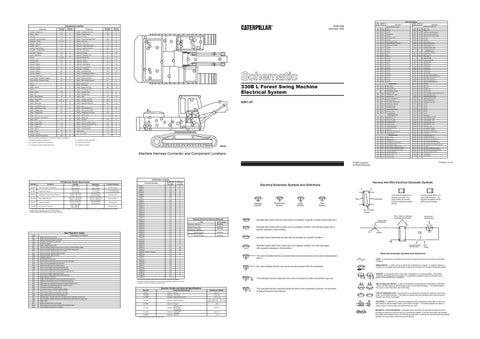

Component Location Schematic Location

Machine Location

Schematic Location

Machine Location

Actuator - Engine Gov

A-9

1

Sender - Hydraulic Oil Temp

A-5

11

Alarm - Travel

G-9

2

Sensor - Engine Speed

B-8

Alternator

C-8

3

Sensor-Fuel Level

F-8

D

H-8, l-8

Breaker - Alternator

Wire Number

SENR1688 December 1996

Wire Description

Wire Color

Wire Number

Description

Wire Color

Description Accessory Circuits Cont

Power Distribution Circuits 101

RD

Bat (+)

576

PK

Wiper - Aux

103

RD

Aux Ckt

578

BU

Washer - Aux

105

RD

Key Sw

590

GY

Wiper Sw to Intermittent Module

6

107

RD

Eng Shutdown

592

BU

DC/DC Converter Power Output

A-5

12

108

BU

Aux Ckt

A513

RD

DC/DC Converter Memory Output

Sensor - Pump Discharge Press

B-8

13

109

RD

Alt Output (+) Term

A571

PU

Aux Ckt 1

4

Sensor - Sun Load

F-1

E

111

RD

Aux Ckt

A572

PK

Aux Ckt 2

112

PU

Main Power Rly Output

A579

OR

Wiper Motor (+)

I-8

D

Solenoid - A/C Clutch

C-9

14

113

OR

Opr Mon Panel B (+) Switched

A586

OR

Wiper Sw to Wiper Cant

Breaker - Main

I-8

D

Solenoid - Eng/Pump Control

A-7

15

114

RD

Warning Horn (Forward)

A588

GN

Safety Sal Relay to Sol

Control - Engine/Pump

F-2

C

Solenoid - Engine Shutdown

B-8

6

115

PK

Aux Ckt

C537

GN

A/C Photo Sensor (+) Sig

Controller - Wiper/Washer

E-1

E

Solenoid - Fine Swing

E-7

16

118

GY

Aux Ckt

C538

OR

A/C Photo Sensor (-) Sig

120

YL

Aux Ckt

Converter - Voltage

C-S

A

Solenoid - Grapple

E-7

16

123

WH

Aux Ckt

607

PK

Flood Lamps - FrontBoom

Diode - Main Relay

H-7

D

Solenoid - Hydraulic Lock

I-1

F

124

GN

A/C

615

YL

Cab Flood Lamp

I-4,5,6

B

Solenoid-Level Finish

A-7

15

129

BU

Aux Ckt

616

BU

140

BU

Aux Ckt

147

PU

Aux Ckt

763

BU

Torque Converter Sw

149

PU

Aux Ckt

786

GN

Eng Speed Cant

150

RD

Bat (+)

788

YL

Eng Speed (+)

151

GN

Aux Ckt

791

PK

Eng Speed Cont

152

BU

Aux Ckt

A755

PK

Throttle Sw #1

154

RD

Aux Ckt

A756

BU

Throttle Sw #2

168

RD

Aux Ckt

A757

GY

Throttle Sw #3

172

RD

Aux Ckt

A758

BR

Throttle Sw #4

177

RD

Main Brkr

A761

PU

Elec Pump Cont Gov Feedback

180

GN

Aux Ckt

A762

PU

Elec Pump Cant Eng Speed Ground

185

YL

Aux Ckt

A768

BU

Pump Control Valve #1 (+)

Component

Assembly - Terminal Block Batteries - 12VDC

Fuses

Component

17

B 18

2 10

4

20

D

9

A

5 8

3

14

F

C

E

7

24

Lighting Circuits

Flood Lamp Control Circuits

Ground - Cab

B-5

5

Solenoid - Rotate

D-7

16

Ground - Cab

E-1

E

Solenoid - Start Aid

H-9

17

Ground - Chassis

A-3

6

Solenoid - Swing Brake

E-7

16

Ground - Chassis

A-8

7

Solenoid - Travel Speed

A-7

15

Ground - Chassis

I-8

D

Solenoid - Trenching

A-7

15

Ground - Platform

G-2

F

Switch - Air Cleaner Flow

H-9

18

H-1

F

H-3

B

Ground - Relay Panel

H-7

D

Switch - Backup EPR Valve

E-5

C

Ground Strap - Chassis to Platform

I-6

8

Switch - Backup Governor

D-5

C

Ground Strap - Chassis to Riser

H-1

F

Switch - Boom Raise Pressure

D-7

C

189

RD

Aux Ckt

A769

GY

Pump Control Valve #2 (-)

Horn

A-2

7

Switch-Coolant Level

H-9

17

191

WH

Aux Ckt

A770

PK

Elec Pump Control Bypass Sw

Lighter

E-1

E

Switch - Disconnect

I-8

D

A771

PU

Float Sw

Meter - Service

F-1

E

Switch - Engine Oil Press

B-9

19

Monitor

F-1

E

Switch - Fine Swing Control

D-4

C

Motor - Starter

B-B

6

Switch - Grapple Close

F-2

C

Motor - Tilt

I-9

F

Switch - Grapple Open

I-1

B

Motor - Upper Washer

I-9

D

Switch - Horn

I-1

B

Motor - Upper Wiper

C-5

9

Switch - Hydraulic Oil Filter

A-5

11

C-6, I-3

A

Switch - Hydraulic Oil Level

A-5

11

Relay - Boom Lamp

I-7

D

Switch - Implement Pressure

D-7

16

Relay - Cab/Chassis Lamp

E-8

D

Switch - Key

F-2

C

Relay - Cab/Chassis Lamp

I-7

D

Switch - Neutral Start Limit

I-1

B

H-6

F

F-2

C

Relay - Grapple Open

H-5

F

Switch - Refrigerant Low Press

C-9

17

Relay - Horn

I-7

D

Switch - Rotate CCW

F-2

C

Relay - Hydraulic Lock Solenoid

I-7

D

Switch - Rotate CW

I-1

B

Relay - Main

G-7

D

Switch - Start Aid

D-5

C

Relay - Neutral Start

F-7

D

Switch - Start Aid Coolant Temp

B-9

10

Relay - Rotate CCW

H-6

F

Switch - Suction Line Shutoff Limit

A-6

11

Relay - Rotate CW

H-5

F

Switch - Throttle Position

E-3

C

Relay - Start

F-8

D

Switch - Travel Pressure

D-7

16

Relay - Timer

E-7

D

Switch Panel

F-2

C

Resistor - Backup

I-B

D

Unit - A/C, Heater

H-5

20

Sender - Coolant Temperature

B-9

10

Ground - Platform

Radio - 12VDC

Relay - Grapple Close

Switch - Aux Hydraulic Pressure

Switch - One Touch Low Idle

16

1

12

19

21

23

22

6

13

11 15

Ground Circuits

330B L Forest Swing Machine Electrical System 5

9 A 24

6DR1-UP

23

B

10 3

14

21 2

16

18 11

6

13

20 22 8

4

15

Main Chassis

F771

OR

Backup Sw

201

BK

Opr Mon Panel

F772

WH

Backup Sw

235

BK

Elec Pump Ctrl Gnd

F773

OR

Governor Accel

Basic Machine Circuits

F774

WH

Governor Decel

301

BU

Starter No. 1 Sol

J704

WH

Hyd Lock Sal Relay to Grapple and Rotate Sw

304

WH

Starter Rly No. 1 Output

J705

WH

Rotate CCW Relay to Sol

306

GN

Starter Rly Coil

J706

PU

Grapple Close Relay to Sol

307

OR

Key Sw to Neut Start Sw

J707

YL

Grapple Open Relay to Sol

308

YL

Main Power Rly Coil

J708

BR

Rotate CW Relay to Sol

310

PU

Start Aid Sw to Start Aid Sol

J709

GN

Cab/Chassis Lamp Relay

311

WH

Start Aid Sol to Temp Sw

J710

WH

Aux Ckt

320

OR

Horn Rly Coil to Sw

J711

GN

Aux Ckt

321

BR

Travel Alarm Lamp

J712

YL

Aux Ckt

322

GY

Warning Horn (Forward)

J713

BU

Aux Ckt

326

RD

Key Sw "C" Term

J714

BR

Aux Ckt

386

PK

Air Shutoff Enable

J715

OR

Aux Ckt

961

GN

Hyd Cont Sw

Monitoring_Circuits

F

D

BK

E

1

19

17

C

200

12 7

403

GN

Alternator (R) Term

K903

BR

Dual HP Relay to Controller

405

GY

Opr Mon Oil Press

K904

GN

Pump Discharge - Signal

412

BU

Opr Mon Cool Flow

K905

RD

Pump Discharge - (+) B

430

BU

Opr Mon Air Filter

K906

GN

Swing Brake Sol - Signal

487

OR

Hyd Oil Flow Sw

K907

BU

Swing Brake Sal - (+) B

491

PK

Hyd Oil Temp Sensor

K909

BU

Backup Sw - (+) B

492

GY

Coolant Temp Sensor

K911

PK

E/P Controller - RS485 (+)

495

GN

Fuel Level

K912

GN

E/P Controller - RS485 (-)

496

WH

Opr Mon Panel Hyd Oil Level

K915

GN

Fine Swing Sw - E/P Controller

C468

BU

Engine Oil Level

K997

BU

(+) V Sensor

L908

OR

Controller RS-232C TX

Accessory Circuits

Machine locations are repeated for components located close together.

501

GN

Wiper - Front

L909

BU

Controller RS-232C RX

506

PU

Washer - Front

L968

OR

Elec Pump Control PS Valve (-)

508

PU

Radio Speaker - Left

L969

WH

Elec Pump Control PS Valve (+)

A Located in operator’s compartment.

D = Located on or near relay panel.

B = Located in operator’s left console area.

E = Located in dash area.

509

WH

Radio Speaker - Left (Common)

L970

GY

Elec Pump Control to Switch Return

C = Located in operator’s right console area.

F = Located in Cab Riser.

511

BR

Radio Speaker - Right

L971

GN

Elec Pump Control to Travel Pressure Sw

512

GN

Radio Speaker - Right (Common)

L972

BU

Low Idle Sw

513

OR

A/C Compressor/Refrigerant Press Sw

L973

GN

Fine Swing Cont Relay to Sol Valve

519

PK

Thermostat to Refrigerant Press Sw

L974

GN

Elec Pump Cant Boom Raise Press Sw

546

BU

Aux Hyd - Rotate CW

L975

PK

Start Aid Cant Lamp 1 Output

547

OR

Aux Hyd - Rotate CCW

L977

YL

Trenching Sol

548

GY

Aux Hyd - Open

L978

GY

Level Finish Sol

549

PK

Aux Hyd - Close

Machine Harness Connector and Component Locations

Printed in U.S.A.

© 1996 Caterpillar All Rights Reserved

Part No. 3E-6449 3E-6455 106-0179 106-0180 106-0181

Function

Off Machine Switch Specification

Connector Location

Actuate

Deactuate

Contact Position

38.0 ± 3.0°C (100.4 ± 5.4°F)

27 °C MIN (80.6 °F MIN)

Normally Closed

90 ± 21 kPa (13 ± 3.0 psi)

70 ± 21 kPa (10 ± 3.0 psi)

A-B, Normally Open A-C, Normally Closed

Implement Pressure Travel Pressure

1225.00 ± 98.00 kPa (177.67 ± 14.21 psi)

882.00 kPa MIN (127.92 psi MIN)

Normally Open

Boom Raise Pressure

2646.00 ± 196.00 kPa (383.77 ± 28.43 psi)

2156.00 ± 196.00 kPa (312.70 ± 28.43 psi)

Normally Open

490.00 ± 49.00 kPa (71.07 ± 7.11 psi)

290.00 kPa MIN (42.06 psi MIN)

Normally Open

Start Aid Coolant Temperature Engine Oil Pressure

Hydraulic Pressure

275 to 1750 kPa ¹ 114-5333 A/C High/Low Pressure Normally Open ² (40 to 255 psi) ¹ A hysteresis band exists: with increasing pressure the closed condition can be maintained up to 2800 kPa (405 psi), with decreasing pressure the closed condition can be maintained down to 170 kPa (25psi). ² Contact postion at the contacts of the harness connector.

Real Time Error Codes Code

Description of Problems

Schematic Location

Machine Location

CONN 1

A-9

21

CONN 2

F-9

D

CONN 3

F-9

D

CONN 4

G-9

D

CONN 5

G-9

D

CONN 6

G-8

D

CONN 7

G-8

D

CONN 8

G-8

D

CONN 9

F-8

D

CONN 10

C-6

5

CONN 11

C-5

5

CONN 12

C-5

F

CONN 13

C-5

F

CONN 14

F-5

C

CONN 15

F-5

C

CONN 16

F-5

C

CONN 17

F-5

C

CONN 18

F-4

C

CONN 19

F-4

C

CONN 20

F-4

C

Alternator: (100-5047)

SENR2082

CONN 21

F-4

C

CONN 22

H-5

B

Engine/Pump Control

SENR9291

CONN 23

H-5

B

SENR9292

CONN 24

H-5

B

CONN 25

H-4

B

CONN 26

H-4

B

Starting And Charging Starting Motor: (6V-0512) Consist: 6V-0512 Starting Motor: (6V-5227) Consist: 6V-5538

CONN 27

H-4

B

CONN 28

H-3

B

CONN 29

H-3

B

CONN 30

C-3

F

CONN 31

B-3

7

CONN 32

A-3

22

CONN 33

B-2

23

CONN 34 Service Connector

D-2

C

CONN 35

B-2

24

CONN 36

G-5

F

CONN 37

G-5

F

CONN 38

G-8

F

CONN 39

G-8

F

CONN 40

G-8

F

CONN 41

F-9

F

CONN 42

F-9

F

CONN 43

G-9

F

CONN 44

G-9

F

CONN 45

G-9

D

CONN 46

H-9

F

Connector Number

A

Pressure Symbol

Related Electrical Service Manuals Title

Form Number

1304

Air filter is clogged.

1305

Battery voltage is not normal.

2201

Governor actuator feedback sensor circuit is open or shorted battery voltage.

2202

Governor actuator feedback sensor circuit is shorted to body ground.

2301

Governor actuator feedback signal is not stable.

2302

Governor actuator feedback signal deviates.

2303

Governor actuator does not move.

2304

Calibration data error.

3201

Monitor RAM is not normal.

4101

Electric power supply to the controller is too much (43 volts).

4102

Over-current in proportional reducing valve.

4103

Proportional reducing valve circuit is open.

4105

Over-current in digital output (trenching solenoid).

4106

Over-current in digital output (fine control solenoid).

4107

Over-current in digital output (travel speed change solenoid).

4108

Over-current in digital output (travel alarm).

410A

Over-current in digital output (swing break solenoid).

4201

Engine speed is not normal.

4202

Engine coolant temperature sensor is shorted to body ground.

4203

Hydraulic oil temperature sensor is shorted to body ground.

4204

PWM sensor of pump delivery pressure is shorted to body ground.

4207

PWM sensor of pump delivery pressure is open in circuit.

420A

Fuel sensor is shorted to body ground.

420B

Fuel sensor is open or shorted to battery voltage.

420C

Electric power supply is too low (below 23 volts).

420D

Electric power supply is too high (above 32 volts).

102-8017

Resistor - Backup

52.0 ± 2.6

420E

Engine speed dial is not one of the specified 10.

134-3998

Solenoid - A/C Clutch

17.6 ± 0.6

4301

Data mismatch 1 between alternator and speed sensor (alternator is abnormal).

111-9916

Solenoid - Engine/Pump Control

4302

Data mismatch 2 between alternator and speed sensor (speed sensor is abnormal).

A202

Monitor takes too much time to respond to controller’s signal.

A203

Communication is abnormal in controller.

Component Description

Solenoid - Engine Shutdown

3E-9205

Solenoid - Grapple

121-1491 121-1490 3E-6332 ¹ At room temperature unless otherwise noted.

Hydraulic Lock Solenoid - Swing Brake Travel Speed Level Finish Solenoid Trenching Solenoid - Start Aid

Normally open switch that will close with an increase of a specific condition (temp-press-etc.).

Component Part Number

Single Wire Connector C

Normally open switch that is closed due to an applied condition, and will open again with a specific decrease in that condition.

A

A 325-PK-14

Pin

AA 1

9X-1123 325-PK-14

Wire Color

Socket

2

FUSE - A component in an electrical circuit that will open the circuit if too much current flows through it. REED SWITCH - A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

No circle indicates that the wire cannot be disconnected from the component.

Resistance (Ohms)¹

11.7 ± 1 .2 Start (Latch) Coil - 1.55 ± 0.15 Stop (Unlatch) Coil - 10.3 ± 1.03 24.9

This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine.

Wire Gauge

Electrical Schematic Symbols And Definitions

The circle indicates that the component has screw terminals and a wire can be disconnected from it.

This indicates that the component has a wire connected to it that is connected to ground.

200-BK-14

Circuit Number Identification

Normally closed switch that is open due to an applied condition, and will close again with a specific decrease in that condition.

CONN 47 H-9 F The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart.

Resistor, Sender and Solenoid Specifications

Wire, Cable, or Harness Assembly Identification

Normally closed switch that will open with an increase of a specific condition.

Hydraulic oil temperature is too high.

3E-7985

2

Typical representation of a Sure-Seal connector. The plugand receptacle contain both pins and sockets.

SENR4975

1303

Monitor communication is not normal.

Flow Symbol

SENR3860

Engine coolant temperature is too high.

Engine stalls.

Level Symbol

Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

Pin or Socket Number

1302

4303

Temperature Symbol

1 2

1 2

Receptacle

Plug

T

Engine oil pressure is too low.

A201

AA 1

1301

Part No.

Harness And Wire Electrical Schematic Symbols

Electrical Schematic Symbols And Definitions

T

SENDER - A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure. RELAY (Magnetic Switch) - A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay. CIRCUIT BREAKER (C/B) - A component in an electrical circuit that will open the circuit if too much current flows through it. This does not destroy the circuit breaker and it can be reset to become part of the circuit again. SOLENOID - A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work.

32.0 ± 3.2 32.0 ± 3.2 6.0

MAGNETIC LATCH SOLENOID - A magnetic latch solenoid is an electrical component that is activated by electricity and held latch by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.