Wire Description

Control - Powertrain

E-9

Transmission Shift Solenoid Number 2

Control - Stick

F-5

BU

Transmission Shift Solenoid Number 3 Or 1

Flasher

F-2

OR

Transmission Shift Solenoid Number 4 Or 5

Lamp - Quickshift Indicator

892

BR

893

GN

Converter

900

PU

Transmission Shift Solenoid Number 5 Or 4

YL

Backup Alarm To Lamp

939

PK

Between Connector 4 And 5

123

WH

Temperature Gages and Lockup

975

WH

CST Autoshift-Solenoid Return

124

GN

A/C

6706

WH

Cruise Control On/Off

127

OR

Flood Lamp

6709

BU

Set/Accelerate

128

PK

Kickouts

A273

BK

MAC-14 Transmission Control B -

129

BU

Cigar Lighter

C491

PU

Park Brake Pressure

130

GN

Heater Blower Motor

C922

PU

Service Brake Switch To Powertrain Control

199

OR

Powertrain Control Battery +

C985

BU

Volts +8

Ground Circuits

E705

BU

Impeller Clutch Pressure

Wire Color

102

RD

Battery +

108

BU

Throttle Lock

113

OR

Opr Mon Panel VMIS B+ Switched

118

GY

Front Wiper

119

PK

Rear Wiper

120

YL

121

Description

Wire Number

Wire Color

752

YL

754 755

Power Circuits

Solenoid - Second Gear Clutch #4

A-10

Machine Location 47

C

Solenoid - Third Clutch #3

B-10

47

B

Solenoid - Throttle Lock

B-4

46

C-1

B

Suppressor - Arc

B-5

A

VMIS Start Mod Right (-) Port/Cat Data Link (-)

Lamp - Reducing Rimpull indicator

C-1

B

Switch - Brake Accum Pressure

D-10

10

VMIS Start Mod Right (+) Port/Cat Data Link (+)

LED - Actual Gear

B-10

B

Switch - Hazard

E-1

B

Relay - Backup Alarm

A-8

C

Switch - Key Start

C-6

A

Relay - Throttle Lock

A-5

A

Switch - Park Brake Pressure

D-10

10

Sensor - Impeller Clutch Pressure

E-10

9

Switch - Quickshift

E-1

B

Sensor - LH Pedal

E-4

A

Switch - Reduced Max Rimpull

A-6

A

Sensor - Torque Converter Oil Temp

E-10

9

Switch - Reducing Rimpull Selector

C-1

B

Sensor - Torque Converter Speed

F-10

9

Switch - RH Service Brake Pedal

C-4

A

Solenoid - Air Start

E-10

8

Switch - Steering Trans Lock

F-5

C

Solenoid - First Gear Clutch #5

A-10

47

Switch - Stop Lamp

D-10

10

Solenoid - Forward Clutch #2

B-10

47

Switch - Throttle Lock

B-4

A

Solenoid - Impeller Clutch

F-10

9

Switch - Torque Converter Lockup

D-1

B

Solenoid - Lockup Clutch

F-10

9

Switch - Turn signal

F-1

B

Solenoid - Reverse Clutch #1

B-10

47

200

BK

Main Chassis

E988

PU

WL Rimpull Switch Input 1

201

BK

Operator Monitor Panel

E989

WH

WL Rimpull Switch Input 2

202

BK

Xmsn Cont

F741

WH

Impeller Clutch Resume Switch

240

BK

Engine Speed Con

G746

WH

Transmission Control Torque Limit

241

BK

Operator Monitor Time Delay Pin 3

G747

OR

Transmission Control Lockup Prop Solenoid

G747

WH

Lockup Clutch Solenoid

Basic Machine Circuits

Component

Description Control Circuits (Continued)

306

GN

Starter Relay Coil To Neut Start Sw or Key Sw

G748

PU

Transmission Control Steer Console Switch 1

307

OR

Key Start Switch To Battery +

G749

YL

Transmission Control Steer Console Switch 2

321

BR

Backup Alarm Lamp Travel Alarm

G750

BU

Transmission Control Forward Switch to Ground

331

OR

Backup Alarm Relay Coil

G753

YL

Park Brake Pressure Switch To Powertrain Ctrl

Monitoring Circuits

G755

GY

Transmission Control Reverse Switch To Gnd

Schematic Location

Component Location Machine Location C

Wire Number

Schematic Location

Component

Connector Location

Schematic Location

Connector Number CONN 1

47

CONN 2

9

CONN 3

8

CONN 4

9

CONN 5

A

CONN 6

A

407

PK

Operator Mon Converter/Retarder Oil Temp

G758

PU

Quickshift Switch (N.C.) Lever Steer

432

PK

Operator Monitor Brake Press. (Oil)

G759

WH

Quickshift Switch (N.O.) Lever Steer

452

PU

Torque Converter

G760

WH

Transmission Cont Speed 2 Switch To Ground

467

WH

System Fault (Xmsn)

G761

YL

Transmission Cont Speed 3 Switch To Ground

CONN 7

A

G762

BR

Transmission Cont Speed 4 Switch To Ground

CONN 8

B

CONN 9

B

CONN 10

6

BR

Hazard Indicator Lighting Circuits

G763

PU

G765

GN

Transmission Cont Lever Enable

G768

GN

Transmission Cont Speed 1 Switch To Ground

600

BR

Dash Lamp Basic

G794

OR

Transmission Quickshift Indicator Lamp

604

OR

Stop Lamp

G939

PK

MAC-14 Switch Return

605

YL

Turn Lamp Left

H724

YL

XMSN Cont Impeller Clutch Prop Sol (Was D724)

606

GY

Turn Lamp Right

H735

GY

Driver Signal 1

679

GY

Impeller Clutch Memory Indicator

H736

BU

Driver Signal 2

Control Circuits

H737

YL

Driver Signal 3

709

OR

Sensor Power Supply

P911

PU

Rimpull Switch Input 3

710

GN

Xmsn Speed Pickup Signal

P912

BU

Rimpull Switch Input 4

751

GN

Transmission Shift Solenoid Number 1 or 3

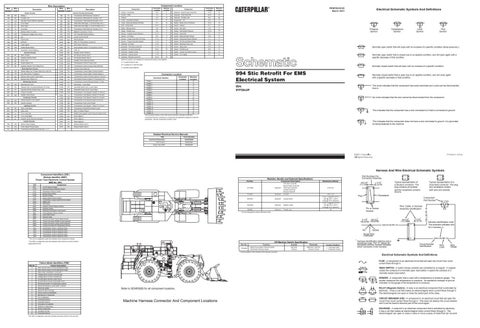

994 Stic Retrofit For EMS Electrical System

Machine Location

Park Brake - Lever Steer

WH

Normally open switch that is closed due to an applied condition, and will open again with a specific decrease in that condition.

Normally closed switch that will open with an increase of a specific condition.

YL

538

Flow Symbol

Level Symbol

Normally open switch that will close with an increase of a specific condition (temp-press-etc.).

B = Located on or near the Dash.

G756

536

Temperature Symbol

Pressure Symbol

C =Located under platform.

Alternator (R) Term.

Transmission Cont Neutral Switch to Ground

T

A = Located inside of cab.

GN

Hazard Switch to turn Switch

Electrical Schematic Symbols And Definitions

RENR6040-00 March 2001

Machine locations are repeated for components located close together.

403

Accessory Circuits

CJLTERPILLAR®

CONN 11

6

CONN 12

B

CONN 13

B

CONN 14

B

Normally closed switch that is open due to an applied condition, and will close again with a specific decrease in that condition.

w

994: 9YF28-UP

The circle indicates that the component has screw terminals and a wire can be disconnected from it.

No circle indicates that the wire cannot be disconnected from the component.

~

CONN 15 B The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart.

~

This indicates that the component has a wire connected to it that is connected to ground.

i¥11-

This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine.

Related Electrical Service Manuals Title

Form Number

Electrical Schematic:

SENR5929

STIC Control:

RENR3306

Power Train ECM:

RENR2522

©2001 Caterpillar Ail Rights Reserved

~'rinled in U.S.A.

Harness And Wire Electrical Schematic Symbols

CID

Part No.

Resistor, Sender and Solenoid Specifications Component Description

147-5399

Solenoid:

First Gear Clutch #5 Second Gear Cl;utch #4 Third Gear Clutch #3 Forward Clutch #2 Reverse Clutch #1

5T-4434

Solenoid:

Air Start

Component

1-----------------------------------0041 +8 Volt Sensor Supply 0138 0143 0144 0168 0190 0191 0248 0444 0603 0623 0626 0627 0628 0650 0672 0678 0679 0826 1401 1402 1403 1404

Reduced Rimpull Selection Switch Neutralizer Pressure Switch Backup Alarm Relay System Voltage Engine Speed Sensor Signal Transmission Output Speed Sensor Signal

1405

Transmission Clutch 5 Solenoid Valve

r C

__

183-2047

Data Link

Start Relay Impeller Clutch Pressure Sensor Direction Switch Steering/Transmission Lock Switch Parking Brake Pressure Switch Quick-Shift Switch Harness Code Torque Converter Output Speed Sensor Torque Converter Impeller Clutch Solenoid Torque Converter Lockup Clutch Solenoid Torque Converter Oil Temperature Sensor Transmission Clutch 1 Solenoid Valve Transmission Clutch 2 Solenoid Valve Transmission Clutch 3 Solenoid Valve Transmission Clutch 4 Solenoid Valve

l

\ ____\_\

Solenoid:

8.15± 0.6

42.0 ± 4.0 7.75 ± 1.0 @ 25°C (77°F) 5.81 @ -40°C (-40°F) 12.68 @ 121°C (249.8°F)

Lockup Clutch

10

9

47

A 6

8

129-6303

B 46

Solenoid:

9X9482

Solenoid:

Resistance (Ohms)¹

7.75 ± 1.0 @ 25°C (77°F) 5.81 @ -40°C (-40°F) 12.68 @ 121°C (249.8°F)

Impeller Clutch Throttle Lock

C 6

Data valid but above normal operational range. Data valid but below normal operational range.

2

Data erratic, intermittent, or incorrect.

3

Voltage above normal or shorted high.

4

Voltage below normal or shorted low.

5

Current below normal or open circuit.

6

Current above normal or grounded circuit.

7

Mechanical system not responding properly.

8

Abnormal frequency, pulse width, or period.

9

Abnormal update.

10

Abnormal rate of change.

11

Failure mode not identifiable.

12

Bad device or component.

13

Out of calibration.

14

Parameter failures.

15

Parameter failures.

16

Parameter not available.

17

Module not responding.

18

Sensor supply fault.

19

Condition not met.

20

Parameter failures.

¹The FMI is a diagnostic code that indicates what type of failure has occurred.

Wire, Cable, or Harness Assembly Identification

~

Pin or Socket Number

68

Part No. 175-3245

Function

Off Machine Switch Specification

Brake Accumulation Pressure Switch Park Brake Pressure Switch

Actuate

Deactuate

Contact Position¹

8270 kPa 1200 psi

6890 kPa ± 345 kPa 1000 psi ± 50 psi

1 - 2 Normally Open 1 - 3 Normally Closed

Typical representation of a Sure-Seal connector. The plug and receptacle contain both pins and sockets. Component Part Number

\. I\\·>+-L-C12* 3E-5179

AG-C4* 111-7898 1

9X-1123

Harness identification code This example indicates wire 32 in harness "L'.

I

Socket

Single Wire Connector * Harness identification letter(s) and a serializing code. The "C" stands for connector and the number indicates which connector in the harness.

2

I

/

200-L32 BK-14

Circuit Number Identification

Wire Color

Wire Gauge

¹ Contact position at the contacts of the harness connector.

9

1

Receptacle

' 2 --H ___

Pin

B

0

H--

\

Plug /

□.

Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

L-C12 * 3E-5179

325-A135 PK-14

A

Failure Description

·--·--·---·--···--·--

□

* C-C4* AG-C3 130-6795 130-6795

² The MID is a diagnostic code that indicates which electronic control module diagnosed the fault.

FMI No.

_l

~, 1

¹ At room temperature unless otherwise noted.

¹ The CID is a diagnostic code that indicates which component is faulty.

Failure Mode Identifiers (FMI)¹

AG-C4 * 111-7898

1 2

1 ' 2

Part Numbers For Connector Assembly

325-L25 PK-14

Component Identifiers (CID¹) Module Identifier (MID²) Power Train Electronic Control System (MID No. 081)

Electrical Schematic Symbols And Definitions

46

10 47

FUSE - A component in an electrical circuit that will open the circuit if too much current flows through it.

8

REED SWITCH - A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

£¥3-1~1 T

Refer to SENR5929 for all component locations.

Machine Harness Connector And Component Locations

--~--6 -'6-t:3-

SENDER - A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure. RELAY (Magnetic Switch) - A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay. CIRCUIT BREAKER (C/B) - A component in an electrical circuit that will open the circuit if too much current flows through it. This does not destroy the circuit breaker and it can be reset to become part of the circuit again. SOLENOID - A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work.