SENR1361-01 April 2001 Schematic Location

Alarm - Action

D-5

Machine Location B

Sender - Converter

D-9

Machine Location 20

Alarm - Backup

B-9

1

Sender - Coolant

D-3

20

Alternator

C-2

21

Sender - Fuel Level

B-9

2

Batteries - 12V

F-2

23

Sender - Hydraulic

D-3

18

Breaker - Lamps Circuit (15A)

A-2

C

Solenoid - Diff Lock

C-9

3

Breaker - Main (80A)

A-3

C

Solenoid - Fuel Shut Dn

C-2

C

Control - Caterpillar Monitoring System

E-4

B

Solenoid - Start Aid

E-2

18

Control - Relay

C-3

C

Solenoids - CST Valve

D-9,E-9

13

Control - Secondary Steering

E-3

C

Suppressor - Arc

C-9

20

B-5

B

Switch - Accumulator Charge Pressure

C-3

C

Component

CID

0096 0100 0110 0177 0248 0263 0271 0324 0600 0819 0821 0830

Component Identifiers (CID¹) Module Identifier (MID²) Caterpillar Monitoring System (MID No. 030) Component

Fuel Level Sender Engine Oil Pressure Sensor Engine Coolant Temperature Sensor Torque Converter Oil Temperature Sensor Data Link Sensor Power Supply Action Alarm Action Lamp Hydraulic Oil Temperature Sensor Display Data Link Display Power Supply Brake Oil Temperature Sensor

Electronic Transmission Control System (MID No. 081)

CID

0070 0149 0168 0190 0248 0356 0363 0367 0368 0596 0621 0622 0623 0631 0632 0633 0634 0635 0636 0638 0650 0671 0687 1521

Component

Parking Brake Switch Ride Control Solenoid 2 Electrical System Voltage Engine Speed Sensor CAT Data Link Tilt Dump Solenoid 1 Ride Control Solenoid 1 Ride Control Switch Transmission Auto/Manual Switch Implement ECM Downshift Switch Upshift Switch Directional Switch Transmission Clutch 1 Solenoid Transmission Clutch 2 Solenoid Transmission Clutch 3 Solenoid Transmission Clutch 4 Solenoid Transmission Clutch 5 Solenoid Transmission Clutch 6 Solenoid Starter Solenoid Harness Code Transmission Output Speed Sensor Options ID Code Part-Throttle Autoshift Selector Switch

¹ The CID is a diagnostic code that indicates which component is faulty. ² The MID is a diagnostic code that indicates which electronic control module

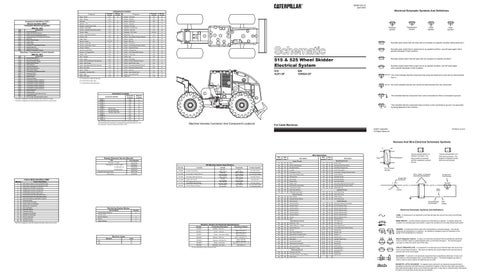

Electrical Schematic Symbols And Definitions

Component Location

Control - Shift

Component

Schematic Location

F-4

B

Switch - Coolant

D-1

20

C-2,F-2

21

Switch - Diff Lock

B-7

A

Ground - Lower Cab

A-7

9

Switch - Disconnect

F-2

21

Ground - Lower Cab - Frame

A-7

9

Switch - Cat Monitoring System Select

C-5

B

Ground - Platform

B-7

9

Switch - Engine Oil Press

D-2

19

Ground - To Cab Roof

E-8

A

Switch - Forward Horn

B-6

B

Ground - To Engine Block

C-2

21

Switch - Front Differential Pressure

F-5

12

Holder - Fuse

B-3

C

Switch - Front Lamp

D-6

14

Horn - Forward

D-1

11

Switch - Key

C-6

B

Lamp - Action

D-5

B

Switch - Park Brake

D-3

C

Lamp - Primary Steering Press Warning

B-6

B

Switch - Primary Steering Pressure

F-3

3

Lamp - Quad Gauge

F-4

B

Switch - Rear/Center Lamp

D-6

14

Lamp - Secondary Steer Press Warning

B-6

B

Switch - Secondary Steering Pressure

E-3

3

Motor - Sec Steer

D-2

3

Switch - Secondary Steering Test

B-6

B

Motor - Starting

C-2

19

Switch - Start Aid

C-7

B

Receptacle - Auxiliary Start

F-2

21

Switch - Xmsn Neutral Lock

C-6

B

Relay - Main

A-2

C

Switch - Xmsn Press Filter

F-7

13

Relay - Sec Steer

D-2

C

Switch As.

C-6

B

Gage - Quad Ground - Frame

T

8

10 12

4

2 3

1

5

17

7

11 9

6

B

22

13

A

20

18

15

C

14

Flow Symbol

Level Symbol

23

21

19

Temperature Symbol

Pressure Symbol

Normally open switch that will close with an increase of a specific condition (temp-press-etc.).

16

Normally open switch that is closed due to an applied condition, and will open again with a specific decrease in that condition.

515 & 525 Wheel Skidder Electrical System 6

7

10

14

515 4LR1-UP

16 15

17

Normally closed switch that will open with an increase of a specific condition.

Normally closed switch that is open due to an applied condition, and will close again with a specific decrease in that condition.

525 1DN524-UP

The circle indicates that the component has screw terminals and a wire can be disconnected from it.

A = Components in right console area. B = Components in dash area.

B

C = Components in relay panel area.

4

C

8

Connector Number

Schematic Location

Machine Location

1

CONN 1 C-9 1 CONN 2 D-9 5 CONN 3 C-8 A CONN 4 B-7 A CONN 5 C-5 B CONN 6 Service Tool D-5 B CONN 7 Service Mode Plug D-5 B CONN 8 Harness Code Plug E-5 B CONN 9 C-4 C CONN 10 D-3 C CONN 11 B-2 C CONN 12 A-2 C The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart.

18

9

3

Connector Location

No circle indicates that the wire cannot be disconnected from the component.

A 12

19

21

22

20

This indicates that the component has a wire connected to it that is connected to ground.

13

2

23

11

5

This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine.

Machine Harness Connector And Component Locations

For Cable Machines Printed in U.S.A.

© 2001 Caterpillar All Rights Reserved

Harness And Wire Electrical Schematic Symbols A

AA

Related Electrical Service Manuals Title

Form Number

Alternator: 114-2401

FMI No. 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

SENR3536

6V-5226 (F8.0)

SENR4975

Caterpillar Monitoring System:

SENR1394

Shift Control:

SENR6685

Failure Mode Identifiers (FMI)¹ Failure Description

Data valid but above normal operational range. Data valid but below normal operational range. Data erratic, intermittent, or incorrect. Voltage above normal or shorted high. Voltage below normal or shorted low. Current below normal or open circuit. Current above normal or grounded circuit. Mechanical system not responding properly. Abnormal frequency, pulse width, or period. Abnormal update. Abnormal rate of change. Failure mode not identifiable. Bad device or component. Out of calibration. Parameter failures. Parameter failures. Parameter not available. Module not responding. Sensor supply fault. Condition not met. Parameter failures.

Off Machine Switch Specification

SENR3581

6V-5023 (KE 7.5)

Wire Color

Wire Number

Wire Color

101

RD

Bat (+)

411

PK

Action Lamp

103 105

YL

Panel Lamps/Gauges

417

GY

Secondary Steering Control

RD

Key Start Switch

419

YL

108

Park Brake Pressure Sw.

BU

To Seat

426

BR

Xmsn Filter Switch

109

RD

Alt Output (+) Term.

432

PK

Accumulator Charge Pressure Switch

112

PU

Main Power Relay Output

441

OR

Coolant Sender

114

RD

Forward Horn

442

GY

Hydraulic Sender

115

RD

Std. Lamps

443

YL

Converter Sender

124

GN

Blower Motor

447

PK

Fuel Level Sender

126

PK

Battery +24V

453

PK

Secondary Steering Pressure Switch

127

OR

Rear/Center Lamp Switch

484

YL

Primary Steering Pressure Switch

136

GN

Tranmission Control

498

WH

Differential Lock

136

RD

Secondary Steering

165

YL

Differential Lock Switch

Description Power Circuits

SENR7508

Starting Motor: 6V-5207 (42MT)

Wire Number

Wire Description

Part No.

Function

3E-6625

Coolant Temperature

3E-7806

Accumulator Charge Pressure

3E-7808

Secondary Steering Pressure

101-5459

Engine Oil Pressure

117-7773

Front Differential Pressure/ Transmission Pressure Filter

128-5091

Actuate 38 ± 3°C (100.4 ± 5.4°F) 9500 kPa (1377 psi MAX) 1100 kPa MAX (160 psi MAX) 90 kPa (13.0 psi MAX) 138 ± 28 kPa (20 psi ± 4 kPa) 551 kPa MAX (80 psi MAX)

Primary Steering Pressure

Deactuate 27 °C (80.6°F MIN) 8300 ± 350 kPa (1200 ± 50psi) 860 ± 170 kPa (125 ± 25 psi) 70 ± 20 kPa (10.0 ± 3.0 psi) 69 kPa MIN (9 psi MIN) 344 ± 20 kPa (50 ± 3 psi)

Contact Position Normally Closed A-B: Normally Open A-C Normally Closed Normally Closed Normally Open Normally Closed A-C: Normally Closed A-B Normally Open

Ground Circuits

Monitoring System Modes

Description Monitoring Circuits

PK

Front Flood Lamp

608

GN

Rear Flood Lamp

200

BK

Main Chassis

614

PU

Switch Lamps

201

BK

Operator Monitor Return

630

GY

Front Flood Lamp

202

BK

Xsmn Ground

270

BK

Harness Code 0

727

GN

Secondary Steering Test Switch

271

BK

Harness Code 1

751

GN

#1 CST Solenoid Valve

272

BK

Harness Code 2

752

YL

#2 CST Solenoid Valve

273

BK

Harness Code 3

754

BU

#3 CST Solenoid Valve

0

274

BK

Harness Code 4

755

OR

#4 CST Solenoid Valve

Harness Code

1

275

BK

Harness Code 5

900

PU

#5 CST Solenoid Valve

Numeric Readout

2

290

BK

Service

901

WH

#6 CST Solenoid Valve

Service

3

291

BK

Clear

921

WH

Solenoid Return

Digital Tattletale

4

944

OR

CAT Data Link +

Number

¹The FMI is a diagnostic code that indicates what type of failure has occurred.

Basic Machine Circuits 301

BU

Starter No. 1 Sol

945

BR

CAT Data Link -

304

WH

Starter Relay No. 1 Output

991

WH

Xsmn Neutral Lock

306

GN

Starter Relay Coil

C436

BU

Front Differential Pressure Switch

307

OR

Key SW

C413

YL

Module Data

308

YL

Main Power Relay Coil

C414

BU

Module Load

310

PU

Start Aid SW To Start Aid Sol

E707

GN

Cluster +V

311

WH

Start Aid Sol To Temp SW

E708

PK

Module Clock

Latch 1.55±10% Unlatch 10.3±10% Empty 96 ± 3; Full 1.75 ± 1.75

321

BR

Bckp Alarm

E735

PU

Operator Switch Input

322

GY

Forward Horn Switch

G750

BU

Forward Sw.

322

GY

Warning Horn (Forward)

G755

GY

Reverse Sw.

31±3 at 25±5 °C

324

BU

Diff Lock Switch to Diff Lock Solenoid

G760

WH

Upshift (N/O)

326

RD

Key SW "C" Term.

G761

YL

Downshift (N/C)

G762

BR

Downshift (N/O)

Resistor, Sender and Solenoid Specifications

Part No. 3E-6332

Machine

Machine Codes

Code

Component Description Solenoid - Start Aid

4W-9972

Sender - Hydraulic

7N-8532

Sender - Converter/ Coolant

152-8385

Solenoid - Diff Lock Solenoid - Fuel Shut Dn

515

59

155-4653

525

60

157-8852

Sender - Fuel Level

186-1526

Solenoids - CST Valve

¹ At room temperature unless otherwise noted.

Resistance (Ohms)¹ 6 560 to 716 at 54 °C 72 to 72 at 110 °C 560 to 716 at 54 °C 72 to 72 at 110 °C 32.6 ± 1.6 at 25 ± 5 °C

Monitoring Circuits 403

GN

Alternator (R) Term.

G763

PU

Neutral Sw.

405

GY

Opr Mon Oil Press. (Low Setting)

G768

GN

Upshift (N/C)

410

WH

Action Alarm

Typical representation of a Sure-Seal connector. The plugand receptacle contain both pins and sockets.

Pin or Socket Number Wire, Cable, or Harness Assembly Identification

Component Part Number

Single Wire Connector C

A

A 325-PK-14

Pin

AA 1

9X-1123 325-PK-14

Wire Color

Socket

2

Control Circuits

Operator Mode Sequence

Service Mode

2

Lighting Circuits 607

Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

Receptacle

Plug

1 2

1 2

1

200-BK-14

Circuit Number Identification

Wire Gauge

Electrical Schematic Symbols And Definitions FUSE - A component in an electrical circuit that will open the circuit if too much current flows through it. REED SWITCH - A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

T

SENDER - A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure. RELAY (Magnetic Switch) - A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay. CIRCUIT BREAKER (C/B) - A component in an electrical circuit that will open the circuit if too much current flows through it. This does not destroy the circuit breaker and it can be reset to become part of the circuit again. SOLENOID - A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work. MAGNETIC LATCH SOLENOID - A magnetic latch solenoid is an electrical component that is activated by electricity and held latch by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.