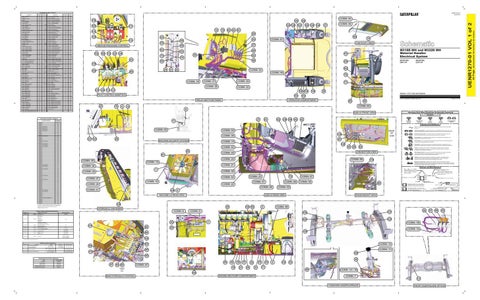

Component Location - Volume 1 Component

Schematic Location

Machine Location

Alarm - Travel / HCR

I-14

1

Sensor - Brake System Pressure

I-3

84

Alternator

C-16

2

Sensor - Fan Speed

H-14

85

Antenna - Product Link

H-16

3 (V2)

Sensor - Hydraulic Oil Temperature

G-14

86

Batteries

C-15

4

Sensor - Left ATCH Pedal Position

I-3

87

Camera - Rear View

D-16

5

Sensor - Transmission Output Speed

A-14

88

Coil - Exciter (MSS)

E-1

6

Sensor - Transmission Pressure

F-12

89 90

Control - Engine

D-15

7

Sensor - Travel Pedal Position

I-3

Control - Generator 15 KW

J-16

8 (V2)

Socket - 12V / 5A

C-3

91

Control - Implement

J-8

9

Solenoid - A/C Clutch

D-16

92

Control - Machine

J-10

10

Solenoid - Aux Port A Flow / Hammer

B-12

93

Control - MSS Keyreader

D-1

11

Solenoid - Aux Port A Line Release Pres

B-12

94

Control - Product Link

G-16

12 (V2)

Solenoid - Aux Port B Flow

B-12

95

Control Box - Generator 12.5KW

F-16

13

Solenoid - Aux Valve Directional

B-12

96

Converter - 24V to 12V

D-7

14

Solenoid - Aux Valve Load Sense

B-12

97

Diode - Wiper Cut Off

C-9

15

Solenoid - Boom Float

E-12

98

Fuse - Alternator

D-15

16

Solenoid - Boom Float Down

E-12

99

Fuse - Engine Control

C-15

17

Solenoid - Dozer Blade Lockout (Rear)

A-16

100

Fuse - Glow Plug

D-15

18

Solenoid - Generator 12.5 KW

H-16

101 (V2)

Fuse - Main Power

D-15

19

Solenoid - Generator 15 KW

H-16

102 (V2)

Fuse - Reserve

C-15

20

Solenoid - HCR Lower

D-12

104

Fuse - Starter Relay

D-15

21

Solenoid - HCR Raise

D-12

105

Fuse Panel - Battery (+24V)

B-9

22

Solenoid - Heavy Lift

G-12

106

Fuse Panel - Key Switch On (+24V)

B-11

23

Solenoid - Hyd Fan (RVS)

G-14

107 (V2)

Generator - 12.5 kw

H-16

24 (V2)

Solenoid - Hydraulic Fan

G-14

108

Generator - 15 kw

J-13

25 (V2)

Solenoid - Hydraulic Modulation

E-13

109

Glow Plugs

D-14

26

Solenoid - Implement Lockout

G-12

110

A-5

27

Solenoid - Joystick Steering Left

C-12

111

Ground - Cab Basic RH Rear Ground - Chassis 1 LH Front

I-3

28

Solenoid - Joystick Steering Protection

B-12

112

Ground - Chassis 2 LH Center

H-5

29

Solenoid - Joystick Steering Right

C-12

113

Ground - Chassis 3 RH Front

C-1

30

Solenoid - Main Pump Power Shift Pressure

F-12

114

Ground - Chassis 4 RH Center

C-16

31

Solenoid - Medium Pressure Port A

D-12

115

Ground - Engine 1

C-16

32

Solenoid - Medium Pressure Port B

D-12

116

Ground - Engine 2

C-16

33

Solenoid - MH Dozer Front Lock

A-13

117

Ground - Fuse / Relay Base

D-10

34

Solenoid - Oscillating Axle

G-12

118

Ground - Operator Platform

I-2

35

Solenoid - Quick Coupler

D-2

119

Ground - Undercarriage

A-13

36

Solenoid - Reverse Fan

G-14

120 (V2)

Joystick - L.H.

H-16

37

Solenoid - Stabilizer Lockout (Left Front)

A-13

121

Joystick - R.H.

F-1

38

Solenoid - Stabilizer Lockout (Left Rear)

A-16

122

LED - 12.5 KW Genset Magnet Control

E-2

39 (V2)

Solenoid - Stabilizer Lockout (Right Front)

A-13

123

LED - 15 KW Magnet GND Fault (-)

E-2

40 (V2)

Solenoid - Stabilizer Lockout (Right Rear)

A-16

124

LED - 15 KW Magnet GND Fault (+)

E-2

41

Solenoid - Swing Brake

G-12

125

Module - Switch Panel

C-4

42

Solenoid - Swing Pump Power Shift Pressure

F-12

126

Monitor - Operator

B-3

43

Solenoid - Transmission Gear Shift 1

G-12

127

G-12

128

I-3

129

Motor - Auto Lube Pump

H-14

44 (V2)

Solenoid - Transmission Gear Shift 2

Motor - Refueling Pump

H-14

45 (V2)

Solenoid - Travel Lock Magnet

Motor - Starter

C-16

46

Solenoid - Travel Motor Swash Plate Angle L

F-12

130

Motor - Washer

H-14

47

Solenoid - Travel Pilot Pressure

F-12

131

Motor - Wiper

J-1

48

Suppressor - A/C

D-16

132

Potentiometer - Magnet Drop Time

B-3

49 (V2)

Switch - Air Filter Clog Pressure

C-2

133

Relay - Auto Lube

A-10

50

Switch - Armrest position

H-16

134

Relay - Beacon

A-10

51

Switch - Boom Down Pilot Pressure

D-12

135

Relay - Boom Lamp

C-10

52

Switch - Brake Oil Accumulation Pressure

I-3

136

Relay - Brake Light

B-10

53

Switch - Disconnect

C-15

137

Relay - Flasher

F-11

54

Switch - Dozer Blade Lockout (Rear)

G-1

138

Relay - Front Cab Flood Lamp

C-10

55

Switch - Flood Lights

A-4

139

Relay - Hi Beam LH

D-11

56

Switch - Generator Enable

A-4

140 (V2)

Relay - Hi Beam RH

D-11

57

Switch - Ground Level Shut Down

I-14

141

Relay - Horn

C-10

58

Switch - Hazard

A-3

142

Relay - Hydraulic Fan Reverse

F-11

59 (V2)

Switch - HCR Door

I-14

143 144

Relay - Implement Lockout

B-10

60

Switch - HCR Enable

G-2

Relay - Interval Wiper

E-11

61

Switch - HCR Position

F-6

145

Relay - Lowbeam LH

D-11

62

Switch - Head Lamp

A-4

146

Relay - Lowbeam RH

D-11

63

Switch - Hydraulic Oil Clog Pressure

G-14

147 148

Relay - Main Power

E-10

64

Switch - Joystick Steering Enable

G-1

Relay - MH Dozer Front 1

B-16

65

Switch - Key

E-1

149

Relay - MH Dozer Front 2

B-16

66

Switch - Lever

J-1

150

Relay - MH Dozer Front 3

A-16

67

Switch - Main Pump Pressure

G-12

151

Relay - Position Light LH

E-11

68

Switch - Medium Pressure/2nd High

A-5

152

Relay - Position Light RH

E-11

69

Switch - Mirror Heater

F-1

153

Relay - Refueling Pump

F-10

70

Switch - Radio On/Off

F-2

154

Relay - Start Aid Control

C-13

71

Switch - Refueling Pump

F-10

155 (V2)

Relay - Starter

C-13

72

Switch - Seat / Heat Control

F-1

156

Relay - Travel Alarm / HCR

B-10

73

Switch - Seat Control

F-1

157

Relay - Wiper Cut Off

B-10

74

Switch - Stabilizer Lockout (Left Front)

G-2

158

Resistor - Alternator

C-3

75

Switch - Stabilizer Lockout (Left Rear)

G-1

159

Resistor - CAN BUS A #1

D-13

76

Switch - Stabilizer Lockout (Right Front)

G-1

160

Resistor - CAN BUS A #2

B-3

77

Switch - Stabilizer Lockout (Right Rear)

G-1

161

Resistor - CAN BUS B #1

J-12

78

Switch - Swing Pilot Pressure

G-12

162

Resistor - CAN BUS B #2

B-3

79

Switch - Window Lower Limit

C-3

163

Resistor - Fan Speed

H-14

80 (V2)

Switch - Window Upper Limit

E-5

164

Swivel - Electric

B-14

165

Sender - Fuel Level

I-14

81

Sensor - Boom Cylinder Head End Pressure

D-2

82

Sensor - Boom Cylinder Rod End Pressure

C-12

83

UENR1270-01 June 2012

116

159

105

134 138

111

15

115

70

CONN: 44

158

161

160 148 144

37

CONN: 45

64 54 61 69

104

164

52 113

63

59 55

MEDIUM PRESSURE CONTROL

60 125

106 110 127 128

57

53

68 34

73 151

58

CAB ROOF LINER

56

50

M318D MH and M322D MH Material Handler Electrical System

43

62

74

14

CONN: 61

M318D MH: D9X1-UP

150

118 162

23

89

51

22

163

CONN: 33 CONN: 49

CONN: 18

79

CONN: 29

CONN: 31 CONN: 28

77

CONN: 25

130 126 114 131

156 154 157 RELAY AND FUSE PANEL

78

9

149

38 Volume 1 of 2: Cab and Chassis

PILOT CONTROL MANIFOLD

47

M322D MH: D3X1-UP

153 © 2012 Caterpillar, All Rights Reserved

OPERATOR COMPARTMENT

90

Printed in U.S.A.

48 CONN: 60

10 6

Harness And Wire Electrical Schematic Symbols

CAB LH FRONT VIEW

Symbols Connector Location - Volume 1 Connector Number

Schematic Location

CONN 1A

27

11

91

152 139 146 142

42

T

Pressure Symbol

B-16 , B-14

CONN 1B

B-14

CONN 2

H-16

CONN 3 (On Volume 2)

J-16

CONN 4 (On Volume 2)

J-16

CONN 5 (On Volume 2)

I-15

CONN 6 (On Volume 2)

J-15

CONN 7

B-14

CONN 8

F-14

CONN 9

F-14

CONN 10 (On Volume 2)

G-14

CONN 11

B-13

CONN 12

B-13

CONN 13

D-13

CONN 14 (On Volume 2)

F-12

CONN 15

F-12

CONN 16 (On Volume 2)

F-12

CONN 17 (On Volume 2)

E-12

CONN 18 (On Volume 2)

E-10

CONN 19

E-9

CONN 20

E-9 D-9

CONN 22

D-9

CONN 23

D-9

CONN 24

G-9

CONN 25

F-9

CONN 26

G-9

CONN 27

G-8

CONN 28

F-8

CONN 29

F-8

CONN 30

G-8

CONN 31

F-8

CONN 32 (On Volume 2)

F-7

CONN 33 (On Volume 2)

F-7

CONN 34

G-7

CONN 35 (On Volume 2)

G-6

CONN 36

F-6

CONN 37

G-6

CONN 38

G-6

CONN 39

F-6

CONN 40 (On Volume 2)

G-6

CONN 41

G-5

CONN 42

F-5

CONN 43 (On Volume 2)

F-5

CONN 44

E-5

CONN 45

E-5

CONN 46

F-5

CONN 47

I-4

CONN 48

F-4

CONN 49

F-4

CONN 50

E-4

CONN 51 (On Volume 2)

F-4

CONN 52 (On Volume 2)

F-4

CONN 53

D-3

CONN 54

D-3

CONN 55

D-3

CONN 56

D-3

CONN 57 SERVICE CONNECTOR

C-3

CONN 58

C-2

CONN 59

D-2

CONN 60

I-2

CONN 61

H-2

CONN: 55

CONN: 50

29

141 143

REAR OF CAB

129

CONN: 39

Switch (Normally Open): A switch that will close at a specified point (temp, press, etc.). The circle indicates that the component has screw terminals and a wire can be disconnected from it. Switch (Normally Closed): A switch that will open at a specified point (temp, press, etc.). No circle indicates that the wire cannot be disconnected from the component. Ground (Wired): This indicates that the component is connected to a grounded wire. The grounded wire is fastened to the machine.

87

MACHINE SECURITY SYSTEM

Ground (Case): This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine.

CONN: 19 136

Reed Switch: A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

84

35 28

CONN: 42 85

Sender: A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure.

CONN: 20

CONN: 30

1

CONN: 61

108

195-7747

Solenoid:

CONN: 55

Part Number: for Connector Receptacle

Plug

82

CONN: 53

Receptacle Pin or Socket Number

1 2

Deutsch connector: Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

1 2

Sure-Seal connector: Typical representation of a Sure-Seal connector. The plug and receptacle contain both pins and sockets.

5A 9X-1123

Fuse (5 Amps)

132 92

33

Harness identification code: This example indicates wire group 325, wire 135 in harness "AG".

BOOM MOUNT VIEW

CONN: 8

CONN: 58

2

CONN: 9

195-9089

Solenoid:

279-6832

Solenoid:

291-5803

Solenoid:

322-5722

Solenoid:

Generator 12.5 KW

2.4 at 12 VDC 400 at 24 VDC

322-6342

Solenoid:

Aux Port A , B Flow Hammer Genrator 15 KW

2.4 at 12 VDC 120 at 24 VDC

342-4355

Resistor:

Fan Speed

34.9

Hydraulic Fan (RVS) Aux Port A Line Relief Pressure Aux Valve Load Sense Pressure

147

98

20.9 ± 1 11.5 ± 0.6

Pin 1 to 2 = 1.3K ± 13 Pin 2 to 3 = 620 ± 6.2 Pin 3 to 4 = 330 ± 3.3 Pin 1 to 4 = 2250 ±

Off-Machine Switch Specification Deactuate

Contact Position

Normally Open

----

A-B Normally Closed B-C Normally Open

----

A-B Normally Closed B-C Normally Open

122

123

36

67

66

65

CONN: 1B

26

CONN: 1A 124

135

¹ At room temperature unless otherwise noted.

294 kPa MIN (42.6 PSI MIN)

100

121

7

99

86 112

83

CONN: 12

96

CONN: 11 165

95 Related Electrical Service Manuals Title

36

Form Number

Alternator:

KENR5290

Starting Motor:

KENR5290

Engine Control:

KENR5429

M300D Electronic Systems:

UENR1770

M300D Monitoring Systems:

UENR1771

97

46 94 93

16

18

17

72

32

CONN: 47 19

HAMMER VALVE ONLY

21

20

31

137

4

133

30

71 88

CONN: 1A / 1B

109 MAIN HYDRUALIC CONTROL

ENGINE AND PUMP COMPARTMENT

Component Part Number

325-AG135 PK-14

CAB LH REAR VIEW

76

Dozer Blade Front / Rear Locks Left / Right Front and Rear Stabilizers MH Dozer Front Lock Joystick Steering Protection

Hydraulic Oil Clog Pressure

CONN: 56

34.9

250 ± 50 kPa and Up (36 ± 7 psi and Up)

1

Part Number: for Connector Plug

5

HYDRUALIC CAB RISER 17.6 ± 0.6

8000 ± 500 KpA and Down 1160 ± 72.5 psi )

CONN: 57

L-C12 3E-5179

Harness Connector Serialization Code: The "C" stands for "Connector" and the number indicates which connector in the harness (C1, C2, C3, ...).

145

Resistance (Ohms)¹

Actuate

L-C12 3E-5179

AG-C4 111-7898

CONN: 22

MACHINE LH REAR VIEW

65.9 ± 3.6

337-5788

75

Harness Identification Letter(s): (A, B, C, ..., AA, AB, AC, ...)

2

CONN: 41

Travel Lock Magnet Boom Float Boom Float Down Heavy Lift Fan Reverse Implement Lock Oscillating Axle Swing Brake Transmission Gear Shift 1,2

Brake Oil Pressure

CONN: 23

CONN: 54

CONN: 46

Solenoid:

337-5776

Wire, Cable, or Harness Assembly Identification: Includes Harness Identification Letters and Harness Connector Serialization Codes (see sample).

CONN: 36

CONN: 24

129-4508

309-5769

Magnetic Latch Solenoid: A magnetic latch solenoid is an electrical component that is activated by electricity and held latched by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.

CONN: 16

A/C Clutch

490 ± 49kPa (71 PSI ± 7.1 PSI)

119

Harness and Wire Symbols

CONN: 27

Component Description

Solenoid: A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work.

CONN: 21

CONN: 26

Solenoid:

Main Pump Pressure Swing Pump Pressure Boom Down Pilot

CONN: 59

Relay (Magnetic Switch): A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay.

CONN: 15

CONN: 34

106-5122

Function

CAB BOTTOM VIEW

CONN: 48

81

Resistor, Sender and Solenoid Specifications

Part No.

Circuit Breaker Symbol

Flow Symbol

Fuse: A component in an electrical circuit that will open the circuit if too much current flows through it.

The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart.

Part No.

Level Symbol

Symbols and Definitions

T

CONN 21

Temperature Symbol

CONN: 7 117 STANDARD UNDERCARRIAGE

FRONT DOZER BLADE OPTION

Wire Gauge Wire Color

(Dimensions: 56 inches x 35 inches)

Machine Location

42 Page,

Component

UENR1270-01 VOL 1 of 2

Schematic Location