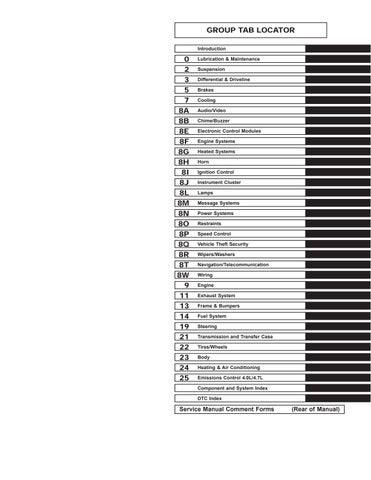

GROUPTABLOCATOR CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

INTRODUCTION TABLEOFCONTENTS VEHICLEIDENTIFICATIONNUMBER

VEHICLEIDENTIFICATIONNUMBER

DESCRIPTION

TheVehicleIdentificationNumber(VIN)plateis attachedtothetopleftsideoftheinstrumentpanel. TheVINcontains17charactersthatprovidedataconcerningthevehicle.Refertothedecodingchartto determinetheidentificationofavehicle.

Toprotecttheconsumerfromtheftandpossiblefraud themanufacturerisrequiredtoincludeaCheckDigit attheninthpositionoftheVehicleIdentificationNumber.Thecheckdigitisusedbythemanufacturerand governmentagenciestoverifytheauthenticityofthe vehicleandofficialdocumentation.Theformulatouse thecheckdigitisnotreleasedtothegeneralpublic.

VEHICLEIDENTIFICATIONNUMBERDECODINGCHART

POSITIONINTERPRETATIONCODE=DESCRIPTION

1CountryofOrigin1=ManufacturedByDaimlerChrysler Corporation

2MakeJ=Jeep

3VehicleType4=MPVLessSideAirBags

8=MPVWithSideAirBags

4GrossVehicleWeightRatingG=5001-6000lbs.

5VehicleLine(WK)S=GrandCherokee4X2 R=GrandCherokee4X4

5VehicleLine(WH)C=GrandCherokee4X4(LHD) D=GrandCherokee4X4(RHD)

6Series4=GrandCherokeeLAREDO 5=GrandCherokeeLIMITED E=5SpeedAuto

7BodyStyle8=SportUtility4Door

8EngineK=3.7K6cyl.MPIGasoline N=4.7L8cyl.MPIGasoline 2=5.7L8cyl.HEMIMultipleDisplacement Gasoline M=3.0L6cyl.TurboDiesel

9CheckDigit0through9orX

10ModelYear5=2005

11AssemblyPlantC=JeffersonNorthAssembly Y=ChryslerSteyerAssembly 12thru17VehicleBuildSequence

VEHICLEEMISSIONCONTROLINFORMATION(VECI) DESCRIPTION

Allvehiclesareequippedwithacombinedvehicleemissioncontrolinformation(VECI)label(s).Thelabelislocated intheenginecompartmentonthevehiclehood.Twolabelsareusedforvehiclesbuiltforsaleinthecountryof Canada.

TheVECIlabel(s)containthefollowing:

• Enginefamilyanddisplacement

• Evaporativefamily

• Emissioncontrolsystemschematic

• Certificationapplication

• Sparkplugandgap

Thelabelalsocontainsanenginevacuumschematic. Thereareuniquelabelsforvehiclesbuiltforsalein thestateofCaliforniaandthecountryofCanada. CanadianlabelsarewritteninboththeEnglishand Frenchlanguages.Theselabelsarepermanently attachedandcannotberemovedwithoutdefacing informationanddestroyinglabel.

VEHICLECERTIFICATIONLABEL DESCRIPTION AvehiclecertificationlabelisattachedtoeveryDaimlerChryslerCorporationvehicle.Thelabelcertifiesthatthe vehicleconformstoallapplicableFederalMotorVehicleStandards.Thelabelalsolists:

• Monthandyearofvehiclemanufacture.

• GrossVehicleWeightRating(GVWR).Thegrossfrontandrearaxleweightratings(GAWR’s)arebasedona minimumrimsizeandmaximumcoldtireinflationpressure.

• VehicleIdentificationNumber(VIN).

• Typeofvehicle.

• Typeofrearwheels.

• Barcode.

• Month,DayandHour(MDH)offinalassembly.

• PaintandTrimcodes.

• Countryoforigin.

Thelabelislocatedonthedriver-sidedoorshut-face.

FASTENERIDENTIFICATION DESCRIPTION TheSAEboltstrengthgradesrangefromgrade2tograde8.Thehigherthegradenumber,thegreaterthebolt strength.Identificationisdeterminedbythelinemarksonthetopofeachbolthead.Theactualboltstrengthgrade correspondstothenumberoflinemarksplus2.Themostcommonlyusedmetricboltstrengthclassesare9.8and 10.9.Themetricstrengthclassidentificationnumberisimprintedontheheadofthebolt.Thehighertheclass number,thegreatertheboltstrength.Somemetricnutsareimprintedwithasingle-digitstrengthclassonthenut face.RefertotheFastenerIdentificationandFastenerStrengthCharts.

BoltMarkingsandTorques-Metric BoltMarkings8.8/8.910.912.9

BoltMarkingsandTorques-U.S.Customary BoltMarkingsGrade5Grade8 BoltDia.N·mFt.LbsN·mFt.Lbs 1/4-201095*14125* 1/4-281095*17150* 5/16-1822200*30270* 5/16-2426240*33300* 3/8-1640305540 3/8-2447356045 7/16-1468508865 7/16-2074559570 1/2-1310175135100 1/2-2011585150110 9/16-12135105182135 9/16-18155115202150 5/8-11202150263195 5/8-18215160284210 3/4-10230170297220 3/4-16236175304225 7/8-14405300540400 *InchLbs.

FASTENERUSAGE DESCRIPTION

FASTENERUSAGE

WARNING:Useofanincorrectfastenermayresultincomponentdamageorpersonalinjury.

FastenersandtorquespecificationsreferencesinthisServiceManualareidentifiedinmetricandSAEformat. Duringanymaintenanceorrepairprocedures,itisimportanttosalvageallfasteners(nuts,bolts,etc.)forreassembly.Ifthefastenerisnotsalvageable,afastenerofequivalentspecificationmustbeused.

THREADEDHOLEREPAIR DESCRIPTION

THREADEDHOLEREPAIR

MoststrippedthreadedholescanberepairedusingaHelicoil .FollowthevehicleorHelicoil recommendationsfor applicationandrepairprocedures.

INTERNATIONALSYMBOLS DESCRIPTION-INTERNATIONALSYMBOLS

ThegraphicsymbolsillustratedinthefollowingInternationalControlandDisplaySymbolsChartareusedtoidentify variousinstrumentcontrols.Thesymbolscorrespondtothecontrolsanddisplaysthatarelocatedontheinstrument panel.

METRICSYSTEM DESCRIPTION Themetricsystemisbasedonquantitiesofone,ten,onehundred,onethousandandonemillion. ThefollowingchartwillassistinconvertingmetricunitstoequivalentEnglishandSAEunits,orviseversa.

CONVERSIONFORMULASANDEQUIVALENTVALUES MULTIPLYBYTOGETMULTIPLYBYTOGET

in-lbsx 0.11298 =NewtonMeters (N·m) N·mx8.851=in-lbs

ft-lbsx 1.3558 =NewtonMeters (N·m) N·mx 0.7376 =ft-lbs

InchesHg(60°F)x3.377=Kilopascals(kPa)kPax 0.2961 =InchesHg

psix6.895=Kilopascals(kPa)kPax0.145=psi

Inchesx25.4=Millimeters(mm)mmx 0.03937 =Inches

Feetx 0.3048 =Meters(M)Mx3.281=Feet

Yardsx 0.9144 =MetersMx 1.0936 =Yards mphx 1.6093 =Kilometers/Hr. (Km/h) Km/hx 0.6214 =mph

Feet/Secx 0.3048 =Meters/Sec(M/S)M/Sx3.281=Feet/Sec

mphx 0.4470 =Meters/Sec(M/S)M/Sx2.237=mph

Kilometers/Hr.(Km/h)x 0.27778 =Meters/Sec(M/S)M/Sx3.600Kilometers/Hr.(Km/h)

COMMONMETRICEQUIVALENTS 1inch=25Millimeters1CubicInch=16CubicCentimeters

1Foot=0.3Meter1CubicFoot=0.03CubicMeter

1Yard=0.9Meter1CubicYard=0.8CubicMeter

1Mile=1.6Kilometers

RefertotheMetricConversionCharttoconverttorquevalueslistedinmetricNewton-meters(N·m).Also,usethe charttoconvertbetweenmillimeters(mm)andinches(in.).

TORQUEREFERENCES DESCRIPTION IndividualTorqueChartsappearwithinmanyortheGroups.RefertotheStandardTorqueSpecificationsChartfor torquereferencesnotlistedintheindividualtorquecharts.

LUBRICATION&MAINTENANCE INTERNATIONALSYMBOLS DESCRIPTION

DaimlerChryslerCorporationusesinternationalsymbolstoidentifyenginecompartmentlubricantandfluid inspectionandfilllocations.

PARTS&LUBRICANTRECOMMENDATION DESCRIPTION

LUBRICANTRECOMMENDATIONS

Chassis

ComponentFluid,Lubricant,orGenuinePart

SteeringGear&Linkage,Ball Joints,PropShafts&Yokes, WheelBearings

Body

Mopar Multi-PurposeLubricantNLGIGrade2EP,GC-LB

ComponentFluid,Lubricant,andGenuinePart Hinges:

Door&HoodMopar EngineOil

SwingGateMopar Multi-PurposeLubeNLGIGrade2EP,GC-LB

Latches:Door,Hood/Safety Catch,SwingGate

Mopar Multi-PurposeLubeNLGIGrade2EP,GC-LB

SeatRegulator&TrackMopar Multi-PurposeLubeNLGIGrade2EP,GC-LB

LockCylindersMopar LockCylinderLube

FLUIDTYPES Whenserviceisrequired,DaimlerChryslerCorporationrecommendsthatonlyMopar brandparts,lubricantsand chemicalsbeused.Mopar providesthebestengineeredproductsforservicingDaimlerChryslerCorporationvehicles.

OnlylubricantsbearingdesignationsdefinedbythefollowingorganizationshouldbeusedtoserviceaChrysler Corporationvehicle.

• SocietyofAutomotiveEngineers(SAE)

• AmericanPetroleumInstitute(API)

• NationalLubricatingGreaseInstitute(NLGI)

APIQUALITYCLASSIFICATION Thissymbolonthefrontofanoilcontainermeans thattheoilhasbeencertifiedbytheAmericanPetroleumInstitute(API)tomeetallthelubricationrequirementsspecifiedbyDaimlerChryslerCorporation.

GEARLUBRICANTS SAEratingsalsoapplytomultigradegearlubricants.Inaddition,APIclassificationdefinesthelubricantsusage. SuchasAPIGL-5andSAE75W-90.

FLUIDTYPES DESCRIPTION ENGINEOIL WARNING:NEWORUSEDENGINEOILCANBEIRRITATINGTOTHESKIN.AVOIDPROLONGEDOR REPEATEDSKINCONTACTWITHENGINEOIL.CONTAMINANTSINUSEDENGINEOIL,CAUSEDBYINTERNALCOMBUSTION,CANBEHAZARDOUSTOYOURHEALTH.THOROUGHLYWASHEXPOSEDSKINWITH SOAPANDWATER.DONOTWASHSKINWITHGASOLINE,DIESELFUEL,THINNER,ORSOLVENTS, HEALTHPROBLEMSCANRESULT.DONOTPOLLUTE,DISPOSEOFUSEDENGINEOILPROPERLY.CONTACTYOURDEALERORGOVERNMENTAGENCYFORLOCATIONOFCOLLECTIONCENTERINYOUR AREA.

Whenserviceisrequired,DaimlerChryslerCorporationrecommendsthatonlyMopar brandparts,lubricantsand chemicalsbeused.Mopar providesthebestengineeredproductsforservicingDaimlerChryslerCorporationvehicles.

Onlylubricantsbearingdesignationsdefinedbythefollowingorganizationshouldbeused.

• SocietyofAutomotiveEngineers(SAE)

• AmericanPetroleumInstitute(API)

• NationalLubricatingGreaseInstitute(NLGI)

• AssociationdesConstructeursEuropéensd’Automobiles(EuropeanAutomobileManufacturersAssociation) (ACEA)

APISERVICEGRADECERTIFIED UseanengineoilthatisAPICertified.MOPAR providesengineoils,thatmeetorexceedthisrequirement.

SAEVISCOSITY AnSAEviscositygradeisusedtospecifytheviscosity ofengineoil.Useonlyengineoilswithmultipleviscositiessuchas5W-30or10W-30.Thesearespecified withadualSAEviscositygradewhichindicatesthe cold-to-hottemperatureviscosityrange. For3.7L/4.7L enginesSAE5W-30engineoilisrecommendedfor alloperatingtemperatures.For5.7Lengines,SAE 5W-20engineoilisrecommendedforalloperating temperatures.Vehicleswith5.7Lenginesequipped withMultipleDisplacementSystem,(MDS),must useSAE5W-20oil.Failuretodosomayresultin improperoperationoftheMultipleDisplacement System(MDS).Theseengineoilsimprovelowtemperaturestartingandvehiclefueleconomy.Refer toyourengineoilfillercapfortherecommendedengineoilviscosityforyourvehicle.

ACEACategories ForcountriesthatusetheACEAEuropeanOilCategoriesforServiceFillOils,useengineoilsthatmeettherequirementsofACEAA1/B1,A2/B2,orA3/B3.

ENERGYCONSERVINGOIL AnEnergyConservingtypeoilisrecommendedforgasolineengines.ThedesignationofENERGYCONSERVING islocatedonthelabelofanengineoilcontainer.

CONTAINERIDENTIFICATION Standardengineoilidentificationnotationshavebeen adoptedtoaidintheproperselectionofengineoil. Theidentifyingnotationsarelocatedonthefrontlabel ofengineoilplasticbottlesandthetopofengineoil cans.

Thissymbolmeansthattheoilhasbeencertifiedby theAmericanPetroleumInstitute(API).DiamlerChrysleronlyrecommendAPICertifiedengineoils. UseMopar engineoilorequivalent.

SYNTHETICENGINEOILS Thereareanumberofengineoilsbeingpromotedaseithersyntheticorsemi-synthetic.Ifyouchosetousesuch aproduct,use only thoseoilsthatmeettheAmericanPetroleumInstitute(API)andSAEviscositystandard.Follow theserviceschedulethatdescribesyourdrivingtype.

ENGINEOILADDITIVES/SUPPLEMENTS Themanufacturer doesnotrecommend theadditionofanyengineoiladditives/supplementstothespecified engineoil.Engineoiladditives/supplementsshouldnotbeusedtoenhanceengineoilperformance.Engineoiladditives/supplementsshouldnotbeusedtoextendengineoilchangeintervals.Noadditiveisknowntobesafefor enginedurabilityandcandegradeemissioncomponents.Additivescancontainundesirablematerialsthatharmthe longtermdurabilityofenginesby:

• DoublingthelevelofPhosphorusintheengineoil.TheILSAC(InternationalLubricantStandardApproval Committee)GF-2andGF-3standardsrequirethatengineoilcontainnomorethan0.10%Phosphorustoprotectthevehiclesemissionsperformance.Additionofengineoiladditives/supplementscanpoison,fromthe addedsulfurandphosphorus,catalystsandhindereffortstoguaranteeemissionsperformanceto80,000 miles.

• Alteringtheviscositycharacteristicsoftheengineoilsothatitnolongermeetstherequirementsofthespecifiedviscositygrade.

• Creatingpotentialforanundesirableadditivecompatibilityinteractionintheenginecrankcase.Generallyitis notdesirabletomixadditivepackagesfromdifferentsuppliersinthecrankcase;therehavebeenreportsof lowtemperatureenginefailurescausedbyadditivepackageincompatibilitywithsuchmixtures.

GEARLUBRICANTS SAEratingsalsoapplytomultigradegearlubricants.Inaddition,APIclassificationdefinesthelubricantsusage. SuchasAPIGL-5andSAE75W-90.

ENGINECOOLANT ETHYLENE-GLYCOLMIXTURES CAUTION:Richerantifreezemixturescannotbemeasuredwithnormalfieldequipmentandcancauseproblemsassociatedwith100percentethylene-glycol.

Therequiredethylene-glycol(antifreeze)andwatermixturedependsupontheclimateandvehicleoperatingconditions.Therecommendedmixtureof50/50ethylene-glycolandwaterwillprovideprotectionagainstfreezingto-37° C(-35°F).Theantifreezeconcentration mustalways beaminimumof44percent,year-roundinallclimates. If percentageislowerthan44percent,enginepartsmaybeerodedbycavitation,andcoolingsystemcomponentsmaybeseverelydamagedbycorrosion. Maximumprotectionagainstfreezingisprovidedwitha68 percentantifreezeconcentration,whichpreventsfreezingdownto-67.7°C(-90°F).Ahigherpercentagewillfreeze atawarmertemperature.Also,ahigherpercentageofantifreezecancausetheenginetooverheatbecausethe specificheatofantifreezeislowerthanthatofwater.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

Useof100percentethylene-glycolwillcauseformationofadditivedepositsinthesystem,asthecorrosioninhibitive additivesinethylene-glycolrequirethepresenceofwatertodissolve.Thedepositsactasinsulation,causingtemperaturestorisetoashighas149°C(300°F).Thistemperatureishotenoughtomeltplasticandsoftensolder. Theincreasedtemperaturecanresultinenginedetonation.Inaddition,100percentethylene-glycolfreezesat22° C(-8°F).

PROPYLENE-GLYCOLMIXTURES It’soveralleffectivetemperaturerangeissmallerthanthatofethylene-glycol.Thefreezepointof50/50propyleneglycolandwateris-32°C(-26°F).5°Chigherthanethylene-glycol’sfreezepoint.Theboilingpoint(protection againstsummerboil-over)ofpropylene-glycolis125°C(257°F)at 96.5kPa(14psi),comparedto128°C(263° F)forethylene-glycol.Useofpropylene-glycolcanresultinboil-overorfreeze-uponacoolingsystemdesignedfor ethylene-glycol.Propyleneglycolalsohaspoorerheattransfercharacteristicsthanethyleneglycol.Thiscan increasecylinderheadtemperaturesundercertainconditions.

Propylene-glycol/ethylene-glycolMixturescancausethedestabilizationofvariouscorrosioninhibitors,causingdamagetothevariouscoolingsystemcomponents.Also,onceethylene-glycolandpropylene-glycolbasedcoolantsare mixedinthevehicle,conventionalmethodsofdeterminingfreezepointwillnotbeaccurate.Boththerefractiveindex andspecificgravitydifferbetweenethyleneglycolandpropyleneglycol.

HOATCOOLANT WARNING:ANTIFREEZEISANETHYLENE-GLYCOLBASECOOLANTANDISHARMFULIFSWALLOWEDOR INHALED.IFSWALLOWED,DRINKTWOGLASSESOFWATERANDINDUCEVOMITING.IFINHALED,MOVE TOFRESHAIRAREA.SEEKMEDICALATTENTIONIMMEDIATELY.DONOTSTOREINOPENORUNMARKED CONTAINERS.WASHSKINANDCLOTHINGTHOROUGHLYAFTERCOMINGINCONTACTWITHETHYLENEGLYCOL.KEEPOUTOFREACHOFCHILDREN.DISPOSEOFGLYCOLBASECOOLANTPROPERLY,CONTACTYOURDEALERORGOVERNMENTAGENCYFORLOCATIONOFCOLLECTIONCENTERINYOUR AREA.DONOTOPENACOOLINGSYSTEMWHENTHEENGINEISATOPERATINGTEMPERATUREORHOT UNDERPRESSURE,PERSONALINJURYCANRESULT.AVOIDRADIATORCOOLINGFANWHENENGINE COMPARTMENTRELATEDSERVICEISPERFORMED,PERSONALINJURYCANRESULT.

CAUTION:UseofPropylene-Glycolbasedcoolantsisnotrecommended,astheyprovidelessfreezeprotectionandlesscorrosionprotection.

Thecoolingsystemisdesignedaroundthecoolant.Thecoolantmustacceptheatfromenginemetal,inthecylinder headareaneartheexhaustvalvesandengineblock.Thencoolantcarriestheheattotheradiatorwherethetube/ finradiatorcantransfertheheattotheair.

Theuseofaluminumcylinderblocks,cylinderheads,andwaterpumpsrequiresspecialcorrosionprotection. Mopar Antifreeze/Coolant,5Year/100,000MileFormula(MS-9769),ortheequivalentethylene-glycolbasecoolant withorganiccorrosioninhibitors(calledHOAT,forHybridOrganicAdditiveTechnology)isrecommended.Thiscoolantoffersthebestenginecoolingwithoutcorrosionwhenmixedwith50%ethylene-glycoland50%distilledwaterto obtainafreezepointof-37°C(-35°F).Ifitlosescolororbecomescontaminated,drain,flush,andreplacewithfresh properlymixedcoolantsolution.

CAUTION:Mopar Antifreeze/Coolant,5Year/100,000MileFormula(MS-9769)maynotbemixedwithany othertypeofantifreeze.Mixingofcoolantsotherthanspecified(non-HOATorotherHOAT),mayresultin enginedamagethatmaynotbecoveredunderthenewvehiclewarranty,anddecreasedcorrosionprotection.

COOLANTPERFORMANCE Therequiredethylene-glycol(antifreeze)andwatermixturedependsuponclimateandvehicleoperatingconditions. Thecoolantperformanceofvariousmixturesfollows:

PureWater- Watercanabsorbmoreheatthanamixtureofwaterandethylene-glycol.Thisisforpurposeofheat transferonly.Wateralsofreezesatahighertemperatureandallowscorrosion.

100percentEthylene-Glycol- Thecorrosioninhibitingadditivesinethylene-glycolneedthepresenceofwaterto dissolve.Withoutwater,additivesformdepositsinsystem.Theseactasinsulationcausingtemperaturetorisetoas

highas149°C(300°F).Thistemperatureishotenoughtomeltplasticandsoftensolder.Theincreasedtemperature canresultinenginedetonation.Inaddition,100percentethylene-glycolfreezesat-22°C(-8°F).

50/50Ethylene-GlycolandWater- Istherecommendedmixture,itprovidesprotectionagainstfreezingto-37°C (-34°F).Theantifreezeconcentration mustalways beaminimumof44percent,year-roundinallclimates.Ifpercentageislower,enginepartsmaybeerodedbycavitation.Maximumprotectionagainstfreezingisprovidedwitha 68percentantifreezeconcentration,whichpreventsfreezingdownto-67.7°C(-90°F).Ahigherpercentagewill freezeatawarmertemperature.Also,ahigherpercentageofantifreezecancausetheenginetooverheatbecause specificheatofantifreezeislowerthanthatofwater.

CAUTION:Richerantifreezemixturescannotbemeasuredwithnormalfieldequipmentandcancauseproblemsassociatedwith100percentethylene-glycol.

COOLANTSELECTIONANDADDITIVES Theuseofaluminumcylinderblocks,cylinderheadsandwaterpumpsrequiresspecialcorrosionprotection.Only Mopar Antifreeze/Coolant,5Year/100,000MileFormula(glycolbasecoolantwithcorrosioninhibitorscalledHOAT, forHybridOrganicAdditiveTechnology)isrecommended.Thiscoolantoffersthebestenginecoolingwithoutcorrosionwhenmixedwith50%distilledwatertoobtaintoobtainafreezepointof-37°C(-35°F).Ifitlosescoloror becomescontaminated,drain,flush,andreplacewithfreshproperlymixedcoolantsolution.

CAUTION:Donotusecoolantadditivesthatareclaimedtoimproveenginecooling.

AXLE NOTE:DaimlerChryslerrecommendsusingMopar lubricantsorlubricantsofequalquality

FRONTAXLE

• 200MM-Mopar SyntheticGearLubricant75W-140

REARAXLE

• 213MM-Mopar SyntheticGearLubricant75W-140

NOTE:Vari-lok equippedaxlesrequire118ml(4ounces)ofLimitedSlipAdditivebeaddedtothelubricant.

TRANSFERCASE RecommendedlubricantfortheNV140transfercaseisMopar ATF+4,AutomaticTransmissionFluid.RecommendedlubricantfortheNV245transfercaseisMopar NV245/247TransferCaseFluid.

AUTOMATICTRANSMISSIONFLUID NOTE:RefertoServiceProceduresinthisgroupforfluidlevelcheckingprocedures.

Mopar ATF+4,AutomaticTransmissionFluidistherecommendedfluidforDaimlerChryslerautomatictransmissions.

DexronIIfluidISNOTrecommended.Clutchchattercanresultfromtheuseofimproperfluid.

Mopar ATF+4,AutomaticTransmissionFluidwhennewisredincolor.TheATFisdyedredsoitcanbeidentified fromotherfluidsusedinthevehiclesuchasengineoilorantifreeze.Theredcolorisnotpermanentandisnotan indicatoroffluidcondition.Asthevehicleisdriven,theATFwillbegintolookdarkerincolorandmayeventually becomebrown. Thisisnormal. ATF+4alsohasauniqueodorthatmaychangewithage.Consequently,odorand colorcannotbeusedtoindicatethefluidconditionortheneedforafluidchange.

FLUIDADDITIVES DaimlerChryslerstronglyrecommendsagainsttheadditionofanyfluidstothetransmission,otherthanthoseautomatictransmissionfluidslistedabove.Exceptionstothispolicyaretheuseofspecialdyestoaidindetectingfluid leaks.

Various“special”additivesandsupplementsexistthatclaimtoimproveshiftfeeland/orquality.Theseadditivesand othersalsoclaimtoimproveconverterclutchoperationandinhibitoverheating,oxidation,varnish,andsludge. TheseclaimshavenotbeensupportedtothesatisfactionofDaimlerChryslerandtheseadditives mustnotbe used. Theuseoftransmission“sealers”shouldalsobeavoided,sincetheymayadverselyaffecttheintegrityof transmissionseals.

POWERSTEERINGFLUID Thissystemrequirestheuseofhydraulicsystem/powersteeringfluidwhichmeetsDaimlerChryslerspecification MS-10838,suchasMoparpartnumber05142893AA,orequivalent,DONOTMIXPOWERSTEERINGFLUID TYPES.Damagemayresulttothepowersteeringpumpandsystemifanyotherfluidisused,andDONOTOVERFILL.

OPERATION-AUTOMATICTRANSMISSIONFLUID Theautomatictransmissionfluidisselectedbaseduponseveralqualities.Thefluidmustprovideahighlevelof protectionfortheinternalcomponentsbyprovidingalubricatingfilmbetweenadjacentmetalcomponents.Thefluid mustalsobethermallystablesothatitcanmaintainaconsistentviscositythroughalargetemperaturerange.Ifthe viscositystaysconstantthroughthetemperaturerangeofoperation,transmissionoperationandshiftfeelwillremain consistent.Transmissionfluidmustalsobeagoodconductorofheat.Thefluidmustabsorbheatfromtheinternal transmissioncomponentsandtransferthatheattothetransmissioncase.

FLUIDCAPACITIES SPECIFICATIONS-FLUIDCAPACITIES EngineOil-withFilter-3.7L4.7L(5.0qts.)

EngineOil-withFilter-4.7L5.6L(6.0qts.)

EngineOil-withFilter-5.7L6.6L(7.0qts.)

CoolingSystem-3.7L10.0L(9qts.)***

CoolingSystem-4.7L13.7L(14.5qts.)*** CoolingSystem-5.7L13.7L(14.5qts.)***

POWERSTEERINGSYSTEM Powersteeringfluidcapacitiesaredependentonengine/chassisoptionsaswellassteeringgear/cooleroptions. Dependingontypeandsizeofinternalcooler,lengthandinsidediameterofcoolerlines,oruseofanauxiliary cooler,thesecapacitiesmayvary.Referto19,Steeringforproperfillandbleedprocedures.

AUTOMATICTRANSMISSION ServiceFill-545RFE

2WD-5.2L(11pts.)

4WD-6.2L(13pts.)

ServiceFill-NAG15.0L(10.6pts.)

O-haulFill-545RFE13.33L(28.0pts.)

O-haulFill-NAG17.7L(16.3pts)

DryfillcapacityDependingontypeandsizeofinternalcooler,lengthandinsidediameterofcoolerlines,oruseof anauxiliarycooler,thesefiguresmayvary.(Refertoappropriate21-TRANSMISSION/AUTOMATIC/FLUIDSTANDARDPROCEDURE).

TRANSFERCASE

NV1400.65L(1.4pts.)

NV2451.8L(3.8pts.)

FRONTAXLE±0.3L(2oz.)

C200F1.7L(57.5oz.)

C200FE1.7L(57.5oz.)

REARAXLE±0.3L(2oz.)

C213R2.07L(70oz.)* C213RE2.24L(75.5oz.)

*Vari-Lok,add0.07L(2.5oz.)ofFrictionModifier. ***Includes0.9L(1.0qts.)forcoolantreservoir.

****Nominalrefillcapacitiesareshown.Avariationmaybeobservedfromvehicletovehicleduetomanufacturing toleranceandrefillprocedure.

FLUIDFILL/CHECKLOCATIONS INSPECTION-FLUIDFILL/CHECKLOCATIONS

Thefluidfill/checklocationsandlubricationpointsarelocatedineachapplicablegroup.

MAINTENANCESCHEDULES DESCRIPTION MAINTENANCESCHEDULES Therearetwomaintenanceschedulesthatshowthe required serviceforyourvehicle. FirstisSchedule B .Itisforvehiclesthatareoperatedundertheconditionsthatarelistedbelowandatthebeginningoftheschedule.

• Dayornighttemperaturesarebelow32°F(0°C)

• Stopandgodriving

• Excessiveengineidling

• Drivingindustyconditions

• Shorttripsoflessthan10miles(16.2km)

• Morethan50%ofyourdrivingisatsustainedhighspeedsduringhotweather,above90°F(32°C)

• Trailertowing

• Taxi,police,ordeliveryservice(commercialservice)

• Off-roadordesertdriving

• IfequippedforandoperatedwithE-85(ethanol)fuel.

NOTE:MostvehiclesareoperatedundertheconditionslistedforSchedule“B.”

NOTE:IfANYoftheseapplytoyou,changeyourengineoilevery3,000miles(5000km)or3months, whichevercomesfirst,andfollowthemaintenancerecommendationsin“MaintenanceScheduleB.”

NOTE:IfANYoftheseapplytoyouthenflushandreplaceyourenginecoolantevery102,000miles(163000 km)or60months,whichevercomesfirst,andfollow“ScheduleB”ofthe“MaintenanceSchedules”section ofthismanual.

SecondisSchedule “A”.ItisforvehiclesthatarenotoperatedunderanyoftheconditionslistedunderSchedule “B.”

Usetheschedulethatbestdescribesyourdrivingconditions.Wheretimeandmileagearelisted,followtheinterval thatoccursfirst.

CAUTION:Failuretoperformtherequiredmaintenanceitemsmayresultindamagetothevehicle.

AtEachStopforFuel

• Checktheengineoillevelabout5minutesafterafullywarmedengineisshutoff.Checkingtheoillevelwhile thevehicleisonlevelgroundwillimprovetheaccuracyoftheoillevelreading.Addoilonlywhenthelevelis atorbelowtheADDorMINmark.

• Checkthewindshieldwashersolvent,addasrequired.

OnceaMonth

• Checkthetirepressureandlookforunusualwearordamage.

• Inspectthebatteryandcleanandtightentheterminalsasrequired.

• Checkthefluidlevelsofthecoolantreservoir,brakemastercylinder,andtransmission,andaddasneeded.

• Checkalllightsandallotherelectricalitemsforcorrectoperation.

AtEachOilChange

• Changetheengineoilfilter.

• Inspecttheexhaustsystem.

• Inspectbrakehoses.

• Checktheenginecoolant/anti-freezelevel,hoses,andclamps.

• Aftercompletionofoff-roadoperation,theundersideofthevehicleshouldbethoroughlyinspected.Examine threadedfastenersforlooseness.

Schedule“B” Followthisscheduleifyouusuallyoperateyourvehicleunderoneormoreofthefollowingconditions.

• Dayornighttemperaturesarebelow32°F(0°C)

• Stopandgodriving

• Excessiveengineidling

• Drivingindustyconditions

• Shorttripsoflessthan10miles(16.2km)

• Morethan50%ofyourdrivingisatsustainedhighspeedsduringhotweather,above90°F(32°C)

• Trailertowing

• Taxi,police,ordeliveryservice(commercialservice)

• Off-roadordesertdriving

• IfequippedforandoperatedwithE-85(ethanol)fuel.

NOTE:IfANYoftheseapplytoyou,changeyourengineoilevery3,000miles(5000km)or3months, whichevercomesfirst,andfollowthemaintenancerecommendationsin“MaintenanceScheduleB.”

NOTE:IfANYoftheseapplytoyouthenflushandreplaceyourenginecoolantevery102,000miles(163000 km)or60months,whichevercomesfirst,andfollow“ScheduleB”ofthe“MaintenanceSchedules”section ofthismanual.

Miles3,0006,0009,00012,00015,000 (Kilometers)(5000)(10000)(14000)(19000)(24000) Changetheengineoilandengineoilfilter,ifnot replacedat3months.

Rotatethetires.XX

Inspecttheengineaircleanerfilter,replaceif necessary. X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Drainandrefillthefrontandrearaxles.X Inspectthebrakelinings. X Cleanandlubricatethebrakecaliperpins.X

Miles18,00021,00024,00027,00030,000 (Kilometers)(29000)(34000)(38000)(43000)(48000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XXX

Inspecttheengineaircleanerfilter,replaceif necessary. X

InspectthePCVValve,replaceifnecessary. X

Replacethesparkplugs. X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XXX

Drainandrefillthefrontandrearaxles.X

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainthetransfercaseandrefill. X

Miles33,00036,00039,00042,00045,000 (Kilometers)(53000)(58000)(62000)(67000)(72000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XX

Inspecttheengineaircleanerfilter,replaceif necessary. X

Drainandrefillthefrontandrearaxles.X

Inspectthebrakelinings.X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Cleanandlubricatethebrakecaliperpins.X

Miles48,00051,00054,00057,00060,000 (Kilometers)(77000)(82000)(86000)(91000)(96000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XXX

Inspecttheengineaircleanerfilter,replaceif necessary. X

InspectthePCVValve,replaceifnecessary. X

Replacethesparkplugs. X

Inspecttheignitioncables,replaceifnecessary (5.7LOnly). X

Inspectdrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XXX

Cleanandlubricatebrakecaliperpins.XX

Inspectthebrakelinings.XX

Drainandrefillthefrontandrearaxles.XX

Drainandrefilltheautomatictransmissionfluid,and replacemainsumpfilter(4.7L/5.7LOnly).‡ X

Miles48,00051,00054,00057,00060,000 (Kilometers)(77000)(82000)(86000)(91000)(96000)

Drainandrefillthetransfercasefluid. X

Flushandreplaceenginecoolant/anti-freezeat60 months,ifnotdoneat102,000miles(163000km). X

NOTE:‡Appliesonlyifvehicleisusedforfrequenttrailertowing,orfleet/commercialservice.

Miles63,00066,00069,00072,00075,000 (Kilometers)(101 000) (106000)(110

Changetheengineoilandengineoilfilter,ifnot replacedat3months.

Inspecttheengineaircleanerfilter,replaceif necessary. X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Inspectthebrakelinings. X

Cleanandlubricatethebrakecaliperpins.X

Drainandrefillthefrontandrearaxlefluid.X

Miles78,00081,00084,00087,00090,000 (Kilometers)(125 000) (130000)(134 000) (139 000) (144 000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months.

Inspecttheengineaircleanerfilter,replaceif necessary. X

InspectthePCVValve,replaceifnecessary. X

Replacethesparkplugs. X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints.

Drainandrefillthetransfercasefluid. X

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainandrefillthefrontandrearaxlefluid.X

Miles93,00096,00099,000102,000105,000 (Kilometers)(149000)(154000)(158000)(163000)(168000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months.

Rotatethetires.XX

Inspecttheengineaircleanerfilter,replaceif necessary. X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering &suspensionballjoints. XX

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainandrefillthefrontandrearaxlefluid.X

Flushandreplacetheenginecoolant/anti-freeze, ifnotdoneat60months. X

Miles108,000111,000114,000117,000120,000 (Kilometers)(173000)(178000)(182000)(187000)(192000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XXX

Inspecttheengineaircleanerfilter,replaceif necessary. X

InspectthePCVValve,replaceif necessary. X

Replacethesparkplugs. X

Inspecttheignitioncables,replaceif necessary(5.7LOnly). X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering &suspensionballjoints. XXX

Inspectthebrakelinings.XX

Cleanandlubricatethebrakecaliperpins.XX

Drainandrefillthefrontandrearaxlefluid.XX

Drainandrefilltheautomatictransmissionfluid, replacemainsumpfilter,andspin-oncooler returnfilter(ifequipped).(4.7L/5.7LOnly).‡

Drainandrefillthetransfercasefluid.X

Flushandreplacetheenginecoolant/anti-freeze at120months,ifnotreplacedat102,000miles (163000km).

NOTE:‡Appliesonlyifvehicleisusedforfrequenttrailertowing,orfleet/commercialservice.

Inspectionandserviceshouldalsobeperformedanytimeamalfunctionisobservedorsuspected.Retainall receipts.

Thismaintenanceisrecommendedbythemanufacturertotheowner,butisnotrequiredtomaintainemissions warranty.

Schedule“A” Miles6,00012,00018,00024,00030,000 (Kilometers)(10000)(19000)(29000)(38000)(48000) [Months][6][12][18][24][30]

Changetheengineoilandengineoilfilter.XXXXX

Rotatethetires.XXXXX

Inspecttheengineaircleanerfilter,andreplaceif necessary. X

Replacethesparkplugs. X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainthetransfercaseandrefill. X

Miles36,00042,00048,00054,000 (Kilometers)(58000)(67000)(77000)(86000) [Months][36][42][48][54]

Changetheengineoilandengineoilfilter.XXXX

Rotatethetires.XXXX

Inspectthebrakelinings.XX

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Cleanandlubricatethebrakecaliperpins.XX

Miles60,00066,00072,00078,000 (Kilometers)(96000)(106000)(115000)(125000) [Months][60][66][72][78]

Changetheengineoilandengineoilfilter.XXXX

Rotatethetires.XXXX

Inspecttheengineaircleanerfilter,andreplaceif necessary. X

InspectthePCVValve,replaceifnecessary. X

Replacethesparkplugs. X

Inspecttheignitioncables,replaceifnecessary(5.7L Only). X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Flushandreplacetheenginecoolant/anti-freeze,at60 monthsifnotdoneat102,000miles(163000km). X

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainthetransfercaseandrefill.X

Miles84,00090,00096,000102,000 (Kilometers)(134000)(144000)(154000)(163000)

[Months][84][90][96][102]

Changetheengineoilandengineoilfilter.XXXX Rotatethetires.XXXX

Inspecttheengineaircleanerfilter,andreplaceif necessary. X

InspectthePCVValve,replaceifnecessary. X

Replacethesparkplugs. X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints.

Cleanandlubricatethebrakecaliperpins.X

Inspectthebrakelinings.X

Flushandreplacetheenginecoolant/anti-freezeifnot replacedat60months. X

Drainthetransfercaseandrefill.X

Miles108,000114,000120,000 (Kilometers)(173000)(182000)(192000) [Months][108][114][120]

Changetheengineoilandengineoilfilter.XXX Rotatethetires.XXX

Inspecttheengineaircleanerfilter,andreplaceifnecessary. X

InspectthePCVValve,replaceifnecessary. X

Replacethesparkplugs. X

Inspecttheignitioncables,replaceifnecessary(5.7LOnly). X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering&suspensionball joints.

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Flushandreplacetheenginecoolant/anti-freezeifnotdoneat 102,000miles(163000km). X

Drainthetransfercaseandrefill. X

Inspectionandserviceshouldalsobeperformedanytimeamalfunctionisobservedorsuspected.Retainall receipts.

Thismaintenanceisrecommendedbythemanufacturertotheowner,butisnotrequiredtomaintainemissions warranty.

WARNING:Youcanbebadlyinjuredworkingonoraroundamotorvehicle.Doonlythatserviceworkfor whichyouhavetheproperequipment.Ifyouhaveanydoubtaboutyourabilitytoperformaservicejob, takeyourvehicletoacompetentmechanic.

MAINTENANCESCHEDULES-GASOLINEENGINES-EXPORT Therearetwomaintenanceschedulesthatshowthe required serviceforyourvehicle.

FirstisSchedule B .Itisforvehiclesthatareoperatedundertheconditionsthatarelistedbelowandatthebeginningoftheschedule.

• Dayornighttemperaturesarebelow32°F(0°C)

• Stopandgodriving

• Excessiveengineidling

• Drivingindustyconditions

• Shorttripsoflessthan10miles(16.2km)

• Morethan50%ofyourdrivingisatsustainedhighspeedsduringhotweather,above90°F(32°C)

• Trailertowing

• Taxi,police,ordeliveryservice(commercialservice)

• Off-roadordesertdriving

• IfequippedforandoperatedwithE-85(ethanol)fuel.

NOTE:MostvehiclesareoperatedundertheconditionslistedforSchedule“B.”

NOTE:IfANYoftheseapplytoyou,changeyourengineoilevery3,000miles(5000km)or3months, whichevercomesfirst,andfollowthemaintenancerecommendationsin“MaintenanceScheduleB.”

NOTE:IfANYoftheseapplytoyouthenflushandreplaceyourenginecoolantevery102,000miles(163000 km)or60months,whichevercomesfirst,andfollow“ScheduleB”ofthe“MaintenanceSchedules”section ofthismanual.

SecondisSchedule “A”.ItisforvehiclesthatarenotoperatedunderanyoftheconditionslistedunderSchedule “B.”

Usetheschedulethatbestdescribesyourdrivingconditions.Wheretimeandmileagearelisted,followtheinterval thatoccursfirst.

CAUTION:Failuretoperformtherequiredmaintenanceitemsmayresultindamagetothevehicle.

AtEachStopforFuel

• Checktheengineoillevelabout5minutesafterafullywarmedengineisshutoff.Checkingtheoillevelwhile thevehicleisonlevelgroundwillimprovetheaccuracyoftheoillevelreading.Addoilonlywhenthelevelis atorbelowtheADDorMINmark.

• Checkthewindshieldwashersolvent,addasrequired.

OnceaMonth

• Checkthetirepressureandlookforunusualwearordamage.

• Inspectthebatteryandcleanandtightentheterminalsasrequired.

• Checkthefluidlevelsofthecoolantreservoir,brakemastercylinder,andtransmission,andaddasneeded.

• Checkalllightsandallotherelectricalitemsforcorrectoperation.

AtEachOilChange

• Changetheengineoilfilter.

• Inspecttheexhaustsystem.

• Inspectbrakehoses.

• Checktheenginecoolant/anti-freezelevel,hoses,andclamps.

• Aftercompletionofoff-roadoperation,theundersideofthevehicleshouldbethoroughlyinspected.Examine threadedfastenersforlooseness.

Schedule“B”

Followthisscheduleifyouusuallyoperateyourvehicleunderoneormoreofthefollowingconditions.

• Dayornighttemperaturesarebelow32°F(0°C)

• Stopandgodriving

• Excessiveengineidling

• Drivingindustyconditions

• Shorttripsoflessthan10miles(16.2km)

• Morethan50%ofyourdrivingisatsustainedhighspeedsduringhotweather,above90°F(32°C)

• Trailertowing

• Taxi,police,ordeliveryservice(commercialservice)

• Off-roadordesertdriving

• IfequippedforandoperatedwithE-85(ethanol)fuel.

NOTE:IfANYoftheseapplytoyou,changeyourengineoilevery3,000miles(5000km)or3months, whichevercomesfirst,andfollowthemaintenancerecommendationsin“MaintenanceScheduleB.”

NOTE:IfANYoftheseapplytoyouthenflushandreplaceyourenginecoolantevery102,000miles(163000 km)or60months,whichevercomesfirst,andfollow“ScheduleB”ofthe“MaintenanceSchedules”section ofthismanual.

Miles3,0006,0009,00012,00015,000 (Kilometers)(5000)(10000)(14000)(19000)(24000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XX

Inspecttheengineaircleanerfilter,replaceif necessary. X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints.

Miles18,00021,00024,00027,00030,000 (Kilometers)(29000)(34000)(38000)(43000)(48000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XXX

Inspecttheengineaircleanerfilter,replaceif necessary. X

InspectthePCVValve,replaceifnecessary. X Replacethesparkplugs. X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints.

Drainandrefillthefrontandrearaxles.X

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainthetransfercaseandrefill. X

Miles33,00036,00039,00042,00045,000 (Kilometers)(53000)(58000)(62000)(67000)(72000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XX

Inspecttheengineaircleanerfilter,replaceif necessary. X

Drainandrefillthefrontandrearaxles.X

Inspectthebrakelinings.X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Cleanandlubricatethebrakecaliperpins.X

Miles48,00051,00054,00057,00060,000 (Kilometers)(77000)(82000)(86000)(91000)(96000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XXX

Inspecttheengineaircleanerfilter,replaceif necessary. X

InspectthePCVValve,replaceifnecessary. X

Replacethesparkplugs. X

Inspecttheignitioncables,replaceifnecessary (5.7LOnly). X

Inspectdrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XXX

Cleanandlubricatebrakecaliperpins.XX

Inspectthebrakelinings.XX

Drainandrefillthefrontandrearaxles.XX

Drainandrefilltheautomatictransmissionfluid,and replacemainsumpfilter(4.7L/5.7LOnly).‡ X

Drainandrefillthetransfercasefluid. X

Flushandreplaceenginecoolant/anti-freezeat60 months,ifnotdoneat102,000miles(163000km).

NOTE:‡Appliesonlyifvehicleisusedforfrequenttrailertowing,orfleet/commercialservice.

Miles63,00066,00069,00072,00075,000 (Kilometers)(101000)(106000)(110000)(115000)(120000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XX

Inspecttheengineaircleanerfilter,replaceif necessary. X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering &suspensionballjoints. XX

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainandrefillthefrontandrearaxlefluid.X

Miles78,00081,00084,00087,00090,000 (Kilometers)(125000)(130000)(134000)(139000)(144000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XXX

Inspecttheengineaircleanerfilter,replaceif necessary. X

InspectthePCVValve,replaceif necessary. X

Replacethesparkplugs. X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering &suspensionballjoints. XXX

Drainandrefillthetransfercasefluid.X

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainandrefillthefrontandrearaxlefluid.X

Miles93,00096,00099,000102,000105,000 (Kilometers)(149000)(154000)(158000)(163000)(168000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XX

Inspecttheengineaircleanerfilter,replaceif necessary. X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering &suspensionballjoints. XX

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainandrefillthefrontandrearaxlefluid.X

Flushandreplacetheenginecoolant/anti-freeze, ifnotdoneat60months. X

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

Miles108,000111,000114,000117,000120,000 (Kilometers)(173000)(178000)(182000)(187000)(192000)

Changetheengineoilandengineoilfilter,ifnot replacedat3months. XXXXX

Rotatethetires.XXX

Inspecttheengineaircleanerfilter,replaceif necessary. X

InspectthePCVValve,replaceif necessary. X

Replacethesparkplugs. X

Inspecttheignitioncables,replaceif necessary(5.7LOnly). X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering &suspensionballjoints. XXX

Inspectthebrakelinings.XX

Cleanandlubricatethebrakecaliperpins.XX

Drainandrefillthefrontandrearaxlefluid.XX

Drainandrefilltheautomatictransmissionfluid, replacemainsumpfilter,andspin-oncooler returnfilter(ifequipped).(4.7L/5.7LOnly).‡ X

Drainandrefillthetransfercasefluid.X

Flushandreplacetheenginecoolant/anti-freeze at120months,ifnotreplacedat102,000miles (163000km). X

NOTE:‡Appliesonlyifvehicleisusedforfrequenttrailertowing,orfleet/commercialservice.

Inspectionandserviceshouldalsobeperformedanytimeamalfunctionisobservedorsuspected.Retainall receipts.

Thismaintenanceisrecommendedbythemanufacturertotheowner,butisnotrequiredtomaintainemissions warranty.

Schedule“A

Miles6,00012,00018,00024,00030,000 (Kilometers)(10000)(19000)(29000)(38000)(48000) [Months][6][12][18][24][30]

Changetheengineoilandengineoilfilter.XXXXX

Rotatethetires.XXXXX

Inspecttheengineaircleanerfilter,andreplaceif necessary. X

Replacethesparkplugs. X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainthetransfercaseandrefill. X

Miles36,00042,00048,00054,000 (Kilometers)(58000)(67000)(77000)(86000)

[Months][36][42][48][54]

Changetheengineoilandengineoilfilter.XXXX

Rotatethetires.XXXX

Inspectthebrakelinings.XX

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Cleanandlubricatethebrakecaliperpins.XX

Miles60,00066,00072,00078,000 (Kilometers)(96000)(106000)(115000)(125000)

[Months][60][66][72][78]

Changetheengineoilandengineoilfilter.XXXX

Rotatethetires.XXXX

Inspecttheengineaircleanerfilter,andreplaceif necessary. X

InspectthePCVValve,replaceifnecessary. X

Replacethesparkplugs. X

Inspecttheignitioncables,replaceifnecessary(5.7L Only). X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Flushandreplacetheenginecoolant/anti-freeze,at60 monthsifnotdoneat102,000miles(163000km). X

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Drainthetransfercaseandrefill.X

Miles84,00090,00096,000102,000 (Kilometers)(134000)(144000)(154000)(163000)

[Months][84][90][96][102]

Changetheengineoilandengineoilfilter.XXXX

Rotatethetires.XXXX

Inspecttheengineaircleanerfilter,andreplaceif necessary. X

InspectthePCVValve,replaceifnecessary. X Replacethesparkplugs. X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering& suspensionballjoints. XX

Cleanandlubricatethebrakecaliperpins.X

Inspectthebrakelinings.X

Flushandreplacetheenginecoolant/anti-freezeifnot replacedat60months. X

Drainthetransfercaseandrefill.X

Miles108,000114,000120,000 (Kilometers)(173000)(182000)(192000)

[Months][108][114][120]

Changetheengineoilandengineoilfilter.XXX

Rotatethetires.XXX

Inspecttheengineaircleanerfilter,andreplaceifnecessary. X

InspectthePCVValve,replaceifnecessary. X

Replacethesparkplugs. X

Inspecttheignitioncables,replaceifnecessary(5.7LOnly). X

Inspectthedrivebelt,replaceifnecessary.X

Lubricatetheupperknuckleballstudatsteering&suspensionball joints. XX

Inspectthebrakelinings.X

Cleanandlubricatethebrakecaliperpins.X

Flushandreplacetheenginecoolant/anti-freezeifnotdoneat 102,000miles(163000km). X

Drainthetransfercaseandrefill. X

Inspectionandserviceshouldalsobeperformedanytimeamalfunctionisobservedorsuspected.Retainall receipts.

Thismaintenanceisrecommendedbythemanufacturertotheowner,butisnotrequiredtomaintainemissions warranty.

WARNING:Youcanbebadlyinjuredworkingonoraroundamotorvehicle.Doonlythatserviceworkfor whichyouhavetheknowledgeandtherightequipment.Ifyouhaveanydoubtaboutyourabilitytoperform aservicejob,takeyourvehicletoacompetentmechanic.

SUSPENSION WHEELALIGNMENT DESCRIPTION

NOTE:Suspensioncomponentswithrubber/urethanebushingsshouldbetightenedwiththevehicleatnormalrideheight.Itisimportanttohave thespringssupportingtheweightofthevehicle whenthefastenersaretorqued.Ifspringsarenot attheirnormalrideposition,vehicleridecomfort couldbeaffectedandprematurebushingwear mayoccur.

Wheelalignmentinvolvesthecorrectpositioningofthe wheelsinrelationtothevehicle.Thepositioningis accomplishedthroughsuspensionandsteeringlinkageadjustments.Analignmentisconsideredessential forefficientsteering,gooddirectionalstabilityandto minimizetirewear.Themostimportantmeasurements ofanalignmentarecaster,camberandtoe.

CAUTION:Neverattempttomodifysuspensionorsteeringcomponentsbyheatingorbending.

OPERATION • CASTER(1) istheforwardorrearwardtiltofthe steeringknucklefromvertical.Tiltingthetopof theknuckleforwardprovideslesspositivecaster. Tiltingthetopoftheknucklerearwardprovides morepositivecaster.Positivecasterpromotes directionalstability.Thisangleenablesthefront wheelstoreturntoastraightaheadpositionafter turns.

• CAMBER(2) istheinwardoroutwardtiltofthe wheelrelativetothecenterofthevehicle.Tilting thetopofthewheelinwardprovidesnegative camber.Tiltingthetopofthewheeloutwardprovidespositivecamber.Incorrectcamberwill causewearontheinsideoroutsideedgeofthe tire.

• TOE(4) isthedifferencebetweentheleading insideedgesandtrailinginsideedgesofthefronttires.Wheeltoepositionoutofspecificationcause’sunstable steering,uneventirewearandsteeringwheeloff-center.Thewheeltoepositionisthe final frontwheelalignmentadjustment.

• THRUSTANGLE(3) istheangleoftherearaxlerelativetothecenterlineofthevehicle.Incorrectthrustangle cancauseoff-centersteeringandexcessivetirewear.Thisangleisnotadjustable,damagedcomponent(s) mustbereplacedtocorrectthethrustangle.

DIAGNOSISANDTESTING PRE-ALIGNMENTINSPECTION Beforestartingwheelalignment,thefollowinginspectionandnecessarycorrectionsmustbecompleted.Referto SuspensionandSteeringSystemDiagnosisChartbelowforadditionalinformation.

1.Inspecttiresforsize,airpressureandtreadwear.

2.Inspectfrontwheelbearingsforwear.

3.Inspectfrontwheelsforexcessiveradialorlateralrunoutandbalance.

4.Inspectballstuds,linkagepivotpointsandsteeringgearforlooseness,roughnessorbinding.

5.Inspectsuspensioncomponentsforwearandnoise.

6.Checksuspensionrideheight.

7.Roadtestthevehicle.

SUSPENSIONANDSTEERINGSYSTEMDIAGNOSIS

CONDITIONPOSSIBLECAUSESCORRECTION

FRONTENDNOISE1.Looseorwornwheelbearing.1.Replacewheelbearing.

2.Looseorwornsteeringor suspensioncomponents.

3.Looseorwornsteeringor suspensioncomponents.

EXCESSIVEPLAYIN STEERING

2.Tightenorreplacecomponentsas necessary.

3.Tightenorreplacecomponentsas necessary.

1.Looseorwornwheelbearing.1.Replacewheelbearing.

2.Looseorwornsteeringor suspensioncomponents.

2.Tightenorreplacecomponentsas necessary.

3.Looseorwornsteeringgear.3.Replacesteeringgear.

FRONTWHEELSSHIMMY1.Looseorwornwheelbearing.1.Replacewheelbearing.

2.Looseorwornsteeringor suspensioncomponents.

2.Tightenorreplacecomponentsas necessary.

3.Tireswornoroutofbalance.3.Replaceorbalancetires.

4.Alignment.4.Alignvehicletospecifications.

VEHICLEINSTABILITY1.Looseorwornwheelbearing.1.Replacewheelbearing.

2.Looseorwornsteeringor suspensioncomponents.

2.Tightenorreplacecomponentsas necessary.

3.Tirepressure.3.Adjusttirepressure.

4.Alignment.4.Alignvehicletospecifications.

EXCESSIVESTEERING EFFORT

VEHICLEPULLSTOONE SIDE

1.Looseorwornsteeringgear.1.Replacesteeringgear.

2.Columncouplerbinding.2.Replacecoupler.

3.Tirepressure.3.Adjusttirepressure.

4.Alignment.4.Alignvehicletospecifications.

1.Tirepressure.1.Adjusttirepressure.

2.Tire.2.Criss-CrossFrontTires.

3.Alignment.3.Alignvehicletospecifications.

4.Looseorwornsteeringor suspensioncomponents. 4.Tightenorreplacecomponentsas necessary.

5.Radialtirelead.5.Rotateorreplacetireasnecessary.

6.Brakepull.6.Repairbrakeasnecessary.

8.Rideheight.8.Measureandadjustrideheight.

STANDARDPROCEDURE CAMBER,CASTERANDTOEADJUSTMENT NOTE:SUSPENSIONHEIGHTMEASUREMENTMUSTBEPERFORMEDBEFOREANALIGNMENT.

Camberandcasterangleadjustmentsinvolvechangingthepositionofthelowercontrolarmwiththeslotsinthe framebracketstomovethelowercontrolarminwardsoroutwardsforproperadjustment. Thiscanbeachievedby usingalongprybarwithacurvedtipandinsertingtheprybarintothelowercontrolarmframebrackets andpryinginwardsoroutwards.

NOTE:CamberandcasteradjustmentsmustbemadeatthelowercontrolarmDonotusetheuppercontrol armforCamberandCasteradjustments.

NOTE:Whenthelowercontrolarmpivotboltsareloosenedthelowercontrolarmwillnormallygooutwards automaticallywiththeweightofthevehicle.

CASTER Movingtherearpositionofthelowercontrolarmattheframeinorout,willchangethecasteranglesignificantly andcamberangleonlyslightly.Tomaintainthecamberanglewhileadjustingcaster,movetherearofthelower controlarminorout.Thenmovethefrontofthelowercontrolarmslightlyintheoppositedirection.

CAMBER Moveboththefrontandrearofthelowercontrolarmtogetherinorout.Thiswillchangethecamberanglesignificantlyandcasterangleslightly.

Afteradjustmentismadetightenthelowercontrolarmbolt&nutsto FRONT169N·m(125ft.lbs.)andthe REAR 88N·m(65ft.lbs.).

TOEADJUSTMENT Thewheeltoepositionadjustmentisthefinaladjustment.

1.Starttheengineandturnwheelsbothwaysbefore straighteningthewheels.Securethesteering wheelwiththefrontwheelsinthestraight-ahead position.

2.Loosenthetierodjamnuts(3).

NOTE:Eachfrontwheelshouldbeadjustedfor one-halfofthetotaltoepositionspecification. Thiswillensurethesteeringwheelwillbecenteredwhenthewheelsarepositionedstraightahead.

3.Adjustthewheeltoepositionbyturningtheinner tierod(4)asnecessary.

4.Tightenthetierodjamnut(3)to75N·m(55ft.lbs.).

5.Verifythespecifications.

6.Turnoffengine.

TOEADJUSTMENT SUSPENSIONHEIGHTMESUREMENTMUSTBE PERFORMEDBEFOREANALIGNMENT.

Thewheeltoepositionadjustmentisthefinaladjustment.

1.Starttheengineandturnwheelsbothwaysbefore straighteningthewheels.Securethesteering wheelwiththefrontwheelsinthestraight-ahead position.

2.Loosenthetierodjamnuts(3).

NOTE:Eachfrontwheelshouldbeadjustedfor one-halfofthetotaltoepositionspecification. Thiswillensurethesteeringwheelwillbecenteredwhenthewheelsarepositionedstraightahead.

3.Adjustthewheeltoepositionbyturningtheinnertierod(4)asnecessary. 4.Tightenthetierodjamnut(3)to75N·m(55ft.lbs.).

5.Verifythespecifications.

6.Turnoffengine.

SPECIFICATIONS

ALIGNMENT

NOTE:Specificationsareindegrees.

FRONT SPECIFICATIONS

REARAXLE

SPECIFICATIONS

FRONT DESCRIPTION NOTE:Suspensioncomponentswithrubber/urethanebushingsshouldbetightenedwiththevehicleatnormalrideheight.Itisimportanttohavethespringssupportingtheweightofthevehiclewhenthefasteners aretorqued.Ifspringsarenotattheirnormalrideposition,vehicleridecomfortcouldbeaffectedandprematurebushingwearmayoccur.

Thefrontsuspensionisdesignedtoalloweachwheeltoadapttodifferentroadsurfacesindependently.Thewheels aremountedtohubbearingsonthesteeringknucklespindles.Thedouble-rowhubbearingsaresealedandlubricatedforlife.Thesteeringknucklesturn(pivot)onballjointsintegraltotheoutboardportionoftheuppercontrol armsandpressedintothelowersteeringknuckle.Theballjointsarelubricatedforlife.

SPECIFICATIONS TORQUECHART

TORQUESPECIFICATIONS

DESCRIPTIONN·mFt.Lbs.In.Lbs. ShockAbsorberUpperNuts9570— ShockAbsorberClevisBracket8160— ClevisBrackettoLowerControlArm169125— UpperControlArmBolt/NuttoBody12290— LowerControlArmBolt142105— LowerControlArmBolt/Nut FrontPivot 169125— UpperBallJointNut7555— LowerBallJointNut9570— StabilizerBarRetainerBolts142105— StabilizerBarLinkUpperNut135100— StabilizerBarLinkLowerBolt11585— HubBearingKnuckleBolts136100—

SPECIALTOOLS FRONTSUSPENSION CLEVISBUSHING-9653

PULLER-8677

BALLJOINT-9654

BALLJOINT-C-4212-3

BUSHINGS DESCRIPTION Suspensioncomponentswithrubber/urethanebushingsshouldbetightenedwiththevehicleatnormalrideheight. Itisimportanttohavethespringssupportingtheweightofthevehiclewhenthefastenersaretorqued.Ifspringsare notattheirnormalrideposition,vehicleridecomfortcouldbeaffectedandprematurebushingwearmayoccur.

REMOVAL STABILIZERBARTOFRAMEBUSHING 1.Raiseandsupportthevehicle.

2.Removethefrontsplashshield.

3.Removethetwostabilizerbarretainerbracketbolts (2).

4.Removethebushingclamp(2).

5.Removethestabilizerbarbushing(3).

CLEVISBRACKETBUSHING 1.Removetheclevisbracket(3)fromtheshock(1) (Referto2-SUSPENSION/FRONT/CLEVIS BRACKET-REMOVAL).

NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsure properoperationduringtheremovalandinstallationprocess.

2.PressthebushingoutusingspecialtoolsC-4212-F (Press)(1),9653–1(driver)(4)and9653–2 (Receiver)(2)fromthelowercontrolarm(3).

INSTALLATION STABILIZERBARTOFRAMEBUSHING 1.Installthestabilizerbarbushing(3)tothebar(1).

2.Installthestabilizerbarbushingreatainerbracket (2)boltsandtightenthetwomountingbolts.

3.Installthefrontsplashshield.

4.Lowerthevehicle.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

CLEVISBRACKETBUSHING NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsure properoperationduringtheremovalandinstallationprocess.

1.Installthenewclevisbracketbushing(3)intothe lowercontrolarm(5)usingtoolsC-4212-F(Press) (1),9653–3(driver)(2),9653–4(Depthgauge)(4) thedepthgaugewillautomaticallysetthedepthof thebushing(3)inthecontrolarm(5).

2.Installtheclevisbracket(3)totheshock(1)(Refer to2-SUSPENSION/FRONT/CLEVISBRACKETINSTALLATION).

HUB/BEARING DESCRIPTION Thebearingusedonthefronthubofthisvehicleisthecombinedhubandbearingunittypeassembly.Thisunit assemblycombinesthefrontwheelmountinghub(flange)andthefrontwheelbearingintoaonepieceunit.The wheelmountingstudsaretheonlyreplaceablecomponentofthehub/bearingassembly.

OPERATION Thehub/bearingassemblyismountedtothesteeringknuckleandisretainedbythreemountingboltsaccessible fromthebackofthesteeringknuckle.Thehub/bearingunitisnotserviceableandmustbereplacedasanassembly ifthebearingorthehubisdeterminedtobedefective.

REMOVAL 1.Raiseandsupportthevehicle.

2.Removethewheelandtireassembly. Supportthecaliper,Donotletthecaliperhangby thehose.

3.Removethediscbrakecaliper(1)(Referto5BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKECALIPERS-REMOVAL).

4.Removethebrakecaliperadaptor(1)(Referto5BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKECALIPERADAPTER-REMOVAL).

5.Removeanddiscardtheo-ring(2)andthen removethediscbrakerotor(1)(Referto5BRAKES/HYDRAULIC/MECHANICAL/ROTORSREMOVAL).

6.Removethewheelspeedsensornut(2).

7.Removethewheelspeedsensor(Referto5BRAKES/ELECTRICAL/FRONTWHEELSPEED SENSOR-REMOVAL).

8.Removethe3hubbearingmountingboltsfromthe backofthesteeringknuckle.Removehubbearing (3)fromthesteeringknuckle.

INSTALLATION 1.Installthehubbearing(3)totheknuckle.

2.Installthehubbearingtoknuckleandthe3bolts thentightento136N·m(100ft.lbs.).

3.Installthewheelspeedsensor(Referto5BRAKES/ELECTRICAL/FRONTWHEELSPEED SENSOR-INSTALLATION).

4.Installthewheelspeedsensornut(2).

5.Installthebrakerotor(1)(Referto5-BRAKES/ HYDRAULIC/MECHANICAL/ROTORSINSTALLATION).

6.Installthebrakecaliperadaptor(1)(Referto5BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKECALIPERADAPTER-INSTALLATION).

7.Installthecaliper(1)(Referto5-BRAKES/HYDRAULIC/MECHANICAL/DISCBRAKECALIPERS -INSTALLATION).

8.Installthewheelandtireassembly(Referto22-TIRES/WHEELS-STANDARDPROCEDURE).

9.Removethesupportandlowerthevehicle.

KNUCKLE DESCRIPTION Theknuckleisasinglecastingwithlegsmachinedfortheupperandlowerballjoints.Theknucklealsohas machinedmountinglocationsforthefrontbrakecalipersandhubbearing.

OPERATION Thesteeringknucklepivotbetweentheupperandlowerballjoint.Steeringlinkageattachedtotheknuckleallows thevehicletobesteered.

REMOVAL 1.Raiseandsupportthevehicle.

2.Removethetireandwheelassembly.

CAUTION:Neverallowthediscbrakecaliperto hangfromthebrakehose.Damagetothebrake hosewillresult.Provideasuitablesupportto hangthecalipersecurely.

3.Removethebrakecaliper(1).

4.Removethecaliperadapter(1).(Referto5BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKECALIPERADAPTER-REMOVAL).

5.Removetheo-ring(2)anddiscardthenremove discbrakerotor(1).(Referto5-BRAKES/HYDRAULIC/MECHANICAL/ROTORS-REMOVAL).

6.Removethewheelspeedsensor(2).(Referto5BRAKES/ELECTRICAL/FRONTWHEELSPEED SENSOR-REMOVAL).

7.Removetheaxleshaftnut.(ifequippedwithfour wheeldrive)

8.Removethehub/bearing(3).(Referto2-SUSPENSION/FRONT/HUB/BEARING-REMOVAL).

9.Removetheoutertierodendretainingnut.

10.Seperatetheoutertierodend(3)fromthesteeringknuckleusingspecialtool8677(5).(Referto 19-STEERING/LINKAGE/TIERODENDREMOVAL).

11.Removethelowerballjointnut.

12.Seperatethelowerballjointfromtheknuckle(1) usingtoolC–4150A(2).

13.Removetheupperballjointnut.

14.Seperatetheupperballjoint(2)fromtheknuckle (3)usingtool8677(1).

15.Removetheknuckle(3)fromthevehicle.

INSTALLATION 1.Installtheknuckle(1)tothevehicle.

2.Installthelowerballjointintotheknuckle.

3.Installthelowerballjointnut.Tightenthenutto81 N·m(60ft.lbs.).

4.Installtheupperballjoint(2)intotheknuckle(3)

5.Installtheupperballjointnut(4).Tightenthenutto 81N·m(60ft.lbs.).

6.Installtheoutertierodendtothesteeringknuckle. (Referto19-STEERING/LINKAGE/TIERODEND -INSTALLATION).

7.Installthehub/bearing(3),Tightento136N·m(100 ft.lbs.).(Referto2-SUSPENSION/FRONT/HUB/ BEARING-INSTALLATION).

8.Installtheaxleshaftnut.Tightenthenutto135 N·m(96ft.lbs.).(ifequippedwithfourwheeldrive).

9.Installthewheelspeedsensor(2).(Referto5BRAKES/ELECTRICAL/FRONTWHEELSPEED SENSOR-INSTALLATION).

10.Installthediscbrakerotor(1).(Referto5BRAKES/HYDRAULIC/MECHANICAL/ROTORSINSTALLATION).

11.Installthecaliperadapter(1).(Referto5BRAKES/HYDRAULIC/MECHANICAL/DISC BRAKECALIPERADAPTER-INSTALLATION).

12.Installthetireandwheelassembly.(Referto22TIRES/WHEELS/WHEELS-STANDARDPROCEDURE).

13.Performwheelalignment(Referto2-SUSPENSION/WHEELALIGNMENT-STANDARD PROCEDURE).

LOWERBALLJOINT DIAGNOSISANDTESTING LOWERBALLJOINT NOTE:Iftheballjointisequippedwithalubricationfitting,greasethejointthenroadtestthevehiclebefore performingtest.

1.Raisethefrontofthevehicle.Placesafetyfloorstandsunderbothlowercontrolarmsasfaroutboardaspossible.Lowerthevehicletoallowthestandstosupportsomeorallofthevehicleweight.

2.Mountadialindicatorsolidlytothetopsideofthelowercontrolarmandthenzerothedialindicator.

3.Positiontheindicatorplungeragainstthebottomsurfaceofthesteeringknuckle.

NOTE:Thedialindicatorplungermustbeperpendiculartothemachinedsurfaceofthesteeringknuckle.

4.Positionaprybarunderthetireassembly.Pryupwardsonthetireassembly.

5.Ifthetravelexceeds0.5mm(0.020in.),replacethelowerballjoint(Referto2-SUSPENSION/FRONT/LOWER BALLJOINT-REMOVAL).

REMOVAL 1.Removethetireandwheelassembly.

2.Removethebrakecaliperandrotor(Referto5BRAKES/HYDRAULIC/MECHANICAL/ROTORSREMOVAL).

3.Disconnectthetierod(1)fromthesteeringknuckle usingspecialtoolC-3894-A(1)(Referto19STEERING/LINKAGE/TIERODEND-REMOVAL).

4.Separatetheupperballjoint(2)fromtheknuckle (3)usingspecialtool8677(1).

5.Separatethelowerballjoint(3)fromthesteering knuckle(1)usingspecialtool8677(2).

6.Removethesteeringknuckle(Referto2-SUSPENSION/FRONT/KNUCKLE-REMOVAL).

7.Movethehalfshafttothesideandsupportthehalfshaftoutoftheway 4X4only 8.Chiselouttheballjointstakes.

NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsure properoperationduringtheremovalandinstallationprocess.

9.Presstheballjointfromthelowercontrolarm(3) usingspecialtoolsC-4212-F(PRESS)(1), C–4212–3(Driver)(2)and9654–3(Receiver)(4).

INSTALLATION NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsure properoperationduringtheremovalandinstallationprocess.

1.Installtheballjoint(4)intothecontrolarm(3)and pressinusingspecialtoolsC-4212-F(press)(1), 9654–1(Driver)(5)and9654–2(Receiver)(2).

2.Staketheballjointflangeinfourevenlyspacedplacesaroundtheballjointflange,usingachiselandhammer.

3.Removethesupportforthehalfshaftandinstallintoposition 4X4only

4.Installthesteeringknuckle(Referto2-SUSPENSION/FRONT/KNUCKLE-INSTALLATION).

5.Installthetierodendintothesteeringknuckle(Referto19-STEERING/LINKAGE/TIERODEND-INSTALLATION).

6.Installandtightenthehalfshaftnutto251N·m(185ft.lbs.).(IfEquipped).

7.Installthebrakecaliperandrotor(Referto5-BRAKES/HYDRAULIC/MECHANICAL/ROTORS-INSTALLATION).

8.Installthetireandwheelassembly(Referto22-TIRES/WHEELS/WHEELS-STANDARDPROCEDURE).

9.Checkthevehiclerideheight(Referto2-SUSPENSION/WHEELALIGNMENT-STANDARDPROCEDURE).

10.Performawheelalignment(Referto2-SUSPENSION/WHEELALIGNMENT-STANDARDPROCEDURE).

LOWERCONTROLARM DESCRIPTION Thefrontlowersuspensionarmsarecastiron.

OPERATION Thebushingsprovideisolationfromtheroad.Thearmsmounttothecradlebracketandtheknuckle.Thearmand bushingsprovidelocationandreacttoloadsfromtheroad.

REMOVAL 1.Raiseandsupportthevehicle.

2.Removethetireandwheelassembly.

3.Removethesteeringknuckle(3).(Referto2SUSPENSION/FRONT/KNUCKLE-REMOVAL).

4.Removetheshockclevisbracket(2)fromthelower controlarm.

5.Removethenutandboltfromthefrontofthelower controlarm.

6.Removetherearboltsandflagnutsfromthelower controlarm.

7.Removethelowercontrolarmfromthevehicle.

INSTALLATION 1.Positionthelowersuspensionarmintotheframe railbracket.

2.Installtherearboltsforthelowercontrolarmtothe frame,Tightento142N·m(105ftlbs).

3.Installthenutandboltforthefrontofthelower controlarmTightento169N·m(125ftlbs).

4.Installthelowerclevisbolt(2)atthelowercontrol armandtightento88N·m(65ft.lbs.).

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

5.Installthesteeringknuckle(3)andtightenthenut to75N·m(55ft.lbs.)(Referto2-SUSPENSION/ FRONT/KNUCKLE-INSTALLATION).

6.Installthetireandwheelassembly.

7.Lowerthevehicle.

8.Performwheelalignment(Referto2-SUSPENSION/WHEELALIGNMENT-STANDARDPROCEDURE).

SHOCK DESCRIPTION Thetopoftheshockabsorbersareboltedtothebody.Thebottomoftheshocksareboltedtothelowercontrol arm.Thestandardshockshaveconventionaltwintubeconstructionandarelowpressuregascharged.Gaschargingpreventscavitationduringroughroadoperation.

OPERATION Theshockabsorbersdampenjounceandreboundmotionofthevehicleovervariousroadconditionsandlimitsuspensionreboundtravel.

REMOVAL RIGHTFRONT 1.Removetheairboxcoverandairintakehose.

2.Disconnectthecruisecontrolservoelectricalconnector.

3.Removethecoolantreservoirmountingboltandmovethecoolantreservoirofftotheside.

4.Removethefouruppershockmountingnuts(1).

5.Raiseandsupportthevehicle.

6.Removethetire.

7.Removethetwobrakecaliperadapterbolts.

8.Supportthebrakecaliperadaptorandcaliper. Donotallowthecalipertohangbythebrakehose.

9.Removethediscbrakerotor.

10.Removetheupperballjointnut.

11.Separatetheupperballjoint(2)fromtheknuckle (3)usingspecialtool8677(1).

12.Removethelowerclevisbolt(2)atthelowercontrolarm.

13.Removethelowerstabilizerbolt(3)atthelower controlarm.

14.Removetheshockfromthevehicle.

15.Removethespringifnecessary(Referto2SUSPENSION/FRONT/SPRING-REMOVAL).

LEFTFRONT 1.Removetheairboxcoverandairintakehose.

2.Removethe3PDCbracketnuts(1).

3.MovethePDC(1)offtothesidetoaccessthefour uppershockmountnuts(2).

4.Removethefouruppershockmountnuts(2).

5.Raiseandsupportthevehicle.

6.Removethetire.

7.Removethetwobrakecaliperadapterbolts.

8.Supportthebrakecaliperadaptorandcaliper. Donotallowthecalipertohangbythebrakehose.

9.Removethediscbrakerotor.

10.Removetheupperballjointnut.

11.Separatetheupperballjoint(2)fromtheknuckle (3)usingspecialtool8677(1).

12.Removethelowerclevisbolt(2)atthelowercontrolarm.

13.Removethelowerstabilizerbolt(3)atthelower controlarm.

14.Removetheshock(3)fromthevehicle.

15.Removethespringifnecessary(Referto2SUSPENSION/FRONT/SPRING-REMOVAL).

INSTALLATION RIGHTFRONT 1.Installtheclevisbracket(4)totheshock(3)and tightento122N·m(90ft.lbs.)..

2.Installtheshockassembly(3)tothevehicle.

3.Installthefouruppershocknuts(1),Tightento95 N·m(70ft.lbs.).

4.Installthecoolantreservoirbolt.

5.Reconnectthecruisecontrolservowiringconnector.

6.Installtheairboxcoverandairintakehose.

7.Raisethevehicleup.

8.Installthelowerstabilizerbolt(2)atthelowercontrolarm.

9.Installthelowerclevisbolt(3)atthelowercontrol armandtightento169N·m(125ft.lbs.).

10.Installtheupperballjointintotheknuckle(1)and tightenthenutto75N·m(55ft.lbs.).

11.Installthediscbrakerotor.

12.Installthecaliperadaptormountingboltsto176N·m(130ft.lbs.).

13.Installthetireandwheelassembly.

14.Lowerthevehicle.

LEFTFRONT 1.Installtheclevisbracket(4)totheshock(3)and tightento122N·m(90ft.lbs.)..

2.Installtheshockassembly(3)tothevehicle.

3.Installthefouruppershocknuts(2),Tightento95 N·m(70ft.lbs.).

4.Installthe3PDC(1)bracketnuts.

5.Raisethevehicleup.

6.Installthelowerstabilizerbolt(2)atthelowercontrolarmandtightento115N·m(85ft.lbs.).

7.Installthelowerclevisbolt(3)atthelowercontrol armandtightento169N·m(125ft.lbs.).

8.Installtheupperballjointintotheknuckle(1)and tightenthenutto75N·m(55ft.lbs.).

9.Installthediscbrakerotor.

10.Installthecaliperadaptormountingboltsto176N·m(130ft.lbs.).

11.Installthetireandwheelassembly. 12.Lowerthevehicle.

SPRING REMOVAL 1.Removetheshock(Referto2-SUSPENSION/ FRONT/SHOCK-REMOVAL).

2.InstalltheshockassemblyintheBranick7200 springremoval/installationtoolorequivalent(1).

3.Compressthespring(2).

4.Removetheuppershocknut(2).

NOTE:Thenub(1)intheuppershockmount(3) mustbe180°fromthecenterlineofthelower bracket(9)ontheshock(8)forproperinstallation.

5.Removetheshock(8).

6.Removetheshockuppermountingplate(3).

7.Removeandinspecttheupper(5)andlower(7) springisolators.

INSTALLATION 1.Compressthespring(2).

2.Installthelowerisolator(7).

3.Positiontheshock(8)intothecoilspring(6) make surethejouncebumper(4)isontheshockrod

4.Installtheupperisolator(5).

NOTE:Forproperorientationthenubhole(1)in theuppershockplate(3)mustbe180°inacenterlinefromthebracket(9)atthebottomofthe shock(8).

5.Installtheuppershockmountingplate(3).

6.Installtheshockuppermountingnut(2)Tightento 39N·m(25ft.lbs.).

7.Decompressthespring.

8.Removetheshockassemblyfromthespringcompressortool(1).

9.Installtheshockassembly(Referto2-SUSPENSION/FRONT/SHOCK-INSTALLATION).

STABILIZERBAR DESCRIPTION Thebarextendsacrossthefrontundersideofthechassisandismountedtothecradle.Linksareconnectedfrom thebartothelowercontrolarms.Thestabilizerbarandlinksareisolatedbyrubberbushings.

OPERATION Thestabilizerbarisusedtocontrolvehiclebodyswayduringturns.Thespringsteelbarhelpstocontrolthevehicle bodyinrelationshiptothesuspension.

REMOVAL 1.Raiseandsupportthevehicle.

2.Removethefrontsplashshield.

3.Removethestabilizerbarlinkuppernut(1)&bolt (2).

4.Removethetwostabilizerbushingclampbolts(2).

5.Removethestabilizerbar(1).

INSTALLATION 1.Installthestabilizerbar(1)tothevehicle.

2.Installthestabilizerbushingclamp(2)andtighten theboltsto142N·m(105ft.lbs.).

3.Installtheupperstabilizerlink(3)andtightennut (1)&bolt(2)to135N·m(100ft.lbs.).

4.Installthefrontsplashshield.

5.Lowerthevehicle.

STABILIZERLINK REMOVAL 1.Raiseandsupportthevehicle.

2.Removethetireandwheelassembly.

3.Removetheupperlinkbolt/nut(1&2).

4.Removethelowerlinkbolt(6).

5.Removethestabilizerlink(3).

INSTALLATION 1.Installthestabilizerlink(3)tothevehicle.

2.Installthelowerlinkbolt(6)andtightento115N·m (85ft.lbs.)

3.Installtheupperlinkbolt/nut(1&2)andtightento 135N·m(100ft.lbs.).

4.Installthetireandwheelassembly.

5.lowerthevehicle.

UPPERBALLJOINT DIAGNOSISANDTESTING UPPERBALLJOINT

1.Raisethefrontofthevehicle.Placesafetyfloor standsunderbothlowercontrolarmsasfaroutboardaspossible.Lowerthevehicletoallowthe standstosupportsomeorallofthevehicleweight.

2.Removethefronttires.

3.Mountadialindicator(1)solidlytotheframeand thenzerothedialindicator.

4.Positiondialindicatorplungeronthetopsideofthe upperballjoint(5).

NOTE:Thedialindicatorplungermustbeperpendiculartothemachinedsurfaceoftheballjoint.

NOTE:Usecarenottopryorteartheballjoint boot,whencheckingthefreeplay.

5.Positionaprybar(3)betweenthesteeringknuckle(4)andtheuppercontrolarm(2).Pryupwardsontheupper controlarm.

6.Ifthetravelexceeds0.5mm(0.020in.),replacetheupperballjoint(Referto2-SUSPENSION/FRONT/UPPER BALLJOINT-REMOVAL).

7.Iftheupperballjointiswithinspecsreinstallthefronttires(Referto22-TIRES/WHEELS/WHEELS-STANDARDPROCEDURE).

REMOVAL 1.Raisevehicleandsupporttheaxle.

2.Removethetireandwheel.

3.Removetheupperballjointretainingnut.

4.Separatetheupperballjoint(2)fromtheknuckle (3)usingspecialtool#8677(1).

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

5.Removethewheelspeedsensorwirefromthe uppercontrolarm(1).

6.Movetheknuckle(3)outofthewaytoallowball jointremovaltoolaccess.

NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsure properoperationduringtheremovalandinstallationprocess.

7.Presstheballjointfromtheuppercontrolarm(1) usingspecialtoolsC-4212-F(PRESS)(2)and 9652(Driver)(3).

INSTALLATION NOTE:Extremepressurelubricationmustbeused onthethreadedportionsofthetool.Thiswill increasethelongevityofthetoolandinsure properoperationduringtheremovalandinstallationprocess.

1.Installtheballjoint(4)intotheuppercontrolarm (5)andpressinusingspecialtoolsC-4212-F (press)(2),9652(Driver)(1)and8975–2 (Receiver)(4).

2.Installtheupperballjoint(2)intotheknuckle(3).

3.Installtheupperballjointretainingnut(4)and tightento75N·m(55ft.lbs.).

4.Installthewheelspeedsensorwiretotheupper controlarm.

5.Installthetireandwheel.

6.Removethesupportsandlowerthevehicle.

7.Performawheelalignment(Referto2-SUSPENSION/WHEELALIGNMENT-STANDARD PROCEDURE).

UPPERCONTROLARM DESCRIPTION

Theuppersuspensionarmsareforgedsteelanduserubberbushingsateachendofthearm.

OPERATION

Thearmsmounttotheunibodyframerailbracketandtheknuckle.Thearmandbushingsprovidelocationand reacttoloadsfromtheroad.Thebushingsprovideisolationfromtheroad.

REMOVAL 1.Raisevehicleandsupporttheaxle.

2.Removethetireandwheel.

3.Removetheinnerfenderwell(2).

4.Removetheupperballjointretainingnut.

5.Seperatetheupperballjoint(2)fromtheknuckle (3)usingspecialtool#8677(1).

6.Removethewheelspeedsensorwirefromthe uppercontrolarm(5).

7.Removethenutandbolt(1)securingtheupper controlarm(5)tothebody.

8.Removetheuppercontrolarm(5)fromthevehicle.

INSTALLATION 1.Installtheuppercontrolarm(5)tothevehicle.

2.Installthenutandbolt(1)securingtheuppercontrolarm(5)tothebody.

3.Installthewheelspeedsensorwiretotheupper controlarm(5).

4.Installtheupperballjoint(2)intotheknuckle(3).

5.Installtheupperballjointretainingnut(4)and tightenthenutto81N·m(60ft.lbs.).

6.Installtheinnerfenderwell(2).

7.Installthetireandwheel.

8.Removethesupportsandlowerthevehicle.

9.Performawheelalignment(Referto2-SUSPENSION/WHEELALIGNMENT-STANDARD PROCEDURE).

CLEVISBRACKET REMOVAL 1.Raiseandsupportthevehicle.

2.Removethetire.

3.Removethetwobrakecaliperadapterbolts(3).

4.Supportthebrakecaliperadaptorandcaliper. Do notallowthecalipertohangbythebrakehose.

5.Removethediscbrakerotor.

6.Removetheupperballjointnut(4).

7.Separatetheupperballjoint(2)fromtheknuckle (3)usingspecialtool8677.

8.Removetheclevisbolt(2)attheshock(1).

9.Removethelowerclevisbolt/nut(4)atthelower controlarm.

10.Removethelowerstabilizerlinkbolt(6).

11.Removetheclevisbracket(3).

INSTALLATION 1.Installtheclevisbracket(3)totheshock(1)and tightento122N·m(90ft.lbs.)..

2.Installthelowerstabilizerlinkbolt(6)andtightento 115N·m(85ft.lbs.)..

3.Installthelowerclevisbolt/nut(4)atthelowercontrolarmandtightento169N·m(125ft.lbs.)..

4.Installtheupperballjoint(2)intotheknuckle(3) andtightenthenutto75N·m(55ft.lbs.).

5.Installthediscbrakerotor.

6.Installthecaliperadaptormountingbolts(3)to25 N·m(18ft.lbs.).

7.Installthetireandwheelassembly.

8.Lowerthevehicle.

REAR DESCRIPTION

Therearsuspensioniscomprisedof:

• Driveaxle

• Shockabsorbers

• Coilsprings

• Lowersuspensionarms(3)

• Uppersuspensionarm

• Stabilizerbar

CAUTION:Suspensioncomponentswithrubber/urethanebushingsshouldbetightenedwiththevehicleat normalrideheight.Itisimportanttohavethespringssupportingtheweightofthevehiclewhenthefastenersaretorqued.Thiswillmaintainvehicleridecomfortandpreventprematurebushingwear.

WARNING

WARNING:Suspensioncomponentswithrubberbushingsmustbetightenedwiththevehicleatnormalride height.Itisimportanttohavethespringssupportingtheweightofthevehiclewhenthefastenersare torqued.Ifspringsarenotattheirnormalrideposition,vehicleridecomfortwillbeaffectedandcause prematurebushingwear.

DIAGNOSISANDTESTING-REARSUSPENSION CONDITIONPOSSIBLECAUSESCORRECTION

VEHICLEINSTABILITY1.Looseorwornwheelbearings.1.Replacewheelbearings.

2.Loose,wornorbentsuspension components.

2.Inspect,tightenorreplacecomponents asnecessary.

3.Tirepressure.3.Adjusttirepressure.

VEHICLEPULLSTOONE SIDE

KNOCKING,RATTLING ORSQUEAKING

1.Weakorbrokenspring.1.Replacespring.

2.Alignment.2.Alignvehicletospecifications. 3.Tires.3.Replacetires.

4.Brakes.4.Repairasnecassary.

1.Wornshockbushings.1.Replaceshock. 2.Looseshockmounting.2.Tightentospecifications.

3.Shockvalve.3.Replaceshock. 4.Weakorbrokenspring.4.Replacespring.

5.Loose,wornorbentsuspension components. 5.Inspect,tightenorreplacecomponents asnecessary.

IMPROPERTRACKING1.Loose,wornorbentsuspension components.

1.Inspect,tightenorreplacecomponents asnecessary.

2.Bentaxle.2.Replaceaxle.

SPECIFICATIONS TORQUECHART TORQUESPECIFICATIONS

DESCRIPTIONN·mFt.Lbs.In.Lbs. ShockAbsorberUpperBolt9570— ShockAbsorberLowerBolt11585— SuspensionArmsLowerAxleBracketNut210155— SuspensionArmsLowerFrameBracketNut176130— SuspensionArmsUpperAxleBracketNut136100— SuspensionArmsUpperFrameBracketNut12995— TrackBartoAxle190140— TrackBartoRearStructure190140— StabilizerBarRetainerBolts4634— StabilizerLinkNuttoStabilizerBar8865— StabilizerLinktoBody Bolt 10275— JounceBumperBolttoBody5440—

LOWERCONTROLARM DESCRIPTION

Thelowersuspensionarms(3)aretubularsteeland useavoidedovalbushingatthearmontheaxleside.