11 minute read

Face Shovel Operation – Restricted Operation

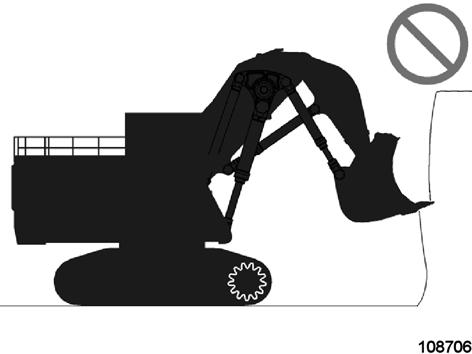

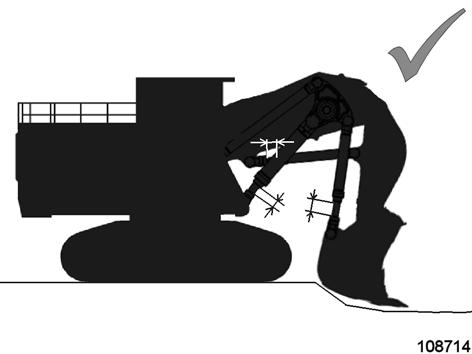

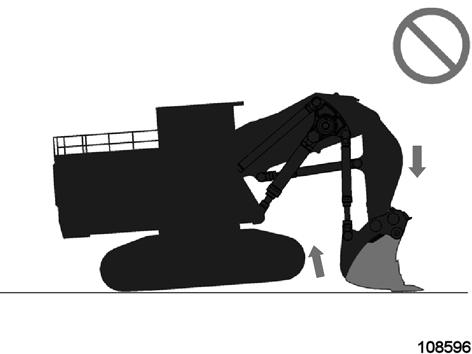

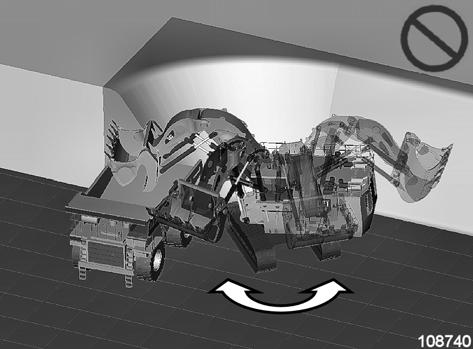

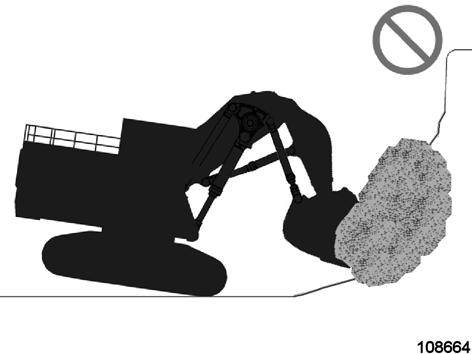

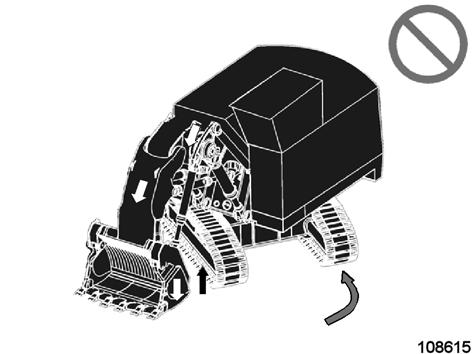

Avoid extreme positions of the attachment. Parts of the attachment may damage the machine e.g. the tracks if they are moved to close to the machine (Fig. 2-170:).

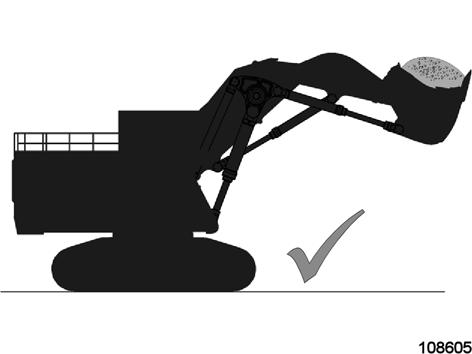

Do not operate the machine when

- one or several teeth

- parts of the hardfacing

- lip shrouds or side shrouds

- or other parts of the bucket are worn or missing (Fig. 2-171:).

Working under these conditions reduces digging performance, results in heavy wear, potentional damage and high repair costs.

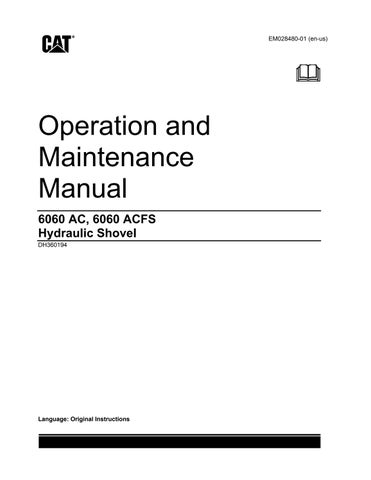

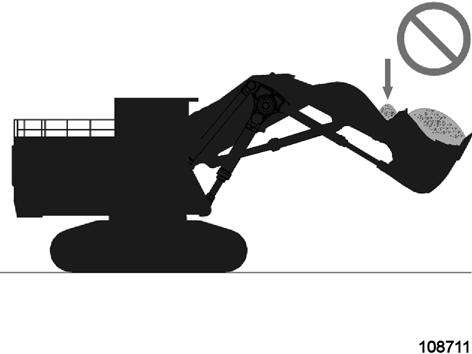

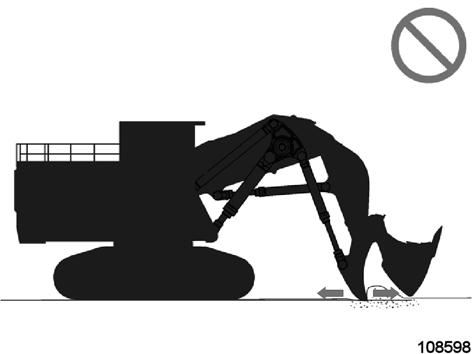

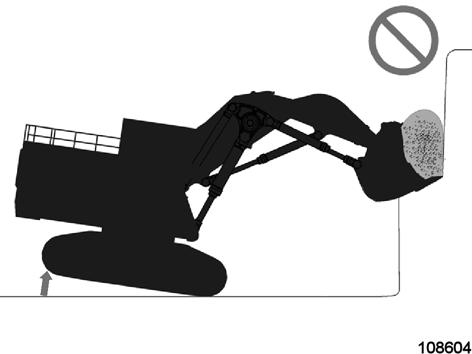

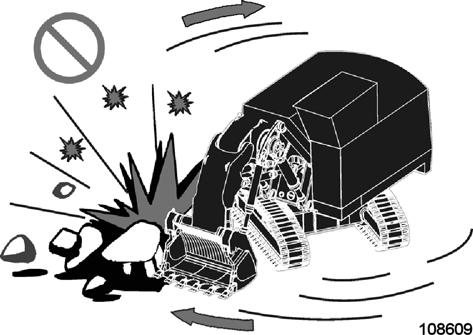

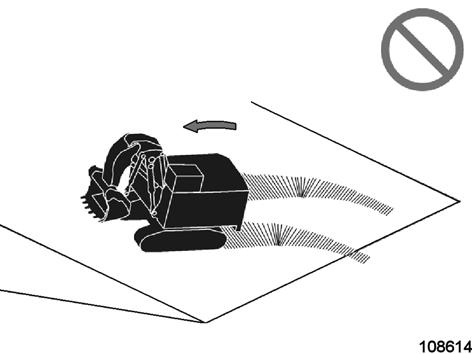

Do not operate the machine on uneven, rough ground (Fig. 2-172:).

Doing so is extremely detrimental to undercarriage component life.

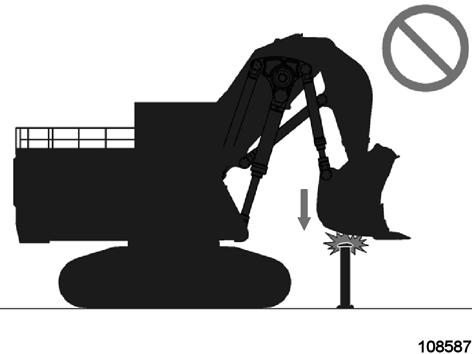

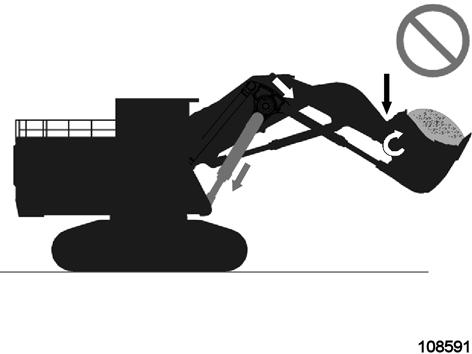

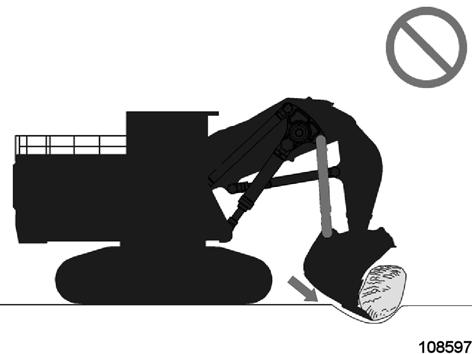

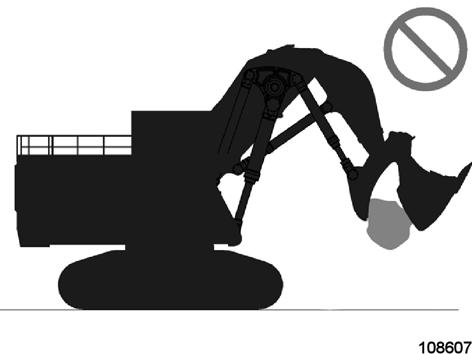

Do not use the dropping force of the bucket as a hammer, breaker or pile driver (Fig. 2-173:). This will bring excessive force on the machine and possible damage to the machine could result.

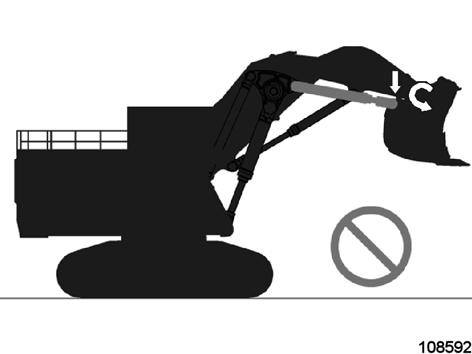

Do not operate the machine with the final drives facing the attachment (Fig. 2-174:). There is a risk of damaging components of the gearboxes and sprockets and hydraulics.

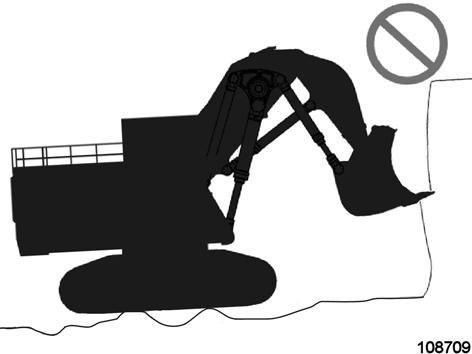

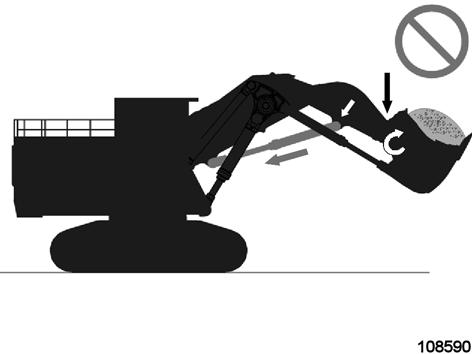

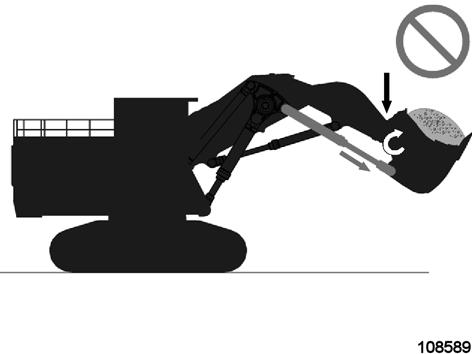

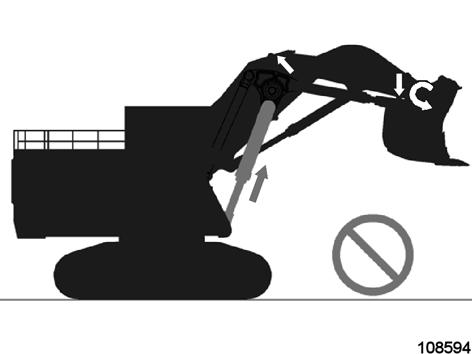

Do not operate the cylinders to the end of stroke during operation (Fig. 2-175:), excessive force will occur on the inside of the cylinder. This will reduce the life of the cylinder and the structures. To avoid this issue, always leave a small margin of play when the cylinder is operated (Fig. 2-176:). If cylinders must be operated to the end of stroke, extend or retract speed must be reduced to 10%.

Do not operate cylinders to the end of stroke during operation, excessive force will occur on the inside of the cylinder.

This will reduce the life of the cylinder and structures.

To avoid this issue, always leave a small margin of play when the cylinder is operated (Fig. 2-176:).

If cylinders must be operated to the end of stroke, extend or retract speed must be reduced to 10%.

Do not operate the machine in unsuitable material for digging (Fig. 2-177:).

Ensure material is blasted or has appropriate penetrability and material fragmentation.

Operating the machine in inappropriate conditions will reduce durability, productivity and increase cost of ownership.

If material conditions cannot improve, the bucket or working tool may need to be exchanged. Please consult your dealer for machine bucket and/or work tool options and recommended operational/maintenance techniques in severe applications.

Avoid working in materials having higher density than appropriate for bucket or work tool (Fig. 2-178:).

If unavoidable, operate the machine at reduced bucket loads to avoid overloading, tipping and reducing machine durability.

Do not operate the clam cylinders to the end of stroke when opening the shovel clam (Fig. 2-179:), excessive force will occur on the inside of the cylinder. This will reduce the life of the cylinder and the structures.

To avoid this issue, always leave a small margin of play when the clam is opened.

If the clam must be operated to the end of stroke, cylinder speed must be reduced to 10%.

Do not extend the bucket cylinder to cause contact between bucket and stick stops (located on the top of the stick) (Fig. 2-180:).

Curl out the bucket to avoid contact with the stick. The bucket may contact the stick when the stick is retracted or the boom is lowered.

Curl out the bucket when lowering the boom or retracting the stick to avoid contact.

The bucket may contact the end of the travel stops located on the top of the stick when the stick is retracted (Fig. 2-181:).

Curl out the bucket when retracting the stick to avoid contact.

The bucket may contact the end of travel stops located on the top of the stick when the boom is lowered (Fig. 2-182:).

Curl out the bucket when lowering the boom to avoid contact.

Do not retract the bucket cylinder to cause contact between the travel stops between the stick and bucket (located on bottom of the stick) (Fig. 2-183:).

Curl in the bucket to avoid contact.

The bucket may contact the end of the travel stops located on the bottom of the stick when the stick is extended (Fig. 2-184:).

Curl in the bucket when extending the stick to avoid contact.

The bucket may contact the end of the travel stops located on the bottom of the stick when the boom is raised (Fig. 2-185:).

Curl in the bucket when raising the boom to avoid contact.

Be aware that no rocks or other material are between the bucket and the stick (Fig. 2-186:). Crushing rocks or other material between bucket and stick will damage stick and bucket.

Do not engage the bank or any other material when the clam is not fully closed (Fig. 2-187:). This will damage the clam and the clam cylinders.

Do not push down on the attachment with the clam in contact with the ground (Fig. 2-188:).

Do not use the fully curled bucket for tamping the ground.

Doing so will damage the clam, the bucket, the bucket cylinder or other parts of the attachment.

Do not dig with the bucket cylinder fully retracted and the bucket teeth stuck in the ground (Fig. 2-189:). The attachment will be subjected to excessive force.

Do not open the clam and use the bucket backwall or rear of clam for grading operations, as this will damage the bucket backwall and the clam (Fig. 2-190:).

Do not use the bucket clam for loosening or removing anchored rocks or other solid objects, since such operations may result in severe damage to the clam pivot bearings (Fig. 2-191:).

Do not suspend a loaded bucket for more than 5 minutes (Fehler! Verweisquelle konnte nicht gefunden werden.). Ground the bucket.

Do not swing a load over an unprotected truck cab or over personnel (Fig. 2-193:).

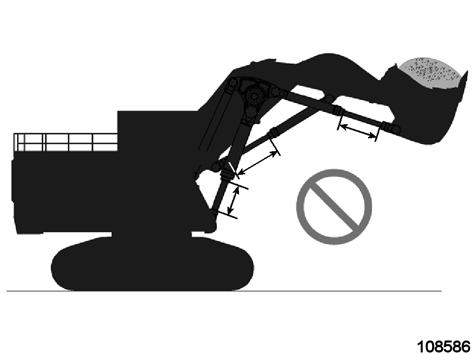

Do not overload the attachment and do not allow the rear of tracks to rise off the ground. Do not undercut a bank (Fig. 2-194:), undercutting a bank could result in bank collapsing and material falling onto the attachment.

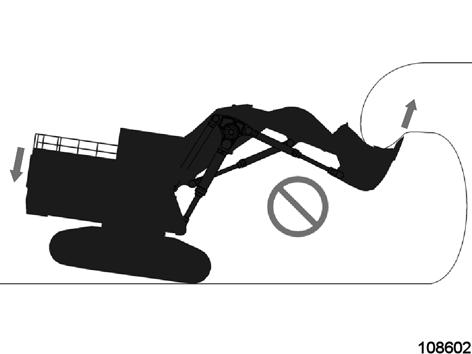

Do not use the dropping force weight of the machine to pry material in the bank or for excavation (Fig. 2-195:). Doing so may damage the machine and the attachment.

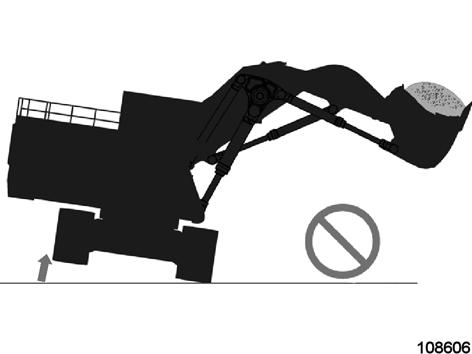

If the tracks rise off the ground while digging, lower the machine back to the ground smoothly (Fig. 2-196:).

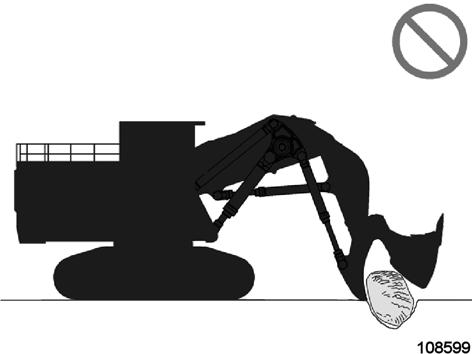

Do not try to move or load oversized material pieces (Fig. 2-197:). Doing so could damage the attachment.

Machine stability is reduced when the load is swung to the side and when operating the attachment perpendicular to the tracks (Fig. 2-198:). Sudden stopping of the attachment movement can result in the tipping of the machine, especially when the attachment is perpendicular to the tracks. Never overload the attachment.

Machine stability is greater when the load is positioned parallel with the tracks and over the front idlers (Fig. 2-199:).

Never try to catch falling / rolling material using the attachment (Fig. 2-200:). Doing so can extremely overload the structures and can result in severe damage of mechanical and hydraulic components.

Do not use the clam to grip rocks or other objects (Fig. 2-201:).

Do not use the clam, the bucket backwall, or the bucket to scrap down rocks or material (Fig. 2-202:).

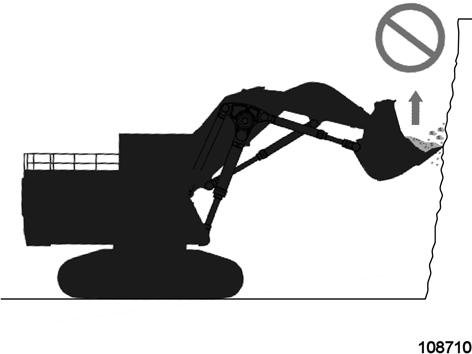

Do not raise the bucket to scrape the wall to loosen or remove material (Fig. 2-203:).

This is an extremely damaging practice and will reduce the lifetime of the shovel.

Do not sweep the pit floor.

Do not swing the machine while the bucket is engaged in the material (Fig. 2-204:).

Do not stop swinging by contacting an object such as a bank or ditch.

Do not start swinging until the bucket is completely removed from the bank.

Do not begin digging before the swing motion is stopped.

Do not propel the machine while the bucket is engaged in the material (Fig. 2-205:).

This operation will potentially damage components of the attachment.

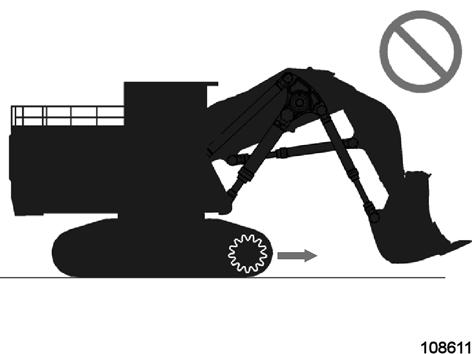

Do not propel the machine longer than 5 minutes with the propel motors to the front (Fig. 2-206:).

Do not attempt to travel on slopes with the bucket loaded or any load suspended from the bucket. Never attempt to ascend or descend steep slopes, refer to the Operation and Maintenance Manual for maximum slope.

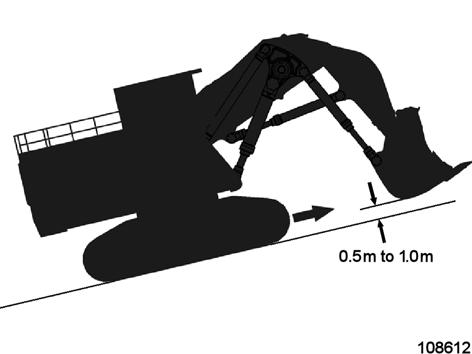

Keep the bucket pointed in the direction of travel, approximately 0.5 to 1.0 m above the ground (Fig. 2-207:).

If the machine starts to skid or becomes unstable, lower the bucket to the ground immediately. Avoid swinging the upper carriage on slopes. Never attempt to swing the upper carriage downhill. The machine may tip over.

If swinging uphill is unavoidable, carefully operate the upper carriage and boom at slow speed.

If the engine stalls on a slope, immediately lower the bucket to the ground. Return joysticks to neutral.

Then, restart engine

Be sure to thoroughly warm-up the machine before ascending steep slopes. If the hydraulic oil has not warmed-up sufficiently, performance may be effected.

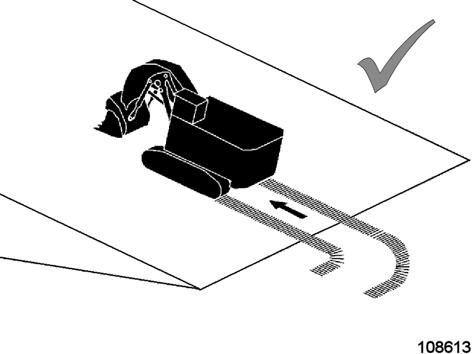

Always ascend the slope at a 90 degree angle (Fig. 2-208:).

Driving across the face of a slope or steering on a slope may cause the machine to slide or tip over (Fig. 2-256:).

If the direction must be changed, move the machine to level ground, then, change the direction to ensure safe operation.

Do not exceed the maximum machine inclination for working operation (Fehler! Verweisquelle konnte nicht gefunden werden.).

Refer to section “Maximum Machine Inclinations” for further information.

Do not use the force of the bucket, the stick or the boom to assist in turning the machine while the machine is propelling (Fig. 2-211:).

This technique is referred to as “jump steering.”

The force applied to the swing motor and swing drive by this method may cause damage to the swing motor and swing drive.

For proper turning procedures refer to section “Traveling”.

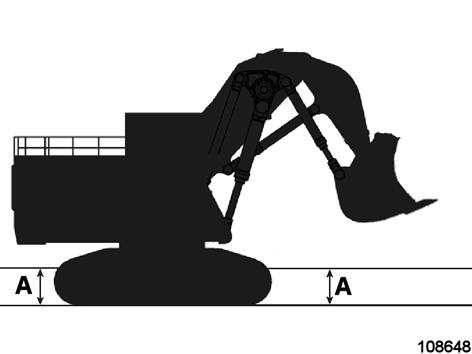

When working in any body of water or mud be careful that the level of water or mud is not higher than the breather valves on top of the final drives (Dimension A, Fig. 2-212:).

Water or mud could enter the gearboxes and cause serious damages.

While you cross any body of water or mud, carefully confirm the depth of the water or mud with the bucket. Do not move the machine into an area that has a water or mud depth that is higher than the breather valves of the final drives (Dimension A, Fig. 2-212:).

TRAVELING Traveling - Safety Instructions

Personnel

Any work with the machine must be executed only by reliable, skilled and well trained personnel in good healthy condition. Statutory minimum age limits must be observed.

Avoid aggressive operating practices and never operate the machine while impared with drugs or alcohol.

Do not overload the machine.

State of operator’s workplace

Inspect and fasten your seat belts. Adjust the operator’s seat for comfortable reach all controls and pedals. Adjust for operator height and weight.

Keep your workplace clean. Remove all unsecured items like tools and other supplies from the cab.

Clean off any earth, mud, snow, ice, grease and oil adhering to your working footwear before operating the machine. There is otherwise a risk of slipping off the pedals and initiating inadvertent movements.

Clean and secure all windows and doors.

Clean and adjust all mirrors and cameras (if equipped) for optimum vision.

Travel the machine only while sitting on the operator’s seat.

State of the machine

The engines must be at operating temperature before being subjected to full load.

If the machine is to be driven a longer distance, the upper structure must be secured against turning by means of the upper structure holding brake.

Sound the horn to warn persons in the immediate vicinity before starting traveling.

Sound the horn and allow adequate time for bystanders to clear the area before moving the machine into a restricted visibility area. Follow local practices for your machine application. For more information refer to Operation and Maintenance Manual, section "Restricted Visibility".

Clear the hazard range of the machine

Check the surrounding area around the machine (the hazard range of the machine):

No personnel around the machine.

No personnel on the machine outside the cab.

State of the site and machine stability

Before starting traveling, inspect the condition of the ground you want to travel on. The machine may sink on soft ground.

Do not travel into a water surface without knowing how deep the water is and how stable the underground is. The underground may be sludgy and with insufficient bearing capacity. The machine may sink.

Do not travel through water or mud that is deeper than the breather valves of the final drives, refer to section “Restricted Operation”.

Ground that has been newly filled with earth / gravel may collapse from the weight of the machine.

Rocks and moisture of the surface material may drastically affect the machine's traction and machine's stability. Rocky surfaces may promote side slipping of the machine.

The machine may be less stable when traveling on uneven ground.

Have the attachment raised only so far as to permit the machine to be driven under overhead power lines without any risk.

Do not exceed the maximum machine inclination (refer to Operation and Maintenance Manual, section “Maximum machine inclinations”).

Do not travel across slopes. Always travel 90° to the slope face (upwards and downwards). Place the heaviest end of the machine uphill when you are traveling on an incline.

Do not drive the machine close to an overhang, to the edge of a cliff, or to the edge of an excavation. Take the utmost care on slippery, greasy ground. If the upper structure is turned by more than 90° from the basic position (refer to section “Upper structure - basic position”), the hydraulic shovel travels in the opposite direction to that selected. If the position of the upper structure in relation to the undercarriage is not exactly known, touch the travel pedals lightly to see which direction the machine takes, before initiating the full traveling movement.

Safe operation on steep slopes may require special machine configuration. Excellent skill of the operator and proper attachment for specific applications are also required. Consult the Operation and Maintenance Manual sections for the proper fluid level requirements and intended machine use.

Trailing cable

Never touch the trailing cable. Risk of voltage drive, if the trailing cable insulation is defective!

Change the position of the trailing cable only by means of a cable hook.

Before starting traveling

Read and observe all notes given in section “Traveling – Safety Instructions”.

Lift up the hydraulic access ladder.

Lift attachment up to the traveling position.

Activate the signal horn.

Release the travel brake switch (if applied).

Watch the mirrors and the camera monitor (if equipped).

Start traveling.

Upper structure - basic position

Travel only with the upper structure in its basic position.

The drive sprockets should be at the rear of the machine.

Before moving the machine, check the position of the undercarriage.

Travel direction and sense of actuation of travel pedals (112 and 113, Fig. 2-213:) are identical only when the upper structure is in its BASIC POSITION (Fig. 2-214:).

In this BASIC POSITION (Fig. 2-214:) the counterweight (3) is positioned above the final drives (4).

The operator’s cab (1) is above the left idler (2). Forwards means: Machine movement in direction of the idlers.

Backwards means: Machine movement in direction of the final drives.

Note: If the upper structure is swung out of its basic position by more than 90° (Fig. 2-215:), the hydraulic shovel moves in a direction opposite to that expected when pedals (112 and 113, Fig. 2-213:) are depressed.

If the operator is not completely sure of the position of the upper structure with regard to the undercarriage, pedals (112 and 113) should be depressed slightly in order to find out which way the hydraulic shovel moves before initiating the full traveling movement.

Travel Speed – Recommendations

Traveling Situation

Adjusting machine position while loading trucks

Travelling rearwards

Traveling long distances on flat or slight ramps and slopes

Turning

Traveling uphill / downhill on ramps and steep slopes

Traveling on soft or inconsistent material

Traveling on rough terrain

Loading machine onto a trailer

For detailed information on Traveling Speed refer to section “Travel Speed – adjust”.