4 minute read

Functional Description – Keypad

from Dynapac 275 DI TU Engine Asphalt Compactor DRA30 Operating & Maintenance Manual 4812333211 - PDF

Working mode Rotating beacon (Option)

Vibration, MAN/AUTO

Working lights

Sprinkler MAN/AUTO

Sprinkler Timer Horn

Engine speed selector (Not applicable)

RIGHT → AUTO Working lights Turns on the working lights of canopy.

OFF

LEFT → Working lights, ON

LEFT → Sprinkler manual

RIGHT → Sprinkler auto

LED LEFT → Sprinkler spray low

LED CENTER → Sprinkler spray medium

LED RIGHT → Sprinkler spray high

Engine speed selector Not Applicable this machine

Rotating beacon (Option)

LED

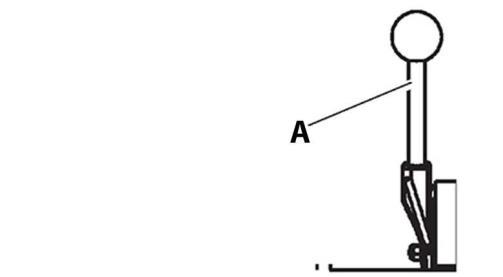

Starter Switch

The starter switch starts and stops the engine. There are three positions in the starter switch, they are:

• OFF position: In this position all the electric systems and the engine are switched off, and the key can be removed

• ON position: In this position, Engine is on run mode Charging circuit and lamp circuit are energized

• Start position: In this position, the engine cranks Make sure to allow the switch to on position until the engine is started

Throttle Lever

The throttle control regulates the speed of the engine Inforwardposition,theengineidlesandin the backward position, the engine runs with a full speed

Work/Transport mode

The 1st number button is used for work or transport mode selection. Press the button to turnon the work mode with Red illumination in button and press again to turn On the transport mode.

Emergency Stop

The emergency button is used to stop the engine in an emergency situation which it cannot be shut off in an usual manner. It switches off the engine and activates the brakes. The emergency stop aborts the entire control operation in a quicker way for the safety of the personnel

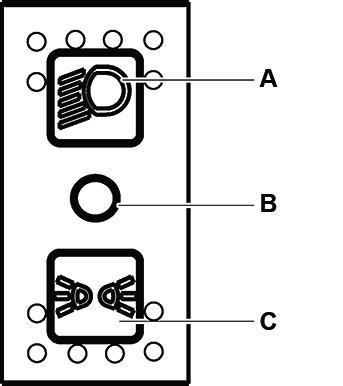

Sprinkler Switch

Figure

A. Sprinkler Manual/Auto

B. Sprinkler timer

Sprinkler timer will work only when AUTO mode Selected.

Forward/Neutral (FNR) Lever

Direction of travel and speed of the roller is regulated with the forward/reverse lever The machine speed increases or decreases in proportion to the position of the lever

Seat Buzzer

Seat buzzer beeps if the operator is not seated during the operation of the roller and it continues to beep until the operator is seated. If the buzzer beeps for long the brakes are activated and engine is forced to stop

Horn Button

The horn button is located on the switch assembly

Press the button to activate the horn

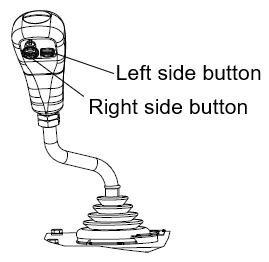

Drum Selector Switch

Depending on the Drum selector, the vibration is activated in the following places

Right side button Activates vibration for front drum.

Left side button Activates vibration for rear drum.

Note – Only front Drum will not activate, for both Drum activation first need to activate Rear Drum then activate Front Drum.

Vibration Activation Switch

In first press, Vibration MAN mode is selected with RED illumination in left side & in second press, Vibration AUTO mode is selected with RED illumination in right side.

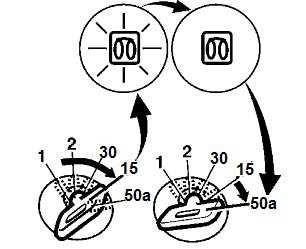

Fuse Box

The fuse box is located on the control column whichcontainsthe fusesfor theelectricalsystem. Fuses protect the electrical components from damage because of a short circuit Refer to electricalsystem forthe description andfunctions of the fuses

Driving Lights Switch

Push up, to switch on the driving lights and depress to switch on the parking lights In Intermediate position the lights are switched off.

Hazard Warning Lights Switch

Hazard warning lights are primarily used to warn other vehicles that there is a problem either with the roller, or there is a hazard in front of roller causing the operator to reduce speed quickly.

A Push up Position

B Intermediate position

C Depressed position

Rotating Beacon Switch (Optional)

Rotatingbeaconlightingisgenerallyusedtowarn the approaching machine of potential hazards, suchasmachinethat isstoppedormovingslower than the rate of the traffic

Depress the switch to switch on the rotating beacon

Working Lights Switch (Optional)

Depresstheswitchtoswitchontheworkinglights

Depress the switch to switch on the hazard warning lights

Direction Indicator Switch

The direction indicators are blinking lamps mounted near the left and right, front and rear cornersof theroller Depress the switch either left or right, to on the left or right indicators. In the intermediate position the function is shut off

Parking Brake On/Off Switch

The parking brake On/Off switch is used to activate the parking brake.

N o t e Parking brake must be activated while starting the engine Always activate the parking brake when the machine is stationary on a sloping surface

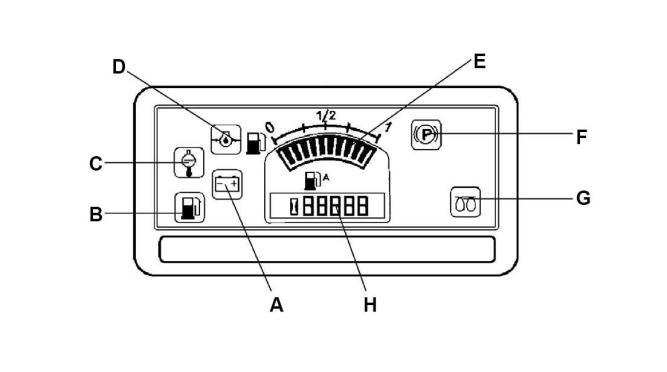

Control Panel

A Battery/charging E Fuel level

B Low fuel level F Parking brake lamp

C Engine water temperature G Glow plug

D Oil pressure, engine H Hour meter

Control Panel Warnings Symbols

Warning lights comes on when the starter switch is turned to the on position and should goes off once the engine has started If the lights comes on when the engine is running indicates a faulty condition

Designation Function Description

Battery charging indicator lamp

If light does not illuminate when ignition is switched on, illuminates after engine is started, the battery is not charging Contact maintenance personnel if the lamp comes on during tramming

Dieselengine lubricating oil pressure indicator lamp

Enginetemperature signal lamp

If the pressure is too low, the lamp comes on and the parking brake is applied In this event, switch the engine off immediately andrectifythecause Contactmaintenance personnel

The lamp comes on when the temperature is too high The engine must be switched off immediately and contact the maintenance personnel if the lamp comes on during tramming

Low fuel level indicator. This lamp comes on if the oil level is low in the fuel tank

Control Panel Notificationion Symbols

Notifications are displayed when the starter switch is turned to the on position and notifies that corresponding systems are operating.

Table

Designation Function Description

Parking brake indicator lamp

The light illuminates when the parking brake is activated

The fuel level gauge

The fuel level gauge monitors the level of fuel in the fuel tanks of the roller The fuel gauge is shown in increments of zero, 1/4, 1/2, 3/4, and one. When the indicator needle shows 1/4, the fuel tank should be filled

Hour meter

It displays the number of hours the engine has run