SENR6243-01 October 2008

23

25

13 36

33

34

35 37

40

7

28 35

2

3

34

42

13 3 14 38 39

11

10

47

29 43

1

31

A

3

1

2 4

5

43

26

23

1 3

9 8

H

30

6

21

31

6

E

20

22

G

8 9

12 22

25

19

3

36

9

1 10 6 5 D

41 42

F

AREA G

AREA E

28 5

44

31 32

7

17

4

45 11

9

42

27

14

35

16

41 42

31 23

20

H 28

34

25

25

33

12 36 3

29

24

G

6

35

13

17 F

15

1 23 9

37

20

A

B

1

26

D 22

1

8 13 3

46

2

3

C 6

44

22

36 34

30

2

12

40 21 19

37 16

43

7

39

19

40 14 38

45 39

1

5 E

2

33 29 10 18

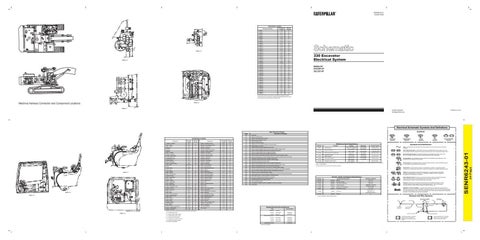

Machine Location

CONN 1

F-18

23

CONN 2

F-17

29

CONN 3

E-17

4F

CONN 4

E-17

35

CONN 5

C-16

36

CONN 6

C-16

1D

CONN 7

D-16

4

CONN 8

E-13

4A

18

B

16

Schematic Location

Connector Number

7

45

4

24

47

33

Connector Location

43 14

46

45

11 17 27

16

20

40

5

17

C

19

39

12 32

1

13

44

29 28

37

44

46

15

2

11

10

47

43

1

46

3 3

4

CONN 9

E-13

3A

CONN 10

E-13

3A 5D

CONN 11

A-13

CONN 12

E-12

2B

CONN 13

E-12

1B

CONN 14

F-12

2C

CONN 15

F-12

1C

CONN 16

B-11

6D

CONN 17

F-9

19

CONN 18

C-4,E-9

3

CONN 19

E-9

14

CONN 20

C-9

22

CONN 21

B-8

2D

CONN 22

C-4,D-8

4E

CONN 23

F-7

13

CONN 24

D-7

1E

CONN 25

D-7

2E

CONN 26

D-7

3E

CONN 27

B-7

4D

CONN 28

B-7

2D

CONN 29

B-7

3D

CONN 30

B-6

4D

CONN 31

D-6

6E

CONN 32

C-4

9B

CONN 33

E-4

19

CONN 34

C-3

39

CONN 35

C-3

39

CONN 36

B-3

20

CONN 37

B-2

20

CONN 38

C-2

39

CONN 39

D-2

3

CONN 40

D-2

3

CONN 41

E-2

1

CONN 42

F-1

18

330 Excavator Electrical System 6ZK64-UP 8CK206-UP 2EL332-UP

The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart. 5

6

4

Machine Harness Connector and Component Locations

AREA H

AREA F Printed in U.S.A.

© 2008 Caterpillar All Rights Reserved

Electrical Schematic Symbols And Definitions Symbols

Real Time Error Codes Code

Component Actuator - Governor Alarm - Action

7

2

4

5

6

10

3

5 6

8

1

2

3 7

4

8

9

7

5 8 9

3

4

AREA C

4 1

1

2

6

3

3

4

2

7

AREA B

3 4

8

AREA A 5

1

2

3

4

1

6

5

3

Solenoid - Combined

F-1

8

Antenna

E-14

4

Solenoid - Engine Pump Control

A-15

4H

Batteries

A-5

5

Solenoid - Engine Shutdown

B-17

21

Block - Terminal

B-7

1D

Solenoid - Fine Swing

C-9

22

Breaker - Alternator

A-12

5D

Solenoid - Hammer Control

D-1

23

B-13

6

F-2

3C

D-5

2B

Solenoid - Hammer Control Solenoid - Level/Finish Solenoid - Start Aid

D-2

43

B-15

1H

F-16

25

Diode Assembly

C-2

33

Solenoid - Travel Speed

A-15

3H

Diode - Main Relay

C-12

4D

Solenoid - Trenching

A-15

2H

Switch - Throttle Position

D-5

3B

Switch - AS. Rocker

B-3

8B

B-9,10,12

7D

Switch - ATCH Pressure

B-1

8

A-2

8

Switch - Backup ACCEL

E-11

6B

A-2,B-2

9

Switch - Boom Raise Pressure

D-15

3G

Lamp - Cab

E-1

43

Switch - Control

F-10

5C

Lamp - Chassis

A-2

10

Switch - Disconnect

A-6

6D

E-5

2A

Switch - EPR Valve Backup

F-11

2C

Meter - ATCH Service

D-1

46

Switch - Engine Oil Pressure

C-18

31

Instrument Panel

E-5

4A

Switch - Fine Swing Control

F-10

4C

F-2

11

Switch - Governor Backup

E-12

7B

Motor - Starter

B-17

12

Switch - Hammer Control

D-4

Motors - Washer

F-16

13

Switch - Hammer Foot

C-1

33

Motor - Upper Wiper

F-2

14

Switch - Horn

F-2

3C

Pump - Refueling

F-17

15

Switch - Implement Pressure

D-15

1G

5B

Relay - Boom Lamp

A-10

8D

Switch - Key

E-9

1B

Relay - Chassis/Cab Lamp

A-12

8D

Switch - Limit

F-1

8

Relays - Dual H.P.

A-9, A-10

8D

Switch - One Touch Low Idle

D-5

2B

Relay - Fine Swing

A-12

8D

Switch - Neutral Start

F-6

33

Relay - Horn

B-9

8D

Switch - Refrigerate Low Pressure

E-18

34

Relay - Main

C-12

4D

Switch - Refueling

E-16

35

Relay - Main (Attachment)

A-11

4D

Switch - Refueling Pump Start

E-17

13

Relay - Refueling Pump

A-9

8D

Switch - Refueling Pump Stop

F-17

36

Relay - Start

B-10

3D

Switch - Safety Pressure

C-1

33

Relay - Washer

B-10

8D

Switch - Seat Heater

F-10

5C

Relay - Wiper

B-12

8D

Switch - Start Aid

D-5

4B

Resistor - Backup

F-12

1C

Switch - Start Aid Coolant Temp

D-17

37

D-2

46

Switches - Travel Pressure

F-5

47

RPM Regulator Seat - Heater

F-13

45

Switch - Windshield

E-5

11

Sensor - Engine Coolant Temp

D-18

16

Unit - Air Conditioner

F-14

40

Sensor - Engine Speed

C-18

19

Sensor - Fuel Level

F-16

1F

Machine locations are repeated for components located close together.

AREA D

20

D-17

Motor - Lower Wiper 2

E-18

Alternator

Meter - Service

1

Solenoid - A/C Compress Clutch

5H 43

Lamps - Boom

6

3A

B-14 D-2

Horns

10

E-5

Sensor - Hydraulic Oil Temp Solenoid - Boom Down

Fuse - Block

1

1

Machine Location

2

Control Group - RH

6

C-13

Component

Schematic Location

E-17

Control Group - LH

7

Machine Location

Alarm - Travel

Control - Engine Pump

1 9 4

Schematic Location

Unit - Heater

F-13

44

E00

No problem.

E1

Engine oil pressure to low.

E2

Engine coolant temperature is to high.

E3

Hydraulic oil temperature is to high.

E4

Battery voltage is to high.

E5

Alternator terminal R is open.

E6

Speed sensor is not installed correctly or it's circuit is open.

E7

Engine speed is not normal.

T

Pressure Symbol

Off Machine Switch Specification Part No.

E11

Governor actuator feedback sensor circuit is shorted to body ground.

E12

Governor actuator feedback sensor voltage is not stable.

E13

Governor actuator motor circuit is shorted to body ground.

E14

Governor actuator motor does not rotate or motor circuit is shorted to battery voltage.

E15

Governor backup switch is in "Man" (backup) position or governor actuator motor circuit is open.

E16

Proportional reducing valve circuit is shorted to body ground.

E17

Proportional reducing valve circuit is shorted to battery voltage.

E18

Proportional reducing valve circuit is open.

E25

Engine coolant temperature sensor circuit is shorted to body ground.

E26

Engine coolant temperature sensor circuit is shorted to battery voltage or open.

490.0 ± 49.0 kPa MAX 290 kPa MIN Normally Open (71.0 ± 7.1 psi MAX) (42.0 psi MIN) 93 ± 21 kPa 69 ± 21 kPa 1-3,Normally Closed 9X-4276 Engine Oil Pressure (13.5 ± 3.0 psi) (10.0 ± 3.0 psi) 1-2,Normally Open 37.8 ± 2.8°C 26.7°C MIN 8C-3569 Engine Coolant Temp (Start Aid) Normally Closed (100 ± 5°F) (80°F MIN) Implement Pressure 1225 ± 343 kPa 735 kPa MIN 102-8041 Normally Open Safety Pressure (178 ± 50 psi) (107 psi MIN) 2450 ± 441 kPa 1470 kPa MIN 102-8042 Boom Raise Pressure Normally Open (355 ± 64 psi) (213 psi MIN) _ 275to1750kPa¹ 114-5334 Refrigerant Pressure (A/C) Normally Open ² _ (40 to 255 psi) ¹ With increasing pressure the closed condition can be maintained up to 2800 kpa (405 psi), with decreasing pressure the closed condition can be maintained down to 170 kpa (25psi).

E27

Hydraulic oil temperature sensor circuit is shorted to body ground.

² Contact position at the contacts of the harness connector.

E28

Hydraulic oil temperature sensor circuit is open or shorted to battery voltage.

E31

Controller receives signal of engine speed other than specified ten from engine speed dial.

E32

There is more than 100 rpm difference between dial setting and actual rpm.

E33

Digital output circuit is shorted to battery voltage.

E34

Governor actuator remains deactivated an elapsed time of 2.5 seconds after speed dial setting.

E36

Monitor takes at least 1 second to respond to controllers signal.

E37

Monitor RAM (Random Access Memory) is not normal.

E38

Controller is informed of it's error signal by monitor.

4I-5387

Controller detects it's error signal by it's self. Error in controller memory.

E41

A controller for a different machine is installed or harness cord problem.

E48

Engine stalls.

Switch (Normally Closed): A switch that will open at a specified point (temp, press, etc.). No circle indicates that the wire cannot be disconnected from the component. Ground (Wired): This indicates that the component is connected to a grounded wire. The grounded wire is fastened to the machine. Ground (Case): This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine. Reed Switch: A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch. Sender: A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure.

T

Component Description

102-8016

Resistor:

Backup

47.0 ± 2.4

116-4416

Solenoid:

Hammmer Control

33.7 ± 1.0

117-6319

Solenoid:

A/C Clutch Compressor ¹

3E-7985

Solenoid:

Engine Shutdown

4I-5394

Sender:

5I-8368

Solenoid:

7Y-3848

Sender:

9G-4365

Solenoid:

Hydraulic Oil Temperature Engine Pump Control Fuel Level Start Aid

Relay (Magnetic Switch): A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay.

Resistance (Ohms)¹

Solenoid: A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work.

14.4 ± 0.6 Latch Coil; 1.55 ± 0.16 Unlatch Coil; 10.3 ± 1.0 6134 to 7496

MAGNETIC LATCH SOLENOID - A magnetic latch solenoid is an electrical component that is activated by electricity and held latched by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.

11.7 ± 0.6 Empty: 83.5 ± 1.5 Half: 33.8 ± 2.0 Full: 8 0 (+ 1 0) (- 0 5) 6

Harness And Wire Symbols

¹ At room temperature unless otherwise noted.

Wire, Cable, or Harness Assembly Identification Pin

Socket

Fuse

Wire Color

A

Component Part Number

AA

105-9344

1

325-PK-14

Receptacle

Related Electrical Service Manuals Title Alternator:

Form Number

Bosch N3

SENR2082

Consist:

6V-5227, 3T-8946¹ Delco 42MT

SENR3581

Consist:

Denso F8.0

SENR4975

Consist:

Delco 50MT¹

SENR3860

Engine/Pump Control: ¹ Use with cold weather.

Circuit Number Identification

Wire Gauge Plug

2

Consist: Electric Starting Motor:

Single Wire Connector

100-5047

B = Located inside of right console.

G =Located under platform.

Switch (Normally Open): A switch that will close at a specified point (temp, press, etc.). The circle indicates that the component has screw terminals and a wire can be disconnected from it.

Resistor, Sender and Solenoid Specifications

E40

Circuit Breaker Symbol

Flow Symbol

Fuse - A component in an electrical circuit that will open the circuit if too much current flows through it.

Travel Pressure

Part No.

E39

Level Symbol

Symbols And Definitions

Contact Position

Voltage of governor actuator feedback sensor is low.

SENR4130

F = Located around pilot manifold.

Deactuate

Governor actuator feedback sensor circuit is shorted to battery voltage or open.

Denso HDB

E = Located around hydraulic oil tank.

Actuate

E9

Consist:

D = Located around relay panel.

Function

E10

A = Located inside of cab. C = Located inside of left console.

Temperature Symbol

SENR5496

Ground Connection

1 2

Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

200-BK-14 Pin or Socket Number

1 2

Typical representation of a Sure-Seal connector. The plug and receptacle contain both pins and sockets.

24 Page

Component Location

Description of Problems

SENR6243-01

3