B

BASIC COMPONENT SYMBOLS

TAP LOCATIONS

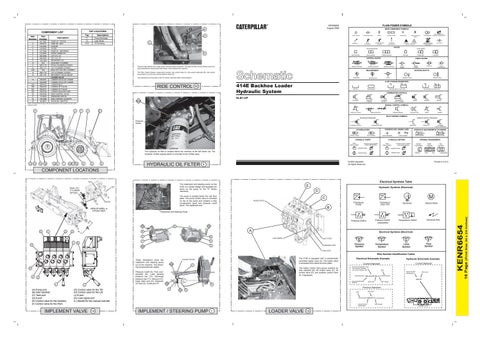

COMPONENT LIST Tap

Item Number

Part Number

Description:

1 2 3 4 5 6 7 8 9 10 11 12 12A

247-7867 245-8777 214-2202 210-6243 247-7868 214-5097 228-3508 206-3553 185-1839 N/A 285-1170 285-1171 N/A

PUMP GP - PISTON TANK GP - MTG COOLER FILTER PUMP GP - METERING FRONT STEER CYL. LIFT CYL. ST TILT CYL. ST MP BUCKET CYL. AUXILIARY CYLINDER PITCH CYLINDER (3 POINT) TILT CYLINDER (3 POINT) DUAL TILT CYL OPT. (3 POINT)

13 14

285-1172 285-1187

15

248-0481 248-0482 259-6732 259-6745 259-6731 259-6729 245-8780 131-9203 162-3960 8J-6875

LIFT CYLINDER (3 POINT) IMPLEMENT VALVE GROUP LOADER VALVE LOADER VALVE (ST) 2-BANK LOADER VALVE (ST) 3-BANK LOADER INLET LOADER LIFT VALVE LOADER TILT VALVE LOADER AUXILIARY (MP) RIDE CONTROL VALVE PRESSURE SWITCH RIDE CONTROL ACCMLTR VALVE AS - SHUTTLE

15A 15B 15C 15D 16 17 18 19

FLUID POWER SYMBOLS

KENR6654 August 2006

MAIN AUX.

Description

T1 T2 SOS

A

Pump Discharge Load Sense Oil Sampling

PUMP or MOTOR

C

LINE RESTRICTION (FIXED)

RESTRICTION

PRESSURE COMPENSATION

LINE RESTRICTION (VARIABLE)

SPRING (ADJUSTABLE)

VARIABILITY

CONTROL VALVES

SPRING

FLUID CONDITIONER

PUMP: VARIABLE and PRESSURE COMPENSATED

2-SECTION PUMP

HYDRAULIC PNEUMATIC ENERGY TRIANGLES

ATTACHMENT

LINE RESTRICTION VARIABLE and PRESSURE COMPENSATED

VALVES VALVE ENVELOPES

D

VALVE PORTS

TWO POSITION

ONE POSITION

TWO-WAY

THREE POSITION

CONTROL VALVES

CHECK VALVES

AB

AB

P T SHIFTED POSITION

P T NORMAL POSITION

Travel at high speeds over rough terrain causes bucket movement. The optional Ride Control System acts as a shock absorber by absorbing bucket forces, which stabilize the machine.

FOUR-WAY

THREE-WAY

INFINITE POSITION

SHUTTLE

SPRING LOADED

BASIC SYMBOL

MEASUREMENT

PILOT CONTROLLED

ROTATING SHAFTS

The Ride Control System components include; ride control relay (A), ride control solenoids (B), ride control accumulator (C), and ride control pressure switch (D). Two solenoids are now used on the "E" Series machines Ride Control System.

RIDE CONTROL

PRESSURE

UNIDIRECTIONAL

BIDIRECTIONAL

FLUID STORAGE RESERVOIRS

414E Backhoe Loader Hydraulic System

16

FLOW

TEMPERATURE

VENTED

RETURN ABOVE FLUID LEVEL

PRESSURIZED

RETURN BELOW FLUID LEVEL

COMBINATION CONTROLS

ELB1-UP SOLENOID or MANUAL

SOLENOID

SOS

NOTE: Numbers15A through 15D are represented by the number 15 only on the machine views.

11

SERVO

SOLENOID and PILOT or MANUAL

SOLENOID and PILOT

DETENT

THERMAL

MANUAL CONTROL SYMBOLS

2

7

3

8 PUSH-PULL LEVER

MANUAL SHUTOFF

GENERAL MANUAL

PUSH BUTTON

PEDAL

SPRING

PILOT CONTROL SYMBOLS RELEASED PRESSURE

REMOTE SUPPLY PRESSURE

Pressure Switch EXTERNAL RETURN

INTERNAL RETURN

SIMPLIFIED

CROSSING AND JOINING LINES

ACCUMULATORS

SPRING LOADED

GAS CHARGED

LINES CROSSING

HYDRAULIC PUMPS FIXED DISPLACEMENT

The hydraulic oil filter is located below the machine at the left frame rail. The hydraulic oil filter bypass switch is mounted to the oil filter base.

13 12

14

19

15 4

1

18 17 16

5

6

HYDRAULIC OIL FILTER

9

HYDRAULIC AND PNEUMATIC CYLINDERS

SINGLE ACTING

LINES JOINING

FIXED DISPLACEMENT

VARIABLE DISPLACEMENT NON-COMPENSATED

UNIDIRECTIONAL

UNIDIRECTIONAL

BIDIRECTIONAL

BIDIRECTIONAL

DOUBLE ACTING

INTERNAL PASSAGEWAYS

HYDRAULIC MOTORS

VARIABLE DISPLACEMENT NON-COMPENSATED

INTERNAL SUPPLY PRESSURE

COMPLETE

FLOW IN ONE DIRECTION

PARALLEL FLOW

CROSS FLOW

FLOW ALLOWED IN EITHER DIRECTION

Printed in U.S.A.

© 2006 Caterpillar All Rights Reserved

4

TWO POSITION

THREE POSITION

INFINITE POSITIONING

COMPONENT LOCATIONS Electrical Symbols Table

TILT The implement and steering pump on the 414E is a similar design and operates the same as the pump on the "A" Series machines.

LIFT

E D

The pump is located below the cab floor plate. The pump control valve is mounted on top of the pump and contains a flow compensator spool and pressure cutoff spool. The implement and

PITCH

G

C Transducer (Fluid)

Transducer (Gas / Air)

Implement and Steering Pump

Pressure Switch (Adjustable)

T2

T2

D

A

B

H

A

Electrical Symbols (Electrical)

B LOAD SENSE

J

INLET PORT

A

F

T

K

C

Electrical Wire

Temperature Switch

STEERING PORT

C

T1

Pressure Symbol

Temperature Symbol

Flow Symbol

Level Symbol

TANK PORT

Wire Number Identification Codes

B

A

Pressure Cutoff (A), Flow compensator (B), Load sensing pressure tap (T2), Discharge pressure tap (T1), Inlet port (C), Case drain port (D), Hydraulic Oil Tank (E), Outlet port (F)

D

L

(A) Pump port (B) Inlet manifold (C) Tank port (D) A port (E) Control valve for the Auxiliary (F) Control valve for the Pitch

L

(G) Control valve for the Tilt (H) Control valve for the Lift (J) B port (K) Load signal port (L) Handle for the manual override

IMPLEMENT VALVE

The 414E is equipped with a mechanically controlled loader valve (A). The loader valve is accessed from below the floor plate.

Hydraulic Oil Filter

These illustrations show the implement and steering pump out of the machine. The following components are visible:

SOS

Electrical Schematic Example

Harness identification code This example indicates wire 135 in harness "AG".

Wire Circuit Number Identification

Wire Color

325-AG135 PK-14 325-PK Circuit Identification Number

T2

Wire Color

Wire Gauge

E F

Previous Standard T1

D

Wire Color

Wire

325-PK-14 B Circuit Number Identification

14

Current Standard

Current Standard

C

The loader control valve group contains an inlet manifold (B), lift control valve (C), tilt control valve (D), and auxiliary control valve (E, if equipped).

Hydraulic Schematic Example

IMPLEMENT / STEERING PUMP

1

LOADER VALVE

15

A

Wire Gauge (EXAMPLE VALVE)

(Print Size 34 x 24 inches)

G

F

Electric Motor

16 Page

E

Generator

B

Pressure Switch

A

M

WORK PORTS

VIEW OF AREA - A

3-Point Hitch

Hydraulic Symbols (Electrical)

KENR6654

DUAL TILT CYLINDER OPTION