Schematic Location

Component

5

C

14

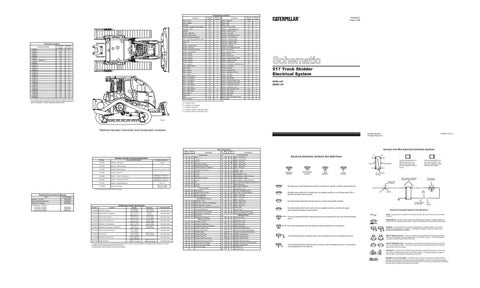

Connector Location Connector Number CONN 1 CONN 2 CONN 3 CONN 4 CONN 5 CONN 6 CONN 7 Diagnostic CONN 8 CONN 9 CONN 10 CONN 11 CONN 12 CONN 13 CONN 14 CONN 15 CONN 16 CONN 17 CONN 18 CONN 19 CONN 22 CONN 23 CONN 24 CONN 25 CONN 26 CONN 27 CONN 28 CONN 29 CONN 30

E

2

Schematic Location F-9 E-9 E-9 D-9 A-8 E-8 F-8 F-7 C-7 A-7 D-6 F-5 D-5 C-S C-5 C-4 F-4 C-3 B-3 D-2 D-2 D-2 D-2 E-2 E-2 F-2 F-2 F-1

Machine Location C C C C C C C C 1 15 A C A A A A C B A 18 18 18 18 18 18 18 18 7

10 18

11

4

B

15 8 22

11

4

The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart.

7

21 6

19

3

1

9

B

D

C

20

14 5

16

12

20 17

2

9

A

D

13

1

17

A

E

8 10 12

16

21 18

15

22

13 19 6

Alarm - Action

E-5

Alarm - Backup

F-9

Alternator

Component Location Machine Location

Component

Schematic Location

Machine Location

1

Relay - Grapple 2

C-8

2

Relay - Main

F-7

C

B-2

3

Relay - Start

F-7

C

Assembly - Grapple Control Handle

B-6

D

Resistor - Blower Motor

A-3

8

Assembly - Relay

D-9

4

Resistor - Starter/Diagnostic

C-2

6

Batteries

F-9

5

Sender - Coolant Temp

E-2

13

Breaker - Alternator

F-8

C

Sender - Fuel Level

E-9

14

Breaker - Blower Motor

F-6

C

Sender - Powertrain Oil Temp

E-2

15

Electronic Monitoring System

E-6

A

Solenoid - Air Conditioner

F-1

16

Fuse - Front Dash and Dome Lamp

F-B

C

Solenoid - Grapple Rotate

A-9

17

Fuse - Key

F-B

C

Solenoid - Grapple Swing

B-9

17

Fuses

F-7

C

Solenoid - Grapple Tong

B-9

17

Gauge - Coolant Temp

C-4

A

Solenoid - Start Aid

F-2

16

Gauge - Fuel Level

C-4

A

Switch - A/C Refrigerant Press

F-2

16

Gauge - Powertrain Oil Temp

C-4

A

Switch - Auto Grab

B-4

D

Ground - Engine Block

B-2

6

Switch - Backup Alarm

E-7

E

Ground - Frame

B-2

6

Switch - Blower

B-3

A

Ground - Frame

F-9

C

Switch - Disconnect

F-9

C

Ground - Module

E-5

A

Switch - Engine Coolant Temp

F-1

13

Ground - Module

F-8

C

Switch - Engine Oil Press

D-1

18

Ground - Module

F-9

C

Switch - Forward Horn

D-6

D

Horn - Forward

F-1

7

Switch - Front Dash and Dome Lamp

C-6

A

Lamp - Master Action

D-6

A

Switch - Front Wiper

B-7

B

Lighter-Cigar

D-6

A

Switch-Fuel Press

C-1

19

Meter - Service

D-6

A

Switch - Grapple Press

C-9

17

Motor - Blower

B-3

8

Switch - Hydraulic Oil Temp

E-9

20

Motor - Blower

D-9

4

Switch - Key Start

C-6

A

Motor - Front Washer

F-8

C

Switch - Left Wiper

B-7

B

Motor - Front Wiper

E-4

9

Switch - Neutral Start

E-7

E

Motor - Left Washer

F-8

C

Switch - Operator Monitor Test

D-6

A

Motor - Left Wiper

E-7

10

Switch - Powertrain Filter Press

A-7

15

RENR2032 August 1998

1

Motor - Rear Washer

F-9

C

Switch - Powertrain Oil Temp

E-1

15

Motor - Rear Wiper

D-8

11

Switch - Powertrain Temp

A-7

15

Motor - Right Washer

F-9

C

Switch - Rear and Side Lamp

C-6

A

Motor - Right Wiper

B-6

12

Switch - Rear Wiper

B-8

B

Motor - Starter

C-2

6

Switch - Right Wiper

B-8

B

Power Post

F-7

C

Switch - Start Aid

D-6

A

Radio Relay - Grapple 1

C-3 C-8

B 1

Switch - Start Aid Coolant Temp Thermostat

F-2 B-3

21 A

517 Track Skidder Electrical System 6PW1-UP 5WW1-UP

Machine locations are repeated for components located close together.

7

A = Located on dash. B = Located in cab overhead.

3

C = Located in fuse panel. D = Located in operator’s right side console. E = Located in operator’s left side console.

D90909

Machine Harness Connector And Component Locations Printed in U.S.A.

© 1998 Caterpillar All Rights Reserved

Wire Number

Wire Color

101

RD

Wire Number

Wire Color

Bat(+)

500

BR

Wiper - Front (Park)

102 105

RD

Hd Lmp

501

GN

Wiper - Front (Low)

RD

Key Sw

502

OR

Wiper - Front (HI)

109

RD

Alt Output (+) Term.

503

BR

Wiper - Rear (Park)

112

PU

Main Power Rly Output

504

YL

Wiper - Rear (Low)

113

OR

Opr Mon Panel B (+) Switched

505

BU

Wiper - Rear (HI)

114

RD

Warning Horn (Forward)

506

PU

Washer - Front

116

BR

Aux Ckt

507

WH

Washer - Rear

118

GY

Aux Ckt

508

PU

Radio Speaker - Left

Description Power Circuits

Resistor, Sender and Solenoid Specifications

Part No.

Component Description

3E-1906

Resistance (Ohms)¹

Solenoid - A/C Clutch

2G-0413

Resistor - OROPS Heater

9G-1950

Resistor - Blower Speed

9G-4365

Solenoid - Start Aid

6N-5926

17.6±0.6 5 Overall 2.0 ± 0.1 Tap 1.0 ± 05

6

Sender - Coolant Temperature

8N-3844

Sender - Powertrain Oil Temp

6T-2217

Resistor - Starter/Diagnostic

123-7408

Sender - Fuel Level

PK

Aux Ckt

509

WH

Radio Speaker - Left (Commom)

524-586 @ 115.6°C(240.1°F) 5806-586 @ 54.4°C(129.9°F)

121

RD

Back Alarm To Lamp

511

BR

Radio Speaker - Right

123

WH

Aux Ckt

512

GN

Radio Speaker - Right (Common)

124

GN

A/C

513

OR

A/C Compressor/Refrigerant Pressure SW

129

BU

Aux Ckt

515

GY

Blower Motor (HI)

158

BR

Aux Ckt Ground Circuits

516

GN

Blower Motor (Medium)

517

BU

Blower Motor (Low)

200

BK

Main Chassis

521

YL

A/C SW To Refrigerant SW

201

BK

Operator Monitor Return

522

WH

A/C Clutch To Thermostat SW

203

BK

Chassis Diagnostic

523

BR

Wiper - Left (Park)

207

BK

Starter Diagnostic Basic Machine Circuits

524

BU

Wiper - Left (Low)

525

GY

Wiper - Left (HI)

150 ± 75 Full: 27.5 - 39.5 Empty: 240-260

Form Number SENR7508

Electronic Monitoring System

SENR2945

Starting and Charging

SENR2947

Starting Motor: 106-8555 Consist No. 6V-5207 Consist No. 6V-5023 Consist No.6V-5226

SENR3581 SENR3536 SENR4979

Part No.

Function

Off Machine Switch Specification

3E-2026 Engine Oil Pressure 3E-2028 Engine Coolant Temperature 3E-6425 Coolant Temp (St Aid) 3E-6451 Hydraulic Oil Temperature 3E-6453 Powertrain Oil Temperature 3E-9350 Powertrain Filter Bypass Temperature 9X-7781 Power Train Filter Pressure 107-0616 Fuel Pressure 114-5334 Refrigerant Pressure (AC) 135-7748 Grapple Pressure

Actuate 60 kPa MAX (8.7 psi MAX) 107.0 ± 3.0°C (224.6 ± 5.4 °F) 38.0 ± 3.0°C (100.0 ± 5.0°F) 107.0 ± 3.0°C (224.6 ± 6.0°F) 129.0 ± 3.0°C (264.0 ± 6.0°F) 52 ± 3°C (125.6 ± 5.4°F) 210 ± 70 kPa (30 ± 10 psi) 93 ± 21 kPa (13.5 ± 3.0 psi) 275 to 1750 kPa¹ (40 to 255 psi) 20103 ± 517 kPa (2915.7 ± 74.9 psi)

Accessory Circuits

119

Related Electrical Service Manuals Alternator: 114-2401

Description

524-586 @ 115.6°C(240.1°F) 5806-586 @ 54.4°C(129.9°F)

¹ At room temperature unless otherwise noted.

Title

Harness And Wire Electrical Schematic Symbols

Wire Description

Deactuate 38 ± 20 kPa (5.5 ± 2.9 psi) 93.00°C (199.4 °F) 27.0°C MIN (81 .0°F MIN) 93.0°C MIN (199.0°F MIN) 118.0°C MIN (244.0°F MIN) 43°C MIN (109.4°F MIN) — — 69 ± 21 kPa (10.0 ± 3.0 psi) — — 18517 ± 517 kPa (2685.6 ± 74.9 psi)

301

BU

Starter No. 1 Sol

526

YL

Wiper - Right (Park)

302

OR

Starter No. 1 Resistor To Diagnostic

527

GN

Wiper - Right (Low)

304

WH

Starter Relay No. 1 Output

528

PK

Wiper - Right (HI)

306

GN

Starter Relay Coil To Neut Start SW Or Key SW

529

WH

Washer Left

308

YL

Main Power Relay Coil

530

OR

Washer Right

310

PU

Start Aid SW To Start Aid Sol

592

BU

DC/DC Converter Power Output

311

WH

Start Aid Sol To Temp SW

593

GN

321

BR

Bckp Alarm

Condenser Fan Relay To Motors Lighting Circuits

322

GY

Warning Horn (Forward) Monitoring Circuits

600

BR

Dash Lamp Basic

607

PK

Flood Lamp - Front

GN

Alternator (R) Term.

608

GN

Flood Lamp - Rear

404

YL

Opr Mon Hyd Oil Temp

609

YL

Flood Lamp - Side

405

GY

Opr Mon Oil Press. (Low Setting)

610

OR

Head Lamp Basic

406

PU

Opr Mon Coolant Temp

630

GY

Flood Lamp Rear (Attach)

Normally Open

410

WH

Opr Mon Action Alarm

A513

PK

DC/DC Converter Memory Output

411

PK

Opr Mon Master

E852

YL

Grapple Tong Close Press Sensor

Normally Closed

413

BR

Opr Mon Fuel Press.

E853

PU

Grapple Tong Open Sol

415

GN

Opr Mon Test SW

E854

GN

Grapple Tong Close Sol

424

GY

Opr Mon Power Train Temp

E855

WH

Grapple Rotate CW Sol

426

BR

Opr Mon Power Train Oil Filter

E856

GY

Grapple Rotate CCW Sol

441

OR

Eng Coolant Temp Gauge

F838

BR

Grapple Tong Close Auto/Manual SW

443

YL

Power Train Temp Gauge

F839

OR

Grapple Tong Off Input

447

PK

Fuel Level Gauge

K932

GN

Swing Sol Left

K934

GN

Swing Sol Right

Contact Position Normally Open Normally Closed Normally Closed Normally Closed Normally Closed Normally Closed

Normally Open² Normally Closed

¹ A hysteresis band exists: with increasing pressure the closed condition can be maintained up to 2800 kPa (405 pressure the closed condition can be maintained down to 170 kPa (25 psi). ² Contact position at the contacts of the harness connector.

403

A

Electrical Schematic Symbols And Definitions

AA

Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

Receptacle

Plug

1 2

1 2

1

2

Typical representation of a Sure-Seal connector. The plug and receptacle contain both pins and sockets.

T

Pressure Symbol

Temperature Symbol

Level Symbol

Flow Symbol

Pin or Socket Number Wire, Cable, or Harness Assembly Identification

Component Part Number

Single Wire Connector C

Normally open switch that will close with an increase of a specific condition (temp-press-etc.).

A

A 325-PK-14

Pin

Normally open switch that is closed due to an applied condition, and will open again with a specific decrease in that condition.

AA 1

Wire Color

Socket

2

Normally closed switch that will open with an increase of a specific condition.

Wire Gauge

Electrical Schematic Symbols And Definitions FUSE - A component in an electrical circuit that will open the circuit if too much current flows through it.

The circle indicates that the component has screw terminals and a wire can be disconnected from it.

REED SWITCH - A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

No circle indicates that the wire cannot be disconnected from the component. T

This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine.

200-BK-14

Circuit Number Identification

Normally closed switch that is open due to an applied condition, and will close again with a specific decrease in that condition.

This indicates that the component has a wire connected to it that is connected to ground.

9X-1123 325-PK-14

SENDER - A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure. RELAY (Magnetic Switch) - A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay. CIRCUIT BREAKER (C/B) - A component in an electrical circuit that will open the circuit if too much current flows through it. This does not destroy the circuit breaker and it can be reset to become part of the circuit again. SOLENOID - A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work. MAGNETIC LATCH SOLENOID - A magnetic latch solenoid is an electrical component that is activated by electricity and held latch by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.