1 minute read

Hydraulic System

Hydraulic System

Design

A 80V / 23,5 kW threephase motor is used to drive the pump.

The thermal gauge for temperature control is sealed in a field coil, the speed sensor is located in the sensor bearing.

Motor overtemperature is displayed via an indicated in the multi-function display.

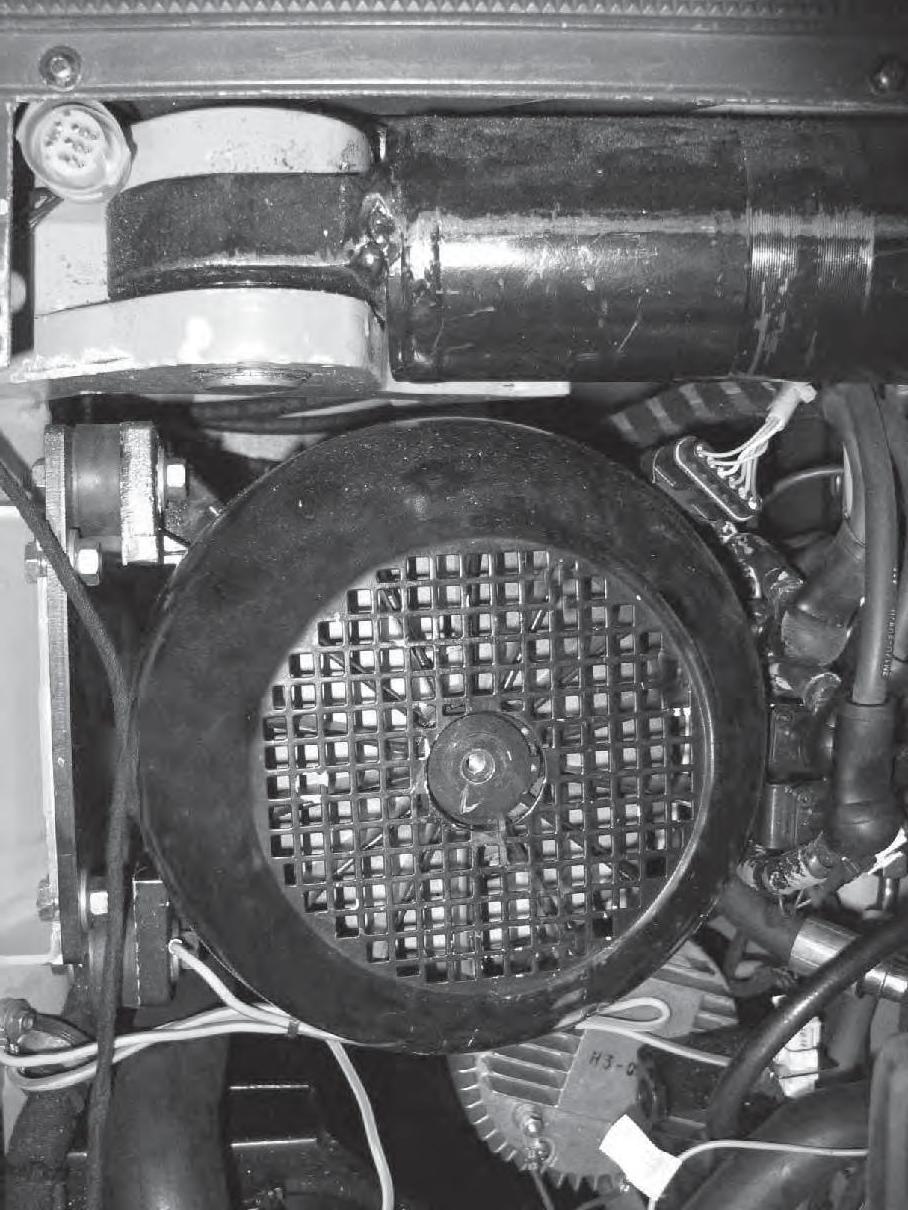

fi g. 80

Item Description Item Description

1 Pump motor 5 Measurement port 2 Cross coupling 6 Pressure fi lter 3 Hydraulic pump 4 Hydraulic oil reservoir 7 Sensor bearing and temperature gauge connector

Hydraulic unit disassembly/assembly

• Park the truck securely • Fully lower the load handler

Set the main switch and key switch “ • OFF”. • Disconnect the battery

STOP

Depressurise the hydraulic lines before disassembly.

• Undo the motor connections

• Turn the eye bolt in the rotor shaft (8)

• Attach the chain pulley to the overhead guard and gently pull the hydraulic unit. Undo the 2 screws (9) on the mounting plate

• Remove the potential compensation wire (green/yellow)

• Remove the temperature transmitter and the sensor bearing

• Disassembly the suction hose from the reservoir and seal it

• Seal the reservoir

• Disassemble the pressure hose from the pump and seal it

Collect any escaping oil and dispose of it in accordance with environmental regulations.

• Using the chain pulley lift the hydraulic unit out of the truck and place it next to the truck

Assembly is the reverse order

! Note cross coupling assembly position

Pump groove depth: 6,5 mm - engine groove depth: 9,5 mm Pre-fill the suction hose before connecting. To bleed the hydraulic system, apply the pump motor at low speed.

8

9

fi g. 81