SENR6758-01 May 1996 Component Location

Module Computerized Monitoring System (CMS) Autoshift Transmission Control

Component Identifier (CID) List CID No.

Component

Computerized Monitoring System (CMS) 096 100 110 168 177 248 270 271 324 600 601 627

Fuel Level Sensor Engine Oil Pressure Sensor Engine Coolant Temperature Sensor Electrical System Voltage Power Train Oil Temperature Sensor Data link Harness Code Action Alarm Action Lamp Hydraulic Oil Temperature Sensor Brake Air Pressure Sensor Parking Brake Switch

Electronic Transmission Control 168 190 248 362 368 617 621 627 631 632 633 634 635 636 650 668 671 680 685 687 688

Electrical System Voltage Engine RPM Sensor CAT Data Link Ride Control Solenoid Auto/Manual Switch Air Inlet Heater Relay Downshift Switch Parking Brake Switch Solenoid 1 (Reverse) Solenoid 2 (Forward) Solenoid 3 (Speed 4) Solenoid 4 (Speed 3) Solenoid 5 (Speed 2) Solenoid 6 (Speed 1) Harness Code Shift Handle Transmission Speed Sensor Ride Control Switch Service Identification Code Options Identification Code Dual Horsepower Solenoid

CID list applies to Monitor and Transmission Controls

Alarm - Action Alarm - Backup Alternator Batteries Breaker - Alternator Breaker - Blower Motors Breaker - Engine Shutdown Breaker - Main Breaker - Running Lamp Breaker - Suspension Seat Buffer - Fuel Level Control - Autoshift Control - Engine Shutdown Control - Payload Monitor Control - Shifter Converter - Voltage Dryer - Brake Air Flasher Fuses Fuses Ground - Starter To Frame Ground - Platform To Frame Horn Lamp - Action (CMS) Lamp - Auto Ride Control Lamp - Ride Control Lamp - Transmission Auto Mode Lamp - Transmission Neut Override Meter - Service Monitor - Operator (CMS) Monitor - Payload (Display) Motor - Blower Motor - Blower Motor - Front Washer Motor - Front Wiper Motor - Rear Washer Motor - Rear Wiper Motor - Starter Radio Receptacle - Auxiliary Start Relay - Main Relay - Start Resistor - Blower Speed Resistor - System Voltage (CMS) Resistor - Starting System Diagnostics Sender - Fuel Level (CMS) Sensor - Brake Air Pressure (CMS)

E-4 D-15 B-12 B-14 F-15 C-5 F-15 F-15 F-15 C-5 E-1 E-8 F-13 C-4 E-3 F-5 A-14 D-6 B-5, C-5 F-15 B-13 A-10 B-1 A-3 B-4 B-4 B-4 B-4 E-10 E-5 C-3 D-11 E-11 A-13 F-3 A-13 E-7 B-13 F-7 A-13 F-15 F-15 E-11 F-14 B-13 E-1 E-1

C 1 2 3 D E D D D E 5 6 F E A A F A E D 7 8 4 B B B B B 26 B B 9 10 F B F A 7 A 7 D D 11 D 7 5 12

Component

Schematic Location

Machine Location

E-14 D-14 A-2 B-2 C-2 D-14 B-2 C-13 B-5 B-5 C-13 A-10 C-13 B-5 B-2 A-13 F-12 F-7 F-1 B-6 C-4 B-1 B-14 B-7 D-14 E-7 F-3 C-9 A-2 D-6 A-1 F-5 F-1 A-2 B-2 E-3 C-14 E-7 D-6 E-14 E-1 E-8 D-5 C-7 B-4 F-1 C-5

13 14 15 16 17 13 18 19 E E 7 8 7 E 16 F 20 26 5 C C 21 7 B 13 C B A 15 C 22 C 12 23 24 B 15 C C 25 12 26 B C B 12 A

Sensor - Engine Coolant Temp (CMS) Sensor - Engine Speed Sensor - Hydraulic Temp (CMS) Sensor - Lift Cyl Press Sensor - Lift Position Sensor - Trans Oil Temp (CMS) Sensor - Trans Output Speed Solenoid - A/C Clutch Solenoid - Bucket Float Solenoid - Bucket Kickout Solenoid - Dual HP Solenoid - Dual Pump Solenoid - Engine Shutdown Solenoid - Lift Kickout Solenoid - Ride Control Solenoid - Start Aid Solenoids - Transmission Switch - Blower Switches - Brake Oil (CMS) Switch - Auto Ride Control Switch - Beacon Switch - Bucket Positioner Switch - Disconnect Switch - Dual Pump Switch - Engine Oil Press (CMS) Switch - Flood Lamp Switch - Front Wiper Switch - Horn Switch - Hydraulic Oil Level (CMS) Switch - Key Start Switch - Lift Positioner Switch - Park Brake Switch - Parking Brake Press Switch - Power Train Filter Press (CMS) Switch - Primary Steering Flow (CMS) Switch- Rear Wiper Switch - Refrigerant Switch - Running Lamp Switch - Start Aid Switch - Start Aid Coolant Temp Switch - Stop Lamp Switch - Thermostat Switch - Trans Auto/Manual Switch - Trans Downshift Switch - Trans Neutralizer Override Switch - Trans Neutralizer Press Switch - Turn Signal

Connector Location Machine Location

Connector

40 Contacts

Harness And/Or Components

Schematic Location

Connector

Machine Location

A-118-8926 B - 118-8495

B-11

F

A-118-3459 Engine Shutdown Control

F-13

*

Autoshift Control B - 118-8495

E-9

C

B-118-8495 MMM -118-8500

D-6

*

B - 118-8495 Computerized Monitoring System

E-5

3

FFF - 7I-3138 Payload Display

C-3

2

A - 118-8926 UU-118-8308

D-13

*

T-117-2890 Radio

F-7

D

A-118-8926 Diagnostic Connector

E-15

B

B-118-8495 L - 118-8927

C-4

20 Contacts

6 Contacts

14 Contacts

l2Contacts

FFF -7I-3138 Payload Monitor Ctrl

C-4

E

B-118-8495 M-118-8496

C-6

3

A - 118-8926 GGG - 104-6727

F-12

8

A- 118-8926 VV - 6C-5912

A-8

1

A-118-8926 B-118-8495

A-11

10

D - 4E-4466 VV-6C-5912

A-3

B

B-118-8495 Control Gp-Transmission

D-3

*

FFF - 7I-3138 Payload Display

C-2

E - 118-7697 G - 118-8307

A-2

A

G-118-8307 JJJ - 119-5642

B-2

B

B-118-8495 P - 6C-4227

D-7

10

G-118-8307 YY - 118-5253

B-2

6

R - 6C-4237 S-6C-4136

F-8

*

Payload Dislpay Customer Data Connection

C-3

B

A-118-8926 C-118-8309

E-15

11

B - 118-8495 Autoshift Options Plug

E-9

8

A - 118-8926 E-1187697

A-8

11

B - 118-8495 Autoshift Service Mode Plug

E-9

4

A - 118-8926 E-118-8499

F-6

B

B-118-8495 CMS Service Mode Plug

E-5

B

B - 118-8495 JJ-118-5611

E-16

B

B - 118-8495 Front Wiper Motor

F-3

B

B-118-8495 L-118-8427

A-4

11

E - 118-7697 FFF - 7I-3138

B-3

8 Contacts

E

B-118-8495 M-118-8496

C-6

A

E-118-7697 G-118-8307

B-3

E

B-118-8495 Q-6C-5853

C-6

*

Q-6C-5853 Rear Wiper Motor

E-6

E

B - 118-8495 R - 6C4237

D-10

Machine locations are repeated for components located close together. * = Connector is located at component. A = Connectors in operator compartment. B = Connectors located in dash. C = Connectors located in right console.

4 Contacts

T

Temperature Symbol

Flow Symbol

Level Symbol

Normally open switch that will close with an increase of a specific condition (temp-press-etc.).

5 10 Contacts

Electrical Schematic Symbols And Definitions

Pressure Symbol

*

5 Contacts

9 Contacts

Schematic Location

1

7 Contacts

25 Contacts

Harness And/Or Components

Normally open switch that is closed due to an applied condition, and will open again with a specific decrease in that condition.

Normally closed switch that will open with an increase of a specific condition.

Normally closed switch that is open due to an applied condition, and will close again with a specific decrease in that condition.

980F Series II Wheel Loader Electrical System 4RN1-UP

The circle indicates that the component has screw terminals and a wire can be disconnected from it.

No circle indicates that the wire cannot be disconnected from the component.

This indicates that the component has a wire connected to it that is connected to ground.

This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine. D = Connectors located at relay panel. E = Connectors located in service compartment - Rt. Side. F = Connectors located in compartment behind operators cab.

Machine locations are repeated for components located close together. A = Components in operator compartment. D = Components at relay panel. B = Components in dash. E = Components in service compartment - Rt. Side. C = Components in right console. F = Components in compartment behind operators cab.

© 1996 Caterpillar, All Rights Reserved

Printed in U.S.A.

Wire Description Wire Number

Wire Color

101

RD

Description

Wire Number

Wire Color

B413

PU

Monitoring Circuits (Continued)

Power Circuits

FMI No. 0 1 2 3 4 5 6 7 8 9 10 11 12 13

Bat

102

BU

Hd Lmp

B414

OR

PMS Norm/Calibrate Out

Failure Description Data valid but above normal operational range. Data valid but below normal operational range. Data erratic, intermittent, or incorrect. Voltage above normal or shorted high. Voltage below normal or shorted low. Current below normal or open circuit. Current above normal or grounded circuit. Mechanical system not responding properly. Abnormal frequency, pulse width, or period. Abnormal update. Abnormal rate of change. Failure mode not identifiable. Bad device or component. Out of calibration.

105

BR

Key Sw

B415

PK

PMS Clear/Chg Out

107

WH

Eng Shut - Down Fire Suppr

B416

WH

PMS Reweigh Sw In

108

BU

Aux Ckt

B417

YL

PMS Store Sw In

109

OR

Alt Output (+) Term.

Related Electrical Service Manuals Title

Form Number

Alternator: (100-5047) Consist No. 100-5046 Consist No. 100-5045 Computerized Monitoring System (CMS) Electronic Transmission Control Starting And Charging Systems Starting Motor: (6V-5539) Consist No. 6V-5540 Consist No. 6V-5582 Consist No. 106-8554

SENR2082 SENR4130 SENR5247 SENR5922 SENR2947 SENR3536 SENR4975 SENR3581

PU

Main Power Rly Output

500

BR

Wiper - Front (Park)

113

OR

Opr Mon Panel VMIS B+ Switched

501

GN

Wiper - Front (Lo)

114

GN

Warning Horn (Forward)

502

OR

Wiper - Front (Hi)

116

BR

Aux Ckt

503

BR

Wiper - Rear (Park)

118

GY

Aux Ckt

504

YL

Wiper - Rear (Lo)

120

YL

Aux Ckt

505

BU

Wiper - Rear (Hi)

121

YL

Bckp Alarm to Lamp

506

PU

Washer - Front

124

GN

A/C

507

WH

Washer - Rear

126

PK

Xmsn Ctrl

508

Pu

Radio Speaker - Left

127

OR

Aux Ckt

509

WH

Radio Speaker - Left (Common)

128

PK

Aux Ckt

511

BR

Radio Speaker - Right

129

BU

Aux Ckt

512

GN

Radio Speaker - Right (Common)

130

GN

Aux Ckt

513

OR

A/C Compressor/Refrigerant Press. Sw

135

BU

Aux Ckt

514

PU

A/C Condenser Moter

138

GN

Auto Lube Pump To Payload Mon

515

GY

Blower Motor (Hi)

158

BR

Aux Ckt

515

GY

Blower Motor (Hi)

164

WH

Hydro Ctrl WTL Powertrain Ctrl

516

GN

Blower Motor (Medium)

177

OR

Main Brkr

517

BU

Blower Motror (Lo)

193

PU

Aux Ckt

520

WH

Opr A/C Sw To Thermostat/Fuse

521

YL

A/C Sw To Refrigerant Sw

200

BK

Main Chassis

522

WH

A/C Clutch To Thermostat Sw

201

BK

Opr Mon Panel VMIS CMS

537

GN

Turn signal Sw To Flasher

202

BK

Xmsn Ctrl

538

BR

Hazard Indicator

203

BK

Chassis Diagnostic

541

GN

Acc 1

206

BK

Bat Side of Disconnect

542

BU

Acc 2

207

BK

Starter Diagnostic

250

BK

Payload Mon - Customer Gnd

603

PK

Rotary Beacon

BK

Payload Mon - System Gnd

604

OR

Stop Lamp

270

BK

CMS Ident Code 0

605

YL

Turn Lamp - Left

271

BK

CMS Ident Code 1

606

GY

Turn Lamp - Right

272

BK

CMS ldent Code 2

608

GN

Flood Lamp - Rear

273

BK

CMS Ident Code 3

610

OR

Head Lamp Basic

274

BK

CMS Ident Code 4

614

PU

Park/Tail/Dash Lamp

275

BK

CMS Ident Code 5

615

YL

Cab Flood Lamp/ROPS

280

BK

Xmsn Ctrl Ident Code 4

617

BR

Tail/Postiion Lamp - Left (Road Pkg)/ Width

281

BK

Xmsn Ctrl Ident Code 5

619

GN

Head Lamp Lo

290

BK

CMS Service

291

BK

CMS Clear

710

GN

Xmsn Speed Pickup Signal

292

BK

CMS US/Metric Units

720

PU

Xmsn Brake Sw

A221

BK

XMSN Ctrl Options Code 0

751

GN

Xmsn Shift Sol No. 1 Or 3

A222

BK

XMSN Ctrl Options Code 1

752

YL

Xmsn Shift Sol No. 2

A232

BK

XMSN Ctrl Options Code 2

754

BU

Xmsn Shift Sol No. 3 Or 1

755

OR

Xmsn Shift Sol No. 4 Or 5

Starter No. 1 Sol

761

GY

Lift Kickout Sol Sw

302

OR

Starter No. 1 Resistor To Diagnostic

762

YL

Bucket Postiioner Sol Sw

304

WH

Starter Rly No. 1 Output

795

YL

Dual HP Sol

306

GN

Starter Rly Coil To Neut Start Sw Or Key Sw

D735

PK

Xmsn Cont Park Brk Lever Sw To Gnd

307

OR

Key Sw To Neut Start Sw Or VMIS Sensor Module

D743

GN

Ride Cont - WTL Impi Cont Sw To Gnd N/O

308

YL

Main Power RIy Coil

D744

WH

Ride Cont - WTL Impi Cont Sw To GND N/C

310

PU

Start Aid Sw To Start Aid Sol

E701

PK

Auto Ride CntI Sw

311

WH

Start Aid Sol To Temp Sw

E702

OR

Auto Ride Cntl Sw

321

BR

Bckp Alarm Lamp Travel Alarm

818

BR

Serial Data (Transmit)

322

GY

Wraning Horm (Forward)

819

GY

Serial Data (Receive)

326

PU

Key Sw "C" Term.

820

BU

Transmit Key

327

PK

Shutdown Sol Monitoring Circuits

863

BU

Payload Mon TRansmit LCD Out

864

BR

Payload Mon Clock LCD Out

403

GN

Alternator (R) Term.

865

GY

Payload Mon latch LCD, Out

405

GY

Opr Mon Oil Press. (Lo Setting)

900

PU

Xmsn Shift Sol No. 5 Or 4

409

OR

Opr Mon Neut

901

WH

Xmsn Shift Sol No. 6

410

WH

Opr Mon Fault Alarm

910

YL

Xmsn Neutizer Override Indicator

411

PK

Opr Mon Master Fault Lamp

944

OR

Data Link + (CAT)

417

GY

Primary Ster Sw

945

BR

Data Link - (CAT)

419

YL

Opr Mon Parking Brake

965

WH

Trans Sol 1 Sw To Gnd

426

BR

Opr Mon Power Train Oil Filter

966

GY

Trans Sol 3 Sw To Gnd

432

PK

Opr Mon Brake Press. (Oil)

968

BR

Trans Sol 2 Sw To Gnd

433

BU

Opr Mon Brake Press. (Oil) Jumper

969

YL

Trans Sol 3 Sw To B+

439

YL

Lamp Indicator

970

GN

Trans Sol 4 Sw To Gnd

440

BR

Air Press. Gage

971

YL

Trans Sol 5 Sw To Gnd

441

OR

Eng Coolant Temp Gage

972

BU

Trans Sol 6 Sw To Gnd

442

GY

Flyd System Temp Gage

973

BR

CST Autoshift - Auto/iVianual Sw 2

443

YL

447

PK

450

YL

496

WH

A401 B412

Power Train Temp Gage

Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

2

Typical representation of a Sure-Seal connector. The plugand receptacle contain both pins and sockets.

Pin or Socket Number Wire, Cable, or Harness Assembly Identification

Component Part Number

Single Wire Connector C

5 7

1

13 14

19

2 D F

2

7

10 6 26 4 8 12 18 5 20 A 3 B 11

6 11 4 E C 9 8 24 23 9 15

1

25

3

A

A 325-PK-14

Pin

AA 1

Wire Color

Socket

2

200-BK-14

Circuit Number Identification

16 10

Wire Gauge

Electrical Schematic Symbols And Definitions

21

22

9X-1123 325-PK-14

FUSE - A component in an electrical circuit that will open the circuit if too much current flows through it.

17

REED SWITCH - A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

T

SENDER - A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure.

RELAY (Magnetic Switch) - A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay. CIRCUIT BREAKER (C/B) - A component in an electrical circuit that will open the circuit if too much current flows through it. This does not destroy the circuit breaker and it can be reset to become part of the circuit again. SOLENOID - A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work.

Control Circuits

BU

301

1 2

1 2

Receptacle

Plug

Lighting Circuits

251

AA 1

Accessory Circuits

112

Basic Machine Circuits

A

PMS Lift Cyl Press. Sensor

Failure Mode Identifiers (FMI) List

Ground Circuits

Harness And Wire Electrical Schematic Symbols

Description

974

PU

CST Autoshift - Slow Mode Sw

Fuel Level Gage

975

WH

CST Autoshift - Sol Return

Tach Sender (+)

976

OR

Ride Cont Sol

Opr Mon Panel Hyd Oil Level

977

YL

CST Autoshift - Auto/Manual Sw 1

YL

Electrical SYstem No.1 Voltage

978

GN

CST Autoshift - Slow Mode Sw 1

YL

PMS Lift Pos Sensor

B999

GN

Trans Sol 1 Sw To B+

MAGNETIC LATCH SOLENOID - A magnetic latch solenoid is an electrical component that is activated by electricity and held latch by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.

A

14 13 25

19

2 1 3

7

7

2

D

11 26 C B 10 F 9 6 E 6 11 1 9 12 5 23 8 24 8 4 4 3 5 18 20

Resistor, Sender and Solenoid Specifications Part No. 9G-1950

Resistor -

Component Description Blower Speed

6T-2217

Resistor -

Starter/Diagnostic Conn

150.0 ± 7.5

6T-2217

Resistor -

Monitor System Voltage (CMS)

150.0 ± 7.5

102-0347

Solenoid -

A/C Clutch

14.4 ± 0.6

8C-9635

Solenoid -

Bucket Float/Kickout

110.0 ± 6.0

Solenoid -

Dual HP Push Coil Pull Coil

4.2 ± 0.42 16.1 ± 1.61

7T-2052

Solenoid -

Dual Pump

110-6465

Solenoid -

Engine Shutdown

5.12 ± 0.26

3E-6424

22 21 17 10

Resistance (Ohms)¹ Overall 2.0 ± .1; Tap 1.0 ± .05

41.90

8C-9634

Solenoid -

Lift Kickout

110.0 ± 6.0

6T-5859

Solenoid -

Ride Control

33.7 ± 1.0

9G-4365

Solenoid -

Start Aid

6.00

3E-3748

Solenoids -

Transmission

8.50

¹ At room temperature unless otherwise noted.

16

15

Off Machine Switch Specification Part No.

Function

Actuate

Deactuate

Contact Position

5 kPa MIN (0.5 psi MIN)

Normally Open

2M-9346

Stoplamp Pressure

45 kPa MAX (6.5 psi MAX)

7T-0988

Park Brake

62 ± 20.8 kPa (9.0 ± 3.0 psi)

37.9 ± 2 kPa (5.5 ± .3 psi)

Normally Open

8N-1693

Engine Coolant Temperature (Start Aid)

37.8 ± 2.8°C (100 ± 5°F)

26.7°C MIN (80°F MIN)

Normally Closed

8T-9792

Parking Brake Pressure

517 ± 35 kPa (75.0 ± 5.0 psi)

448 ± 35 kPa (80°F MIN)

See Note ³

9X-4276

Oil Pressure (CMS)

93.0 ± 20.8 kPa (14.0 ± 3.0 psi)

68.9 ± 20.8 kPa (10.0 ± 3.0 psi)

See Note ³

9X-7781

Power Train Filter Pressure (CMS)

210 ±70 kPa (30 ± 10 psi)

-

Normally Open

9X-9418

Trans Neutralizer Pressure (Shifter)

103± 20 kPa (15.0 ± 3.0 psi)

69 kPa MIN (10.0 psi MIN)

Normally Closed

109-4215

Primary Steering Flow (CMS)

4 grams (.14 oz.)

1.5 grams (.05 oz)

Normally Open

114-5334

Refrigerant Pressure (AC)

275 to 1750 kPa ¹ (40 to 255 psi)

-

Normally Open ²

¹With increasing pressure the closed condition can be maintained up to 2800 kpa (405 psi), with decreasing pressure the closed condition can be maintained down to 170 kpa (25psi). ² Contact postion at the contacts of the harness connector.

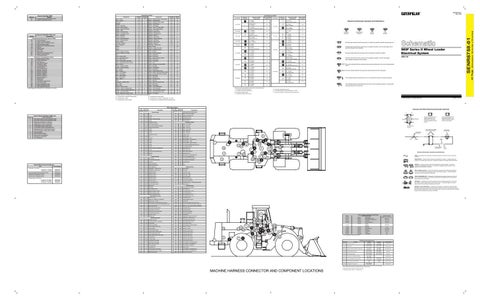

MACHINE HARNESS CONNECTOR AND COMPONENT LOCATIONS

³ 1- 3 Normally Closed; Contacts 1 - 2 Normally Open

(Dimensions: 56 inches x 35 inches)

26 81

Machine Location

42 Page,

MID No.

Component

Schematic Location

SENR6758-01

Module Identifier (MID)