1 minute read

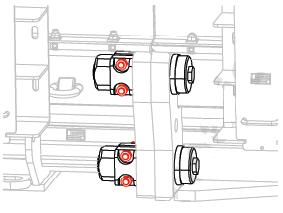

pan line—return head/crusher (image) ........................................................ 4

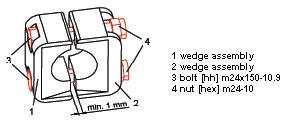

Clamping bolt—fitted

The required pretension of the screw bolt is created by tightening the hex. nuts of the clamping wedges.

The required pre-tensioning of the screw bold is generated by the tightening of the hexagon nuts of the clamp wedges.

Evenly tighten the hexagon nuts of the clamp wedges with a torque of 500 Nm.

Tightening the screw connections of the clamp wedges

THE TWO CLAMP WEDGE HALVES MAY NEVER BE SET TO BLOCK SINCE IT THEN CANNOT BE ENSURED THAT THE REQUIRED PRE-TENSIONING FORCE IS BEING APPLIED TO THE SCREW BOLTS. FOR THIS REASON BE SURE THAT THERE IS ALWAYS A VISIBLE GAP (MIN. 1 MM) BETWEEN THE CLAMP WEDGE HALVES. CHECK THE GAP WIDTH AND THE TIGHTENING TORQUE OF THE CLAMP WEDGE’S M24 SCREW CONNECTIONS EVERY WEEK.

C