Parts Catalog

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

SOW TO: JIM WALTERS RESOURCES, INC.

BIRMINGHAM, AL 35283-0079

SHIP

*53035135 *1490142 5030192 1610415 1610406

DESCRIPTION GENERAL ARRANGEMENT CAUTION STATEMENT

TAG INSTAlLATION TOOLKIT

CABlE OUTIlNE DIAGRAM

SCHEMATIC-RN,NS,RM,RL,20,OE,W,2B

SCHEMATIC lEGEND

COMMON PARTS, ElECT. 95, RL

MOTOR CUTTERHEAD 200 HP

MOTOR 40HP. 950V/550V 60H2 PUMP

KIT, MOTOR & GLAND GATHERING

MOTOR, 40HP. 950/550V,60H2 GATHERING HEAD

ASSEMBLY TRACTION MOTOR

SWITCH, TRAM, ISC

CABlE ASSEMBLY, IS.TRAM

SWITCH ASSEMBLY

TRAILING CABLE ENTRANCE GLAND KIT

RADIO OPTION W/DUAL "E" ANTENNA

RADIO PARTS SUMMARY-RN, (DUAL WHIP)

ElECT. ACCESSORY PLUG ASSEMBLY

LAMP, MARK V WIMICRONAIRT

OPERATOR UNIT,RADIO TRANSCEIVER

JUNCTION BOX ASSEMBLY, XIP

WIRING DIAGRAM, JUNCTION BOX

INSTAlLATION DIAGRAM ME1HANE MONITOR, AEI

DRAWING NO.

DESCRIPTION

1 - ELECTRICAL (continued) 1100290 *30210140 *1100266 1410306 1410241

KOEHLER UGHTING SYSTEM (3+4) UGHTING FIXTURE INCANDESCENT HEADUGHT WWOILKIT OPTION - CONN BOX

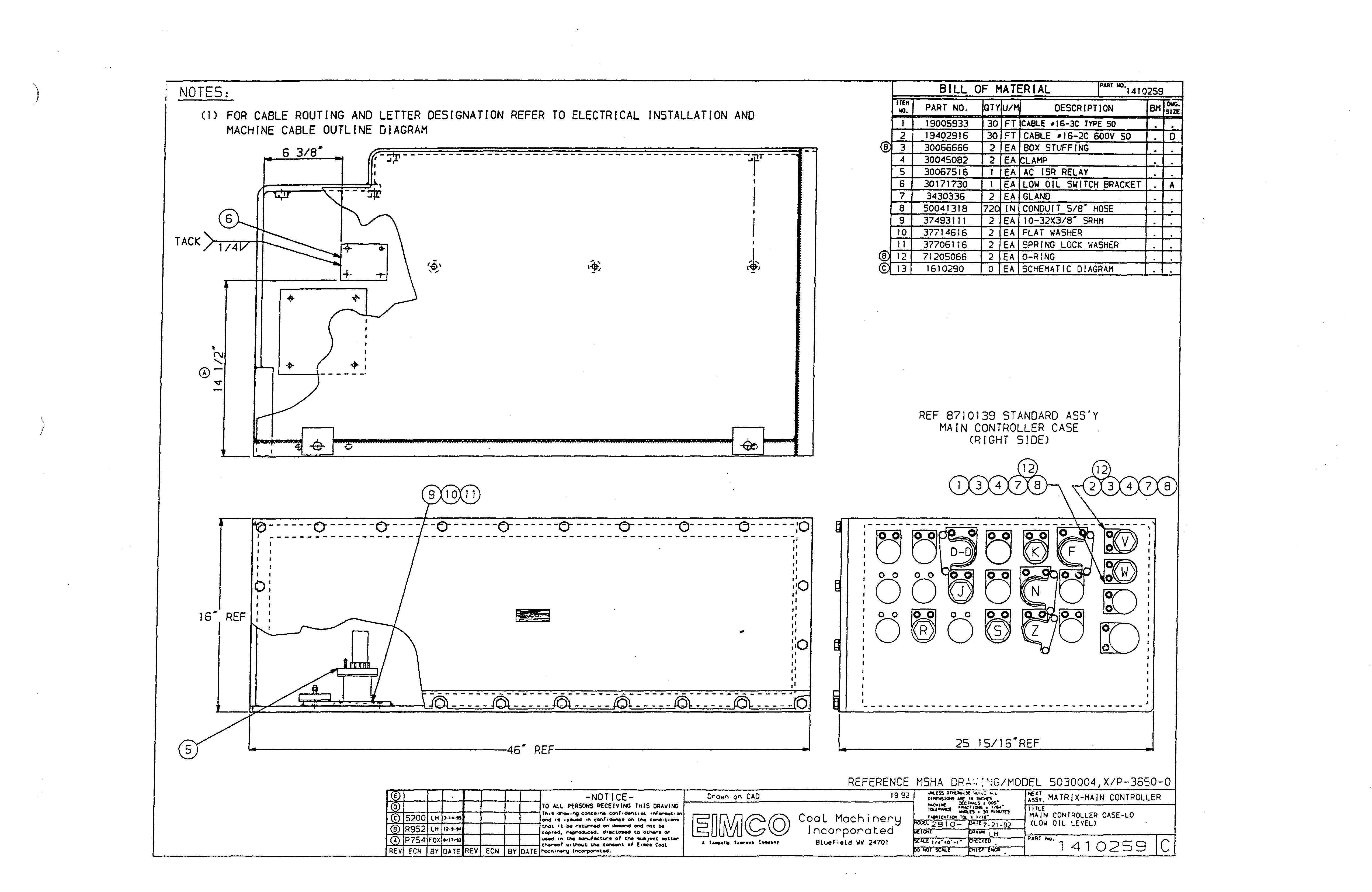

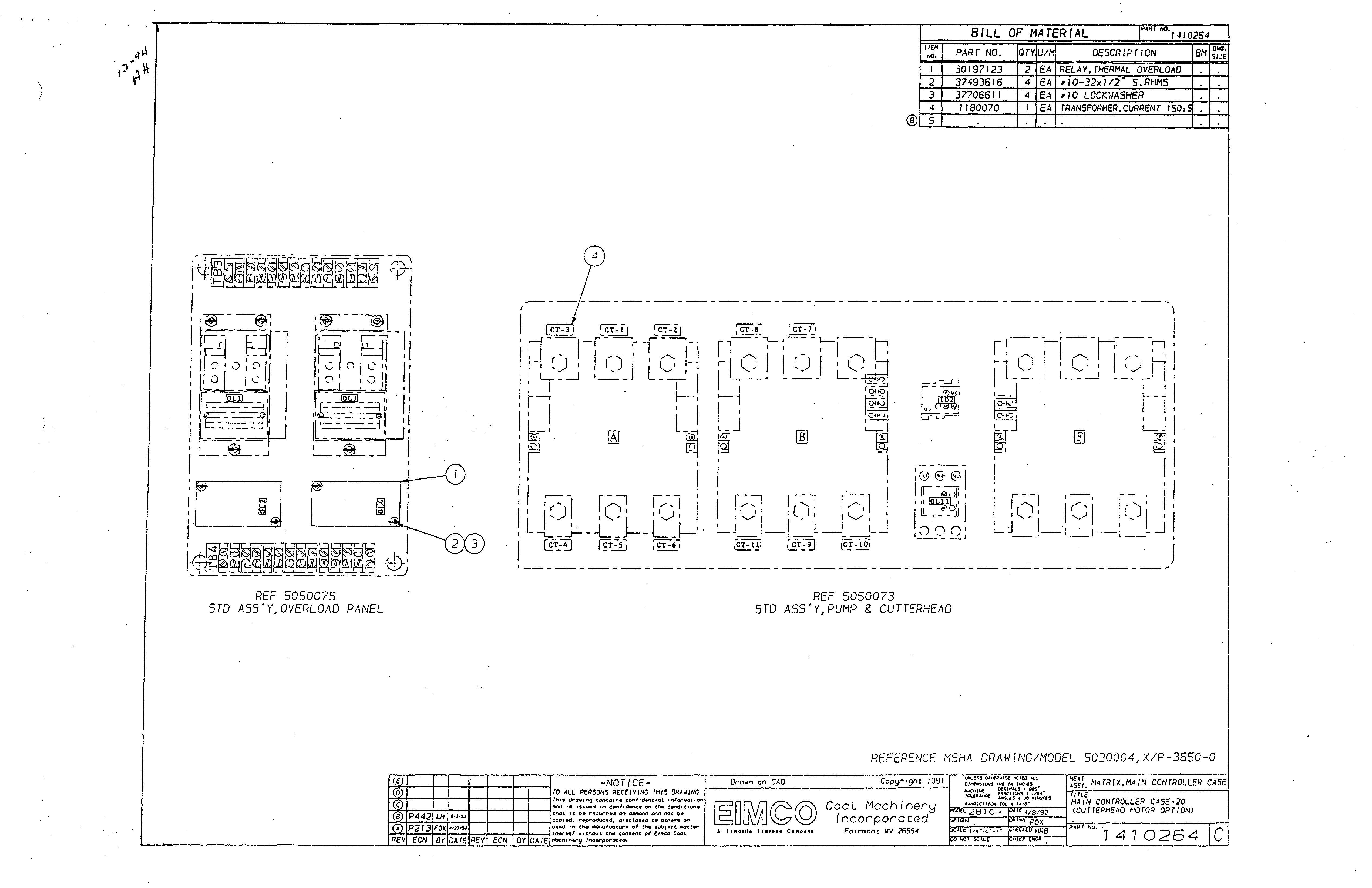

2 - ELECTRICAL - MAIN CASE (LEFT SIDE) 8710207 8710139 1610418 1610417 1610419 1610358 1490144 5050073 5050074 5050075 1410257 1410259 1610290 1410261 1410262 1410264 1410298 1410331 60244621

MATRIX, MAIN CON CASE-RN,NS,W,RM,LR,20

STANDARD ASSEMBLY, MAIN CONT. CASE

WIRING, MAIN CON-RN,RL,RM,20,NS

WIRING PUMP/CUTTERHEAD - 20

WIRING, SWING PANEL - RN

WIRING, OVERLOAD PANEL - 20

RADIO PARTS SUMMARY

PANEL ASSEMBLY, PUMP & CUTTERHEAD

STANDARD ASSEMBLY SWING PANEL

STD. ASSEMBLY OVERLOAD PANEL

MAIN CONTROLLER CASE

MAIN CONTROLLER CASE -W

SCHEMATIC DIAGRAM - W

MAIN CONTROLLER CASE - RM

MAIN CONTROLLER CASE - NF

MAIN CONTROLLER CASE - 20

MAIN CONTROLLER CASE - RL

MAIN CONTROLLER CASE - RN

COVER ASSEMBLY

*Indicates Drawing Not Included In Parts Catalog - For Reference Only.

(continued)

6 - TRACTION FRAME (continued)

60243093 50132709

60238015 60238016 60242820 60230424

60240217

60240509 49203268 60240186 60240512

60236416 60242523 60242228 60236904

60239726 60239728 60239727

60235340 60235339

60235337

60243093 90916131

60233583

60236735 60236757 60239656 60236877 10 - GATHERING HEAD

60246514 60234278 60232480 60232481 60236755

60236345

60022431

SUPERBOLT INSTAlLATION & TORQUE SPEC

TRAM MOTOR & HOSE FITTINGS

TRAM DRIVE ASSEMBLY (R.H.)

TRAM DRIVE ASSEMBLY (LH.)

PRIMARY PLANETARY ASSEMBLY

SECONDARY PLANETARY ASSEMBLY

TRACK BELT ASSEMBLY

TRACK TAKE-UP ASSEMBLY

TAKE-UP CYLINDER

IDlER ASSEMBLY

SHIM PACKAGE - FRONT IDLER

STABIUZER ASSEMBLY

TRAillNG CABLE CLAMP

INSTAILATION DIPSTICK

INS TAIL. KOEHLER 4X3 COVERS/GUARDS

R.H. END DRUM LACING CENTER DRUM LACING

LH. END DRUM LACING

DRUM DRIVE ASSEMBLY R.H.

DRUM DRIVE ASSEMBLY L.H.

CUTTER HEAD ASSEMBLY

INSTAlLATION SUPERBOLT

CLUTCH ASSEMBLY

BOOM ASSEMBLY

BOOM STOP INSTAILATION

INSTAILATION WELD STRAPS (CENTER CUTTER DRUM)

INSTL., BOOM CYLINDER HOSE GUARD

INSTL., BOOM COVERS SPECIAL

GATHERING HEAD ASSEMBLY FOOTSHAFT ASSEMBLY

GATHERING HEAD GEAR CASE ASSEMBLY L.H.

GATHERING HEAD GEAR CASE ASSEMBLY R.H.

INSTAlLATION STOP GATHERING HEAD

CONVEYOR ASSEMBLY

ROLLER ASSEMBLY

CONVEYOR CHAIN

LUBRICATION

EIMCO warrants that there are no defects of material or workmanship in new machines, replacement parts, service exchange or rebuilt parts or units for the period shown below after delivery of said item. The Seller also reserves the right to prorate warranty in the case of wear items.

New machines - six months

Replacement parts - four months

Service exchange parts - four months

Rebuilt units/parts - four months

Standard usage items - Not warranted (cable, hose, fittings, filters, fuses, etc.)

Any repair or replacement of defective material or workmanship shall not extend said warranty period.

Warranty, on part replaced under a new machine warranty, will end on the same date as the machine warranty.

Warranty on parts sold or replaced after new machine warranty has expired will have the warranty period noted above.

If within such warranty period it is established that any material or workmanship in the goods was defective, the Seller shall, at it option, either repair or replace such defective material or workmanship F.O.B. its factory or where the goods are located.

The foregoing warranty is exclusive and is in lieu of all other warranties where written, oral, or implied (including any warranty of merchantability or fitness of purpose). Purchaser agrees that no representations, promises, or statements have been made by Seller unless endorsed herein in writing except that Seller hereby extends to Purchaser the Seller's warranty against defective material and workmanship set forth above.

No allowance will be made for repairs or replacement not authorized in writing by the Seller through thtEIMCO warranty claim request system (WeR); such allowance will be credited to the Purchaser only after it has returned to the Seller the material which is claimed to be defective as follows:

Parts within 5 working days.

Service exchange units within 15 working days.

SHIPPING ADDRESS

CORPORATE OFFICE

ROUTE 52 NORTH BLUEFIELD, WV 24701

1ELEPHONE: 304/325-0481

FACSIMILE: 304/324-3658

MANUFACTURING

ROUTE 52 NORTH BLUEFIELD, WV 24701

1ELEPHONE: 304/325-0481

FACSIMILE: 304/324-3658

BENTON, ILLINOIS

1201 BLAKELY (WEST CITY) BENTON, IL 62812

1ELEPHONE: 618/439-7506

FACSIMILE: 618/438-0705

BOLT, WEST VIRGINIA ROUTE 99

BOLT, WV 25817

TELEPHONE: 304/934-5351

FACSIMILE: 304/934-6062

NORTHERN REGION WAREHOUSE

2 PAISLEY INDUSTIAL PARK CARMICHAELS, PA 15320

1ELEPHONE: 412/966-8700

FACSIMILE: 412/966-2810

NORTON, VIRGINIA

ROUTE 23, NORTH (ESSERVILLE) WISE, VA 24293

1ELEPHONE: 540/679-0194

FACSIMILE: 540/679-5806

FACILITIES LIST/SALES AGENTS

MAILING ADDRESS

P.O. Box 1100 BLUEFIELD, WV 24701

P.O. BOX 1100 BLUEFIELD, WV 24701

P.O. BOX 775 BENTON, IL 62812

P. O.BOX 159 BOLT, WV 25817

SAME AS SHIPPING

P. O. BOX 630 WISE, V A 24293

SHIPPING ADDRESS

HAGER EQUIPMENT

1901 MORGAN ROAD SOUTHEAST BESSEMER, AL 35023

1ELEPHONE: 205/424-1363 FACSIMILE: 205/424-1367

TRIUNE, INC. GENERAL OFFICES 23281-70 FRONTAGE ROAD GRAND JUNCTION, CO 81505

1ELEPHONE: 303/242-2200 FACSIMILE: 303/241-4198

TRITRONICS (DIVISION OF TRIUNE) 23281-70 FRONTAGE ROAD GRAND JUNCTION, CO 81505

1ELEPHONE: 303/241-9100 FACSIMILE: 303/241-4198

TRIUNE, INCORPORATED

175 EAST 200 SOUTH PRICE, UT 84501

1ELEPHONE: 801/637-4836

FACSIMILE: 801/637-9730

#8 BOWKER STREET ROCK SPRINGS, WY 82901

1ELEPHONE: 307/362-1515

FACSIMILE: 307/362-4901

1912 RATCLIFF DRIVE GILLET1E, WY 82717

1ELEPHONE: 307/686-1515

FACSIMILE: 307/686-9161

1602 EAST GREEN CARLSBAD, NM 88220

1ELEPHONE: 505/887-7600

FACSIMILE: 505/887 -7792

MAILING ADDRESS SAME AS SHIPPING SAME AS SHIPPING ADDRESS SAME AS SHIPPING ADDRESS

P.O. BOX 1405 PRICE, UT 84501

P. O. BOX 1148 ROCK SPRINGS, WY 82901

SAME AS SHIPPING ADDRESS

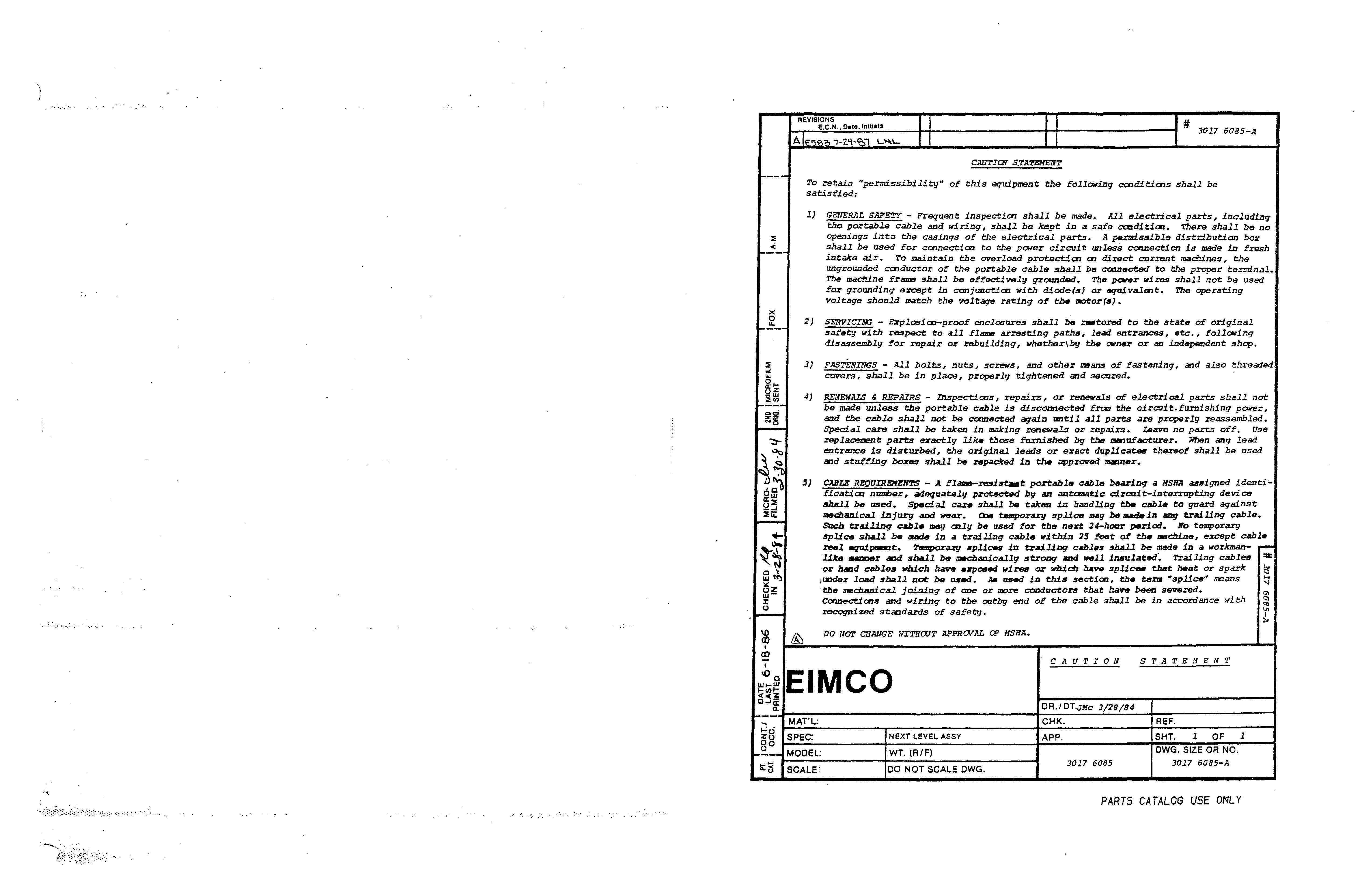

REVISIONS

E.e.N .• Oa18. InitialS

CAT:1'1'ICN S:tATBHENT

To retain "permissibility" of this equipaent the follOflling Ca:lditions shall be satisfied:

1) G'ENF:RAI. SAFETY - Frequent inspecticn shall be made. All electrical parts, including the portable cable and wiring, sball be kept in a safe Ca:ldition. Thare shall be no openings ineo the casings of the elecerical parts. A diseributiOlJ box shall be used for connection to the power circuit unless CCXl.Cection is made in fresh intake cd.r. To maineain the overload protection on direct current machines, the ungrounded conductor of the portable cable sball be C'alll.cted to the proper ter.ni.nal. machine fraIM shall be effectJ.velg grounded. 7'1le pater wi:r:es shall not be used for grounding ezcept in conjunction with diode{tJ) or sqalvalsnt. The operating voltage should match the voltage rating tn. motor{s).

2) SERVICIM:; - Erplosion-proof enclosares sball be rrwtored to the state of anginal safetg loll th respect to all flame ar:re:Jting paths, lead entrances, etc., follCMing disassemblg for repair or rebuilding, whether\bg tbe cwner or au independent shop.

3) FASTENINGS - All bolts, nuts, screws, and other lII!ans of fastening, and also threaded covers, shall be in place, properlg tightened and secured.

4) RENEWALS & REPAIRS - Inspections, repairs, or renewals of electrical parts shall not be made unless the portable cable is disconnected from the circa1t. fUrnishing power, and the cable shall not be coanected again ootil all parts are properlg reassembled. Special care shall be taken in making renewa13 or repairs. Isave no parts off. Use .replacement parts e%actly liM those famished bg the When any lead entrance is disturbed, the onginal leads or ezact daplicatetl thereof shall be used and stuffing oozes shall be repacked in t:JJ. approved llIaIlJ2er.

3} CABU REOumElfnt'rS - A flazIJe-resin.t: portable cable bearing a HS11A all/signed identif.!catica nlIlDber, adeqllatelg protectsd b!J an antazaatic c::frcait-interrapting devi ce shall be ased. Spec::fal care shall be takeu in bandling tbe cable to guard against: mechanical injury and wear. OW te.porary splice lJJa!J be lNdein aug trailing cable. SUch trail:!ng cabl. lJJag onlg be rzslSd for t:be nert 24-hoar period. No tettrporarg splice shall be l1JlIdA!I in a trailing cable within 25 feet _dUne, ezcepe cable reel equipaBJt:. 2'lIIIIpOrarg .plic. in tra1ling cMJles shall be made in a loIorkman- ,...... like -.r aDd sball be rz»cball.icallg serang .md _11 Trai ling cables or bill2d cables wb.1cb bave e%pOlled ..,ires or wblcb 1uve that: heat or spark IUDder load sball nIX be u..a. A& ased in this section, the term "splice" means !::i the 11IIIc/:uuJi.cal joining of one or IlIOre cozxlactors that have beea severed. a. Connecticns and "iring to the oatbg end of the cable shall be in accordance wi th recognized standards of safetg. Y' !l:I

DO NOT CHANGE WITHaJT APPRWAL OF MSHA.

CAUTION STATE.'fENT

TOOLKIT

1 60210960 1 EA SLIDE HAMMER 2 60210986 2 EA GUIDE PINS

NOTES:

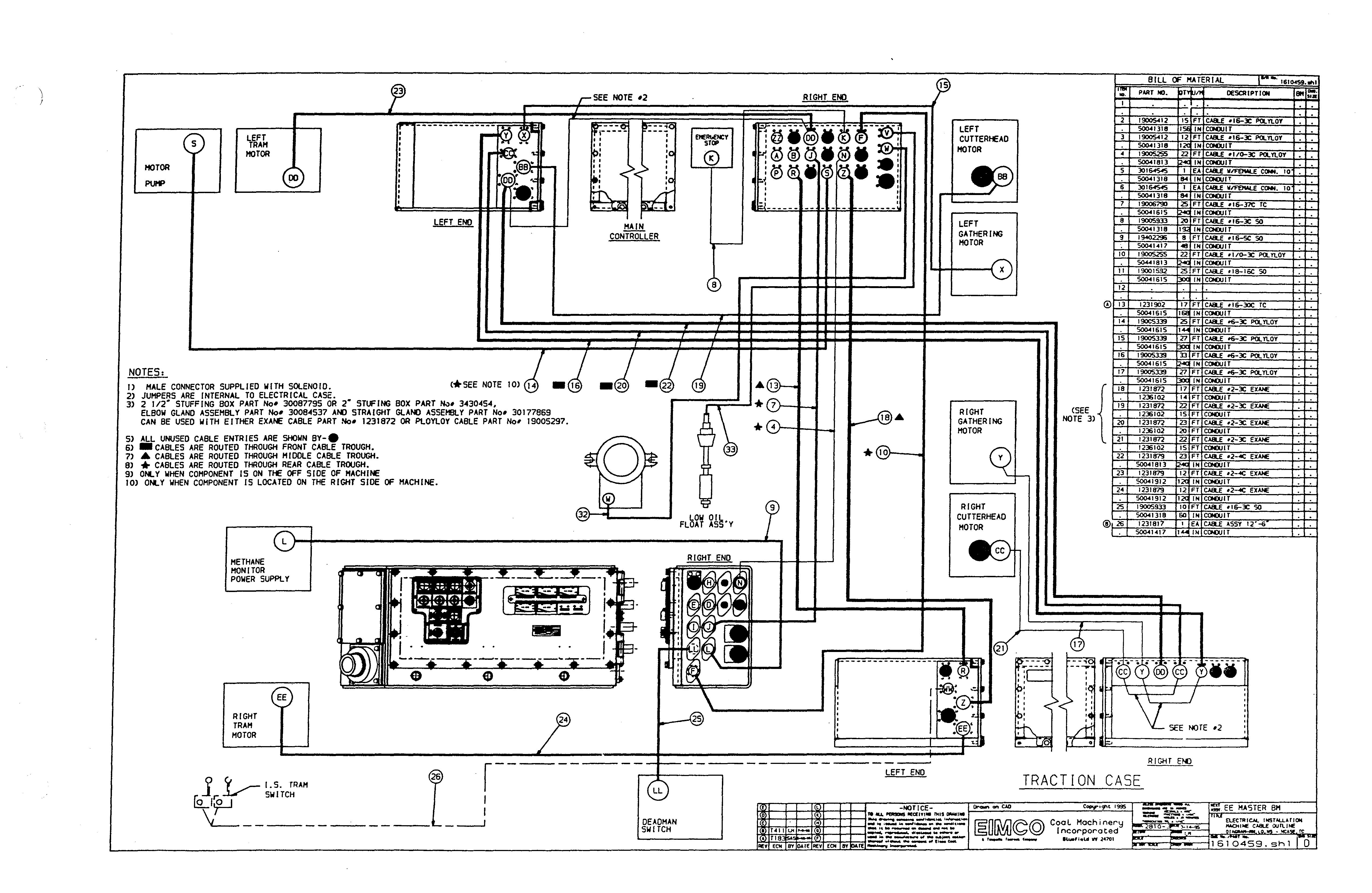

I) HALE CONNECTOR SUPPLIED WITH SOLENOID. NOTE 10)

2) JUMPERS ARE INTERNAL TO ELECTRICAL CASE.

3) 2 1/2- STUFFING BOX PART No' 30087795 OR 2- STUFING BOX PART No. 3430454, ELBOW GLAND ASSEMBLY PART No. 30084537 AND STRAIGHT GLAND ASSEHBLY PART No. 30177869 CAN BE USED WITH EITHER EXANE CABLE PART No. 1231872 OR PLOYLOY CABLE PART No' 19005297,

5) ALL UNUSED CABLE ENTRIES ARE SHOWN

6) _ CABLES ARE ROUTED THROUGH FRONT CABLE TROUGH.

7) CABLES ARE ROUTED THROUGH MIDDLE CABLE TROUGH.

8) CABLES ARE ROUTED THROUGH REAR CABLE TROUGH.

9) ONLY WHEN COMPONENT 15 ON THE OFF SIDE OF MACHINE 10) ONLY WHEN COMPONENT IS LOCATED ON THE RIGHT SlOE OF MACHINE.

REFER TO IOIIITIiR Hit YAC INSTAlLATlOII ORAIiIlIi FOR S'7PECIFIC".RING Yft Iio rAC

t,) RADIO HANUAL SWITCH SHOWN IN I1AMJAL POSITION, 2,) • - ASTERIK INOICATES LOCATION OF SOLID STATE SHORT CIRCUIT PROTECTION IN TH! RADIO MACHINE UNIT "H/U", AN OUTPUT PROTECTED WITH THIS Will TRIP WHEN TIE OUTPUT SEES A SHORT CIRCUIT, TO ReSET SOLID STATE SHORT CIRCUIT PROTECTlON,OUTPUT (I ••• StEAR-IJPl I1UST BE TURNED OFF FOR APPROXIHATELY ONE HINUTE BEFORE ReTRYING. THIS WilL ALLOW AUTOMATIC RESET OF SOLID STATE SHORT CIRCUIT PROTECTION. 3.> INDICATES OUTPUT FROH RADIO TRANSCEIVER (H/U) I.

A -lEFT CUTTER MOTOR g CONTACTOR

LEGEND

E -SCRUBBER MOTOR & CONTACTOR Oll O-ovERlOAD. SCRUBBER. THERMAL

AA -lEFT MOTOR AMMETER STOP RELAY Olll-OVERLOAD,PUMP THERMAL

B -RIGHT CUTTER MOTOR & CONT.

BA -RIGHT CUTTER MOTOR AMMETER

BRI -BRIDGE RECTIFiER F/METHANE MONITOR

BR2 -BRIDGE RECTIFIER (RADIO RELAY BOX)

BR4 - BRIDGE RECTlr!ER F/FS SOLENOID

I C -LEFT G:'"7"'-i H::AD

F -PUMP MOTOR & CONTACTOR OlI2-0VERLOAD,lEFT TRAM THERMAL

F3 -120V CONTROL CIRCUIT FUSE OlI3-0VERLOAD,RIGHT TRAM THERMAL

F4 -120V CONTROL CIRCUIT FUSE POR-PUMP OFF RELAY

FS -AREA lIGHT FUSE PSR-PUMP START RELAY

F6 -AREA lIGHT FUSE REV-REVERSE

F7 -HEADLIGHT FUSE RFR-RIGHT FORWARD RELAY

Fa -HEADLIGHT FUSE RRR-RIGHT REVERSE RELAY

I I ;=9 -METHANE MaN I TOR FUSE SOR-SHEAR DOWN REL.AY __ __M_O_T_O_R_A_M_M_E_T_E_R__

CBI-CIRCUl: BREAKER. MAIN

CB2-CIRCUIT BREAKER,AUXllIARY

CD -CUTTER/OUST SOLENOID

FiO -METHANE MONITOR FUSE SS -SCREEN SPRAY SOLENOID

FI3-RADIO RELAY BOX FUSE SSR-SCRUBBER START RELAY

FI4-RADIO RELAY BOX FUSE 5T -SHUNT TRIP

FI5-RADIO RELAY BOX FUSE STD-STAB DOWN RELAY

COR-CONVEYOR DOWN R=L.AY I FS -FIRE SPRAY SOLENOID STU-STAB UP

CF -CONVEYOR FORWARD CONTACTOR FWD-FORWARD SUR-SHEAR UP RELAY

ClR-CONVEyer:: L.EF 1 R=LA Y I G -L.EFT TRAM MOTOR TO - Tl ME DELAY I COM -COMMeN I GA -LEFT TRAM MOTOR AMMETER T02- II ME DELAY

irl SOR-CUIT::=:( v ?E:... ..:.v I GFK-GATH HD FORWARD RELAY ID3-TIME DELAY

I C?R-CODE "AN [C Y I GHO-GA TH HD DOWN RELAY T04- Ii ME DELAY r·

TDS-TIME DELAY ONCINLINE SOLID STATE) -I CRR-CONVEYOR RiGHT REL.AY I GOR-GA TH HD OFF RELAY V -VOLTMETER

I

i C1 4-CURREN. i!"{AM:::.

i CTS-CURREI\7 :RAMS.

CSR-CUTTER s-:- ART RE:""AY H -R IGriT TRAM MOTOR I CTi-CURREN7 iRAMS. F/LEFT CUTTER HEAD AMMETER HA -RIGHT TRAM MOTOR AMMETER i =IL=FT CUTTERHEAD INST OVERLOAD I HR -HEADLIGHT RELAY I Ci3-CURRE"; =ITRAM INTERFACE I HlR-'-iEADLIGH RELAY CRAO I0) I -/LEFT CUTTERHEAD THERMAL OVERLOAD . HM -HOUR METER CCUTTERHEAO & GATH.HD.MOTORS CUTTER HEAD THERMAL OVERLOAD IRI-ISOLATION RELAY

CIS-CURRENT :RAMS. F/LEFT CUTTER HEAD THERMAL OVERLOAD IR2-ISOLATION RELAY

CT7-CURRENT TRAMS. F/RIGHT CUTTERHEAD AMMETER I.S.-INTRINSICAllY SAFE

CTS-CURRENT TRAMS. F/RIGHT CUTTERHEAD INST. OVERLOAD lFR-LEFT FORWARD RELAY

CT9-CURRENT TRAMS. F/RIGHT CUTTERHEAD THERMAL OVERLOAD lOl-LOW OIL WARNING lIGHT

Cil O-CURRENT TRAMS. F/RIGHT CUTTERHEAD THERMAL OVERLOAD LOR-lOW OIL lEVEL RELAY

CTII-CURRENT IRAMS. F/RIGHT CUTTERHEAD THERMAL OVERLOAD LRR-lEFT REVERSE RELAY

I CT T iRAMS. F/LEFT GATH HEAO AMMETER MMR-METHANE MONITOR RELAY

CTI3-CURRENT TRAMS. F/lEFT GATH HEAD INSTANEOUS MOVI-METAL OXIDE VARISTOR (RADIO)

. CT1il-CURRENT iRAM=. F/RIGHT GATH HEAD INSTANEOUS OVERLOAD Oll-OVERLOAD,lEFT CUTT INST.

CT16-CURRENT TRAMS. F/lEFT TRAM AMMETER

CT17-CURR::Ni TRAMS. F/RIGHT TRAM AMMETER

CTIS-CURRENT TRAMS. F/RIGHT GATH HEAD AMMETER

Ol2-0VERLOAD,lEFT CUTT THERMAL

Ol3-0VERLOAD,RIGHT CUTT INST.

Ol4-0VERLOAO,RIGHT CUTT THERMAL

CUR-CONVEYOR UP RELAY GATH INST.

D -RIGHT GATn HD MOiOR

DA -RIGHT GA;H. HO. MOTOR AMMETER

OMR-DEADMAN RELAY

Ol6-0VERLOAO,LEFT GATH THERMAL

OL7-0VERLOAD,RIGHT GATH INST.

Ol8-0VERLOAD,RIGHT GATH THERMAL

60H 19005339 36 FT CABLE, -6-3C POLYLOY 30066666 2 EA BOX, STUFFING B 30087183 2 EA STUFFING BOX PLUG B 3004S082 4 EA CLAMP A 30098883 2 EA GLAND ASSEMBLY A

6 EA 3/8-16 x 7/8- SHCS GR.8 37707189 8 EA LOCKWASHER, 3/850041615 360 IN CONDU I THOSE, 1- A 3236085 REF EA SEAL WIRE B 37559818 2 EA 3/8-16 x 718- SHCS DR 37400975 8 EA 1/4-20 x 5/8 HHCS CP 37101813 8 EA 1/4-20 HEX NUT CP 37706512 8 EA 1/4

DESCRIPTION

BRACKET MACHINED, B.E. SNAP

SHAFT INNER CAP, B.E. INNER CAP, F.E. SHAFT, MACHINED

ARMATURE ASSEMBLY ROCKER CLAMP COVER,HAND HOLE BRUSH BRUSH HOLDER

ARMATURE CORE END PLATE, ARMATURE M8-1 .2sx2SMM SHCS

M8-HI COLLAR LW 2.MH SPACEP. COMMUTATOR

COMMUTATOR ':OIL SUPPORT

BEARING, BALL SNAP RING '0' RING, F.E. & B.E. ROCKER RING W/STUDS '0' RING, SHOULDER SCREW '0' RING, H.H. COVER COVER, F.E. BRACKET PLUG, SHAFT

SNAP RING, SHAFT PLUG WATER JACKET

'0' RING BRACKET COVER '0' RING" SHAFT PLUG

MI2-1.7S x 30MM L SHCS

Ml2 HI-COLLAR L.W.

MIO-I.S x 2SMM L HHCS

MIO HI-COLLAR L.W. SEAL t3.E. OUTER

SIZE

A A 200 No. 9261

12 COND, A

No. 20AWG. BELDEN BLACK 200 BL.ACK -WH I TE

B RED 50 B RED-BLACK 40 2 1190379 1 EA HEAT SHRINK TUBE WYE

C ORANGE 59 C ORG-BLACK 49 CABLE SPLITTING DEVICE,

0 GREEN 151 0 GRN-BLACK 141

THERMOFIT No.3B2012-3

CONNECTOR E BLUE 60 E BLUE-BLACK 61 3 1460061 9 IN 1/2" I . D. HE AT SHR 1NK

PIN DESIGNATION ® F WHITE 52 F WHITE-BLACK 42 ®

1 • AFTER SHRINKING THERMOFIT SPLITTING DEVICE

TUB!NG, VOlTREX TYPE

FPS-032

4 30153142 6 IN 3/16" I. D. HEAT SHR!

IN PLACE PUT'1/2" DIA. SHRINK TUBE OVER EACH 5 1190380 2 EA CONNECTOR ASSEMBLY,

LEG OF THERMOFIT AND EXTEND UNDER THE CONNECTOR

BUSHING TO WITHIN ONE INCH ON END OF WIRES.

2. 3/16" DIA. SHRINK TUBE, 1/2'" LONG - TO BE APPLIED

· AMPHENOl 6 - PIN,

CONS I STI NG OF:

CONNECTOR No.MS3106A-14S-6S TO EA.CH WIRE WHERE IT IS SOLDERED TO THE CONNECTORS.

CLAMP No.97-3057-1007

BUSHING No.9779-513-6

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

TAMROCK COAL

FEMALE

o 1. TERMINAL wEw OF CONNECTOR 1030729 TO BE SOLDERED TO (RED) POSITIVE WIRE.

o 2. TERMINAL wFw OF CONNECTOR 1030729 TO BE SOLDERED TO (BLACK) NEGATIVE WIRE.

3. * REMOVE CABLE· FROM 53U41778 (CORD ASS' Y. ) AND REPLACE WITH 53036414.

ALL OTHER HOLES

NOT USED TO BE PLUGGED.

o USE INSTRUCTIONS IN wVEAMw TOOL KIT FOR CONNECTOR INSTALLATION.

® REMOVE 1 1/2· OF OUTER CABLE JACKET & PUSH SLACK INTO CONNECTOR SHELL, TIGHTEN LOCKING RING FIRMLY.

BILL OF MATERIAL 1 8/H No PART NO. QTY U/M DESCRIPTION x x p ,,- BLK I ... -127 ,,- WHT I ... -128 ,,- RED I -130 V- GRN I ... -1 32 V- ORN I -129 V- BL U I .•. -136

vWHTIBLK-133

V RED I BLK -138

r GRN IBLK- •.• ,,- ORN IBLK- •.. r BLUIBLK-, ,,-BLKIWHT- ••. ,,-REOIWHT-131

V- GRN I WH T -135

V-BLUIWHT-137

Y' BLK I REO-l 34

1. WIRE CORRESPONDING COLOR AND NUMBERS ON CABLE BETWEEN TERMINAL STRIP.

1 1410311 I EA AEI METH. MONT. SYSTEM

WHT

} 2 30210140 1 EA HEADLIGHT, DUAL GLAND

. 3 30136162 1 EA PLUG

REO} 4 3430441 I EA STRAIGHT GLAND 1--190 GRN 12V S 1500044 I FT 3/8" DIA PACKING

J 91 ORG 12V 6 1100335 1 EA SO W LAMP, 12V RUN 7 19402916 15 FT .16-2C SO CABLE 8 50041318 168 IN CONDUIT 5/8' HOSE 9 1410312 REF EA 102A W/AUTORESET READOU

10 1410313 REF EA POWER SUPPLY

11 1410314 REF EA DETECTOR ASSEMBLY 12 1410315 REF EA SENSOR ELEMENT

13 19402269 REF FT 16-SC SO CABLE

14 50041417 REF IN CONOUIT 3/4' HOSE

PREPARED BY KAG

DATE 3-25-94

3

1

TAMROCK COAL

KIT LOW OIL LEVEL

TAMROCK COAL

. EIMCO COAL MACHINERY INCORPORATED

OPTION CONN BOX IN-LINE FITLC

1 19407733 25 FT CABLE TRAIL#2/0-3CSHD

2 50042118 300 IN CONDUIT HOSE 3"

3 5120030 1 EA BOX CONN ASSEMBLY(BEUMOUTII Gill)

9

7

6

5

4

3

2

1

12

MATRIX MAIN CONTROLLER -

PNL. ASSY 5050074 EA SWiNG PANEL ASSEMBLY 5050075 EA VERLOAD PANEL ASSEMBLY 37419462 24 EA 1/2-13 X 1 1/2' HHCs 37708013 36 EA LOCKWASHER, 1/2'

8 EA 1/2-13 X I' HHCs

2 EA 1/2-13 X 1/2' HHCS

2 EA 1/2-13 X 1 1/8' HHCs 30084867 3 EA ELBOW GLAND ASSEMBLY 3430452 3 EA STUFFING BOX, 2 1/2' 30045684 7 EA STUFFING BOX CLAI1P, 2 1.'2' 3"1559818 38 EA 3/8-16 X 7/S' sHCs 37707189 40 EA LOCKWASHER, 3/8'

30098883 4 EA STRAIGHT GLAND ASSEMBLY

30066666 6 EA STUFFING BOX, 2' 30045082 12 EA STUFFING BOX CLAMP, 2" 74401902 4 EA CLAMP, HOSE

1 EA ELBOW GLAND ASSEMBLY

3 EA ELBOW GLAND ASSEMBLY

2 E.A STUFFING BOX 2 1/2'

5 EA STUFFING BOX PLUG, 2'

"16-3C SO CABLE

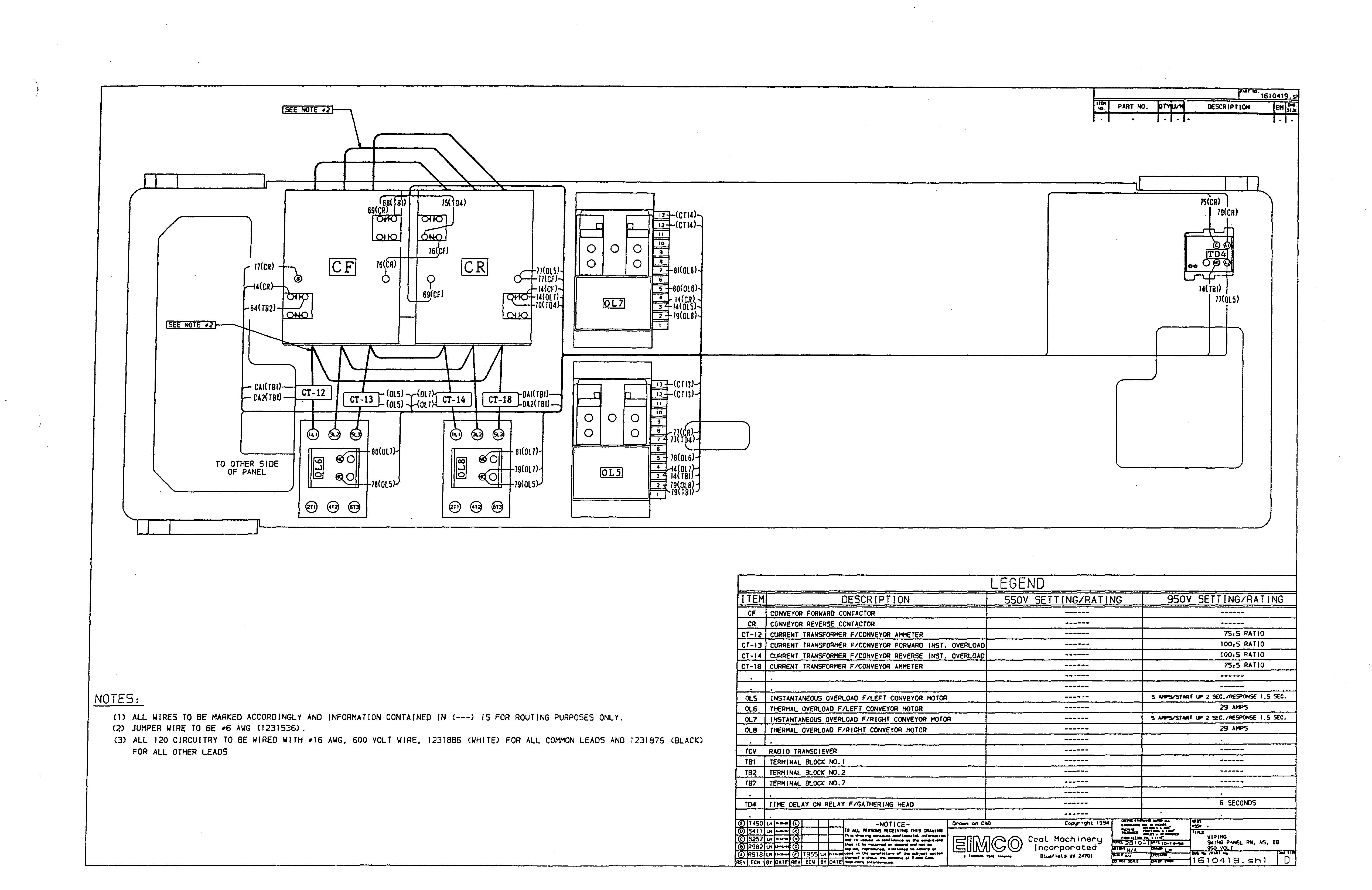

el) ALL WIRES TO BE HARKED ACCORDINGLY AND INFORMATION CONTAINED IN e••• ) IS FOR ROUTING PURPOSES ONLY

(2) ALL 120 CIRCUITRY TO BE WIRED WITH #16 AWG, 600 VOLT WIRE, 1231B66 (WHITE) FOR ALL COMMON LEADS ANO 1231876 (BLACK) FOR AlL OTHER LEADS

(3) JUMPER WIRE TO BE #6 AWG (1231536)

(4) J\)MPER WIRE TO BE #1/0 AWG (1231543)

LEGEND

SYM OEseR IPTI ON SSOV

RIGHT CUTTER HEAD CONTACTOR

LEFT CUTTERHEAD CONTACTOR

CT-l CURRENT TRANSFORMER F/RIGHT CUTTERHEAD AMMETER CT-2 CURRENT TRANSFORMER F/RIGHT CUTTERHEAD INST. OVERLOAD CT-3 CURRENT TRANSFORMER F/TRAM INTERFACE CT-4 CURRENT TRANSFORMER F/RIGHT CUTTERHEAD THERMAL OVERLOAD CT-5 CURRENT TRANSFORMER

CUTTERHEAD INST. OVERLOAD CT-9 CURRENT TRANSFORMER F!LEFT CUTTERHEAD THERMAL OVERLOAD CT-l0 CURRENT TRANSFORMER F!LEFT CUTTERHEAD THERMAL OVERLOAD

TRANSFORMER F!LEFT CUTTERHEAD THERMAL OVERLOAD

PUMP MOTOR CONTACTOR

11 THERMAL OVERLOAD FIPlM> MOTOR

13A (FI3) 127CT82)

(1) ALL WIRES TO BE MARKED ACCORDINGLY AND INFORMATION CONTAINEO IN (---) IS FOR ROUTING PURPOSES ONLY. 12A (FI 4)

10<7JI_13)10(7JI -I I)

12 (7JI -IS) 12 (7JI-6)/L.L.......::---1-l 12 (8J I-I )12 (7 J 1-17)

13 (F 13) 13 (6J I -8) 14 CCl5) 14 (F I 5)

CA I (CTT2)

CA2(CT12) 13 1-2)

68(CF)

DA I (CTT8)

DA2(CTT8) 74 CTD4)

79 (7PI-3)

148 (5JI) TO OTHER SIDE OF PANEL 7 <7 JI-4)

79 (Ol5) N.C.

88(7JI -7)

11 <7Jl-12) 11 (7Jl-14) 21 (6JI-5) 22 (6JI-3)

28(6JI-6)

(PNL2}-64(CF) 64 (6JI-7)

87 (7 JI_16)8::.:7...::(:...;7 12(FI4) 25(7Jl-l0)

121 (5JI-5)

122(5J2-3)

164 (5JI-3)

167 (5JI-2)

138 (J JI-6)

138 (2J2-6)

139(3J2_1)139(3JI-5)

127 (1 J2-1) 127 (I J 1-1)

127 (2J2 _ 1

128 (5JI-4) 24A (7 JI-9)

138 (BRS-)

139(4PJ)

127 (BRS+)

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

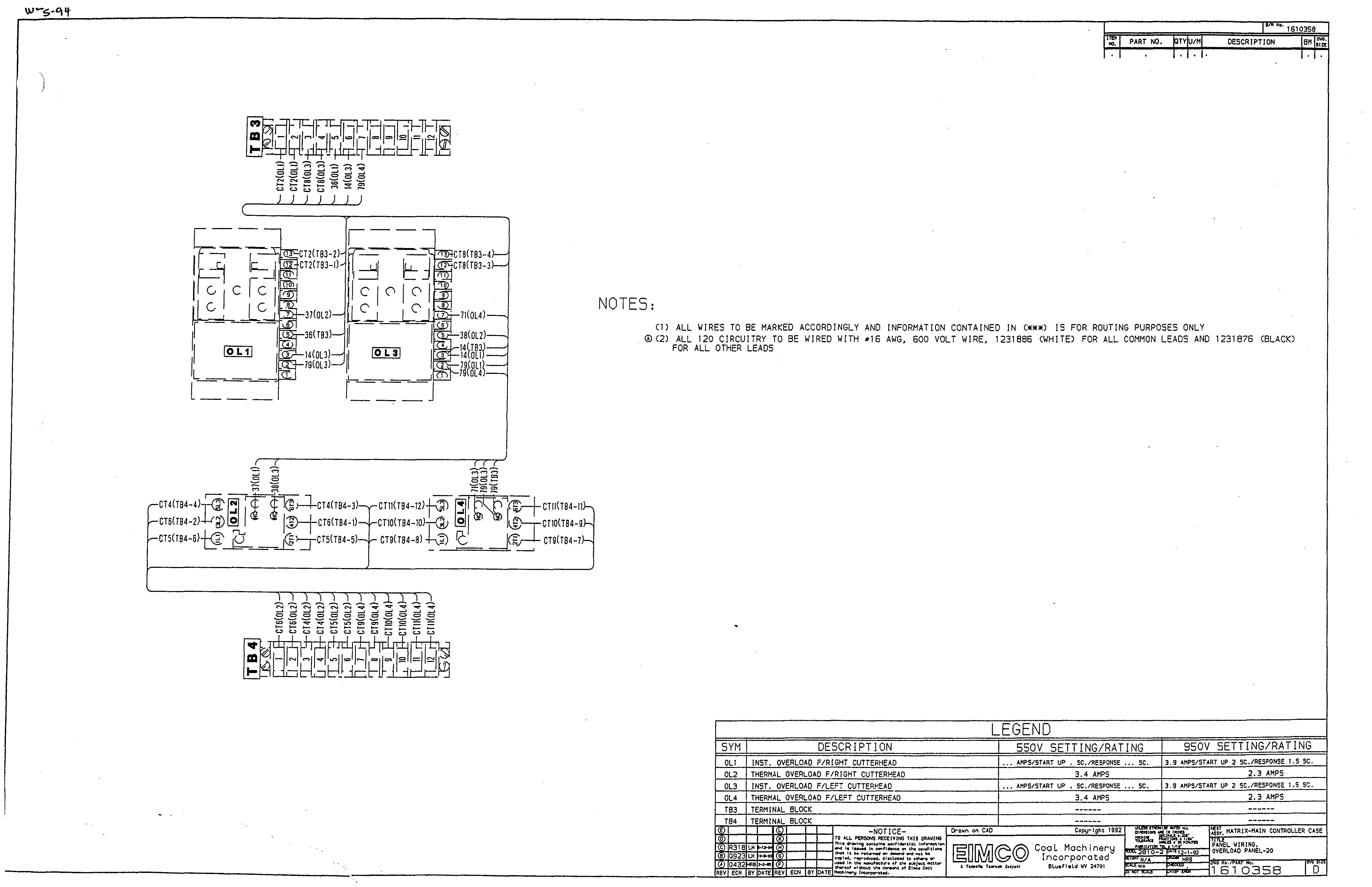

NOTES:

(I) ALL WIRES TO BE MARKED ACCORDINGLY AND INFORMATION CONTAINED IN (***) IS FOR ROUTING PURPOSES ONLY

0(2) ALL 120 CIRCUITRY TO BE WIRED WITH #16 AWG, 600 VOLT WIRE. 1231886 (WHITE) FOR ALL COMMON LEADS AND 1231876 (BLACK) FOR ALL OTHER LEADS

LEGEND

© (1) @(2) WIRE- TIE ITEMS 8 AND 9 TO TOP OR BOTTOM SIDE OF APPROORIATE REFER TO PANEL WIRING DIAGRAM TO LOCA TE ITEMS 8 AND 9, FOR SYMBOL DESCRIPTIONS AND OVERLOAD OR TIME SETTINGS.

NOTES:

(1) SEE RADIO OPTION FOR ADDITIONAL INFORMATION

(2) SEE SCRUBBER OPTION FOR ADDITIONAL INFORMATION

(3) REFER TO PANEL WIRING DIAGRAM DRAWING TO LOCATE ITEMS #17 & 18, FOR SYMBOL DESCRIPTIONS AND OVERLOAD OR TIME SETTINGS.

(4) SEE NON RADIO OPTION FOR ADDITIONAL INFORMATION

(5) SEE STANDARD CONTACTOR OPTION FOR ADDITIONAL INFORMATION SEE VACUUM CONTACTOR OPTION FOR ADDITIONAL INFORMATION

NOTES:

(1) REFER TO PANEL WIRING DIAGRAM IN THIS SECTION FOR SYMBOL DESCRIPTIONS ® AND OVERLOAD OR TIME SETTINGS.

(2) THIS IS A CUTTERHEAD MOTOR OPTION. SEE CUTTER MOTOR OVERLOAD OPTION DRAWING IN THIS SECTION FOR FURTHER DETAILS.

(1) FOR CABLE ROUTING AND LETTER DESIGNATION REFER TO ELECTRICAL INSTALLATION AND MACHINE CABLE OUTLINE DIAGRAM

NOTES: (1) FOR CABLE ROUTING AND LETTER DESIGNATION REFER TO ELECTRICAL INSTALLATION AND MACHINE OUTLINE DiAGRAM

TO ALL PERSCNS RECEIVING THiS DRAWING

This drawing contains conFidentiaL inFormation and is issued in conFidence on the conditions that i t return.d on demand ond not b. copied. repr<>du<:ed. discLosed to others or used in the IIIOnUFactUf"'e of the subject IIOtter thereoF Itith«lt th. consent of Ei/JIco CooL

BILL OF MATERIAL

-CONNECT #201 TO OPEN ENDED RESISTOR OIL LEVEL SWITCH WHT TOP OF BANK.

lH.ESS OTrERlllSE HaTED AU. NEXT 871 0082 OllEHSla6 ARE IN IHO£S ASSY HAOWE DEC HALS :t.005_ .' TCI.aWICE FRACTlONS:t 1/64 TITLE AHGl.ES :t 30 If I HUTE'S FABRICATION rOC, :t 1/16- SCHEMA TIC 0 I AGRAM, 0---9-1-1 lOW 0 III I GH T C I RCU I T

WEIGHT DRAWN WHG SCALE NONE CHECKED KlO CHIEF ENGR DO NO T SCALE D'rIG No. /PART No.

(1) FOR CABLE ROUTING AND LETTER DESIGNATION, REFER TO ELECTRICAL INSTALLATION AND MACHINE CABLE OUTLINE DIAGRAM.

NOTES:

(1) FOR CABLE ROUTING AND LETTER DESIGNATION REFER MACHINE CABLE OUTLINE DIAGRAM TO ELECTRICAL INSTALLATION AND

REF 5050073 STO ASS'Y,PUMP & CUTTERHEAO

REFERENCE MSHA DRAWiNG/MODEL 5030004,X/P-3650-0 O,..own on CAD COPY""9hC ''391 CooL Machinery [ncorporated

(1) FOR CABLE ROUTING AND LETTER DESIGNATION REFER TO ELECTRICAL MACHINE CABLE OUTLINE DIAGRAM

(2) OMIT 3/8· DIA. PACKING SUPPLIED WITH GLAND AND USE ITEM -6.

I NSTALLA TION AND

FOR CA8LE ROUTING AND LETTER DESIGNATION REFER

APPLY SILICONE, ITEM NO.3, TO EDGE OF LENS, PART NO.4, AND TO COVER PLATE, PART NO.1, TO FORM A GAS-TIGHT SEAL UP TO iSO PSI INTERNAL PRESSURE. SEE PROCEDURE SHEET 91927681-A FOR LENS CLEANING, ADHESIVE DIRECTIONS AND CAUTIONS. USE SILICONE PRIMER 554004 F/STEEL AND SILICONE

I I IPREPARED BY KAG I

DATE

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

TO ALL PERSONS REef I v I NG TH I 5 DRAW I NG

This drawing conCains conFidentiaL information

and is issued in confidence on Che'conditions

thac it be reCurned on demand and not be copied, reproduced, discLosed to others or

used in manuFaccure of the subject mottoar thereoF Without the consent of £imco CooL

PREPARED BY KAG EIMCO

DATE 11-08-94

NOTES, I) WHEN [TEM ,20 AND 21 ARE USED, TACKWELD CAP SCREW TO CLAMP.

2) FOR CABLE ROUT[NG AND LETTER DES[GNAT[ON REFER TO ELECTR[CAL [NSTALLAT[ON AND MACH[NE CABLE OUTL[NE D[AGRAM.

3) [TEMS 7,26 & 27 ARE NOT SHOWN, REFER TO W[R[NG D[AGRAM.

4) SEE MOTOR OPT [ON DRAW[NG

5) SEE TRAM DR[VE OPT [ON DRAW[NG

6) BOLT COVER [N PLACES, [NSTALL 1/2- DIA BOLT [NTO HINGE WHEN WELDING DO NOT ALLOW HEAT BUILD UP

BE SURE BOLT [S IN CENTER OF TUBING AFTER COVER IS BOLTED IN PLACE

7) REMOVE ACTIVATION PROTECTIVE PAPER JUST PRIOR TO SHIPMENT. RECOMMENDED REPLACEMENT EVERY TWO YEARS.

1 -BLK I •.•...

2-REO I -63

3-BLU I -R61

4-0RG I -197

5-YEL I .,. -34

6-BRN I ... -196

7-RED IBLK-79

8-BLU IBLK-19

9-0RG IBLK-14

10 - YEL IBLK -139

ll-BRN IBLK-179

12-BLK IRED-39

13-BLUIRED-R60

14 -ORG IRED -R59

15-YEL IREO-R48

16-BRNIRED-R49

17-BLK IBLU-114

18-REO IBLU- ...

19-0RGIBLU-R58

20-YELlBLU- .. .

21-BRNIBLU- .. .

22-BLKIORG- r------------

23-REO IORG-. .. I

24-BLUIORG- , 25- YEll ORG-. , 26-8RNIORG- ,

27-8LKIYEL- I

28-REDIYEL- I

29-8LUIYEL- ... I

30-0RG IYEL -. ,

WHTIREO-L31

WHTIWHT-L32

WHTIBLK-L33

l--RED Al ,r--WHITE A2 ... 51 'r--BLACK..

-:;7 !--RED ..... Al '·-·WHITE. _ .A2 II--GREEN. _ .52 ij--BLACK._.Sl

TROUBLE SHOOTING PROCEDURE:

1. VERIFY THAT 120VAC IS AT THE TWO A-C TERMINALS.

2. VERIFY THAT SVDC IS PRESENT FROM fS TO COM.

3. VERIFY THAT ALL THREE PHASES ARE PRESENT AT THE THREE POWER TERMINALS.

4. CONTROL CHECKSI

NOTEI APPROPRIATE PRECAUTIONS MUST BE TAKEN BECAUSE OF JHE PRESENCE OF ENERGIZED CIRCUITS WHILE TROUBLE SHOOTING.

A. FORWARD - WITH NO INPUT, THERE SHOULD 8E SVDC FROM FWD. TO COM. A FORWARD INPUT FROM THE TRAM WIL CAUSE THIS TO GO TO OVDC.

B. REVERSE - WITH NO INPUT, THERE SHOULD BE SVDC FROM REV. TO COM. A REVERSE INPUT FROM THE TRAM LEVER WILL CAUSE THIS TO GO TO OVDC.

C. OTHER FORWARD - THE INPUT ON OTH FWD. IS FROM THE INPUT TO THE OTHER DRIVE, TELLING THIS DRIVE THAT THE OTHER DRIVE IS IN FORWARD.

D. OTHER REVERSE - THE INPUT ON OTH REV. 15 FROM THE INPUT TO THE OTHER DRIVE, TELLING THIS DRIVE THAT THE OTHER DRIVE IS IN REVERSE.

E. SPEED REFERENCE - VOLTAGES FROM 0 TO 2 1/2vDC TELL THE DRIVE HOW MUCH OUTPUT VOLTAGE IS REQUESTED, o = OFF, 2 1/2VDC = FULL ON.

F. COMMON - THE COM. INPUT IS WHAT ALL OTHER CONTROL VOLTAGES ARE MEASURED IN RESPECT TO.

S. POWER CHECKSI

A. FIELD CONNECTIONS - THE MOTOR FIELD LEADS MUST BE CONNECTED TO THE FIELD TERMINALS, REVERSING THESE LEADS WILL REVERSE THE DIRECTION OF THE MOTOR.

B. ARMATURE CONNECTIONS - THE MOTOR ARMATURE LEADS MUST" BE CONNECTED TO THE ARMATURE TERMINALS, REVERSING THESE TWO LEADS WILL REVERSE THE DIRECTION OF THE MOTOR.

C. THREE PHASE AC - THE AC POWER MUST BE CONNECTED TO THE PHASE A,B,C TERMINALS, ROTATION 15 NOT IMPORTANT, BUT ALL THREE VOLTAGES SHOULD BE BALANCED.

6. OUTPUT CHECKS,

A. WITH A FWD. OR REV. INPUT AND SOME REF. INPUT, THERE WILL BE AN OUTPUT VOLTAGE PRESENT ACROSS THE ARMATURE TERMINALS - MORE REF. = MORE OUTPUT VOLTAGE.

B. WITH BOTH A FWD. AND OTH FWD. OR REV. AND OTH REV., THE MAXIMUM OUTPUT VOLTAGE WILL BE 2SX HIGHER THAN WITH JUST ONE CAT OR A SPLIT CAT SITUATION.

C. CURRENT LIMIT HAS BEEN SET AT 250 AMPS DC - THIS IS APPROXIMATELY 200 AMPS AC.

(L) -NOT ICE- Drown on CAD i ght 1991

@ CD TO ALL PERSONS RECEIVING

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it. CLICK HERE TO DOWNLOAD THE