5 minute read

Initial 100 Hours Service

from Daewoo Doosan ADT MT25 MT26 MT31 MT36 MT41 Operation and Maintenance Manual MX519828 - PDF DOWNLOAD

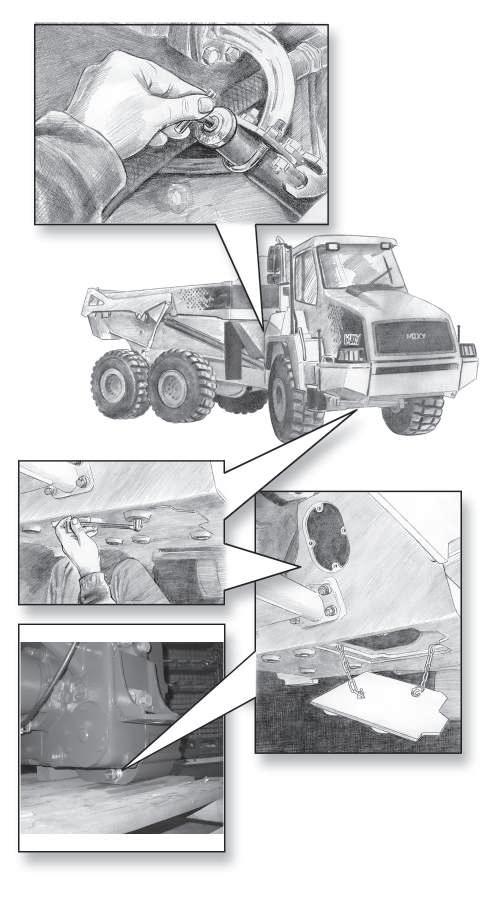

Cap Drain nipple

Rear cover Initial 100 Hours Service Maintenance to be performed after the fi rst 100 hours only.

1. Transmission

1.1. Change oil 20* Replace fi lter element 21* Clean strainer 22*, at least once a year • Changing transmission oil, replacement of transmission filter and cleaning of the strainer shall also be carried out every 1000 hours.

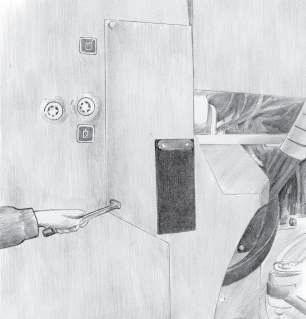

Drain oil: 1. The dump truck must be standing on level ground. 2. The oil must be at operating temperature. 3. Unscrew the dip stick (located behind the cab).

4. Remove cover plate under the transmission, by removing the 4 M12 bolts. 5. Remove cap. 6. Place drain hose with connection on drain nipple. 7. Once transmission oil is emptied remove hose and replace cap.

CAUTION

Use gloves when checking the oil level or fi lling oil. The exhaust pipes and nearby area may be hot and fi ngers and hands could be burnt.

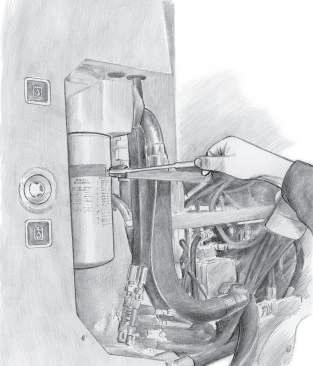

Replace fi lter elements (located on the left hand side): Access to the fi lters through the engine bottom guard 8. Remove the engine bottom guard (front cover)

9. Clean well around the fi lters. 10. Place a suitable container beneath the fi lters to catch spillage. 11. Unscrew the fi lter elements. 12. Check for wear particles in the oil. 13. Apply oil to the seals on the new elements. 14. Screw the fi lter elements in until contact with the sealing surface is obtained. Tighten the elements fi rmly by hand.

continued overleaf

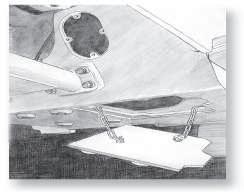

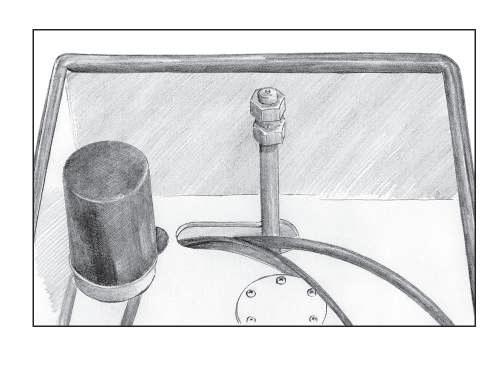

Access to remove the strainer

Rear cover

1

2

3

4

Initial 100 Hours Service Maintenance to be performed after the fi rst 100 hours only.

Clean strainer: 15. The strainer is located on the left hand side of the drain plug. 16. Unscrew the three nuts (1) and washers (2). 17. Remove the cover (3). 18. Replace the O-ring on the cover, if necessary.

19. Remove the strainer (4) and clean it. 20. Reassemble and torque nuts to 23 Nm. 21. Remount the all bottom guards and covers.

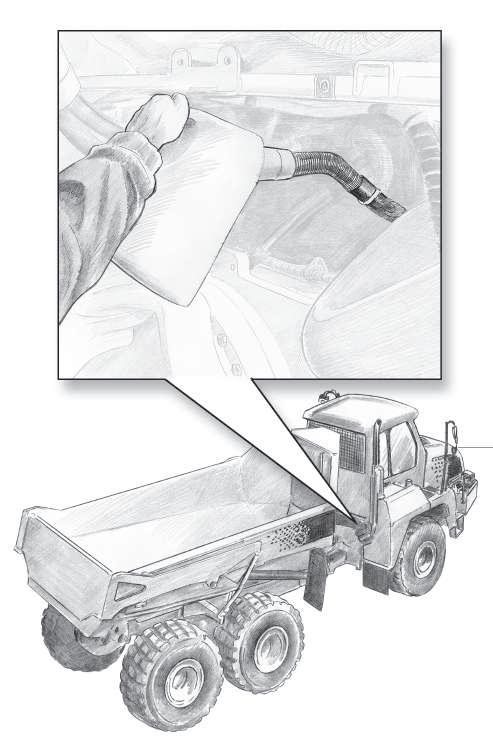

Fill new oil: 22. Fill new oil, according to the transmission oil list and oil specifi cation sheet (chapter 6), through the dip stick tube. 23. Insert the dip stick again and turn handle clockwise to tighten the sealing.

Check: 24. Start the engine and check oil level (see daily maintenance, for procedure) at low idle. Both too low and too high level can cause serious internal damage! 25. Warm up the oil and check for leaks. Re-check level and adjust if necessary.

NOTE

• Do not overfi ll! Both too high and too low level can cause serious internal damage! • For rough operation conditions the oil and the filter element must be changed more often (every 500 hours) and the strainer must be cleaned as well.

Initial 100 Hours Service Maintenance to be performed after the fi rst 100 hours only.

Fill 4 litres hydraulic oil throguh the oil fi ller. 2. Hydraulic System

2.1. Replace hydraulic return fi lter element 43*. • Replacement of hydraulic return fi lter element shall also be carried out every 1000 hours of operation. 1. Accumulators contain oil under high pressure! Empty the accumulators, before unscrewing the fi lter. Procedure is described in chapter 2, item 27. 2. The fi lter is located on the back of the hydraulic tank. Remove the cover to get into the fi lter. 3. Clean well around the fi lter housing. 4. Place a suitable container beneath the draining hose to catch spillage. 5. Use a fi lter key to unscrew the old fi lter (counterclockwise). Remove also the old O-ring. The old fi lter contains 4 litres oil. Discard the fi lter element, and oil according to environmental requirements. 6. Check for wear particles in the oil. 7. Clean the O-ring groove, apply oil to the new O-ring and install it. 8. Apply oil or grease to the threads and install a new fi lter element by turning it clockwise until seals make contact. Then tighten by hand 1/4 to 1/3 turn more. 9. Fill 4 litres hydraulic oil, as specifi ed in chapter 6, lubricants, through the oil fi ller on the top of the fi lter unit (under the cover on the top of the hydraulic tank). 10. Screw the oil plug back into place and clean off any oil spill. 11. Start engine and check for leaks. The accumulators will be recharged with oil when the engine is re-started.

CAUTION

Pay special attention to cleanliness when working with the hydraulic system! Contamination can give steering disturbance and reduce safety.

Initial 100 Hours Service Maintenance to be performed after the fi rst 100 hours only.

2.2. Replace hydraulic high pressure fi lter element 43a*. • R ep l a c e m e n t o f hy d r a u l i c h i g h p r e s s u r e f i l t e r element shall also be carried out every 1000 hours of operation. 1. Accumulators contain oil under high pressure! Empty the accumulators, before unscrewing the fi lter. Procedure is described in chapter 2, item 27. 2. The fi lter is located on the inside of the main frame and the engine. 3. Clean well around the fi lter housing. 4. Place a suitable container beneath the draining hose to catch spillage. 5. Use a fi lter key to unscrew the old fi lter (counterclockwise). Remove also the old O-ring. 6. Check for wear particles in the oil. 7. Clean the O-ring groove, apply oil to the new O-ring and install it. 8. Apply oil or grease to the threads and install a new fi lter element by turning it clockwise until seals make contact. Then tighten by hand 1/4 to 1/3 turn more. 9. Screw the oil plug back into place and clean off any oil spill. 10. Start engine and check for leaks. The accumulators will be recharged with oil when the engine is re-started.

CAUTION

Pay special attention to cleanliness when working with the hydraulic system! Contamination can give steering disturbance and reduce safety.