is warm, preferably after operation of the machine.

Refill the hydraulic oil with the prescribed hydraulic oil according to Chapter 3.2.3.

Stop the oil soaking into the ground. Hand over the dismounted hydraulic oil filter for disposal according to the national regulations.

3.6 Lubrication and maintenance operations

3.6.30 Gas line hose replacement

Perform gas line hose replacement when the machine is parked on a flat and solid surface with the engine and battery disconnecter off and with the closed gas bottle shut-off valve.

Have the gas line hose replacement performed by an authorised service plant or qualified personnel.

Gas line hose removal procedure:

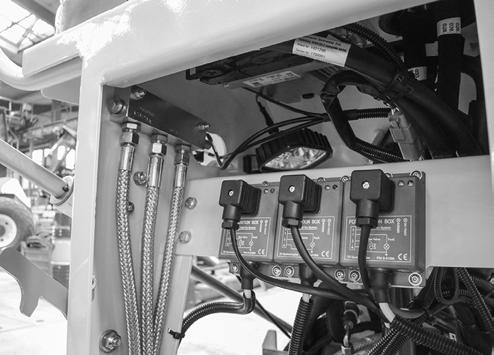

• Close the gas bottle (2) shut-off valve (1).

• Remove the gas line hose (3) from the safety valve (4).

• Remove the gas line hose (3) from the solenoid valve of the gas supply (5).

• Remove the gas line hoses (6) from the gas supply distributor (7).

• Remove the gas line hoses (6) from the burners (8).

Gas line hose mounting procedure:

• Mount the new gas line hoses (6) on the burners (8).

• Mount the new gas line hoses (6) on the gas supply distributor (7).

• Mount the new gas line hose (3) on the solenoid valve of the gas supply (5).

• Mount the new gas line hose (3) on the safety valve (4).

Procedure to check the hoses of the gas distribution for leakage.

• Perform the gas equipment tightness check according to Chapter 3.6.8.

• In case you detect a leak on the gas system again, repeat the gas equipment tightness check procedure.

Perform gas line hose replacement when the machine is parked on a flat and solid surface with the engine and battery disconnecter off and with the closed gas bottle shut-off valve.

The machine must be equipped with a fire extinguisher. Have the fire extinguisher ready on the driver's stand at a place intended for this purpose.

Pay extra attention to potential gas leaks and in doubt, shut off the gas supply.

Check the tightness of the gas equipment, e.g. with a gas leak detector.

If you detect gas leakage, immediately shut off the gas bottle shut-off valve and have the gas equipment repaired by an authorised service plant or qualified personnel.

Follow safety regulations for handling gas bottles. There is a risk of burns. Use protective equipment. Have the gas equipment tightness check performed by an authorised service plant or qualified personnel.

Maintenance as required

3.6.31 Battery replacement

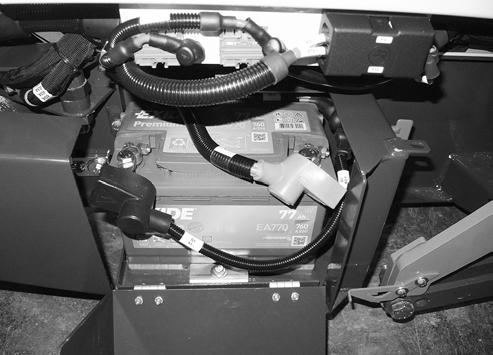

Perform battery replacement when the machine is parked on a flat and solid surface with the engine and battery disconnecter off.

Battery replacement procedure:

• Open the left material hopper side cover (1).

• Open the battery cover (2).

• First, remove the clamp from the (-) pole on the battery, and then remove the clamp from the (+) pole.

• Remove the screw (3) of the battery holder (4).

• Remove the battery from the machine.

• Mount a new battery on the machine.

• Mount the battery holder (4) and the screw (3).

• First, mount the clamp on the (+) pole, and then mount the clamp on the (-) pole.

• Close the battery cover (2).

• Close the left material hopper side cover (1).

Replace the battery when the machine is parked on a flat and solid surface when the engine and the battery disconnector are off and the gas bottle closed.

When replacing the battery, use the prescribed protective equipment.

There is a risk of explosion if the battery is mounted incorrectly!

First disconnect the minus pole cable (-) when disconnecting the battery. First connect the plus pole cable (+) when connecting the battery.

Do not disconnect the battery when the engine is running.

Caution! Never make direct conductive connection between both poles of the battery to avoid a short circuit and a hazard of explosion of the battery.

Hand over the old inoperative battery for disposal according to the national regulations.