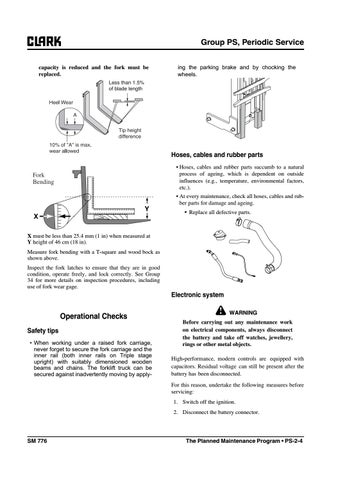

Group PS, Periodic Service capacity is reduced and the fork must be replaced.

ing the parking brake and by chocking the wheels.

Less than 1.5% of blade length

Hoses, cables and rubber parts • Hoses, cables and rubber parts succumb to a natural process of ageing, which is dependent on outside influences (e.g., temperature, environmental factors, etc.). • At every maintenance, check all hoses, cables and rubber parts for damage and ageing. • Replace all defective parts.

X must be less than 25.4 mm (1 in) when measured at Y height of 46 cm (18 in). Measure fork bending with a T-square and wood bock as shown above. Inspect the fork latches to ensure that they are in good condition, operate freely, and lock correctly. See Group 34 for more details on inspection procedures, including use of fork wear gage.

Electronic system

Operational Checks Safety tips • When working under a raised fork carriage, never forget to secure the fork carriage and the inner rail (both inner rails on Triple stage upright) with suitably dimensioned wooden beams and chains. The forklift truck can be secured against inadvertently moving by apply-

!

WARNING

Before carrying out any maintenance work on electrical components, always disconnect the battery and take off watches, jewellery, rings or other metal objects. High-performance, modern controls areG equipped with capacitors. Residual voltageG can still be present after the battery hasGbeen disconnected. For this reason, undertake the followingGmeasures before servicing: 1. Switch off the ignition. 2. Disconnect the battery connector.

SM 776

The Planned Maintenance Program • PS-2-4