Wire Description

SENR5897 January 1996 FMI No.

Wire Number

0

Data valid but above normal operational range.

1

Data valid but below normal operational range.

2

Data erratic, intermittent, or incorrect.

3

Voltage above normal or shorted high.

4

Voltage below normal or shorted low.

5

Current below normal or open circuit.

6

Current above normal or grounded circuit.

7

Mechanical system not responding properly.

8

Abnormal frequency, pulse width, or period.

9

Abnormal update.

10

Abnormal rate of change.

11

Failure mode not identifiable.

12

Bad device or component.

13

Out of calibration.

Part No.

Module Identifiers (MID)

MID No.

Module

36

Engine Control

CID

Form Number

Alternator (3E-7577): Consist No. 3E-7577

SENR4978

Electronic Monitoring System (EMS)

SENR2945

Starting And Charging Systems

SENR2947

Starting Motor: (6V-0890) Consist No. 6V-0890

SENR3860

Troubleshooting Manual 3408E

SENR1052

Description Lighting Circuits

101

RD

BAT(+)

600

BR

DASH LAMP BASIC

102

BU

HEAD LAMP

604

OR

STOP LAMP

105

BR

KEY SW

607

PK

FLOOD LAMP - FRONT

106

WH

AUX CKT

608

GN

FLOOD LAMP - REAR

109

OR

ALT OUTPUT (+) TERM.

610

OR

HEAD LAMP BASIC

PU

MAIN POWER RLY OUTPUT

615

YL

CAB FLOOD LAMP/ROPS

616

BU

BUCKET FLOOD LAMP/BOOM FLOOD LAMP

Actuate

Deactuate

Contact Position

112

362 ± 29mN (45.6mm ID point) (1.3 ± 0.l oz, 1.8in ID point)

303mN MIN (1.1 oz MIN)

113

OR

OPR MON PANEL +B SWITCHED

Normally Open

114

GN

WARNING HORN (FORWARD)

129.44 ± 2.78°C (264.99 ± 37.00°F)

118.33°C MIN (248.66°F MIN)

115

PK

AUX CKT

A700

OR

DIGITAL SENSOR POWER(+8V)

Normally Closed

118

GY

AUX CKT

A701

GY

INJECTOR #1

119

PK

AUX CKT

A702

PU

INJECTOR #2

120

YL

AUX CKT

A703

BR

INJECTOR #3

121

YL

BCKP ALARM TO LAMP

A704

GN

INJECTOR #4

123

WH

AUX CKT

A705

BU

INJECTOR #5

124

GN

A/C

A706

GY

INJECTOR #6

127

OR

AUX CKT

A707

PU

INJECTOR #7

Coolant Flow (CMS)

7N-9560

Torque Converter Temperature

8N-2248

Hydraulic Oil Temp

101.7 ± 2.8°C (215.0 ± 5.0°F)

93.3°C MIN (200.0°F MIN)

Normally Closed

Power Train Oil Filter Temp

51.7 ± 2.8°C (125.0 ± 5.0°F)

43.0°C MIN (110.0°F MIN)

Normally Closed

Park Brake Pressure

8270 kPa MAX (1 200psi MAX)

6890 ± 345 kPa (1000 ± 50 psi)

Normally Closed

128

PK

AUX CKT

A708

BR

INJECTOR #8

1 .5grams MIN (0.05 oz MIN

BU

AUX CKT

A746

PK

TURBO OUTLET PRESSURE

Primary Steering Flow

4.0 grams Max (0.14 oz Max)

129

Normally Closed

130

GN

AUX CKT

A747

GY

ATMOSPHERIC PRESSURE

131

BR

AUX CKT

A751

YL

AFTER COOLER TEMP

210 ± 70 kPa (30 ± 10 psi)

— —

Normally Open

150

OR

BAT(+)

E793

BU

AT A DATA LINK (-)

158

BR

AUX CKT

E794

YL

AT A DATA LINK (+)

30 ± 7.0 kPa (4.3 ± 1.0 psi)

30 ± 7.0 kPa (4.3 ± 1.0 psi)

Normally Closed

E795

YL

CRANKCASE PRESS

275 to 1 750 kPa¹ (40 to 255 psi)

— —

Normally Open ²

9X-0008

Cylinder 1 Injector Solenoid Cylinder 2 Injector Solenoid Cylinder 3 Injector Solenoid Cylinder 4 Injector Solenoid Cylinder 5 Injector Solenoid Cylinder 6 Injector Solenoid Cylinder 7 Injector Solenoid Cylinder 8 Injector Solenoid Rail Control Valve Throttle Position Sensor Engine Oil Pressure Sensor Coolant Temperature Sensor Rail Pressure Reading Electrical System Voltage Fuel Temperature Engine Oil Temperature Engine RPM Sensor CAT Data Link Personality Module Mismatch Internal ECM Failure Timing Calibration Analog Sensor Power Supply Digital Sensor Power Supply Shutdown Inputs Are Incorrect Programmed Parameter Fault Turbo Outlet Pressure Calibration Atmospheric Pressure Calibration Engine Lamp EMS Engine On EMS Coolant Lamp EMS Oil Lamp Invalid Service Brake Switch Loss Of Sec Engine RPM Signal Ether Inject Control Relay Throttle Lock Lamp Ride Control Switch

Wire Color

3E-6428

9W-2653

Component Engine Control 36

001 002 003 004 005 006 007 008 042 091 100 110 164 168 174 175 190 248 253 254 261 262 263 264 268 273 274 281 284 285 286 298 342 545 548 680

Related Electrical Service Manuals Title

Function

9G-3341

Component Identifiers (CID) List

Off Machine Switch Specification

Wire Number

Description Power Circuits

Failure Mode Identifiers (FMI) List Failure Description

Wire Color

9X-7781

Power Train Filter Pressure

105-91 52 114-5333

Oil Pressure (CMS) Refrigerant Pressure (AC)

Ground Circuits

¹ A hysteresis band exists: with increasing pressure the closed condition can be maintained up to 2800 kPa (405 psi), with decreasing pressure the closed condition can be maintained down to 170 kPa (25psi).

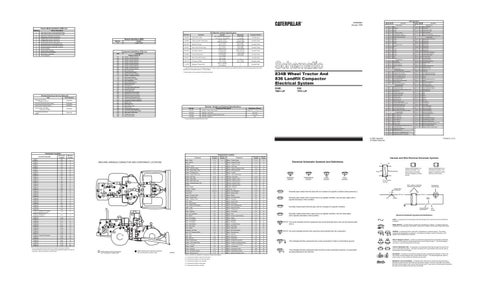

834B Wheel Tractor And 836 Landfill Compactor Electrical System 834B: 7BR1-UP

Part No.

Component Description

836: 7FR1-UP

Resistance (Ohms)¹

9X-4383

Resistor - Blower Motor Speed

100-4512

Solenoid - A/C Clutch

14.4 ± 0.6

107-0677

Solenoid - Injection Actuation Control Valve

10.1 ± 3.0

7N-7259

Solenoid - Start Aid

200

BK

MAIN CHASSIS

E796

GN

OIL PRESS (UNFILTERED)

201

BK

OPR MON PANEL

E797

WH

PWM #3 RETURN

203

BK

CHASSIS DIAGNOSTIC

E798

PK

PWM #3

207

BK

STARTER DIAGNOSTIC

E799

BR

PWM #1 AND #2 RETURN

229

BK

BAT(-)

F700

BU

PWM#1 OUT (3.5A)

A234

BK

J1939 SHIELD GND

F701

BR

PWM#2 OUT (3.5A)

F702

GN

THROTTLE

Basic Machine Circuits

² Contact postion at the contacts of the harness connector.

Resistor, Sender and Solenoid Specifications

Control Circuits

Overall 3.0 ± .15; Tap 1.0 ± .05

302

OR

STARTER NO.1 RESISTOR TO DIAGNOSTIC

F702

GN

THROTTLE

304

WH

STARTER RLY NO.1 OUTPUT

F703

GY

LH TURBINE INLET EXH TEMP

306

GN

STARTER RLY COIL TO KEY SW

F704

OR

RH TURBINE INLET EXH TEMP

307

OR

KEY SW TO SENSOR MODULE

F705

PK

DOUT 6

307

OR

KEY SW TO SENSOR MODULE

F706

PU

DOUT 5

308

YL

MAIN POWER RLY COIL

F707

WH

ETHER CURRENT LEVEL RLY

310

PU

START AID SW TO START AID SOL

F708

YL

DOUT 3

321

BR

BCKP ALARM LAMP

F709

BU

DOUT 2 ETHER ON RELA Y

322

GY

WARNING HORN (FORWARD)

F711

GN

RS232 DATA LINK (T)

Monitoring Circuits

F712

GY

RS232 DATA LINK (R)

403

GN

ALTERNATOR (R) TERM

F713

OR

LEFT TURBO INLET PRESS

404

YL

OPR MON HYD OIL TEMP

F714

PK

RIGHT TURBO INLET PRESS

407

PK

OPR MON CONVERTER/RETARDER OIL TEMP

F715

PU

SHUTDOWN (NO)

409

OR

OPR MON NEUT

F716

WH

SHUTDOWN (NC)

410

WH

OPR MON ACTION ALARM

F717

YL

SW4

411

PK

OPR MON ACTION LAMP

F718

BU

SW5

412

BU

OPR MON COOL FLOW

F719

BR

SW 6/1

414

PK

OPR MON LO FUEL

F720

GN

SW 8/3

415

GN

OPR MON TEST SW

F721

GY

SW 9/4

417

GY

PRIMARY STER SW

F722

OR

SW 10/5

419

YL

OPR MON PARKING BRAKE

F723

PK

TBC PROBE (+)

426

BR

OPR MON POWER TRAIN OIL FIL TER

F724

PU

TDC PROBE (-)

432

PK

OPR MON BRAKE PRESS. (OIL)

F725

WH

FUEL PRESS

441

OR

ENG COOLANT TEMP GAUGE

F726

YL

INJECTOR COMMON

442

GY

HYD SYSTEM TEMP GAUGE

F727

BU

INJECTOR COMMON

443

YL

POWER TRAIN TEMP GAUGE

F728

BR

INJECTOR COMMON

A447

PK

PRELUBE PRESS. SW TO PRE LUBE TIMER

F729

GN

INJECTOR COMMON

F732

PK

BACKUP CAM SPD/TMG

F737

YL

ANALOG SENSOR INPUT 6

Accessory Circuits

6.0

¹ At room temperature unless otherwise noted.

500

BR

WIPER - FRONT (PARK)

501

GN

WIPER - FRONT (LO)

892

BR

CAT DATA LINK (-)

502

OR

WIPER - FRONT (HI)

893

GN

CAT DATA LINK (+)

503

BR

WIPER - REAR (PARK)

993

BR

ANALOG SENSOR COMMON

504

YL

WIPER - REAR (LO)

994

GY

OIL PRESSURE (FIL TERED)

505

BU

WIPER - REAR (HI)

995

BU

COOLANT TEMPERATURE

506

PU

WASHER - FRONT

996

GN

ENGINE SPEED/TIMING SENSOR POWER

507

WH

WASHER - REAR

997

OR

ANALOG SENSOR POWER (+ 5V)

513

OR

A/C COMPRESSOR/REFRIGERANT PRESS. SW

998

BR

DIGITAL SENSOR RETURN

515

GY

BLOWER MOTOR (HI)

999

WH

PRIMARY CAMSHFT SPEED/TIMING

516

GN

BLOWER MOTOR (MEDIUM)

517

BU

BLOWER MOTOR (LO)

519

PK

THERMOSTAT TO REFRIGERANT PRESS. SW

520

WH

OPR A/C SW TO THERMOSTAT/FUSE

593

GN

CONDENSER FAN RELAY TO MOTORS

Printed in U.S.A.

© 1996 Caterpillar All Rights Reserved

Connector Location

Schematic Location

Machine Location

CONN 1

B-2

1

CONN 2

C-2

2

CONN 3

B-3

B

CONN 4

A-4

3

CONN 5

F-4

CONN 6

F-5

CONN 7

F-5

B

CONN 8

E-5

B

CONN 9

D-5

B

CONN 10

C-5

A

CONN 11

B-5

CONN 12

Connector Number

Component Location Schematic Location

Machine Location

Schematic Location

Machine Location

Alarm - Action

C-5

A

Sensor - Coolant Temp

F-13

15

Alarm - Backup

C-15

Alternator

D-9

1

Sensor - Engine Oil Press

E-13

14

2

Sensor - Engine Oil Temp

E-13

14

C

Batteries - 12Volt

C

Breaker - Alternator (80A)

D-15

3

Sensor - Fuel Temp

E-13

14

A-10

D

Sensor - Injection Actuation Press

F-13

16

Breaker - Blower Motor (10A)

B-5

A

Sensor - Primary Cam S/T

F-13

14

Breaker - Condenser Fan

B-9

D

Sensor - Throttle

A-3

17

Breaker - Engine ECM (15A)

A-10

D

Sensor - Turbo Outlet Press

F-13

18

A

Breaker - Key (10A)

B-10

D

Solenoid - A/C Clutch

E-15

19

B-5

A

Breaker - Main (80A)

A-10

D

Solenoid - Injector 1 And 3

E-12

14

CONN 13

A-5

E

Breaker - Rear Wiper (3A)

B-6

A

Solenoid - Injector 2 And 4

D-12

16

CONN 14

A-6

4

CONN 15

C-6

5

Breaker - Running Lamps (10A)

B-10

D

Solenoid - Injector 5 And 7

E-11

20

CONN 16

D-6

C

Bus Bar

E-1 4

3

Solenoid - Injector 6 And 8

D-11

21

CONN 17

D-6

C

Control - Engine

A-1 4

4

Solenoid - Start Aid

C-8

22

CONN 18

D-6

C

B-5

5

Suppressor - Arc

E-15

19

CONN 19

E-6

B

CONN 20

F-7

6

CONN 21

F-7

7

CONN 22

C-7

4

CONN 23

C-7

8

CONN 24

B-7

8

CONN 25

A-7

9

Component

MACHINE HARNESS CONNECTOR AND COMPONENT LOCATIONS

24 15

16

4 18 19

16

15

25 21 12 26

21

1

20

19 12 22

14

3

17

13

18

22

B

6 7

11

C

9

D

11

14 20 10

2

2

6

E

3 17

23

10

7 9

Forward Horn

A

4

8

Converter - Voltage

8

5

1

5

6

13

Component

B-2,F-2

6

Switch - A/C Refrigerant

E-15

19

Fuses (10A)

B-5

A

Switch - Backup Alarm

C-8

23

Gauge - Converter Temp

E-6

B

Switch - Blower

D-6

C

Gauge - Coolant Temp

E-6

B

Switch - Cab Flood Lamp

E-6

B

Gauge - Hydraulic Temp

E-6

B

Switch - Converter

D-8

11

Lamp - Action

E-5

B

Switch - Coolant Flow

F-12

15

CONN 26

B-8

D

Lamp - Check Engine

E-5

B

Switch - Disconnect

D-13

3

CONN 27

C-8

10

Lamp - Throttle Lock Indicator

C-3

B

Switch - Eng Test/Diagnostic

C-6

A

CONN 28

F-9

C

Lighter - Cigar

C-6

A

Switch - Engine Oil Press

B-12

10

CONN 29

E-10

6

CONN 30 Starting and Charging System Diagnostic Connector

Meter - Service

F-5

B

Switch - Forward Horn

D-5

E

A-9

D

Monitor - Operator

B-6

A

Switch - Front Wiper

D-5

B

Motor - A/C Condenser

E-9

C

Switch - Fuel

F-7

24

Motor - Blower

D-6

C

Switch - Ground Level Shutdown

D-14

3

Motor - Floor Heater

A-4

E

Switch - Heater

A-4

A

Motor - Front Washer

F-6

7

Switch - Hydraulic

A-7

13

Motor - Front Wiper

D-5

8

Switch - Key Start

D-5

A

Motor - Rear Washer

F-6

7

Switch - Low Brake Press

F-8

25

Motor - Rear Wiper

F-6

9

Switch - Park Brake

F-7

25

Motor - Starter

D-8

10

Switch - Rear Wiper

D-5

B

Receptacle - Aux Start

D-14

3

Switch - RH Service Brake

C-3

17

Relay - A/C Condenser Motor

B-9

D

Switch - Running Lamp

F-6

B

Relay - Main

A-9

D

Switch - Start Aid

C-6

A

Relay - Start

A-9

D

Switch - Stop Lamp

F-8

25

C

CONN 31 Service Tool Diagnostic Connector

A-10

D

CONN 32

C-10

11

CONN 33

C-12

11

CONN 34

A-11

D

CONN 35

D-11

12

CONN 36

E-11

13

CONN 37

E-12

14

CONN 38

D-12

15

CONN 39

F-12

16

CONN 40

A-12

17

CONN 41

A-12

18

CONN 42 Timing Cal Connector

B-13

19

CONN 43

C-13

20

CONN 44

F-14

14

Relay - Start Aid

B-10

D

Switch - Thermostat

D-6

C

CONN 45

B-15

18

Resistor - Blower Motor

D-6

C

Switch - Throttle Lock On/OFF

C-3

B

CONN 46

B-15

17

Resistor - Floor Heater Motor

A-4

E

Switch - Throttle Lock Resume/Accel

B-3

B

CONN 47

C-15

21

CONN 48

C-15

22

Sender - Converter

E-8

11

Switch - Throttle Lock Set/Decel

B-3

B

Sender - Coolant

D-8

12

Switch - Transmission

D-8

26

Sender - Hydraulic

A-1

13

Switch - Transmission Filter

D-8

26

Sensor - Atmospheric Press

E-13

14

Switch - Transmission Neutral

C-8

23

Sensor - Backup Cam S/T

F-13

14

Valve - Injection Actuation Control

F-13

14

The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart.

9

19

22

16

19

15 12

1 21

3

18

22

20

4 15

16

14 14

21

12

A

10 11

5

B

5

6

17

E

1

6

7

9

11 10

7

8

25

20 13

2 18

D

26

8

23

2

13 24

4 3

17

White callouts are for components, see Component Location chart.

Black callouts are for harness connectors, see Connectorsss Location chart.

D48556

Machine locations are repeated for components located close together. A = Components located in right instrument panel. B = Components located in left instrument panel. C = Components located in cab overhead. D = Components located on relay panel. E = Components located on cab floor.

Harness And Wire Electrical Schematic Symbols

Electrical Schematic Symbols And Definitions

A

AA

2

T

Pressure Symbol

Temperature Symbol

Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

Receptacle

Plug

Level Symbol

Flow Symbol

1 2

1 2

1

Typical representation of a Sure-Seal connector. The plugand receptacle contain both pins and sockets.

Pin or Socket Number Wire, Cable, or Harness Assembly Identification Single Wire Connector

Normally open switch that will close with an increase of a specific condition (temp-press-etc.).

C

A

A 325-PK-14

Normally open switch that is closed due to an applied condition, and will open again with a specific decrease in that condition.

Pin

AA 1

Normally closed switch that will open with an increase of a specific condition.

200-BK-14

Circuit Number Identification

Normally closed switch that is open due to an applied condition, and will close again with a specific decrease in that condition.

Wire Gauge

Electrical Schematic Symbols And Definitions FUSE - A component in an electrical circuit that will open the circuit if too much current flows through it.

The circle indicates that the component has screw terminals and a wire can be disconnected from it.

REED SWITCH - A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

No circle indicates that the wire cannot be disconnected from the component. T

This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine.

9X-1123 325-PK-14

Wire Color

Socket

2

This indicates that the component has a wire connected to it that is connected to ground.

Component Part Number

SENDER - A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure. RELAY (Magnetic Switch) - A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay. CIRCUIT BREAKER (C/B) - A component in an electrical circuit that will open the circuit if too much current flows through it. This does not destroy the circuit breaker and it can be reset to become part of the circuit again. SOLENOID - A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work. MAGNETIC LATCH SOLENOID - A magnetic latch solenoid is an electrical component that is activated by electricity and held latch by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.