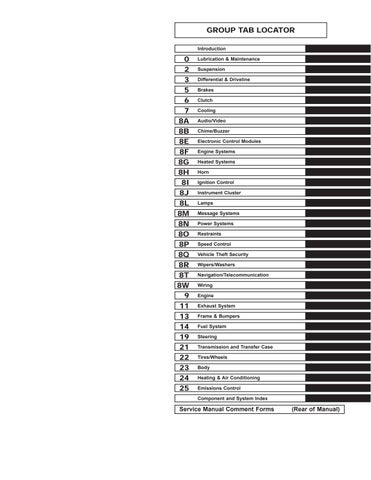

GROUPTABLOCATOR CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

FASTENERIDENTIFICATION DESCRIPTION

TheSAEboltstrengthgradesrangefromgrade2 tograde8.Thehigherthegradenumber,thegreater theboltstrength.Identificationisdeterminedbythe linemarksonthetopofeachbolthead.Theactual boltstrengthgradecorrespondstothenumberofline

marksplus2.Themostcommonlyusedmetricbolt strengthclassesare9.8and10.9.Themetric strengthclassidentificationnumberisimprintedon theheadofthebolt.Thehighertheclassnumber, thegreatertheboltstrength.Somemetricnutsare imprintedwithasingle-digitstrengthclassonthe nutface.RefertotheFastenerIdentificationand FastenerStrengthCharts(Fig.1).

FASTENERUSAGE DESCRIPTION

DESCRIPTION

WARNING:Useofanincorrectfastenermayresult incomponentdamageorpersonalinjury.

Fastenersandtorquespecificationsreferencesin thisServiceManualareidentifiedinmetricandSAE format.

Duringanymaintenanceorrepairprocedures,itis importanttosalvageallfasteners(nuts,bolts,etc.) forreassembly.Ifthefastenerisnotsalvageable,a fastenerofequivalentspecificationmustbeused.

DESCRIPTION

Moststrippedthreadedholescanberepairedusing aHelicoil .FollowthevehicleorHelicoil recommendationsforapplicationandrepairprocedures.

INTERNATIONALSYMBOLS DESCRIPTION

Thegraphicsymbolsillustratedin(Fig.2)andthe followingInternationalControlandDisplaySymbols Chartareusedtoidentifyvariousinstrumentcontrols.Thesymbolscorrespondtothecontrolsanddisplaysthatarelocatedontheinstrumentpanel.

METRICSYSTEM DESCRIPTION

Themetricsystemisbasedonquantitiesofone, ten,onehundred,onethousandandonemillion.

Thefollowingchart(Fig.3)willassistinconvertingmetricunitstoequivalentEnglishandSAE units,orviseversa.

Fig.2INTERNATIONALCONTROLANDDISPLAYSYMBOLS

1HighBeam13RearWindowWasher 2FogLamps14Fuel 3Headlamp,ParkingLamps,PanelLamps15EngineCoolantTemperature 4TurnWarning16BatteryChargingCondition 5HazardWarning17EngineOil 6WindshieldWasher18SeatBelt 7WindshieldWiper19BrakeFailure 8WindshieldWiperandWasher20ParkingBrake 9WindscreenDemistingandDefrosting21FrontHood 10VentilatingFan22Rearhood(Decklid) 11RearWindowDefogger23Horn 12RearWindowWiper24Lighter

Fig.3METRICCONVERSIONCHART

CONVERSIONFORMULASANDEQUIVALENTVALUES MULTIPLYBYTOGETMULTIPLYBYTOGET

in-lbsx 0.11298 =NewtonMeters (N·m) N·mx8.851=in-lbs

ft-lbsx 1.3558 =NewtonMeters (N·m) N·mx 0.7376 =ft-lbs

InchesHg(60°F)x3.377=Kilopascals(kPa)kPax 0.2961 =InchesHg

psix6.895=Kilopascals(kPa)kPax0.145=psi

Inchesx25.4=Millimeters(mm)mmx 0.03937 =Inches

Feetx 0.3048 =Meters(M)Mx3.281=Feet

Yardsx 0.9144 =MetersMx 1.0936 =Yards mphx 1.6093 =Kilometers/Hr. (Km/h) Km/hx 0.6214 =mph

Feet/Secx 0.3048 =Meters/Sec(M/S)M/Sx3.281=Feet/Sec mphx 0.4470 =Meters/Sec(M/S)M/Sx2.237=mph

Kilometers/Hr.(Km/h)x 0.27778 =Meters/Sec(M/S)M/Sx3.600Kilometers/Hr.(Km/h)

COMMONMETRICEQUIVALENTS 1inch=25Millimeters1CubicInch=16CubicCentimeters

1Foot=0.3Meter1CubicFoot=0.03CubicMeter

1Yard=0.9Meter1CubicYard=0.8CubicMeter

1Mile=1.6Kilometers

RefertotheMetricConversionChart(Fig.3)to converttorquevalueslistedinmetricNewtonmeters(N·m).Also,usethecharttoconvertbetween millimeters(mm)andinches(in.).

TORQUEREFERENCES DESCRIPTION IndividualTorqueChartsappearwithinmanyor theGroups.RefertotheStandardTorqueSpecificationsChart(Fig.4)fortorquereferencesnotlistedin theindividualtorquecharts.

TORQUEREFERENCES(Continued)

Fig.4TORQUESPECIFICATIONS

VEHICLEEMISSIONCONTROL INFORMATION(VECI)LABEL DESCRIPTION

AllmodelshaveaVehicleEmissionControlInformation(VECI)Label.DaimlerChryslerpermanently attachesthelabelintheenginecompartment(Fig. 5).Thelabelcannotberemovedwithoutdefacing labelinformationanddestroyinglabel.

Thelabelcontainsthevehicle’semissionspecificationsandvacuumhoseroutings.Allhosesmustbe connectedandroutedaccordingtothelabel.

Thelabelalsocontainsanenginevacuumschematic.Thereareuniquelabelsforvehiclesbuiltfor saleinthestateofCaliforniaandthecountryof Canada.Canadianlabelsarewritteninboththe EnglishandFrenchlanguages.

TheVECIlabelcontainsthefollowing:

• Enginefamilyanddisplacement

• Evaporativefamily

• Emissioncontrolsystemschematic

• Certificationapplication

• Enginetimingspecifications(ifadjustable)

• Idlespeeds(ifadjustable)

• Sparkplugandgap

Fig.5VECILABELLOCATION

1-RADIATORSUPPORT

2-VECILABEL

VEHICLEIDENTIFICATION NUMBER DESCRIPTION

TheVehicleIdentificationNumber(VIN)plateis locatedonthelowerleftA-pillarandisvisible throughthewindshield(Fig.6).TheVINcontains17 charactersthatprovidedataconcerningthevehicle. RefertotheVINdecodingcharttodeterminethe identificationofavehicle.

Fig.6VINNUMBERLOCATION

1-A-PILLAR

2-VINCODEPLATE

TheVehicleIdentificationNumberisalso imprintedonthe:

• VehicleSafetyCertificationLabel.

• Framerail.

Toprotecttheconsumerfromtheftandpossible fraudthemanufacturerisrequiredtoincludea CheckDigitattheninthpositionoftheVehicleIdentificationNumber.Thecheckdigitisusedbythe manufacturerandgovernmentagenciestoverifythe authenticityofthevehicleandofficialdocumentation.Theformulatousethecheckdigitisnot releasedtothegeneralpublic.

VEHICLEIDENTIFICATIONNUMBER(Continued)

VEHICLEIDENTIFICATIONNUMBERDECODINGCHART

POSITIONINTERPRETATIONCODE=DESCRIPTION

1CountryofOrigin1=ManufacturedbyDaimlerChrysler Corporation

2MakeJ=Jeep

3VehicleType4=MPVW/OSideAirbags. 8=MPVWithSideAirbags.

4GrossVehicleWeightRatingF=4001-5000lbs. G=5001-6000lbs.

5VehicleLineK=Liberty4X2(LHD)

L=Liberty4X4(LHD)wihtoutABB M=Cherokee4X4(RHD)

6=Cherokee(LHD)withABB

6Series3=Liberty/Renegade

4=LibertySport/CherokeeSport

5=LibertyLimited/CherokeeLimited

7BodyStyle8=SportUtility-4Door

8EngineK=3.7L6cylMPIGasoline 1=2.4L4cylMPIGasoline 5=2.8L4cylDiesel

9CheckDigit0through9orX

10ModelYear5=2005

11AssemblyPlantW=ToledoNorthAssemblyPlant 12thru17VehicleBuildSequence

VEHICLECERTIFICATION

LABEL

DESCRIPTION

Avehiclecertificationlabel(Fig.7)isattachedto everyDaimlerChryslerCorporationvehicle.Thelabel certifiesthatthevehicleconformstoallapplicable FederalMotorVehicleStandards.Thelabelalsolists:

• Monthandyearofvehiclemanufacture.

• GrossVehicleWeightRating(GVWR).Thegross frontandrearaxleweightratings(GAWR’s)are basedonaminimumrimsizeandmaximumcoldtire inflationpressure.

• VehicleIdentificationNumber(VIN).

• Typeofvehicle.

• Typeofrearwheels.

• Barcode.

• Month,DayandHour(MDH)offinalassembly.

• PaintandTrimcodes.

• Countryoforigin.

Fig.7VEHICLECERTIFICATIONLABEL-TYPICAL

Thelabelislocatedonthedriver-sidedoor shut-face.

LUBRICATION&MAINTENANCE INTERNATIONALSYMBOLS DESCRIPTION

Fig.1INTERNATIONALSYMBOLS

DaimlerChryslerCorporationusesinternational symbols(Fig.1)toidentifyenginecompartment lubricantandfluidinspectionandfilllocations.

PARTS&LUBRICANT RECOMMENDATION DESCRIPTION

LUBRICANTRECOMMENDATIONS

Chassis

ComponentFluid,Lubricant,orGenuinePart SteeringGear &Linkage, BallJoints, PropShafts& Yokes,Wheel Bearings Mopar Multi-PurposeLubricant NLGIGrade2EP,GC-LB

Body

ComponentFluid,Lubricant,andGenuine Part

Hinges:

Door&HoodMopar EngineOil

SwingGateMopar Multi-PurposeLubeNLGI

Latches:Door, Hood/Safety Catch,Swing Gate

SeatRegulator &Track

Grade2EP,GC-LB

Mopar Multi-PurposeLubeNLGI

Grade2EP,GC-LB

Mopar Multi-PurposeLubeNLGI

Grade2EP,GC-LB

LockCylindersMopar LockCylinderLube

FLUIDTYPES Whenserviceisrequired,DaimlerChryslerCorporationrecommendsthatonlyMopar brandparts, lubricantsandchemicalsbeused.Mopar provides thebestengineeredproductsforservicing DaimlerChryslerCorporationvehicles.

Onlylubricantsbearingdesignationsdefinedby thefollowingorganizationshouldbeusedtoservicea ChryslerCorporationvehicle.

• SocietyofAutomotiveEngineers(SAE)

• AmericanPetroleumInstitute(API)(Fig.2)

• NationalLubricatingGreaseInstitute(NLGI)

APIQUALITYCLASSIFICATION

FLUIDTYPES DESCRIPTION ENGINEOIL WARNING:NEWORUSEDENGINEOILCANBE IRRITATINGTOTHESKIN.AVOIDPROLONGEDOR REPEATEDSKINCONTACTWITHENGINEOIL. CONTAMINANTSINUSEDENGINEOIL,CAUSEDBY INTERNALCOMBUSTION,CANBEHAZARDOUSTO YOURHEALTH.THOROUGHLYWASHEXPOSED SKINWITHSOAPANDWATER.DONOTWASH SKINWITHGASOLINE,DIESELFUEL,THINNER,OR SOLVENTS,HEALTHPROBLEMSCANRESULT.DO NOTPOLLUTE,DISPOSEOFUSEDENGINEOIL PROPERLY.CONTACTYOURDEALERORGOVERNMENTAGENCYFORLOCATIONOFCOLLECTION CENTERINYOURAREA.

Onlylubricantsbearingdesignationsdefinedby thefollowingorganizationshouldbeused.

• SocietyofAutomotiveEngineers(SAE)

• AmericanPetroleumInstitute(API)

• NationalLubricatingGreaseInstitute(NLGI)

• AssociationdesConstructeursEuropéensd’ Automobiles(EuropeanAutomobileManufacturers Association)(ACEA)

APISERVICEGRADECERTIFIED UseanengineoilthatisAPICertified.MOPAR providesengineoils,thatmeetorexceedthis requirement.

SAEVISCOSITY AnSAEviscositygradeisusedtospecifytheviscosityofengineoil.Useonlyengineoilswithmultipleviscositiessuchas5W-30or10W-30.Theseare specifiedwithadualSAEviscositygradewhichindicatesthecold-to-hottemperatureviscosityrange. Selectanengineoilthatisbestsuitedtoyourparticulartemperaturerangeandvariation(Fig.3).

ACEACategories Thissymbolonthefrontofanoilcontainermeans thattheoilhasbeencertifiedbytheAmericanPetroleumInstitute(API)tomeetallthelubrication requirementsspecifiedbyDaimlerChryslerCorporation.

GEARLUBRICANTS SAEratingsalsoapplytomultigradegearlubricants.Inaddition,APIclassificationdefinesthe lubricantsusage.SuchasAPIGL-5andSAE75W90.

ForcountriesthatusetheACEAEuropeanOil CategoriesforServiceFillOils,useengineoilsthat meettherequirementsofACEAA1/B1,A2/B2,or A3/B3.

ENERGYCONSERVINGOIL AnEnergyConservingtypeoilisrecommendedfor gasolineengines.ThedesignationofENERGYCONSERVINGislocatedonthelabelofanengineoilcontainer.

CONTAINERIDENTIFICATION Standardengineoilidentificationnotationshave beenadoptedtoaidintheproperselectionofengine oil.Theidentifyingnotationsarelocatedonthefront labelofengineoilplasticbottlesandthetopof engineoilcans(Fig.4).

Thissymbolmeansthattheoilhasbeencertified bytheAmericanPetroleumInstitute(API). DaimlerChrysleronlyrecommendAPICertified engineoils.UseMopar engineoilorequivalent.

SAEVISCOSITYGRADE CAUTION:Lowviscosityoilsmusthavetheproper APIqualityortheCCMCG5designation.

Toassureofproperlyformulatedengineoils,itis recommendedthatSAEGrade10W-40engineoils thatmeetChryslermaterialstandardMS-6395,be usedinaccordancetoACEAB3,B4specification. EuropeanGrade10W-40oilsarealsoacceptable.

OilsoftheSAE5W-40gradenumberarepreferred whenminimumtemperaturesconsistentlyfallbelow -15°C.

AXLE NOTE:DaimlerChryslerrecommendsusingMopar lubricantsorlubricantsofequalquality.

FRONTAXLE • 186FIA(Model30)-Mopar Lubricant80W-90

REARAXLE • 81/4-Mopar GearLubricant75W-90(Trailer Towing-Mopar SynthenticGearLubricant75W-140

NOTE:Trac-lok equippedaxlesrequire118ml(4 ounces)ofLimitedSlipAdditivebeaddedtothe lubricant.

MANUALTRANSMISSION NOTE:DaimlerChryslerrecommendsusingMopar lubricantsorlubricantsofequalquality.

ENGINEOIL-DIESELENGINES

OnlyusesyntheticengineoilsmeetingtheAPI CategoriesSL/CFandChryslerMaterialStandard MS-10725.ThoseengineoilsnotmeetingtheviscosityandAPIQualityandMS-10725requirements shouldnotbeused.

SAEVISCOSITYGRADE

ThepreferredengineoilisSAE0W-40Mobil One Synthetic.IfyoucannotlocateSAE0W-40Mobil OneSynthetic,thenSAE5W-40Mobil OneSyntheticwouldbeacceptable.

ENGINEOIL-DIESELENGINES-EXPORT

UseonlyDieselEngineOilmeetingstandard MIL2104C orAPIClassification CDorhigher or CCML D4,D5

• NSG370-Mopar ManualTransmissionLubricantMS-9224

AUTOMATICTRANSMISSIONFLUID NOTE:RefertoServiceProceduresinthisgroupfor fluidlevelcheckingprocedures.

Mopar ATF+4,AutomaticTransmissionFluidis therecommendedfluidforDaimlerChryslerautomatictransmissions.

DexronIIfluidISNOTrecommended.Clutch chattercanresultfromtheuseofimproper fluid.

Mopar ATF+4,AutomaticTransmissionFluid whennewisredincolor.TheATFisdyedredsoit canbeidentifiedfromotherfluidsusedinthevehicle suchasengineoilorantifreeze.Theredcolorisnot permanentandisnotanindicatoroffluidcondition. Asthevehicleisdriven,theATFwillbegintolook darkerincolorandmayeventuallybecomebrown.

Fig.3Temperature/EngineOilViscosity

Fig.4APICertificationMark

Thisisnormal. ATF+4alsohasauniqueodorthat maychangewithage.Consequently,odorandcolor cannotbeusedtoindicatethefluidconditionorthe needforafluidchange.

FLUIDADDITIVES DaimlerChryslerstronglyrecommendsagainstthe additionofanyfluidstothetransmission,otherthan thoseautomatictransmissionfluidslistedabove. Exceptionstothispolicyaretheuseofspecialdyes toaidindetectingfluidleaks.

Various“special”additivesandsupplementsexist thatclaimtoimproveshiftfeeland/orquality.These additivesandothersalsoclaimtoimproveconverter clutchoperationandinhibitoverheating,oxidation, varnish,andsludge.TheseclaimshavenotbeensupportedtothesatisfactionofDaimlerChryslerand theseadditives mustnotbeused. Theuseoftransmission“sealers”shouldalsobeavoided,sincethey mayadverselyaffecttheintegrityoftransmission seals.

TRANSFERCASE-NV231

RecommendedlubricantfortheNV231transfer caseisMopar ATF+4,AutomaticTransmission Fluid.

TRANSFERCASE-NV241GENII

RecommendedlubricantfortheNV2421GENII transfercaseisMopar ATF+4,AutomaticTransmissionFluid.

TRANSFERCASE-NV242

RecommendedlubricantfortheNV242transfer caseisMopar ATF+4,AutomaticTransmission Fluid.

ENGINECOOLANT WARNING:ANTIFREEZEISANETHYLENEGLYCOL BASECOOLANTANDISHARMFULIFSWALLOWEDORINHALED.IFSWALLOWED,DRINK TWOGLASSESOFWATERANDINDUCEVOMITING.IFINHALED,MOVETOFRESHAIRAREA. SEEKMEDICALATTENTIONIMMEDIATELY.DONOT STOREINOPENORUNMARKEDCONTAINERS. WASHSKINANDCLOTHINGTHOROUGHLYAFTER COMINGINCONTACTWITHETHYLENEGLYCOL. KEEPOUTOFREACHOFCHILDREN.DISPOSEOF GLYCOLBASECOOLANTPROPERLY,CONTACT YOURDEALERORGOVERNMENTAGENCYFOR LOCATIONOFCOLLECTIONCENTERINYOUR AREA.DONOTOPENACOOLINGSYSTEMWHEN THEENGINEISATOPERATINGTEMPERATUREOR HOTUNDERPRESSURE,PERSONALINJURYCAN RESULT.AVOIDRADIATORCOOLINGFANWHEN

ENGINECOMPARTMENTRELATEDSERVICEIS PERFORMED,PERSONALINJURYCANRESULT.

CAUTION:UseofPropyleneGlycolbasedcoolants isnotrecommended,astheyprovidelessfreeze protectionandlesscorrosionprotection.

Thecoolingsystemisdesignedaroundthecoolant. Thecoolantmustacceptheatfromenginemetal,in thecylinderheadareaneartheexhaustvalvesand engineblock.Thencoolantcarriestheheattothe radiatorwherethetube/finradiatorcantransferthe heattotheair.

Theuseofaluminumcylinderblocks,cylinder heads,andwaterpumpsrequiresspecialcorrosion protection.Mopar Antifreeze/Coolant,5 Year/100,000MileFormula(MS-9769),ortheequivalentethyleneglycolbasecoolantwithorganiccorrosioninhibitors(calledHOAT,forHybridOrganic AdditiveTechnology)isrecommended.Thiscoolant offersthebestenginecoolingwithoutcorrosionwhen mixedwith50%EthyleneGlycoland50%distilled watertoobtainafreezepointof-37°C(-35°F).Ifit losescolororbecomescontaminated,drain,flush, andreplacewithfreshproperlymixedcoolantsolution.

CAUTION:Mopar Antifreeze/Coolant,5 Year/100,000MileFormula(MS-9769)maynotbe mixedwithanyothertypeofantifreeze.Mixingof coolantsotherthanspecified(non-HOATorother HOAT),mayresultinenginedamagethatmaynot becoveredunderthenewvehiclewarranty,and decreasedcorrosionprotection.

COOLANTPERFORMANCE Therequiredethylene-glycol(antifreeze)andwater mixturedependsuponclimateandvehicleoperating conditions.Thecoolantperformanceofvariousmixturesfollows:

PureWater-Watercanabsorbmoreheatthana mixtureofwaterandethylene-glycol.Thisisforpurposeofheattransferonly.Wateralsofreezesata highertemperatureandallowscorrosion.

100percentEthylene-Glycol-Thecorrosion inhibitingadditivesinethylene-glycolneedthepresenceofwatertodissolve.Withoutwater,additives formdepositsinsystem.Theseactasinsulation causingtemperaturetorisetoashighas149°C (300°F).Thistemperatureishotenoughtomeltplasticandsoftensolder.Theincreasedtemperaturecan resultinenginedetonation.Inaddition,100percent ethylene-glycolfreezesat-22°C(-8°F).

50/50Ethylene-GlycolandWater-Istherecommendedmixture,itprovidesprotectionagainstfreezingto-37°C(-34°F).Theantifreezeconcentration

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

mustalways beaminimumof44percent,yearroundinallclimates.Ifpercentageislower,engine partsmaybeerodedbycavitation.Maximumprotectionagainstfreezingisprovidedwitha68percent antifreezeconcentration,whichpreventsfreezing downto-67.7°C(-90°F).Ahigherpercentagewill freezeatawarmertemperature.Also,ahigherpercentageofantifreezecancausetheenginetooverheatbecausespecificheatofantifreezeislowerthan thatofwater.

CAUTION:Richerantifreezemixturescannotbe measuredwithnormalfieldequipmentandcan causeproblemsassociatedwith100percentethylene-glycol.

CAUTION:Donotusecoolantadditivesthatare claimedtoimproveenginecooling.

POWERSTEERINGFLUID Mopar ATF+4,AutomaticTransmissionFluidis requiredinthepowersteeringsystem.Substitute fluidscaninducepowersteeringsystemfailure.

Mopar ATF+4,AutomaticTransmissionFluid whennewisredincolor.TheATFisdyedredsoit canbeidentifiedfromotherfluidsusedinthevehicle suchasengineoilorantifreeze.Theredcolorisnot permanentandisnotanindicatoroffluidcondition. Asthevehicleisdriven,theATFwillbegintolook darkerincolorandmayeventuallybecomebrown. Thisisnormal. ATF+4alsohasauniqueodorthat maychangewithage.Consequently,odorandcolor cannotbeusedtoindicatethefluidconditionorthe needforafluidchange.

OPERATION-AUTOMATICTRANSMISSION FLUID Theautomatictransmissionfluidisselectedbased uponseveralqualities.Thefluidmustprovideahigh levelofprotectionfortheinternalcomponentsby providingalubricatingfilmbetweenadjacentmetal components.Thefluidmustalsobethermallystable sothatitcanmaintainaconsistentviscositythrough alargetemperaturerange.Iftheviscositystaysconstantthroughthetemperaturerangeofoperation, transmissionoperationandshiftfeelwillremainconsistent.Transmissionfluidmustalsobeagoodconductorofheat.Thefluidmustabsorbheatfromthe internaltransmissioncomponentsandtransferthat heattothetransmissioncase.

FLUIDCAPACITIES SPECIFICATIONS-FLUIDCAPACITIES

DESCRIPTIONSPECIFICATION

FUELTANK–Gasoline& Diesel 19.5U.S.Gallons (74L)*

ENGINEOIL

2.4LwithFilter4.7L(5.0qts.)

3.7LwithFilter4.7L(5.0qts.)

2.8LDieselwithFilter6.1L(6.4qts.)

ENGINECOOLANT

CoolingSystem-2.4L9.5L(10.0qts.)

CoolingSystem-3.7L13.2L(14.0qts.)

CoolingSystem-2.8LDiesel12.5L(11.8qts.)

POWERSTEERINGSYSTEM

Powersteeringfluidcapacitiesaredependenton engine/chassisoptionsaswellassteeringgear/ cooleroptions.Dependingontypeandsizeofinternalcooler,lengthandinsidediameterofcooler lines,oruseofanauxiliarycooler,thesecapacities mayvary.Referto19,Steeringforproperfilland bleedprocedures.

AUTOMATICTRANSMISSION

ServiceFill-545RFE4.73L(10.0pts) O-haulFill-545RFE13.33L(28.0pts) ServiceFill-42RLE3.8L(8.0pts) O-haulFill-42RLE8.3L(17.6pts)

Dryfillcapacitydependingontypeandsizeofinternalcooler,lengthandinsidediameterofcooler lines,oruseofanauxiliarycooler,thesefigures mayvary.(Referto21-TRANSMISSION/AUTOMATIC/FLUID-STANDARDPROCEDURE) TRANSFERCASE

NV2311.4L(2.95pts.)

NV241GENII2.0L(4.2pts.)

NV2421.6L(3.4pts.)

MANUALTRANSMISSION

NSG370(Approximatedry fillorfilltobottomedgeof thefillplughole.)

FRONTAXLE 1.5L(3.17pts.)

186FIA(Model30)1.24L(2.6pts.) REARAXLE

81/42.08L(4.4pts.)**

*Nominalrefillcapacitiesareshown.Avariationmay beobservedfromvehicletovehicleduetomanufacturingtoleranceandrefillprocedure.

**WhenequippedwithTrac-lok,include118ml(4.0 ounces)ofLimitedSlipAdditive.

MAINTENANCESCHEDULES DESCRIPTION MAINTENANCESCHEDULES-GASOLINE

ENGINES Therearetwomaintenanceschedulesthatshow the required serviceforyourvehicle.

FirstisSchedule B .Itisforvehiclesthatare operatedundertheconditionsthatarelistedbelow andatthebeginningoftheschedule.

• Dayornighttemperaturesarebelow32°F(0°C).

• Stopandgodriving.

• Extensiveengineidling.

• Drivingindustyconditions.

• Shorttripsoflessthan10miles(16.2km).

• Morethan50%ofyourdrivingisatsustained highspeedsduringhotweather,above90°F(32°C).

• Trailertowing.

• Taxi,police,ordeliveryservice(commercialservice).

• Off-roadordesertdriving.

• IfequippedforandoperatedwithE-85(ethanol) fuel.

NOTE:IfANYoftheseapplytoyouthenchange yourengineoilevery3,000miles(5000km)or3 months,whichevercomesfirstandfollow“ScheduleB”ofthe“MaintenanceSchedules”sectionof thismanual.

NOTE:IfANYoftheseapplytoyouthenflushand replaceyourenginecoolant/anti-freezeevery 102,000miles(163000km)or60months,whichever comesfirst,andfollow“ScheduleB”ofthe“MaintenanceSchedules”sectionofthismanual.

NOTE:MostvehiclesareoperatedundertheconditionslistedforSchedule“B.”

SecondisSchedule “A”.Itisforvehiclesthatare notoperatedunderanyoftheconditionslistedunder Schedule“B.”

Usetheschedulethatbestdescribesyourdriving conditions.Wheretimeandmileagearelisted,follow theintervalthatoccursfirst.

CAUTION:Failuretoperformtherequiredmaintenanceitemsmayresultindamagetothevehicle.

AtEachStopforFuel • Checktheengineoillevelabout5minutesafter afullywarmedengineisshutoff.Checkingtheoil levelwhilethevehicleisonlevelgroundwill improvetheaccuracyoftheoillevelreading.Addoil

onlywhenthelevelisatorbelowtheADDorMIN mark.

• Checkthewindshieldwashersolvent,addas required.

OnceaMonth • Checkthetirepressureandlookforunusual wearordamage.

• Inspectthebattery,andcleanandtightenthe terminalsasrequired.

• Checkthefluidlevelsoftheenginecoolant/antifreezereservoir,brakemastercylinder,andtransmission,andaddasneeded.

• Checkalllightsandallotherelectricalitemsfor correctoperation.

AtEachOilChange • Changetheengineoilfilter.

• Inspecttheexhaustsystem.

• Inspectbrakehoses.

• Checktheenginecoolant/anti-freezelevel,hoses, andclamps.

• Inspectmanualtransmissionfluidlevel—if equipped.

• Aftercompletionofoff-roadoperation,the undersideofthevehicleshouldbethoroughly inspected.Examinethreadedfastenersforlooseness.

Schedule“B” Followschedule“B”ifyouusuallyoperateyour vehicleunderoneormoreofthefollowingconditions.

• Dayornighttemperaturesarebelow32°F(0°C).

• Stopandgodriving.

• Extensiveengineidling.

• Drivingindustyconditions.

• Shorttripsoflessthan10miles(16.2km).

• Morethan50%ofyourdrivingisatsustained highspeedsduringhotweather,above90°F(32°C).

• Trailertowing.

• Taxi,police,ordeliveryservice(commercialservice).

• Off-roadordesertdriving.

• IfequippedforandoperatedwithE-85(ethanol) fuel.

NOTE:IfANYoftheseapplytoyouthenchange yourengineoilevery3,000miles(5000km)or3 months,whichevercomesfirstandfollow“ScheduleB”ofthe“MaintenanceSchedules”sectionof thismanual.

NOTE:IfANYoftheseapplytoyouthenflushand replaceyourenginecoolant/anti-freezeevery 102,000miles(163000km)or60months,whichever comesfirst,andfollow“ScheduleB”ofthe“MaintenanceSchedules”sectionofthismanual.

Miles3,0006,0009,00012,00015,000 (Kilometers)(5000)(10000)(14000)(19000)(24000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XX

Inspecttheengineairfilterelement,replaceif necessary. X

Inspectthebrakelinings. X

Drainandrefillthefrontandrearaxlefluid‡X

Miles18,00021,00024,00027,00030,000 (Kilometers)(29000)(34000)(38000)(43000)(48000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XXX

Inspecttheengineairfilterelement,replaceif necessary. X

Replacethesparkplugs. X

InspectandreplacethePCVvalve,ifnecessary. X

Inspectthebrakelinings.X

Drainandrefillthefrontandrearaxlefluid‡X

Inspectthetransfercasefluid,addifnecessary.X

Miles33,00036,00039,00042,00045,000 (Kilometers)(53000)(58000)(62000)(67000)(72000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XX

Inspecttheengineairfilterelement,replaceif necessary. X

Inspectthebrakelinings.X

Drainandrefillthefrontandrearaxlefluid‡X

Inspectthedrivebeltandreplaceasneeded.X

Miles48,00051,00054,00057,00060,000 (Kilometers)(77000)(82000)(86000)(91000)(96000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XXX

Inspecttheengineairfilterelement,replaceif necessary. X

Replacethesparkplugs. X

InspectandreplacethePCVvalve,ifnecessary. X

MAINTENANCESCHEDULES(Continued)

Miles48,00051,00054,00057,00060,000 (Kilometers)(77000)(82000)(86000)(91000)(96000)

Replacetheignitioncables(2.4LOnly). X

Inspectthebrakelinings.XX

Drainandrefillthefrontandrearaxlefluid‡XX

Drainandrefilltheautomatictransmissionfluid,and replacemainsumpfilter.

Inspectthedrivebeltandreplaceasneeded.Not requiredifbeltwaspreviously

Drainandrefillthetransfercasefluid.X

Flushandreplacetheenginecoolant/anti-freezeat 60months,ifnotdoneat102,000miles(163000 km).

Miles63,00066,00069,00072,00075,000 (Kilometers)(101000)(106000)(110000)(115000)(120000)

Changetheengineoilandengineoilfilter,if notreplacedat3months.

Rotatethetires.XX

Inspecttheengineairfilterelement,replace ifnecessary.

Inspectthebrakelinings.X

Drainandrefillthefrontandrearaxlefluid‡X

Inspectthedrivebeltandreplaceasneeded. Notrequiredifbeltwaspreviouslyreplaced.

Miles78,00081,00084,00087,00090,000 (Kilometers)(125000)(130000)(134000)(139000)(144000)

Changetheengineoilandengineoilfilter,if notreplacedat3months.

Rotatethetires.XXX

Inspecttheengineairfilterelement,replace ifnecessary.

Replacethesparkplugs.

InspectandreplacethePCVvalve,ifnecessary.

Inspectthebrakelinings.X

Drainandrefillthefrontandrearaxlefluid‡X

Inspectthedrivebeltandreplaceasneeded. Notrequiredifbeltwaspreviouslyreplaced.

Replacethetimingbelt(2.4LOnly). X

Inspectthetransfercasefluid,addifnecessary.X

Miles93,00096,00099,000102,000105,000 (Kilometers)(149000)(154000)(158000)(163000)(168000)

Changetheengineoilandengineoilfilter,if notreplacedat3months.

Rotatethetires.XX

Inspecttheengineairfilterelement,replace ifnecessary.

Inspectthebrakelinings.X

Drainandrefillthefrontandrearaxlefluid‡X

Inspectthedrivebeltandreplaceasneeded. Notrequiredifbeltwaspreviouslyreplaced.

Flushandreplacetheenginecoolant/antifreeze,ifnotdoneat60months.

Miles108,000111,000114,000117,000120,000 (Kilometers)(173000)(178000)(182000)(187000)(192000)

Changetheengineoilandengineoilfilter,if notreplacedat3months.

Rotatethetires.XXX

Inspecttheengineairfilterelement,replace ifnecessary.

Replacethesparkplugs.

InspectandreplacethePCVvalve,ifnecessary.

Replacetheignitioncables(2.4LOnly). X

Inspectthebrakelinings.XX

Drainandrefillthefrontandrearaxlefluid‡XX

Drainandrefilltheautomatictransmissionfluid, andreplacemainsumpfilter.

Inspectthedrivebeltandreplaceasneeded. Notrequiredifbeltwaspreviouslyreplaced.

Drainandrefillthetransfercasefluid.X

Flushandreplacetheenginecoolant/anti-freeze at120months,ifnotreplacedat102,000miles (163000km).

Inspectionandserviceshouldbeperformedanytimeamalfunctionisobservedorsuspected.Retain allreceipts.

Thismaintenanceisrecommendedbythemanufacturertotheowner,butitisnotrequiredtomaintainemissionswarranty.

‡Off-highwayoperation,trailertowing,taxi,limousine,bus,snowplowing,orothertypesofcommercial serviceorprolongedoperationwithheavyloading, especiallyinhotweather,requirefrontandrearaxle serviceindicatedwitha‡in Schedule“B”.Perform theseservicesifthevehicleisusuallyoperatedunder theseconditions.

MAINTENANCESCHEDULES(Continued)

Schedule“A” Miles6,00012,00018,00024,00030,000 (Kilometers)(10000)(19000)(29000)(38000)(48000) [Months][6][12][18][24][30]

Changetheengineoilandengineoilfilter.XXXXX

Rotatethetires.XXXXX

Inspecttheengineairfilterelement,andreplace ifnecessary. X

Replacethesparkplugs. X

Inspectthebrakelinings.X

Inspectthetransfercasefluid. X

Miles36,00042,00048,00054,000 (Kilometers)(58000)(67000)(77000)(86000) [Months][36][42][48][54]

Changetheengineoilandengineoilfilter.XXXX

Rotatethetires.XXXX

Inspectthebrakelinings.XX

Miles60,00066,00072,00078,000 (Kilometers)(96000)(106000)(115000)(125000) [Months][60][66][72][78]

Changetheengineoilandengineoilfilter.XXXX

Rotatethetires.XXXX

Inspecttheengineairfilterelement,andreplaceif necessary. X

Replacethesparkplugs. X

Inspecttheignitioncables,andreplaceifnecessary (2.4LOnly). X

InspectandreplacethePCVvalve,ifnecessary. X

Inspectthebrakelinings.X

Inspectthedrivebeltandreplace,ifneeded.X

Inspectthedrivebeltandreplaceasneeded.Not requiredifpreviouslyreplaced. X

Flushandreplacetheenginecoolant/anti-freezeat60 months,ifnotdoneat102,000miles(163000km). X

Inspectthetransfercasefluid.X

Miles84,00090,00096,000102,000 (Kilometers)(134000)(144000)(154000)(163000) [Months][84][90][96][102]

Changetheengineoilandengineoilfilter.XXXX Rotatethetires.XXXX

Inspecttheengineairfilterelement,andreplaceif necessary.

Replacethesparkplugs. X

InspectandreplacethePCVvalve,ifnecessary. X

Inspectthebrakelinings.X

Inspectthedrivebeltandreplaceasneeded.Notrequired ifpreviouslyreplaced.

Flushandreplacetheenginecoolant/anti-freezeifnot doneat60months. X

Inspectthetransfercasefluid.X

Miles108,000114,000120,000 (Kilometers)(173000)(182000)(192000) [Months][108][114][120]

Changetheengineoilandengineoilfilter.XXX Rotatethetires.XXX

Inspecttheengineairfilterelement,andreplaceifnecessary.

Replacethesparkplugs.

InspectandreplacethePCVvalve,ifnecessary.

Inspecttheignitioncables,andreplaceifnecessary(2.4L Only).

Inspectthebrakelinings.X

Inspectthedrivebeltandreplaceasneeded.Notrequiredifpreviouslyreplaced.

Flushandreplacetheenginecoolant/anti-freezeifnotdoneat 102,000miles(163000km).

Replacethetimingbelt(2.4LOnly). X

Drainandrefillthetransfercasefluid.X

Inspectionandserviceshouldbeperformedanytimeamalfunctionisobservedorsuspected.Retain allreceipts.

Thismaintenanceisrecommendedbythemanufacturertotheowner,butitisnotrequiredtomaintainemissionswarranty.

MAINTENANCESCHEDULES-DIESELENGINE Therearetwomaintenanceschedulesthatshow the required serviceforyourvehicle.

FirstisSchedule B .Itisforvehiclesthatare operatedundertheconditionsthatarelistedbelow andatthebeginningoftheschedule.

• Dayornighttemperaturesarebelow32°F(0°C).

• Stopandgodriving.

• Extensiveengineidling.

• Drivingindustyconditions.

• Shorttripsoflessthan10miles(16.2km).

• Morethan50%ofyourdrivingisatsustained highspeedsduringhotweather,above90°F(32°C).

• Trailertowing.

• Taxi,police,ordeliveryservice(commercialservice).

• Off-roadordesertdriving.

NOTE:MostvehiclesareoperatedundertheconditionslistedforSchedule“B.”

SecondisSchedule “A”.Itisforvehiclesthatare notoperatedunderanyoftheconditionslistedunder Schedule“B.”

Usetheschedulethatbestdescribesyourdriving conditions.Wheretimeandmileagearelisted,follow theintervalthatoccursfirst.

CAUTION:Failuretoperformtherequiredmaintenanceitemsmayresultindamagetothevehicle.

AtEachStopforFuel • Checktheengineoillevelabout5minutesafter afullywarmedengineisshutoff.Checkingtheoil levelwhilethevehicleisonlevelgroundwill improvetheaccuracyoftheoillevelreading.Addoil onlywhenthelevelisatorbelowtheADDorMIN mark.

• Checkthewindshieldwashersolvent,addas required.

OnceaMonth • Checkthetirepressureandlookforunusual wearordamage.

• Inspectthebattery,cleanandtightentheterminalsasrequired.

• Checkthefluidlevelsofenginecoolant/antifreezedeaerationbottle,brakemastercylinder,and transmission,andaddasneeded.

• Checkalllightsandallotherelectricalitemsfor correctoperation.

AtEachOilChange • Changetheengineoilfilter.

• Inspecttheexhaustsystem.

• Inspectbrakehoses.

• Checktheenginecoolant/anti-freezelevel,hoses, andclamps.

• Inspectengineaccessorydrivebelts.Replaceas necessary.

• Inspectforthepresenceofwaterinthefuelfilter/waterseparatorunit.

TireRotation • Rotatethetiresevery6,000miles(10000km).

Schedule“B” Followschedule“B”ifyouusuallyoperateyour vehicleunderoneormoreofthefollowingconditions.

• Dayornighttemperaturesarebelow32°F(0°C).

• Stopandgodriving.

• Extensiveengineidling.

• Drivingindustyconditions.

• Shorttripsoflessthan10miles(16.2km).

• Morethan50%ofyourdrivingisatsustained highspeedsduringhotweather,above90°F(32°C).

• Trailertowing.

• Taxi,police,ordeliveryservice(commercialservice).

• Off-roadordesertdriving.

Miles6,25012,50018,75025,00031,250 (Kilometers)(10000)(20000)(30000)(40000)(50000)

Changetheengineoilandengineoilfilter.XXXXX

Inspecttheengineairfilterelement.Replaceas necessary. XXXXX

Replacetheengineairfilterelement. XX Replacethefuelfilter/waterseparatorunit.X Inspectthebrakelinings.XX Drainandrefillthefrontandrearaxlefluid.XX

MAINTENANCESCHEDULES(Continued)

Miles37,50043,75050,00056,25062,500 (Kilometers)(60000)(70000)(80000)(90000)(100000)

Changetheengineoilandengineoilfilter.XXXXX

Inspecttheengineairfilterelement. Replaceasnecessary. XXXXX

Replacetheengineairfilterelement. XXX

Replacethefuelfilter/waterseparatorunit.X

Replacetheengineaccessorydrivebelt.X

Inspectthebrakelinings.XXX

Drainandrefillthefrontandrearaxlefluid.XXX

Drainandrefillthetransfercasefluid.X

Drainandrefilltheautomatictransmission fluid,andreplacesumpfilter. X

Miles68,75075,00081,25087,50093,750100,000 (Kilometers)(110000)(120000)(130000)(140000)(150000)(160000)

Changetheengineoilandengineoil filter. XXXXXX

Inspecttheengineairfilterelement.Replaceasnecessary.

Replacetheengineairfilterelement. XXX

Replacetheengineaccessorydrive belt. X

Replacetheenginetimingbeltand idlerpulleys. X

Inspecttheenginetimingbelttensioner,replaceifnecessary.†

Replacethefuelfilter/waterseparatorunit.

Flushandreplacetheenginecoolant/anti-freeze.

Inspectthebrakelinings.XX

Drainandrefillthefrontandrear axlefluid.

Appliesonlyifvehicleisusedforfrequent trailertowing,orfleet/commercialservice.

†Thereplacementofsuchcomponentisrequested ifthereissuperficialwear,bearingclearance,orevidentgreaseleak.

Inspectionandserviceshouldbeperformedanytimeamalfunctionisobservedorsuspected.Retain allreceipts.

Schedule“A”

Miles12,50025,00037,50050,000 (Kilometers)(20000)(40000)(60000)(80000)

Changetheengineoilandengineoilfilter.XXXX

Inspecttheengineairfilterelement.Replaceasnecessary. XXXX

Replacetheengineairfilterelement. XX

Replacethefuelfilter/waterseparatorunit.XX

Inspectthebrakelinings.XX

Inspectthetransfercasefluid.X

Miles62,50075,00087,500100,000 (Kilometers)(100000)(120000)(140000)(160000)

Changetheengineoilandengineoilfilter.XXXX

Inspecttheengineairfilterelement.Replaceasnecessary. XXXX

Replacetheengineairfilterelement. XX

Replacethefuelfilter/waterseparatorunit.XX

Replacetheenginetimingbelt,andidlerpulleys.X

Inspecttheenginetimingbelttensioner,replaceifnecessary.† X

Flushandreplacetheenginecoolant.X

Replacetheengineaccessorydrivebelt.X

Inspectthebrakelinings.XX

Inspectthetransfercasefluid.X

†Thereplacementofsuchcomponentisrequested ifthereissuperficialwear,bearingclearance,orevidentgreaseleak.

Inspectionandserviceshouldbeperformedanytimeamalfunctionisobservedorsuspected.Retain allreceipts.

MAINTENANCESCHEDULES-GASOLINE ENGINES-EXPORT Therearetwomaintenanceschedulesthatshow the required serviceforyourvehicle.

FirstisSchedule “A”.Itisforvehiclesthatarenot operatedunderanyoftheconditionslistedunder Schedule“B.”

SecondisSchedule B .Itisforvehiclesthatare operatedundertheconditionsthatarelistedbelow andatthebeginningoftheschedule.

• Dayornighttemperaturesarebelow0°C(32°F).

• Stopandgodriving.

• Extensiveengineidling.

• Drivingindustyconditions.

• Shorttripsoflessthan16.2km(10miles).

• Morethan50%ofyourdrivingisatsustained highspeedsduringhotweather,above32°C(90°F).

• Trailertowing.

• Taxi,police,ordeliveryservice(commercialservice).

• Off-roadordesertdriving.

Mostvehiclesareoperatedundertheconditions listedforSchedule“B.”

Usetheschedulethatbestdescribesyourdriving conditions.Wheretimeandmileagearelisted,follow theintervalthatoccursfirst.

CAUTION:Failuretoperformtherequiredmaintenanceitemsmayresultindamagetothevehicle.

AtEachStopforFuel • Checktheengineoillevelabout5minutesaftera fullywarmedengineisshutoff.Checkingtheoillevel whilethevehicleisonlevelgroundwillimprovethe accuracyoftheoillevelreading.Addoilonlywhen thelevelisatorbelowtheADDorMINmark.

• Checkthewindshieldwashersolvent,addas required.

OnceaMonth

• Checkthetirepressureandlookforunusual wearordamage.

• Inspectthebattery,andcleanandtightenthe terminalsasrequired.

• Checkthefluidlevelsofthecoolantreservoir, brakemastercylinder,andtransmission,andaddas needed.

• Checkalllightsandallotherelectricalitemsfor correctoperation.

Schedule“A” AtEachOilChange • Changetheengineoilfilter.

• Inspecttheexhaustsystem.

• Inspectbrakehoses.

• Checkthecoolantlevel,hoses,andclamps.

• Inspectmanualtransmissionfluidlevel—if equipped.

• Aftercompletionofoff-roadoperation,the undersideofthevehicleshouldbethoroughly inspected.Examinethreadedfastenersforlooseness.

Kilometers1200024000360004800060000 (Miles)(7,500)(15,000)(22,500)(30,000)(37,500) [Months][6][12][18][24][30]

Changetheengineoilandengineoilfilter.XXXXX

Inspecttheengineairfilterelement,replaceif necessary. X

Replacethesparkplugs. X Inspectthebrakelinings.X

Inspectthetransfercasefluid.X

Kilometers720008400096000108000 (Miles)(45,000)(52,500)(60,000)(67,500) [Months][36][42][48][54]

Changetheengineoilandengineoilfilter.XXXX Rotatethetires.XXXX

Inspecttheengineairfilterelement,replaceifnecessary. X

InspectandreplacethePCVvalve,ifnecessary . X

Inspecttheignitioncables,andreplaceifnecessary (2.4LOnly). X

Replacethesparkplugs. X

Inspectthebrakelinings.XX

InspectandreplacetheAutoTensionDriveBelt,as needed. X

Inspectthetransfercasefluid.X

Kilometers120000132000144000156000 (Miles)(75,000)(82,500)(90,000)(97,500) [Months][60][66][72][78]

Changetheengineoilandengineoilfilter.XXXX Rotatethetires.XXXX

Inspecttheengineairfilterelement,replaceifnecessary. X

MAINTENANCESCHEDULES(Continued)

Kilometers120000132000144000156000 (Miles)(75,000)(82,500)(90,000)(97,500) [Months][60][66][72][78]

Replacethesparkplugs. X

InspectandreplacethePCVvalve,ifnecessary. X

Inspectthebrakelinings.X

Inspectthedrivebeltandreplaceasneeded.Not requiredifpreviouslyreplaced.

Flushandreplacetheenginecoolantat60months, regardlessofmileage. X

Inspectthetransfercasefluid.X

Kilometers160000168000180000192000 (Miles)(100,000)(105,000)(112,500)(120,000) [Months] [84][90][96]

Inspecttheengineairfilterelement,replaceifnecessary. X

Replacethesparkplugs. X

Inspecttheignitioncables,replaceifnecessary(2.4L Only). X

InspectandreplacethePCVvalve,ifnecessary. X

Inspectthebrakelinings.X

Inspectthedrivebeltandreplaceasneeded.Notrequired ifpreviouslyreplaced.

Flushandreplacetheenginecoolantifnotdoneat60 months. X

Replacethetimingbelt(2.4LOnly). X Drainthetransfercase,andrefill. X

Inspectionandserviceshouldbeperformedanytimeamalfunctionisobservedorsuspected.Retain allreceipts.

Thismaintenanceisrecommendedbythemanufacturertotheowner,butitisnotrequiredtomaintainemissionswarranty.

MAINTENANCESCHEDULES(Continued)

Schedule“B”

Followschedule“B”ifyouusuallyoperateyour vehicleunderoneormoreofthefollowingconditions.

• Dayornighttemperaturesarebelow0°C(32°F).

• Stopandgodriving.

• Extensiveengineidling.

• Drivingindustyconditions.

• Shorttripsoflessthan16.2km(10miles).

• Morethan50%ofyourdrivingisatsustained highspeedsduringhotweather,above32°C(90°F).

• Trailertowing.

• Taxi,police,ordeliveryservice(commercialservice).

• Off-roadordesertdriving.

Kilometers500010000140001900024000 (Miles)(3,000)(6,000)(9,000)(12,000)(15,000)

Changetheengineoilandengineoilfilter.XXXXX

Rotatethetires.XX

Inspecttheengineairfilterelement,replaceif necessary. X

Inspectthebrakelinings. X

Drainandrefillthefrontandrearaxlefluid‡X

Kilometers2900034000380004300048000 (Miles)(18,000)(21,000)(24,000)(27,000)(30,000)

Changetheengineoilandengineoilfilter.XXXXX

Rotatethetires.XXX

Inspecttheengineairfilterelement,replaceif necessary. X

Replacethesparkplugs. X

InspectandreplacethePCVvalve,ifnecessary. X

Inspectthebrakelinings.X

Drainandrefillthefrontandrearaxlefluid‡X Inspectthetransfercasefluid,addifnecessary.X

Kilometers5300058000620006700072000 (Miles)(33,000)(36,000)(39,000)(42,000)(45,000)

Changetheengineoilandengineoilfilter.XXXXX

Rotatethetires.XX

Inspecttheengineairfilterelement,replaceif necessary. X

Inspectthebrakelinings.X

Drainandrefillthefrontandrearaxlefluid‡X

Inspectthedrivebeltandreplaceasneeded.X

Kilometers7700082000860009100096000 (Miles)(48,000)(51,000)(54,000)(57,000)(60,000)

Changetheengineoilandengineoilfilter.XXXXX

Rotatethetires.XXX

Inspecttheengineairfilterelement,replaceif necessary. X

MAINTENANCESCHEDULES(Continued) Kilometers7700082000860009100096000

(Miles)(48,000)(51,000)(54,000)(57,000)(60,000)

Replacethesparkplugs. X

InspectandreplacethePCVvalve,ifnecessary. X

Replacetheignitioncables(2.4LOnly). X

Inspectthebrakelinings.XX

Drainandrefillthefrontandrearaxlefluid‡XX

Drainandrefilltheautomatictransmissionfluid,and replacemainsumpfilter. X

Inspectthedrivebeltandreplaceasneeded.Not requiredifbeltwaspreviouslyreplaced. X

Drainandrefillthetransfercasefluid.X

Flushandreplacetheenginecoolant/anti-freezeat 60months,ifnotdoneat102,000miles(163000 km).

Kilometers101000106000110000115000120000

(Miles)(63,000)(66,000)(69,000)(72,000)(75,000)

Changetheengineoilandengineoilfilter.XXXXX

Rotatethetires.XX

Inspecttheengineairfilterelement,replaceif necessary. X

Inspectthebrakelinings. X

Drainandrefillthefrontandrearaxlefluid‡X

Inspectthedrivebeltandreplaceasneeded.Not requiredifbeltwaspreviouslyreplaced.

Kilometers125000130000134000139000144000

(Miles)(78,000)(81,000)(84,000)(87,000)(90,000)

Changetheengineoilandengineoilfilter.XXXXX

Rotatethetires.XXX

Inspecttheengineairfilterelement,replaceif necessary. X

Replacethesparkplugs. X

InspectandreplacethePCVvalve,ifnecessary.

Inspectthebrakelinings.X

Drainandrefillthefrontandrearaxlefluid‡X

Inspectthedrivebeltandreplaceasneeded.Not requiredifbeltwaspreviouslyreplaced. X

Replacethetimingbelt(2.4LOnly). X

Inspectthetransfercasefluid,addifnecessary.X

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

Kilometers149000154000158000163000168000

(Miles)(93,000)(96,000)(99,000)(102,000)(105,000)

Changetheengineoilandengineoilfilter.XXXXX Rotatethetires.XX

Inspecttheengineairfilterelement,replaceif necessary. X

Inspectthebrakelinings.X

Drainandrefillthefrontandrearaxlefluid‡X

Inspectthedrivebeltandreplaceasneeded.Not requiredifbeltwaspreviouslyreplaced.

Flushandreplacetheenginecoolant/anti-freeze,if notdoneat60months.

Kilometers173000178000182000187000192000

(Miles)(108,000)(111,000)(114,000)(117,000)(120,000)

Changetheengineoilandengineoilfilter.XXXXX

Inspecttheengineairfilterelement,replaceif necessary. X

Replacethesparkplugs.

InspectandreplacethePCVvalve,ifnecessary.

Replacetheignitioncables(2.4LOnly). X

Inspectthebrakelinings.XX

Drainandrefillthefrontandrearaxlefluid‡XX

Drainandrefilltheautomatictransmissionfluid,and replacemainsumpfilter.

Inspectthedrivebeltandreplaceasneeded.Not requiredifbeltwaspreviouslyreplaced.

Drainandrefillthetransfercasefluid.X

Flushandreplacetheenginecoolant/anti-freezeat 120months,ifnotreplacedat102,000miles(163 000km).

Inspectionandserviceshouldbeperformedanytimeamalfunctionisobservedorsuspected.Retain allreceipts.

Thismaintenanceisrecommendedbythemanufacturertotheowner,butitisnotrequiredtomaintainemissionswarranty.

‡Off-highwayoperation,trailertowing,taxi,limousine,bus,snowplowing,orothertypesofcommercial serviceorprolongedoperationwithheavyloading, especiallyinhotweather,requirefrontandrearaxle serviceindicatedwitha‡in Schedule“B”.Perform theseservicesifthevehicleisusuallyoperatedunder theseconditions.

DESCRIPTION–DIESELENGINES–EXPORT SCHEDULES Therearetwomaintenanceschedulesthatshow the required serviceforyourvehicle.

FirstisSchedule “A”.Itisforvehiclesthatarenot operatedunderanyoftheconditionslistedunder Schedule B .

SecondisSchedule “B”.Itisforvehiclesthatare operatedundertheconditionsthatarelistedbelow andatthebeginningoftheschedule.

• Extensiveengineidling.

• Drivingindustyconditions.

MAINTENANCESCHEDULES(Continued)

• Morethan50%ofyourdrivingisatsustained highspeedsduringhotweather,above32°C(90°F).

• Trailertowing.

• Taxi,police,ordeliveryservice(commercialservice).

Mostvehiclesareoperatedundertheconditions listedforSchedule B . Usetheschedulethatbestdescribesyourdriving conditions.Wheretimeandmileagearelisted,follow theintervalthatoccursfirst.

CAUTION:Failuretoperformtherequiredmaintenanceitemsmayresultindamagetothevehicle.

AtEachStopforFuel • Checktheengineoillevelabout5minutesafter afullywarmedengineisshutoff.Checkingtheoil levelwhilethevehicleisonlevelgroundwill improvetheaccuracyoftheoillevelreading.Addoil onlywhenthelevelisatorbelowtheADDorMIN mark.

• Checkthewindshieldwashersolventandaddif required.

Schedule“A” OnceaMonth • Checkthetirepressureandlookforunusual wearordamage.

• Inspectthebatteryandcleanandtightenthe terminalsasrequired.

• Checkthefluidlevelsofcoolantreservoir,brake mastercylinder,powersteeringandtransmission andaddasneeded.

• Checkalllightsandallotherelectricalitemsfor correctoperation.

AtEachOilChange • Changetheengineoilfilter.

• Inspecttheexhaustsystem.

• Inspectthebrakehoses.

• Checkthemanualtransmissionfluidlevel—if equipped.

• Checkthecoolantlevel,hoses,andclamps.

• Inspectengineaccessorydrivebelts.Replaceas necessary.

• Inspectforthepresenceofwaterinthefuelfilter/waterseparatorunit.

• Rotatethetires.

Kilometers20000km40000km60000km80000km100000km

Changetheengineoilandengineoilfilter. XXXXX

Inspecttheengineairfilterelement. Replaceasnecessary. XXX

Replacetheengineairfilterelement.XX

Replacethefuelfilter/waterseparator unit. XXXXX

Replacetheenginetimingbelt,andidler pulleys. X

Inspecttimingbelttensioner,andreplace ifnecessary.‡ X

Inspecttheengineaccessorydrivebelt.XXXX

Replacetheengineaccessorydrivebelt.X

Inspecttheballjoints.XXXXX

Inspectthebrakelinings.XX

Inspectthetransfercasefluid.X

Kilometers120000km140000km160000km180000km

Changetheengineoilandengineoilfilter.XXXX

Inspecttheengineaccessorydrivebelts,and replaceifnecessary. XXXX

Inspecttheengineairfilterelement.Replaceas necessary. XX

MAINTENANCESCHEDULES(Continued)

Kilometers120000km140000km160000km180000km

Replacetheengineairfilterelement.XX

Replacethefuelfilter/waterseparatorunit.XXXX

Flushandreplacetheenginecoolant.X

Inspecttheballjoints.XXXX

Inspectthebrakelinings.XX

Drainandrefilltheautomatictransmissionfluid, changesumpfilter,andcoolerreturnfilter(if equipped). X

Inspectthetransfercasefluid.X

Drainandrefillthetransfercasefluid.X

Inspectionandserviceshouldalsobeperformed anytimeamalfunctionisobservedorsuspected.

‡Replaceifthereissuperficialwear,bearingclearance,orevidentgreaseleak.

WARNING:Youcanbebadlyinjuredworkingonor aroundamotorvehicle.Doonlythatservicework forwhichyouhavetheknowledgeandtheright equipment.Ifyouhaveanydoubtaboutyourability toperformaservicejob,takeyourvehicletoa competentmechanic.

Schedule“B” Followschedule“B”ifyouusuallyoperateyour vehicleunderoneormoreofthefollowingconditions.

• Extensiveengineidling.

• Drivingindustyconditions.

• Morethan50%ofyourdrivingisatsustained highspeedsduringhotweather,above32°C(90°F).

• Trailertowing.

• Taxi,police,ordeliveryservice(commercialservice).

Kilometers10000km20000km30000km40000km50000km

Changetheengineoilandengineoilfilter. XXXXX

Inspecttheengineairfilterelement. Replaceasnecessary. XXX

Replacetheengineairfilterelement.XX

Replacethefuelfilter/waterseparatorunit.XX

Inspecttheengineaccessorydrivebelt. XXXX

Replacetheengineaccessorydrivebelt.X

Replacetheenginetimingbeltandidler pulleys. X

Inspectthetimingbelttensioner.‡ X

Inspecttheballjoints. XXXXX

Inspectthebrakelinings.XX

Drainandrefillthefrontandrearaxle fluid. XX

Drainandrefilltheautomatictransmission fluid,andreplacesumpfilter. X

MAINTENANCESCHEDULES(Continued)

Kilometers60000

Changetheengineoilandengineoilfilter.XXXXX

Inspecttheengineairfilterelement.Replace asnecessary. XX

Replacetheengineairfilterelement.XXX

Replacethefuelfilter/waterseparatorunit.XXX

Inspecttheengineaccessorydrivebelt.XXXX

Replacetheengineaccessorydrivebelt.X

Replacetheenginetimingbelt,idlerpulleys, andtensioner. X

Inspecttheballjoints.XXXXX

Inspectthebrakelinings.XXX

Drainandrefillthefrontandrearaxlefluid.XXX

Drainandrefillthetransfercasefluid.X

Drainandrefilltheautomatictransmission fluid,andreplacesumpfilter. X

Kilometers110000

Changetheengineoilandengineoilfilter. XXXXXX

Inspecttheengineairfilterelement. Replaceasnecessary. XXX

Replacetheengineairfilterelement.XXX

Inspecttheengineaccessorydrivebelts, andreplaceifnecessary. XXXXX

Replacetheengineaccessorydrivebelt.X

Inspectthetimingbelttensioner.‡X

Replacetheenginetimingbeltandidler pulleys. X

Replacethefuelfilter/waterseparatorunit.XXX

Flushandreplacetheenginecoolant.X

Inspecttheballjoints. XXXXXX

Inspectthebrakelinings.XXX

Drainandrefillthefrontandrearaxle fluid. XXX

Drainandrefilltheautomatictransmission fluid,andreplacesumpfilter. X

Replacethetransmissioncoolerreturnfilter(ifequipped). X

Inspectionandserviceshouldalsobeperformed anytimeamalfunctionisobservedorsuspected. ‡Replaceifthereissuperficialwear,bearingclearance,orevidentgreaseleak.

FLUIDFILL/CHECK LOCATIONS DESCRIPTION

Thefluidcheck/fillpointlocationsarelocatedin eachapplicableservicemanualsection.

HOISTING STANDARDPROCEDURE-HOISTING RECOMMENDATIONS

RefertotheOwner’sManualforemergencyvehicle liftingprocedures.

Whenproperlypositioned,afloorjackcanbeused toliftaJeepvehicle(Fig.5).Supportthevehiclein theraisedpositionwithjackstandsatthefrontand rearendsoftheframerails.

NOTE:Usethecorrectsub-framerailorframerail liftinglocationsonly.

HOIST RefertotheOwner’sManualforemergencyvehicle liftingprocedures.

Avehiclecanbeliftedwith:

• Asingle-post,frame-contacthoist.

• Atwin-post,chassishoist.

• Aramp-type,drive-onhoist.

NOTE:Whenaframe-contacttypehoistisused, verifythattheliftingpadsarepositionedproperly.

WARNING:THEHOISTINGANDJACKLIFTING POINTSPROVIDEDAREFORACOMPLETEVEHICLE.WHENACHASSISORDRIVETRAINCOMPONENTISREMOVEDFROMAVEHICLE,THE CENTEROFGRAVITYISALTEREDMAKINGSOME HOISTINGCONDITIONSUNSTABLE.PROPERLY SUPPORTORSECUREVEHICLETOHOISTING DEVICEWHENTHESECONDITIONSEXIST.

JUMPSTARTING STANDARDPROCEDURE-JUMPSTARTING PROCEDURE

WARNING:REVIEWALLSAFETYPRECAUTIONS ANDWARNINGSINTHEBATTERYSYSTEMSECTIONOFTHESERVICEMANUAL.(Referto8ELECTRICAL/BATTERYSYSTEM/BATTERY-STANDARDPROCEDURE)

• DONOTJUMPSTARTAFROZENBATTERY, PERSONALINJURYCANRESULT.

• IFEQUIPPED,DONOTJUMPSTARTWHEN MAINTENANCEFREEBATTERYINDICATORDOTIS YELLOWORBRIGHTCOLOR.

Fig.5CorrectVehicleLiftingLocations

1-FrameContactLift(SinglePost) ChassisLift(Non-AxleDualPost) OutboardLift(DualPost) FloorJack

2-FloorJack

CAUTION:DonotattempttoliftaJeepvehiclewith afloorjackpositionedunder:

• Abodysidesill.

• Asteeringlinkagecomponent.

• Adriveshaft.

• Theengineortransmissionoilpan.

• Thefueltank.

• Afrontsuspensionarm.

• Transfercase.

• DONOTJUMPSTARTAVEHICLEWHENTHE BATTERYFLUIDISBELOWTHETOPOFLEAD PLATES.

• DONOTALLOWJUMPERCABLECLAMPSTO TOUCHEACHOTHERWHENCONNECTEDTOA BOOSTERSOURCE.

• DONOTUSEOPENFLAMENEARBATTERY.

• REMOVEMETALLICJEWELRYWORNON HANDSORWRISTSTOAVOIDINJURYBYACCIDENTALARCINGOFBATTERYCURRENT.

• WHENUSINGAHIGHOUTPUTBOOSTING DEVICE,DONOTALLOWBATTERYVOLTAGETO EXCEED16VOLTS.REFERTOINSTRUCTIONS PROVIDEDWITHDEVICEBEINGUSED. FAILURETOFOLLOWTHESEINSTRUCTIONSMAY RESULTINPERSONALINJURY.

JUMPSTARTING(Continued)

CAUTION:Whenusinganothervehicleasa booster,donotallowvehiclestotouch.Electrical systemscanbedamagedoneithervehicle.

TOJUMPSTARTADISABLEDVEHICLE: (1)Raisehoodondisabledvehicleandvisually inspectenginecompartmentfor:

• Generatordrivebeltconditionandtension.

• Fuelfumesorleakage,correctifnecessary.

• Frozenbattery.

• Yelloworbrightcolortestindicator,ifequipped.

• Lowbatteryfluidlevel.

CAUTION:Ifthecauseofstartingproblemondisabledvehicleissevere,damagetoboostervehicle chargingsystemcanresult.

(2)Whenusinganothervehicleasabooster source,turnoffallaccessories,placegearselectorin parkorneutral,setparkbrakeorequivalentand operateengineat1200rpm.

(3)Ondisabledvehicle,placegearselectorinpark orneutralandsetparkbrakeorequivalent.Turn OFFallaccessories.

(4)Connectjumpercablestoboosterbattery.RED clamptopositiveterminal(+).BLACKclamptonegativeterminal(-).DONOTallowclampsatopposite endofcablestotouch,electricalarcwillresult(Fig. 6).Reviewallwarningsinthisprocedure.

(5)Ondisabledvehicle,connectREDjumpercable clamptobatterypositive(+)terminal.Connect BLACKjumpercableclamptotheengineascloseto thegroundcableconnectionaspossible(Fig.6).

CAUTION:Donotcrankstartermotorondisabled vehicleformorethan15seconds,starterwilloverheatandcouldfail.

(6)Allowbatteryindisabledvehicletochargeto atleast12.4volts(75%charge)beforeattemptingto startengine.Ifenginedoesnotstartwithin15seconds,stopcrankingengineandallowstartertocool (15min.),beforecrankingagain.

DISCONNECTCABLECLAMPSASFOLLOWS: • DisconnectBLACKcableclampfromengine groundondisabledvehicle.

• WhenusingaBoostervehicle,disconnect BLACKcableclampfrombatterynegativeterminal. DisconnectREDcableclampfrombatterypositive terminal.

• DisconnectREDcableclampfrombatterypositiveterminalondisabledvehicle.

Fig.6JumperCableClampConnections 1-ENGINEGROUND 2-NEGATIVEJUMPERCABLE 3-BATTERYNEGATIVECABLE 4-POSITIVEJUMPERCABLE 5-BATTERYPOSITIVECABLE 6-BATTERY 7-TESTINDICATOR(IFEQUIPPED)

TOWING STANDARDPROCEDURE-TOWING

AvehicleequippedwithSAEapprovedwheellifttypetowingequipmentcanbeusedtotowJeepvehicles.Whentowinga4WDvehicleusingawheel-lift towingdevice,usetowdolliesundertheoppositeend ofthevehicle.Avehiclewithflatbeddevicecanalso beusedtotransportadisabledvehicle(Fig.7).

Fig.7TowVehiclesWithApprovedEquipment

TOWING(Continued)

SAFETYPRECAUTIONS CAUTION:Thefollowingsafetyprecautionsmustbe observedwhentowingavehicle:

• Securelooseandprotrudingparts.

• Alwaysuseasafetychainsystemthatisindependentoftheliftingandtowingequipment.

• Donotallowtowingequipmenttocontactthe disabledvehicle’sfueltank.

• Donotallowanyoneunderthedisabledvehicle whileitisliftedbythetowingdevice.

• Donotallowpassengerstorideinavehicle beingtowed.

• Alwaysobservestateandlocallawsregarding towingregulations.

• Donottowavehicleinamannerthatcould jeopardizethesafetyoftheoperator,pedestriansor othermotorists.

• Donotattachtowchains,T-hooks,orJ-hooksto abumper,steeringlinkage,driveshaftsoranon-reinforcedframehole.

• Donottowaheavilyloadedvehicle.Useaflatbeddevicetotransportaloadedvehicle.

TWO-WHEEL-DRIVEVEHICLETOWING DaimlerChryslerCorporationrecommendsthata vehiclebetowedwiththerearendlifted,whenever possible.

WARNING:WHENTOWINGADISABLEDVEHICLE ANDTHEDRIVEWHEELSARESECUREDINA WHEELLIFTORTOWDOLLIES,ENSURETHE TRANSMISSIONISINTHEPARKPOSITION(AUTOMATICTRANSMISSION)ORAFORWARDDRIVE GEAR(MANUALTRANSMISSION).

WARNING:ENSUREVEHICLEISONALEVELSURFACEORTHEWHEELSAREBLOCKEDTOPREVENTVEHICLEFROMROLLING.

TWOWHEELDRIVETOWING-REARENDLIFTED CAUTION:Donotusesteeringcolumnlockto securesteeringwheelduringtowingoperation.

2WDvehiclescanbetowedwiththefrontwheels onthesurfaceforextendeddistancesatspeedsnot exceeding48km/h(30mph).

(1)Attachwheelliftdevicetorearwheels.

(2)Placethetransmissioninneutral.

(3)Raisevehicletotowingposition.

(4)Attachsafetychains.Routechainssonotto interferewithtailpipewhenvehicleislifted.

(5)TurntheignitionswitchtotheOFFpositionto unlockthesteeringwheel.

CAUTION:Donotusesteeringcolumnlockto securesteeringwheelduringtowingoperation.

(6)Securesteeringwheelinstraightaheadpositionwithaclampdevicedesignedfortowing.

(7)Placetransmissioninpark.

TWOWHEELDRIVETOWING-FRONTENDLIFTED CAUTION:Manyvehiclesareequippedwithair dams,spoilers,and/orgroundeffectpanels.To avoidcomponentdamage,awheel-lifttowingvehicleoraflat-bedhaulingvehicleisrecommended.

(1)Attachwheelliftdevicetorearwheels.

(2)Placethetransmissioninneutral.

(3)Raisetherearofthevehicleoffthegroundand installtowdolliesunderrearwheels.

(4)Attachwheelliftdevicetofrontwheelsand raisevehicletotowingposition.

(5)Attachthesafetychains.

CAUTION:Donotusesteeringcolumnlockto securesteeringwheelduringtowingoperation.

(6)TurntheignitionswitchtotheOFFpositionto unlockthesteeringwheel.

(7)Securesteeringwheelinstraightaheadpositionwithaclampdevicedesignedfortowing.

(8)Placetransmissioninpark.

FOUR-WHEEL-DRIVEVEHICLETOWING DaimlerChryslerCorporationrecommendsthata 4WDvehiclebetransportedonaflat-beddevice.A Wheel-liftdevicecanbeusedprovided thetrailing wheelsareoffthegroundandpositionedin towdollies.

WARNING:WHENTOWINGADISABLEDVEHICLE ANDTHEDRIVEWHEELSARESECUREDINA WHEELLIFTORTOWDOLLIES,ENSURETHE TRANSMISSIONISINTHEPARKPOSITION.

CAUTION:Manyvehiclesareequippedwithair dams,spoilers,and/orgroundeffectpanels.To avoidcomponentdamage,awheel-lifttowingvehicleoraflat-bedhaulingvehicleisrecommended.

FOURWHEELDRIVETOWING—REARENDLIFTED WARNING:ENSUREVEHICLEISONALEVELSURFACEORTHEWHEELSAREBLOCKEDTOPREVENTVEHICLEFROMROLLING.

(1)Attachwheelliftdevicetofrontwheels. (2)Placethetransmissioninneutral.

TOWING(Continued)

(3)Raisethefrontofthevehicleofftheground andinstalltowdolliesunderfrontwheels.

(4)Attachwheelliftdevicetorearwheelsand raisevehicletotowingposition.

(5)Attachsafetychains.Routechainssonotto interferewithtailpipewhenvehicleislifted.

(6)TurntheignitionswitchtotheOFFpositionto unlockthesteeringwheel.

CAUTION:Donotusesteeringcolumnlockto securesteeringwheelduringtowingoperation.

(7)Securesteeringwheelinstraightaheadpositionwithaclampdevicedesignedfortowing.

(8)Placetransmissioninpark.

FOURWHEELDRIVETOWING—FRONTEND LIFTED

WARNING:ENSUREVEHICLEISONALEVELSURFACEORTHEWHEELSAREBLOCKEDTOPREVENTVEHICLEFROMROLLING.

(1)Attachwheelliftdevicetorearwheels.

(2)Placethetransmissioninneutral.

(3)Raisetherearofthevehicleoffthegroundand installtowdolliesunderrearwheels.

(4)Attachwheelliftdevicetofrontwheelsand raisevehicletotowingposition.

(5)Attachthesafetychains.

CAUTION:Donotusesteeringcolumnlockto securesteeringwheelduringtowingoperation.

(6)TurntheignitionswitchtotheOFFpositionto unlockthesteeringwheel.

(7)Securesteeringwheelinstraightaheadpositionwithaclampdevicedesignedfortowing.

(8)Placetransmissioninpark.

SUSPENSION

SUSPENSION TABLEOFCONTENTS

DIAGNOSISANDTESTING-SUSPENSION ANDSTEERINGSYSTEM ................1

SUSPENSION

DIAGNOSISANDTESTING-SUSPENSIONAND STEERINGSYSTEM

CONDITIONPOSSIBLECAUSESCORRECTION

FRONTENDNOISE1.Looseorwornwheelbearings.1.Replacewheelbearings.

2.Looseorwornsteeringor suspensioncomponents.

2.Tightenorreplacecomponentsas necessary.

EXCESSIVEPLAYIN STEERING

1.Looseorwornwheelbearings.1.Replacewheelbearings.

2.Looseorwornsteeringor suspensioncomponents.

2.Tightenorreplacecomponentsas necessary.

3.Looseorwornsteeringgear.3.Adjustorreplacesteeringgear.

FRONTWHEELSSHIMMY1.Looseorwornwheelbearings.1.Replacewheelbearings.

2.Looseorwornsteeringor suspensioncomponents. 2.Tightenorreplacecomponentsas necessary.

3.Tireswornoroutofbalance.3.Replaceorbalancetires. 4.Alignment.4.Alignvehicletospecifications.

VEHICLEINSTABILITY1.Looseorwornwheelbearings.1.Replacewheelbearings.

2.Looseorwornsteeringor suspensioncomponents. 2.Tightenorreplacecomponentsas necessary.

3.Tirepressure.3.Adjusttirepressure. 4.Alignment.4.Alignvehicletospecifications.

EXCESSIVESTEERING EFFORT

VEHICLEPULLSTOONE SIDEDURINGBRAKING

1.Looseorwornsteeringgear.1.Adjustorreplacesteeringgear.

2.Powersteeringfluidlow.2.Addfluidandrepairleak. 3.Columncouplerbinding.3.Replacecoupler. 4.Tirepressure.4.Adjusttirepressure. 5.Alignment.5.Alignvehicletospecifications.

1.Uneventirepressure.1.Adjusttirepressure. 2.Wornbrakecomponents.2.Repairbrakesasnecessary. 3.Airinbrakeline.3.Repairasnecessary.

SUSPENSION(Continued)

CONDITIONPOSSIBLECAUSESCORRECTION

VEHICLELEADSOR DRIFTSFROMSTRAIGHT AHEADDIRECTIONON UNCROWNEDROAD

KNOCKING,RATTLING ORSQUEAKING

1.Radialtirelead.1.Crossfronttires.

2.Brakesdragging.2.Repairbrakeasnecessary.

3.Weakorbrokenspring.3.Replacespring.

4.Uneventirepressure.4.Adjusttirepressure.

5.WheelAlignment.5.Alignvehicle.

6.Looseorwornsteeringor suspensioncomponents.

6.Repairasnecessary.

7.Crosscasteroutofspec.7.Alignvehicle.

1.Wornshockbushings.1.Replaceshock.

2.Loose,wornorbentsteering/ suspensioncomponents.

3.Shockvalve.3.Replaceshock.

IMPROPERTRACKINGLoose,wornorbentsteering/ suspensioncomponents.

2.Inspect,tightenorreplacecomponents asnecessary.

Inspect,tightenorreplacecomponentsas necessary. 2-2SUSPENSION

WHEELALIGNMENT WHEELALIGNMENT DESCRIPTION NOTE:Suspensioncomponentswithrubber/urethanebushingsshouldbetightenedwiththevehicleatnormalrideheight.Itisimportanttohavethe springssupportingtheweightofthevehiclewhen thefastenersaretorqued.Ifspringsarenotattheir normalrideposition,vehicleridecomfortcouldbe affectedandprematurebushingwearmayoccur.

Wheelalignmentinvolvesthecorrectpositioningof thewheelsinrelationtothevehicle.Thepositioning isaccomplishedthroughsuspensionandsteering linkageadjustments.Analignmentisconsidered essentialforefficientsteering,gooddirectionalstabilityandtominimizetirewear.Themostimportant measurementsofanalignmentarecaster,camber andtoe(Fig.1).

CAUTION:Neverattempttomodifysuspensionor steeringcomponentsbyheatingorbending.

NOTE:Periodiclubricationofthefrontsuspension/ steeringsystemcomponentsmayberequired.Rubberbushingsmustneverbelubricated.Referto LubricationAndMaintenancefortherecommended maintenanceschedule.

OPERATION • CASTER istheforwardorrearwardtiltofthe steeringknucklefromvertical.Tiltingthetopofthe knuckleforwardprovidesnegativecaster.Tiltingthe topoftheknucklerearwardprovidespositivecaster. Positivecasterpromotesdirectionalstability.This

Fig.1WheelAlignmentMeasurements 1-FRONTOFVEHICLE

2-STEERINGAXISINCLINATION

3-PIVOTPOINT

4-TOE-IN

angleenablesthefrontwheelstoreturntoastraight aheadpositionafterturns(Fig.1)

• CAMBER istheinwardoroutwardtiltofthe wheelrelativetothecenterofthevehicle.Tiltingthe topofthewheelinwardprovidesnegativecamber. Tiltingthetopofthewheeloutwardprovidespositive camber.Incorrectcamberwillcausewearonthe insideoroutsideedgeofthetire(Fig.1)

• TOE isthedifferencebetweentheleadinginside edgesandtrailinginsideedgesofthefronttires. Wheeltoepositionoutofspecificationcause’sunstablesteering,uneventirewearandsteeringwheeloffcenter.Thewheeltoepositionisthe final front wheelalignmentadjustment(Fig.1)

• THRUSTANGLE istheangleoftherearaxle relativetothecenterlineofthevehicle.Incorrect thrustanglecancauseoff-centersteeringandexces-

sivetirewear.Thisangleisnotadjustable,damaged component(s)mustbereplacedtocorrectthethrust angle(Fig.1)

STANDARDPROCEDURE STANDARDPROCEDURE-HEIGHT MEASUREMENT

RIDEHEIGHT

NOTE:Thesuspensionisnon-adjustable.

Thevehiclesuspensionheightshouldbemeasured beforeperformingwheelalignmentprocedure.Also whenfrontsuspensioncomponentshavebeen replaced.Thismeasuremustbeperformedwiththe vehiclesupportingit’sownweightandtakenonboth sidesofthevehicle.

Frontandrearrideheightsarenotadjustable.The springselectionsatassemblydeterminerideheight foracceptableappearanceofthevehicle.Rideheight dimensionsassumefullfluids(includingfuel)and zeropassengers.Refertothetablebelowforfront rideheightdimensions.

Vehiclerideheightauditsshouldbeperformedutilizingthefollowingprocedure:

(1)Drivethevehiclestraightandforwardona non-tackysurfaceforaminimumof20feettoneutralizetrackwidth.

(2)Bouncethefrontofthevehiclefivetimes.

(3)Measureandrecordthedimensions

FRONTRIDEHEIGHTFrontrideheightis definedbytherelativeverticaldistancebetweenthe spindlecenterlineandtherearpivotpointofthe frontlowercontrolarmtocradleattachment.The spindlecenterlineistobemeasuredattheouter wheelface(pointA).Therearpivotpointistobe measuredatthecenterofthecam/pivotbolt(point B)atitsrearwardmostend(nutend).(Fig.2)

REARRIDEHEIGHTRearrideheightisdefined bytherelativeverticaldistancebetweenthetopof thelowerspringseatstrikesurfaceandthebottom ofthejouncecup(truemetaltometaljouncetravel). Thisistobemeasuredverticallyinsidethecoilfrom thepointintersectingtheinboardedgeandthefor/ aftcenterofthejouncecup(pointC)downtothe strikesurface(pointD).(Fig.3)

Fig.2FRONTRIDEHEIGHTMESUREMENT

1-POINT-A

2-POINT-B

Fig.3REARRIDEHEIGHTMESUREMENT

1-POINT-C

2-POINT-D

WHEELALIGNMENT(Continued)

STANDARDPROCEDURE-CAMBERAND CASTERADJUSTMENT Camberandcasterangleadjustmentsinvolve changingthepositionofthelowercontrolarmcam bolts.(Fig.4)

(2)Loosenthetierodjamnuts.

NOTE:Eachfrontwheelshouldbeadjustedfor one-halfofthetotaltoepositionspecification.This willensurethesteeringwheelwillbecentered whenthewheelsarepositionedstraight-ahead.

(3)Adjustthewheeltoepositionbyturningthetie rodasnecessary(Fig.5).

Fig.4LOWERCONTROLARM

1-FRONTCAMBOLT

2-OUTERTIERODEND

3-LOWERBALLJOINTNUT

4-LOWERCONTROLARM

5-REARCAMBOLT

STANDARDPROCEDURE-TOEADJUSTMENT 4X4SUSPENSIONHEIGHTMESUREMENT MUSTBEPERFORMEDBEFOREANALIGNMENT.

Thewheeltoepositionadjustmentisthefinal adjustment.

(1)Starttheengineandturnwheelsbothways beforestraighteningthewheels.Securethesteering wheelwiththefrontwheelsinthestraight-ahead position.

Fig.5TIERODEND 1-JAMNUT

2-TIEROD-INNER

3-TIERODEND-OUTER

(4)Tightenthetierodjamnutto75N·m(55ft. lbs.).

(5)Verifythespecifications (6)Turnoffengine.

STANDARDPROCEDURE-CAMBER,CASTER ANDTOEADJUSTMENT Camberandcasterangleadjustmentsinvolve changingthepositionofthelowersuspensionarm cambolts.(Fig.4)

CASTER Movingtherearpositionofthecamboltinorout, willchangethecasteranglesignificantlyandcamber angleonlyslightly.Tomaintainthecamberangle whileadjustingcaster,movetherearofthecambolt inorout.Thenmovethefrontofthecambolt slightlyintheoppositedirection.(Fig.4)

Toincreasepositivecasterangle,movetherear positionofthecamboltoutward(fromtheengine). Movethefrontofcamboltinward(towardthe engine)slightlyuntiltheoriginalcamberangleis obtained.(Fig.4)

WHEELALIGNMENT(Continued)

CAMBER Movebothofthecamboltstogetherinorout.This willchangethecamberanglesignificantlyandcaster angleslightly.(Fig.4)

Afteradjustmentismadetightenthecamboltnuts topropertorquespecification.

TOEADJUSTMENT

Thewheeltoepositionadjustmentisthefinal adjustment.

(1)Starttheengineandturnwheelsbothways beforestraighteningthewheels.Securethesteering wheelwiththefrontwheelsinthestraight-ahead position.

(2)Loosenthetierodjamnuts.

NOTE:Eachfrontwheelshouldbeadjustedfor one-halfofthetotaltoepositionspecification.This willensurethesteeringwheelwillbecentered whenthewheelsarepositionedstraight-ahead.

(3)Adjustthewheeltoepositionbyturningthetie rodasnecessary(Fig.5).

(4)Tightenthetierodjamnutto75N·m(55ft. lbs.).

(5)Verifythespecifications (6)Turnoffengine.

SPECIFICATIONS ALIGNMENT

NOTE:Specificationsareindegrees.

FRONT REAR SPECIFICATIONS

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

FRONT DESCRIPTION NOTE:Suspensioncomponentswithrubber/urethanebushingsshouldbetightenedwiththevehicleatnormalrideheight.Itisimportanttohavethe springssupportingtheweightofthevehiclewhen thefastenersaretorqued.Ifspringsarenotattheir normalrideposition,vehicleridecomfortcouldbe affectedandprematurebushingwearmayoccur.

Thefrontsuspensionisdesignedtoalloweach wheeltoadapttodifferentroadsurfacesindependently.Thewheelsaremountedtohubbearingson thesteeringknucklespindles.Thedouble-rowhub bearingsaresealedandlubricatedforlife.Thesteeringknucklesturn(pivot)onballjointsintegraltothe outboardportionoftheuppercontrolarmsand pressedintothelowersteeringknuckle.Theball jointsarelubricatedforlife.(Fig.1)

FRONT(Continued)

1-SWAYBAR

Fig.1FRONTSUSPENSION 2-SWAYBARBUSHING/BRACKET

3-UPPERCONTROLARM

4-SPRING/SHOCKASSEMBLY

5-STEERINGKNUCKLE

6-OUTERTIERODEND

7-LOWERCONTROLARM

8-SWAYBARLINK

9-CLEVISBRACKET 2-8FRONT

SPECIFICATIONS TORQUECHART WARNING WARNING:Suspensioncomponentswithrubber bushingsmustbetightenedwiththevehicleatnormalrideheight.Itisimportanttohavethesprings supportingtheweightofthevehiclewhenthefastenersaretorqued.Ifspringsarenotattheirnormal rideposition,vehicleridecomfortwillbeaffected andcauseprematurebushingwear.

TORQUESPECIFICATIONS

DESCRIPTIONN·mFt.Lbs.In.Lbs.

FrontShockAbsorber

ClevisBracketUpperNut

FrontShockAbsorber

ClevisBracketLowerNut

FrontShockAbsorberTop (4)MountingNuts

FrontShocktoSpringand InsulatorNut

UpperSuspensionArm FrontNut

UpperSuspensionArm RearNut

LowerSuspensionArm FrontNut

LowerSuspensionArm RearNut

StabilizerBarClampNut149110—

FRONT(Continued)

StabilizerBarLinkUpper Nut 136100—

StabilizerBarLinkLower Nut 11585—

SPECIALTOOLS FRONTSUSPENSION BALLJOINTPRESS-C-4212F

FRONTLOWERCONTROLARM&CLEVIS BUSHINGREMOVER/INSTALLER-8858

RemoverC-4150A

REMOVER/INSTALLERFRONTLOWERBALL JOINT-8859

FRONTLOWERCONTROLBUSHINGREMOVER/ INSTALLER-8830

BUSHINGS REMOVAL REMOVAL-STABILIZERBARBUSHINGS

(1)Raisevehicleonhoist.

(2)Removethestabilizerbushingclamps.

(3)Removethestabilizerbushingsfromthestabilizerbar.

REMOVAL-LOWERCONTROLARMBUSHING (1)Removethelowercontrolarm(Referto2SUSPENSION/FRONT/LOWERCONTROLARMREMOVAL).

(2)Securethecontrolarminavise.

NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsureproper operationduringtheremovalandinstallationprocess.

(3)Pressthebushingoutusingspecialtools 8858-5(Receiver),8858-6(Driver)and8839withthe threadedrodandthebearingasshown(Fig.2)

NOTE:Extremepressurelubricationmustbeusedon thethreadedportionsofthetool.Thiswillincrease thelongevityofthetoolandinsureproperoperation duringtheremovalandinstallationprocess.

(2)Pressthebushingoutusingspecialtools 8858-1(receiver),8858-3(driver)and8839withthe threadedrod8839andthebearingasshown(Fig.3)

Fig.2LOWERCONTROLARMBUSHINGREMOVAL

1-8858-5RECEIVER

2-8858-6DRIVER

3-8839THREADEDROD

REMOVAL-CLEVISBRACKETBUSHING (1)Removetheclevisbracketfromtheshock (Referto2-SUSPENSION/FRONT/CLEVIS BRACKET-REMOVAL).

Fig.3CLEVISBRACKETBUSHING

1-8839THREADEDROD 2-8858-1RECEIVER 3-8858-3DRIVER

REMOVAL-UPPERCONTROLARMBUSHINGS (1)Removetheuppercontrolarm(Referto2SUSPENSION/FRONT/UPPERCONTROLARMREMOVAL).

(2)Securethecontrolarminavise.

NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsureproper operationduringtheremovalandinstallationprocess.

(3)Installbushingremovertools8830-3(Adapter), 8830-2(Receiver)and8830–4(Driver)withthe threadedrod8838andthebearingasshown(Fig.4) (4)Pressoutthebushing.

INSTALLATION INSTALLATION-STABILIZERBARBUSHINGS (1)Installthestabilizerbushingstothestabilizer bar.

(2)Installthestabilizerbushingclamps.Tighten thenutsto149N·m(110ft.lbs.).

(3)Lowerthevehicle.

BUSHINGS(Continued)

Fig.4UPPERCONTROLARMBUSHINGREMOVAL

1-8830-3(ADAPTER)

2-8830-2(RECIEVER)

3-8830-4(DRIVER)

4-8838(THREADEDROD)

INSTALLATION-LOWERCONTROLARM BUSHING NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsureproper operationduringtheremovalandinstallationprocess.

(1)Installthenewlowercontrolarmbushingsinto thelowercontrolarmusingtools8858-5(driver), 8858-6(receiver)andthebearingwiththethreaded rod8839(Fig.5)makingsuretoproperlyorientthe bushinginthecontrol.

(2)Removethecontrolarmfromthevise.

(3)Installthelowercontrolarm(Referto2-SUSPENSION/FRONT/LOWERCONTROLARMINSTALLATION).

(4)Resetthevehiclerideheight(Referto2-SUSPENSION/WHEELALIGNMENT-STANDARD PROCEDURE).

(5)Performawheelalignment(Referto2-SUSPENSION/WHEELALIGNMENT-STANDARD PROCEDURE).

INSTALLATION-CLEVISBRACKETBUSHING NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsureproper operationduringtheremovalandinstallationprocess.

Fig.5LOWERCONTROLARMBUSHINGINSTALLATION

1-8858-5DRIVER 2-8858-6RECEIVER 3-8839THREADEDROD

(1)Installthenewclevisbracketbushingintothe lowercontrolarmusingtools8858-2(driver),8858-1 (receiver)andthebearingwiththethreadedrod 8839(Fig.6)makingsuretoproperlyorientthe bushinginthecontrol.

Fig.6CLEVISBRACKETBUSHING

1-8839THREADEDROD 2-8858-2DRIVER 3-8858-1RECEIVER

(2)Installtheclevisbracket(Referto2-SUSPENSION/FRONT/CLEVISBRACKET-INSTALLATION).

INSTALLATION-UPPERCONTROLARM BUSHINGS NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsureproper operationduringtheremovalandinstallationprocess.

(1)Installthenewuppercontrolarmbushings intotheuppercontrolarmusingtools8830-3 (Adapter),8830-1(Driver)and8830-2(Receiver)the bearingwiththethreadedrod8838(Fig.7)making suretoproperlyorientthebushinginthecontrol arm.

(2)Removethecontrolarmfromthevise.

(3)Installtheuppercontrolarm(Referto2-SUSPENSION/FRONT/UPPERCONTROLARMINSTALLATION).

(4)Resetthevehiclerideheight(Referto2-SUSPENSION/WHEELALIGNMENT-STANDARD PROCEDURE).

(5)Performawheelalignment(Referto2-SUSPENSION/WHEELALIGNMENT-STANDARD PROCEDURE).

(3)Removethecaliperadapter(Referto5BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKECALIPERS-REMOVAL).

CAUTION:Neverallowthediscbrakecaliperto hangfromthebrakehose.Damagetothebrake hosewillresult.Provideasuitablesupporttohang thecalipersecurely.

(4)Removethediscbrakerotor(Referto5BRAKES/HYDRAULIC/MECHANICAL/ROTORSREMOVAL).

(5)Removethewheelspeedsensor(Referto5BRAKES/ELECTRICAL/FRONTWHEELSPEED SENSOR-REMOVAL).

(6)Removethebracketsecuringthewheelspeed sensorwire.

(7)Removetheaxleshaftnut.(ifequippedwith fourwheeldrive)

(8)Removethethreemountingboltsforthehub/ bearingassembly.

(9)Removethehub/bearing.

INSTALLATION (1)Installthehub/bearingassemblytothevehicle.

(2)Installthethreemountingboltsforthehub/ bearing.Tightentheboltto130N·m(96ft.lbs.).

(3)Installtheaxleshaftnut.Tightenthenutto 135N·m(100ft.lbs.).(ifequippedwithfourwheel drive)

(4)Installthebrackettothewheelspeedsensor wire.

(5)Installthewheelspeedsensortothehub. Tightentheboltto13.5N·m(10ft.lbs.)(Referto5BRAKES/ELECTRICAL/FRONTWHEELSPEED SENSOR-INSTALLATION).

(6)Installthediscbrakerotor(Referto5BRAKES/HYDRAULIC/MECHANICAL/ROTORSINSTALLATION).

(7)Installthediscbrakecaliperadapter.Tighten thenutto135N·m(100ft.lbs.)(Referto5BRAKES/HYDRAULIC/MECHANICAL/ROTORSINSTALLATION).

(8)Installthetireandwheelassembly.(Referto 22-TIRES/WHEELS/WHEELS-STANDARDPROCEDURE).

HUB/BEARING REMOVAL (1)Raiseandsupportthevehicle.

(2)Removethetireandwheelassembly.

KNUCKLE REMOVAL (1)Raiseandsupportthevehicle.

(2)Removethetireandwheelassembly.

(3)Removethecaliperadapter.(Referto5BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKECALIPERADAPTER-REMOVAL).