4 minute read

Auxiliary Hoists and Overhead Crane "

AUXILIARY HOISTS AND OVERHEAD CRANE

Adjustment of Load Brake

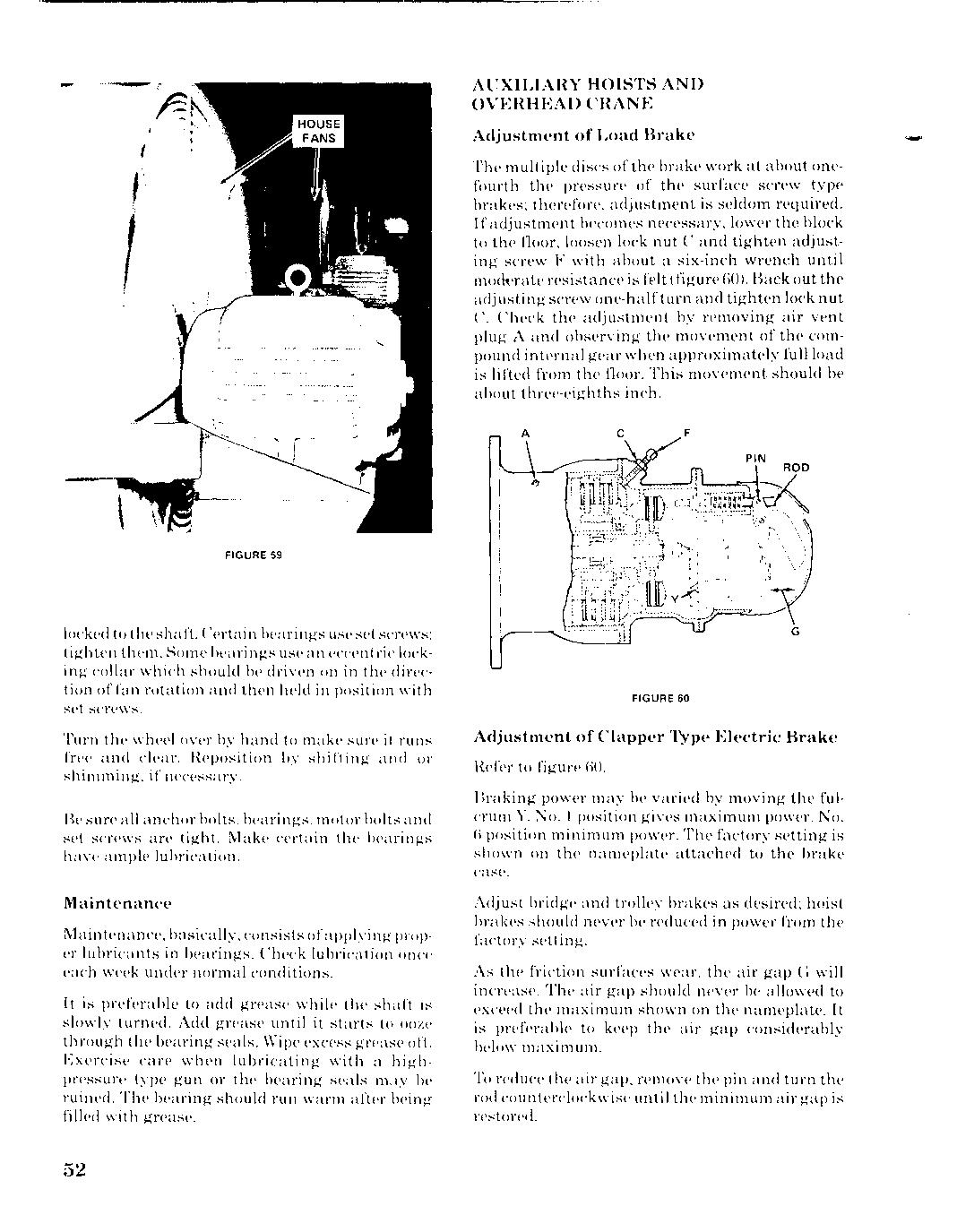

The multiple multiple discs of the brake work at about onefourth the pressure of the surface screw type brakes; therefore, adjustment is seldom required. Ifadjustment becomes necessary, lower the block to the £1001', loosen lock nut C and tighten adjusting ing screw F with about a six-inch wrench until resistance resistance is felt (figure 60). Back outthe adjusting screw one-halfturn and tighten lock nut C. Check the adjustment by removing air air vent plug A and observing the movement of the the compound internal gear when approximately full load is lifted from the £1oor. This movement should be about three-eighths inch.

A c

F

FIGURE 59

locked to the shaft. Certain bearings useset screws; tighten them. Some bearings use an eccentric locking collar which should be driven on in the direction offan rotation and then held in position with set screws. eccentric the

Turn the wheel over by hand to make sure it runs free and clear. Reposition by shifting and or shimming, if necessary. to

Be sure all anchor bolts, bearings, motor bolts and set screws are tight. Make certain the bearings have ampIe ple lubrication.

Maintenance

Maintenance, basically, consists ofapplying proper lubricants in in bearings. Check lubrication once each week under normal conditions. conditions.

It is preferable to add grease while the shaft is slowly turned. Add grease until it starts to ooze through the bearing seals. Wipe excess grease off. Exercise care when lubricating with a highpressure type gun or the bearing seals may be ruined. The bearing should run warm after being filled with grease. while Wipe gun seals

FIGURE 60

Adjustment of Clapper Type Electric Brake

Refer to figure fiO.

Braking power may be varied by moving the fulcrum Y. No.1 position gives maximum power, No. () position minimum power. The factory setting is shown on the nameplate attached to the brake case. moving the

Adjust bridge bridge and trolley brakes as desired; desired; hoist brakes should never be reduced in power from from the factory setting.

As the friction surfaces wear, the air gap G will increase. The air gap should never be allowed to exceed the maximum maximum shown on the nameplate. nameplate. It is preferable to keep the air gap considerably below maximum.

To reduce the air gap, remove the pin and turn the rocl counterclockwise until the minimum air gap is restored.

Inspect the machines daily (figure G1).

Oil level should be maintained as close as possible to the top ofthe oil gauges (figure (2). An excess or deficiency of oil could damage the machine.

Oil should be sufficiently fluid to flow freely into the openings provided and rise within the enclosure to a level corresponding with the top ofthe oil gauge.

To assure correct oiling, the oil gauge should be left open for several minutes after filling to verify the oil does not overflow the oil gauge or sink below the correct level.

When servicing oil gauge B, a good grade of automobile engine oil is preferred (S.A. E. 40 for winter and S.A.E. 50 for summer). For grease connection C, apply a good grade of solidified oil with a vis-

FIGURE 61 A- AIR VENT B- OIL GAUGE C- GREASE CONNECTION D- DRAIN PLUGS E- OIL GAUGE

FIGURE 62

cosity of400 at 100°F. Oil should he drawn offand cases refilled as often as necessary to keep the oil in good condition. Remember this when drain plug D is pulled. Use a very light automobile oil (about S.A.E 10) for oil gauge E.

FREQUENCY

Anti-friction bearing motors require mInImUm lubrication. Motors provided with external means of lubrication should be reluhricated sparingly after approximately 1500 hours operation. Use a good grade of ball bearing grease.

Anti-friction bearings, shafts, axles, sheaves, etc., should be checked monthly. Use a good grade of ball bearing grease.

Check gearboxes for leaks and proper oil levels after 50 hours operation. After this, a semi-annual check should be sufficient. Ifthe equipment is subject to extreme weatherconditions, a lighter weight oil should he used in winter and a heavier weight for the summer. Heavy oil will increase the load on the motor in cold weather. Use a good grade of gear oil (S.A.E. :Hl for 1 HP, S.A.K for :15 HP, S.A.K 90 to fiOO for over:15 lIP).

Open gearing should he checked at least once a month, more often if conditions warrant it. Use a good grade of adhesive gear compound.

The proper oil level of lubricated electric brakes should be checked after 50 hours of operation. Check it at least once a month thereafter. Ifthe oil is dirty from wear particles, f1ush the case and fill it with fresh oil. A non-adhesive S.A.E. 10 weight, non-detergent oil is satisfactory.