6 minute read

Recommended working direction

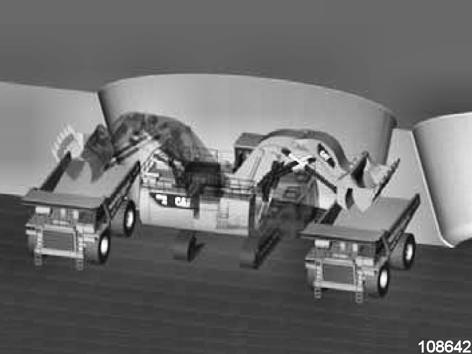

Best practice is:

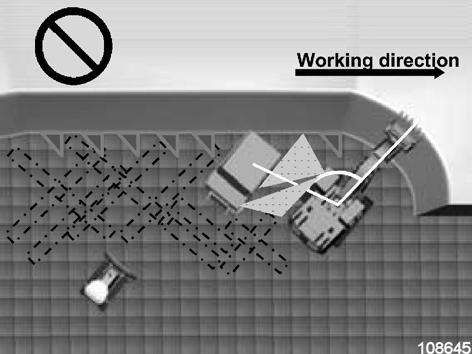

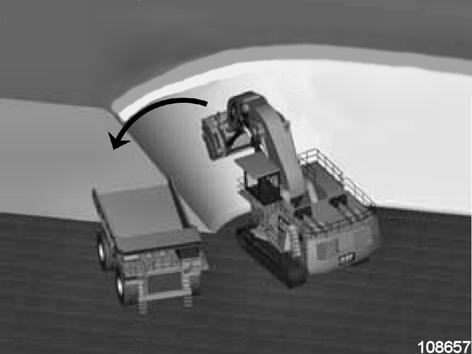

Working from right to left (Fig. 2-147:).

Cleaning of the floor behind and beside the shovel is done by a dozer.

Trucks will drive on levelled and clean ground, this results in less tire / suspension damage. Doing so is a clear separation of loading action and clean-up support.

The hydraulic shovel shall always return to the right end of the face (end of the cut) and start again.

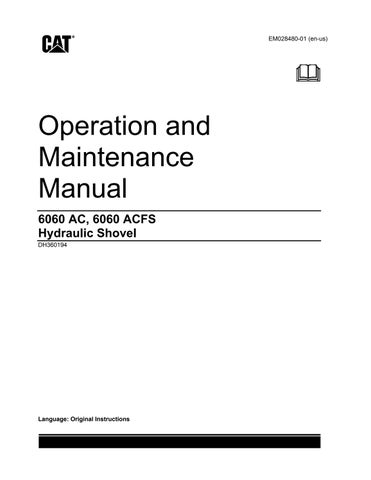

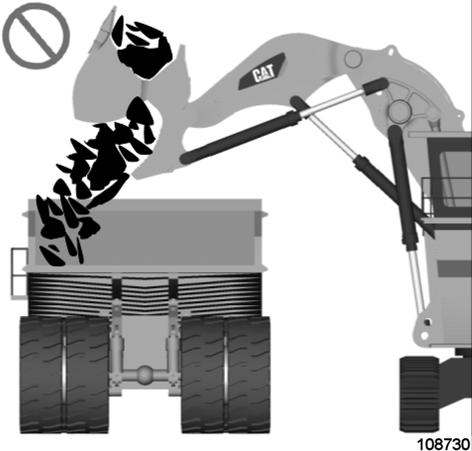

Not recommended – Digging advance left to right

Loading the truck to the left side means increased swing angle and longer cycle times (Fig. 2-148:) = unproductive.

The operator might try to reduce the swing angle, tails are left behind / no straight face.

Truck position on rough ground / spillage, results in cleanup delays, dozer standby required, risk of tire damage.

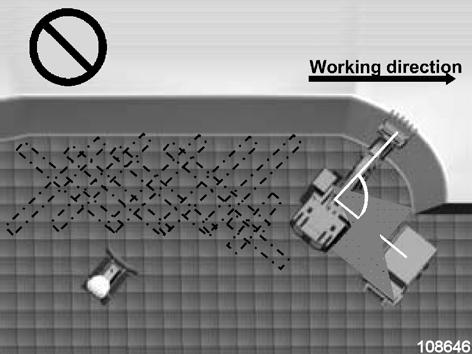

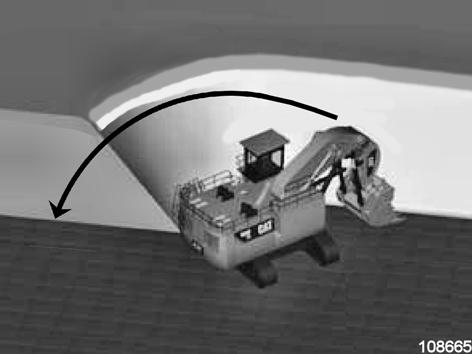

Not recommended – Digging advance left to right

Loading the truck to the right side (Fig. 2-149:) results in loading on the blind side.

Poor visibility of shovel operator to the truck means swing over the blind side.

Poor visibility of truck driver to the shovel means difficult positioning

Loading setups

Single side loading

The hydraulic shovel loads the trucks only on the left hand side (Fig. 2-150:). Truck driver and shovel operator have direct eye contact.

Single side loading with standard truck spotting is the best solution for most applications.

Advantages:

The hydraulic shovel can follow a straight working face without major repositioning effort.

Good floor conditions that are easy to maintain.

Support equipment can clean the excavated area behind the shovel without interfering with the loading action.

The face should always be mined from right to left, then travel back and continue.

The tracks should be positioned 45º toward the face; travel motors to rear.

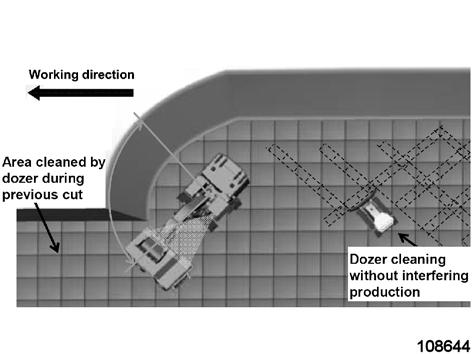

Double side loading

The hydraulic shovel loads the trucks alternately on left and right hand side (Fig. 2-151:).

Double side loading with self spotting increases productivity only short term and only if perfectly executed. A long-term productivity advantage will not be achieved because of the many disadvantages and requirements.

Disadvantages:

Higher risk of collisions.

Well-trained operators are required.

While loading to the right side, both shovel operator and truck driver are on the blind side.

Shovel cannot follow straight working face and has higher repositioning effort.

Permanent clean-up support required.

The tracks should be positioned 90º toward the face; travel motors to rear.

Digging and Loading

Digging

Operation

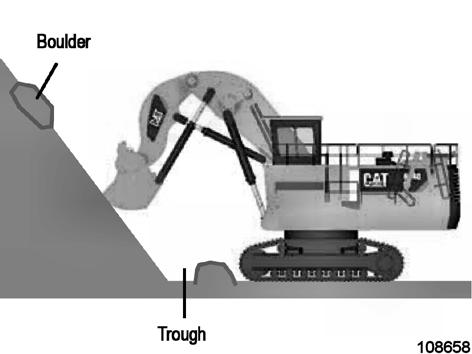

Maintain a digging face which avoids any major slides which could cause an accident

Always check the digging face for large boulders, large rocks, or frozen material which could slide and cause damage to the machine.

Always inspect the bank, it could collapse. Rocks can damage track pads, idler and the track tensioning system.

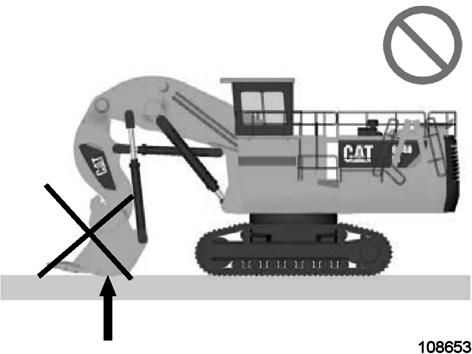

Building a safety trough in front of the tracks will protect the machine (Fig. 2-152:).

Avoid overhanging material.

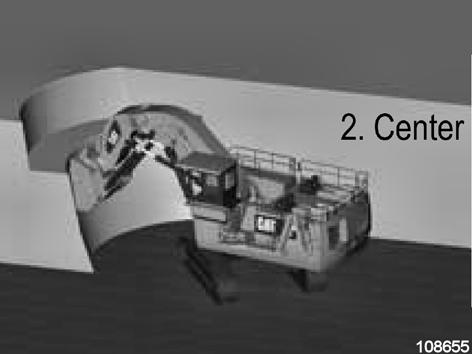

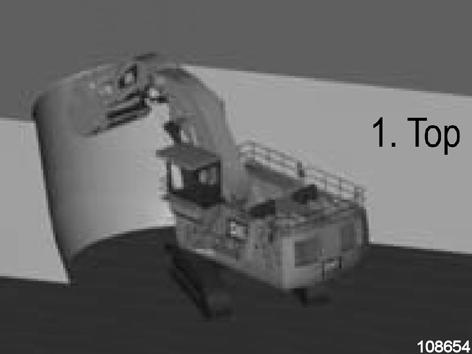

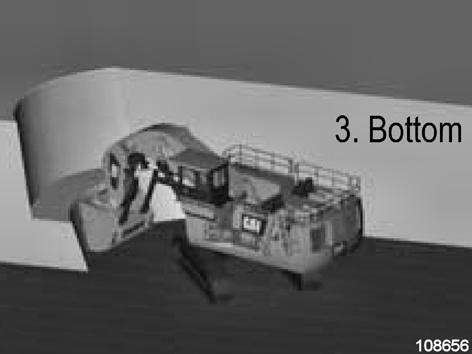

Always strive to work from top to bottom (Top / Center / Bottom in Fig. 2-153: to Fig. 2-155:).

Penetrate as high as possible to reduce lifting effort and shorten cycle times.

Always use the full cutting surface of the shovel lip to contact the bank on each pass. A full face cut combined with a deep bank penetration will result in a well filled shovel.

Use the float function of the boom while penetrating the material.

Always keep the shovel as close as possible to the work area. Short boom trips - high efficiency.

Digging, do not

When swinging towards the bank, the swing motion must not be stopped by the walls of the pit or by the material. Doing so can cause structural damage to the attachment. Use the machines hydraulic system to stop the swing motion.

Do not work with a bucket with missing teeth, missing shrouds or missing components of the hardfacing.

Loosen hard material and rocks with the bucket, not with the stick crowding thrust.

Do not swing the bucket into the material; penetrate only after swing is complete

Never penetrate the material with an open bucket.

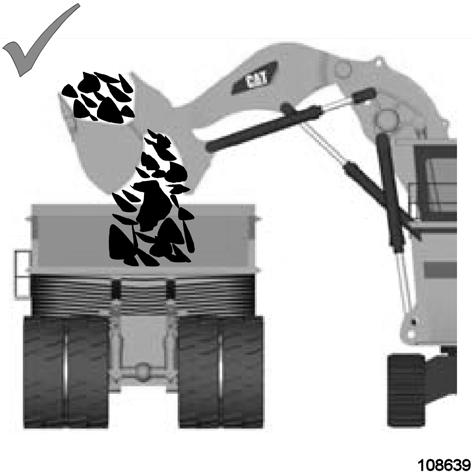

Loading Trucks

Position the truck as closely as possible to the hydraulic shovel (Fig. 2-157:).

Swing the attachment at a sufficient height over the loading platform. Do not swing the attachment over unprotected driver cabs

Distribute material evenly on loading platform.

Do not overload the truck.

Remove sticky material from the bucket.

Utilize the time between trucks (during truck spotting) to prepare the 1st pass for the next truck load (Fig. 2-156:).

Use low penetration height to clean up the ground and fill the shovel. There is enough time for a large swing angle until the next truck arrives.

Take the opportunity to check the face for potential rock fall and large and oversize material.

For the 2nd and the subsequent passes (the truck is in position) dig again from top to bottom maintain smaller swing angles This minimizes truck loading time.

Dumping the load

Correct bucket position during dumping will reduce bucket wear.

To center the load, the bucket should be tipped forward as the clam is opened (Fig. 2-158:).

If the bucket is tipped too far forward, the load will fall to the near side of the truck bed (Fig. 2-159:).

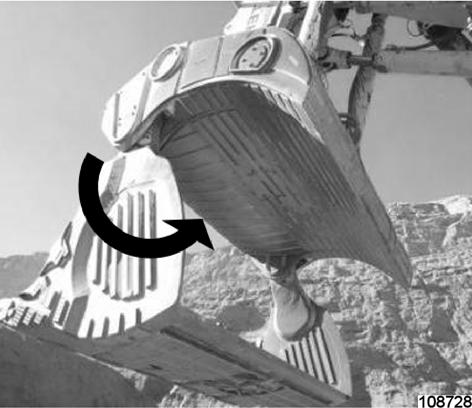

Closing the bucket clam

Close the clam using gravity to resist motion as shown in Fig. 2-161:.

Doing this

will improve control when clam and backwall near contact.

reduces impact forces on clam cylinders, clam and backwall.

Do not close the clam with gravity assisting motion. This motion can be difficult to control. The clam can bang against the backwall and applying impact forces to the clam, backwall and cylinders. These impact forces will reduce the durability of the clam, backwall and cylinders.

If the bucket is fully crowded back, the load will fall to the far side of the truck bed (Fig. 2-160:).

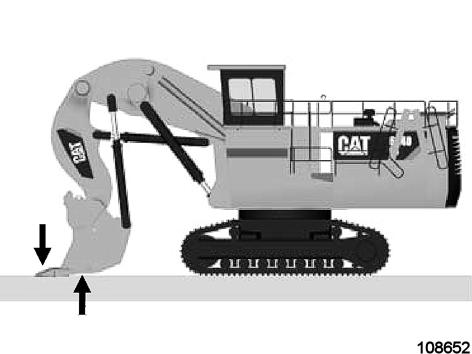

Digging on Ground Level

When digging at ground level, keep the heel of the bucket off the ground (Fig. 2-162:).

Operate with the ground engaging tools (GET) doing all the work.

Forcing the heel into the ground causes premature wear on the rear of the bucket (Fig. 2-163:).

Cleaning up the Pit Floor using the Attachment

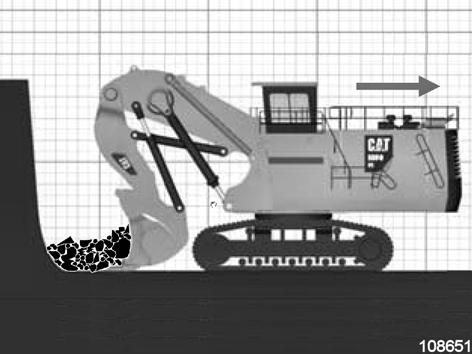

As loading continues it will be necessary to remove material from the lower down the face (Fig. 2-164:). Leave some material between the bucket and the tracks

Once all the material has been removed from the shovels reach move back 1 to 2 meters to enable the material in front of the tracks to be cleaned up (Fig. 2-165:).

Move back to cleanup material.

Maintain clearance between the bucket and the tracks.

If possible this should be completed between trucks and loaded directly into a truck to avoid lost production.

Cuts

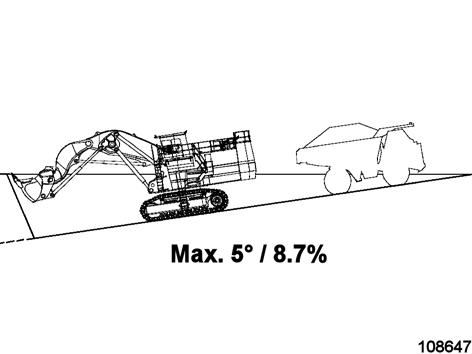

Drop cuts are difficult but possible (Fig. 2-166:).

Drop cuts are uncomfortable for the operator due to working on an inclination.

Slewing uphill puts stress on components.

The operator has to be careful while slewing downhill because of additional acceleration and operate the machine slowly.

The maximum working inclination for CGM HMS Shovels is 8.7%, this is less than the recommended haul road grade of 10%. Procede as follows: Maintain 8.7% with the CGM HMS Shovel and put to final 10% grade with a track type tractor.

For building of ramps, the values specified may be exceeded. In this case, however, a reduced service life of the components can be expected.

Drop cut = Digging down from current level to the next level down, creating a ramp in the process.

Handling Oversized Boulders / Overhangs

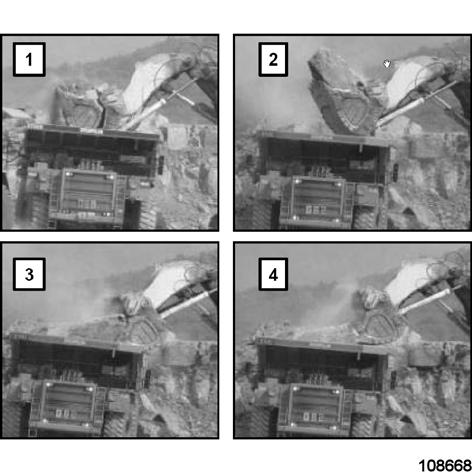

Note: Make sure that no truck or other machine is close proximity or in the projected slope line of the rock.

Ensure the tracks are 90° to the working face.

Position the hydraulic shovel to one side of the boulder/overhang before attempting to undercut. This ensures, that the hydraulic shovel will not be in its path when the rock falls (Fig. 2-167:).

Position the hydraulic shovel little to the right below the boulder/overhang. This ensures best visibility to the boulder/overhang.

Swing to the right hand side and work with the very left tooth.

Watch the size of the boulder; if it is too big to pass through the clam, it should be returned to the face

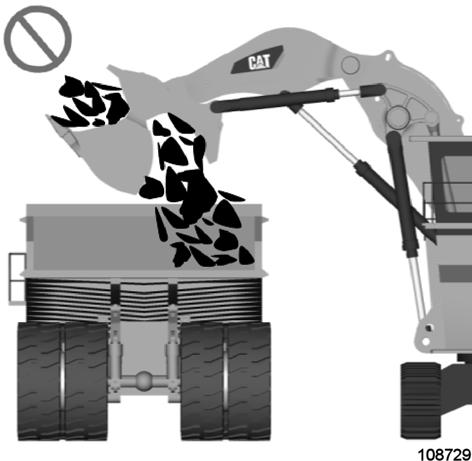

Place some material into the truck body first (1, Fig. 2-168:).

Warn the truck driver using the horn.

Tip the rock off the front of the bucket onto the material as shown (2, 3 and 4, Fig. 2-168:).

Do not try to get oversized boulders through the clam.