Off Machine Switch Specification Part No.

Function

Actuate

3E-6449 Temperature

27°C MIN

38 ± 3°C(100 ± 5°F)

(80.6°F)

Normally Closed

93.0°C MIN

(224.6± 6.0°F)

(199.0°F MIN)

VIB Charge Pressure

1400 kPa MAX

1100 ± 150 kPa

A-C Normally Closed

Propel Charge Pressure

(205 psi MAX)

(160 ± 22 psi)

A-B Normally Open

103-4977 Engine Oil Pressure

60.0 kPa (8.7 psi)

107-611 Engine Oil Pressure

–

93.00 ± 21.00 kPa

70.00 ± 21.00 kPa

(13.49± 3.05 psi)

(10.15 ± 3.05 psi)

110-514 Hydraulic Oil Temperature

Normally Closed

Normally Open Normally Open

92 ± 1.5 °C

85°C

A-B Normally Open

(197.6 ± 34.7 °F)

(185°F MIN)

B-C Normally Closed

275 to 1750 kPa¹

114-5333 A/C High/Low Pressure

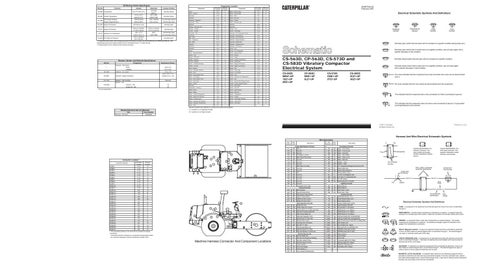

Component Location

Schematic Location

Machine Location

Schematic Location

Machine Location

Alarm

E-2

3

Alarm - Backup

F-10

5

Relay - Neutral Start

G-3

B

Relay - Neutral Start

H-3

Alternator

G-10

B

8

Relay - Start

E-5

4

Amplifier

H-15

B

Relay - Start Aid

E-7

14

Assembly - Regulator Assembly - Timer

I-13

B

Relay - Throttle

E-5

4

E-9

14

Relay - Warning Light

G-2

B

H-10

1

Resistor

B-14

B

Breaker - Alternator Ckt

G-6

B

Rheostat

B-14

B

Breaker - Throttle

F-5

B

Sender - Fuel

G-10

19

Control - Throttle

G-4

A

Sensor - VIB Speed

H-12

20

Controller - VIB

C-15

B

Solenoid - A/C Compressor Group

D-7

8

Converter

F-13

A

Solenoid - Axle Interlock

H-9

11

Dial - CMV

F-15

A

Solenoid - Drum Interlock

H-8

11

Dial - Frequency

G-15

A

Solenoid - Engine Shutdown

Dial - RMV

F-15

A

Diode #1

D-6

Diode #2 Diode #3 Fuses

Contact Position

107.0 ± 3.0°C

3E-6451 Coolant Temperature 3E-7382

Deactuate

– Normally Open² (40 to 255 psi) ¹ A hysteresis band exists: with increasing pressure the closed condition can be maintained up to 2800 kpa (405 psi), with decreasing pressure the closed condition can be maintained down to 170 kpa (25 psi). ² Contact position at the contacts of the harness connector.

Component

Batteries

H-10

7

Solenoid - Speed Shift

E-8

12

A

Solenoid - Throttle Control

H-7

7

D-6

A

Solenoid - VIB Control

H-9

21

D-6

A

Switch - A/C

D-8

B

H-5

B

Switch - A/C Refrigerant

C-6

8

G-12

B

Switch - Backup Alarm

H-4

B

Gauge - Fuel

B-3

A

Switch - Beacon

I-5

B

Gauge - VPM Tach

B-4

A

Switch - Brake

H-4

B

Gauge - Warning

B-5

A

Switch - Coolant Temperature

G-10

8

Ground - Platform

H-12

10

Switch - Disconnect

H-9

2

Group - Conditioner/Heater

B-9

18

Switch - Engine Oil Pressure

H-8

22

Heater - Air Inlet

E-7

13

Switch - Engine Oil Pressure

Horn - Forward

D-2

10

Switch - Fan

Lamp - Alternator Indicator

B-6

A

Meter - Hour

B-2

A

Motor - Front Washer Fluid

C-8

15

Motor - Front Wiper

B-12

Fuse - Recording Module

Resistor, Sender, and Solenoid Specifications Part No.

Component

Resistance (Ohms)¹

Solenoid - VIB Control

–

Fixed:

24.6 ± 2.0

Variable: 3E-1906

21.7 ± 2.0

Solenoid - A/C Clutch

17.6 ± 0.6 Latch:1.55 ± 0.15

8C-3663

Solenoid - Engine Shutdown

137-1761

Resistor - VIB Controller

Unlatch:10.3 ± 1.03 130 ± 6.5

Sender - Fuel 144-9420

Full:27.5 - 39.5

-12

Empty:240 - 260

-20

¹ At room temperature

Component

Motor - Rear Washer Fluid

H-8

22

D-10

B

Switch - Flood Light

H-6

B

Switch - Front Wiper

C-10

B

Switch - Horn

D-2

A

17

Switch - Hydraulic Oil Temperature

E-9

23

C-8

15

Switch - Key

C-6

A

Motor - Rear Wiper

C-12

16

Switch - Neutral Start (Propel Pump)

G-7

14

Motor - Starter

H-10

6

Switch - Propel Charge Pressure

H-7

24

Recorder

I-15

B

Switch - Rear Wiper

C-10

B

Receptacle - Housing

H-14

B

Switch - Ref VIB

C-14

B

Relay - Brake

G-3

B

Switch - Speed Select

D-2

A

Relay - Brake

G-3

B

Switch - Start Aid

C-5

A

Relay - Coolant Temperature

H-2

B

Switch - Temperature

F-9

14

Relay - Engine Oil Pressure

H-2

B

Switch - Throttle

C-2

A

Relay - Function Light

G-2

B

Switch - VIB Charge Pressure

F-7

25

Relay - Hydraulic Oil Pressure

H-3

B

Switch - VIB On/Off

H-4

B

Relay - Hydraulic Temperature

G-2

B

Switch - VIB Select

H-5

B

Relay - Main

E-5

4

KENR7039-02 February 2001

Electrical Schematic Symbols And Definitions

T

Title

Form Number

Alternator: 9W-3043

Flow Symbol

Level Symbol

Normally open switch that will close with an increase of a specific condition (temp-press-etc.). Normally open switch that is closed due to an applied condition, and will open again with a specific decrease in that condition.

CS-563D, CP-563D, CS-573D and CS-583D Vibratory Compactor Electrical System CS-563D: 9MW1-UP 1SZ1-UP 2RZ1-UP

CP-563D: 9ZW1-UP 5LZ1-UP

CS-573D: CMK1-UP 2YZ1-UP

Normally closed switch that will open with an increase of a specific condition.

Normally closed switch that is open due to an applied condition, and will close again with a specific decrease in that condition.

CS-583D: 2CZ1-UP 3GZ1-UP

The circle indicates that the component has screw terminals and a wire can be disconnected from it.

No circle indicates that the wire cannot be disconnected from the component.

This indicates that the component has a wire connected to it that is connected to ground.

This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine.

Machine locations are repeated for components located close togather.

Related Electrical Service Manuals

Temperature Symbol

Pressure Symbol

A = Located in or on Steering Console. B = Located in or on Right Console.

SENR3685

Printed in U.S.A.

© 2001 Caterpillar All Rights Reserved

Harness And Wire Electrical Schematic Symbols Wire Description Wire Number

Wire Color

Description

Wire Number

Wire Color

Power Distribution Circuits

1 5

14

23

24 12

19 8 13

Connector Location¹

21

CONN 1

Schematic Location H-15

Machine Location 10

CONN 2

F-14

A

CONN 3

G-13

A

CONN 4

H-13

10

CONN 5

H-13

10

CONN 6

H-12

10

CONN 7

H-12

10

CONN 8

H-12

10

CONN 9

C-12

16

CONN 10

B-12

17

CONN 11

C-10

26

CONN 12

B-9

18

CONN 13

C-9

B

CONN 14

C-9

B

CONN 15

D-9

B

CONN 16

D-8

26

CONN 17

C-7

8

CONN 18

D-7

8

CONN 19

D-7

8

CONN 20

G-6

9

CONN 22

G-6

9

CONN 23

G-6

9

CONN 24

E-5

4

CONN 25

E-5

4

Connector Number

CONN 26

E-5

4

CONN 27

H-4

B

CONN 28

E-4

10

CONN 29

E-3

10

CONN 30

E-3

10

11

16

A

18

17

7 3

22 6

2

15

26

1

10

B 9 25

4

20

16 A 13 7

8

B 3

14 26

23 2 5

19

6

22

21

RD

Bat (+)

500

BR

Wiper - Front (Park)

103

YL

Aux Ckt

501

GN

Wiper - Front (Low)

105

RD

Key Sw

502

OR

Wiper - Front (HI)

109

RD

Alt Output (+) Term.

503

BR

Wiper - Rear (Park)

112

PU

Main Power Rly Output

504

YL

Wiper - Rear (Low)

115

PK

Aux Ckt

505

BU

Wiper - Rear (HI)

116

BR

Aux Ckt

506

PU

Washer - Front

118

GY

Aux Ckt

507

WH

Washer - Rear

121

YL

Back Alarm To Lamp

513

OR

A/C Compressor/Refrigerant Pressure SW

122

RD

Aux Ckt

515

GY

Blower Motor (HI)

123

WH

Aux Ckt

516

GN

Blower Motor (Medium)

124

GN

A/C

517

BU

Blower Motor (Low)

128

RD

Aux Ckt

521

YL

A/C SW To Refrigerant SW

143

BR

Aux Ckt

522

WH

A/C Clutch To Thermostat SW

143

RD

Aux Ckt

567

WH

A/C SW Jumper

148

WH

Aux Ckt

568

GN

Warning Buzzer To Diodes

160

PU

Aux Ckt

181

GY

Eng Speed Ctrl (+) Bat

603

PK

Rotary Beacon

Ground Circuits

603

PU

Rotary Beacon

BK

Main Chassis

607

PK

Flood Lamp - Front

220

BK

Eng Oil Press Sensor

608

GN

Flood Lamp - Rear

221

BK

Eng Coolant Temp Sensor

226

BK

Hyd Oil Temp Sensor

751

GN

XMSN Shift Sol No1 Or 3

276

BK

XMSN Ctrl Ident Code 0

776

YL

Brake Release Relay Cont

277

BK

XMSN Ctrl Ident Code 1

777

PU

Brake Release Motor

Basic Machine Circuits

916

OR

Scraper XMSN Gear Code 6

9

15 18

4

10

11 12

1 20 24 25

CONN 31 E-2 10 ¹ The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located

BU

Starter No1 Sol

919

GN

Eng Overspeed Test SW

304

WH

Starter Relay No1 Output

920

GN

Oil PressSW To Lift Detent

306

GN

Starter Relay Coil To Neut Start SW

921

WH

XMSN Sol No 1 Or 3 Return

307

OR

Key SW To Neutral Start SW

923

YL

XMSN Sol No 3 Or 1 Return

308

YL

Main Power Relay Coil

924

OR

XMSN Sol No 4 Or 5 Return

309

GY

Alternator Regulator Term.

A919

BU

Left Eng Throttle SW To Relay/Diode

311

PU

Start Aid Sol To Temp SW

A920

BR

Left Eng Throttle SW To Relay/Diode

321

BR

Backup Alarm Lamp

A953

PK

Right Console Eng Throttle SW To Relay/Diode

322

GY

Warning Horn (Forward)

A982

BR

Eng Throttle Cont

326

RD

Key SW "C" Term.

A983

BU

Eng Throttle Cont - Signal

330

YL

Neutral Start Relay Coil

B919

GN

VIB On/Off SW To FWD/REV SW

373

GN

Start Aid Switch To Timer

B920

GN

FWD/REV (Fwd) SW To EDC

377

OR

Start Aid Resistor To Start Aid

B921

WH

FWD/REV (Rev) SW To EDC

C720

BU

Relay Interlock

400

GN

Service Meter SW

C905

OR

Cont to Relay

405

GY

Opr Mon Oil Press(Low Setting)

C906

PU

Cont to SW

406

PU

Opr Mon Coolant Temp

C930

BR

Functional Lights GP to Relay

428

OR

Opr Mon Xmsn Oil Temp

C931

OR

Warning Lights GP to Relay

439

YL

Lamp Indicator

C938

BR

Diagnostic Warning Horn

447

PK

Fuel Level Gauge

F765

BR

Park Brake SW To Relay

450

YL

Tach Sender (+)

465

OR

Low Charge PressWarning

Monitoring Circuits

at or near the component. See the Component Location Chart.

Machine Harness Connector And Component Locations

Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

2

Typical representation of a Sure-Seal connector. The plugand receptacle contain both pins and sockets.

Pin or Socket Number Wire, Cable, or Harness Assembly Identification

Component Part Number

Single Wire Connector C

A

A 325-PK-14

Pin

AA 1

9X-1123 325-PK-14

Wire Color

Socket

2

200-BK-14

Circuit Number Identification

Control Circuits

301

1 2

1 2

Receptacle

Plug

Lighting Circuits

200

AA 1

Accessory Circuits

101

17

A

Description

Wire Gauge

Electrical Schematic Symbols And Definitions FUSE - A component in an electrical circuit that will open the circuit if too much current flows through it. REED SWITCH - A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

T

SENDER - A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure. RELAY (Magnetic Switch) - A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay. CIRCUIT BREAKER (C/B) - A component in an electrical circuit that will open the circuit if too much current flows through it. This does not destroy the circuit breaker and it can be reset to become part of the circuit again. SOLENOID - A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work. MAGNETIC LATCH SOLENOID - A magnetic latch solenoid is an electrical component that is activated by electricity and held latch by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.