CONN 1

H-15

55

CONN 2

A-15

54

CONN 3

C-15

2

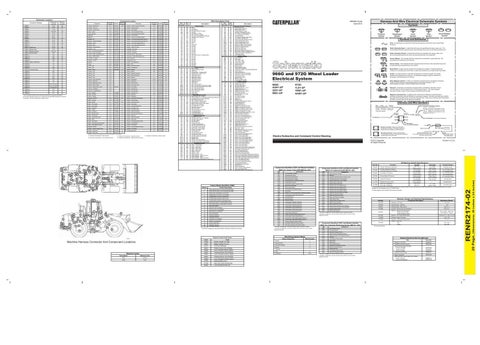

Wire Description Chart

Component Location

Machine Location

Schematic Location H-11

Component Actuator - Blend Door

Part No. 126-5611

Machine Location 56

Schematic Location B-15

Component Sender - Torque Converter Oil Temp

Part No. 4W-9972

Machine Location 20

Wire Number

Wire Color

101 102 105 107 108 109 112 113 114 118 120 122 123 124 126 127 128 129 130 133 134 135 136 138 141 144 146 158 167 175 177 188 199

RD RD RD RD BU RD PU OR GN GY YL BU WH GN PK OR PK BU RD OR YL BU GN GN RD GN GY BR OR PK OR WH RD

200 201 202 250 251 270 271 272 273 274 275 290 291 299 A201 A202 A203 A204 A205 A219 A272 A273

BK BK BK BK BK BK BK BK BK BK BK BK BK BK BK BK BK BK BK BK BK BK

304 306 307 308 310 311 321 322 326 327 334 373 397 398 A300 A301

WH GN OR YL PU WH BR GY PU PK BU GN OR BU GN WH

403 405 410 411 416 417 419 432 441 442 443 447 450 453 484 496 499 C413 C414 E416 G485 G486

GN GY WH PK OR GY YL PK OR GY YL PK YL PK YL WH GY YL BU PU BU GN

500 501 502 503 504 505 506 507 508 509 511 512 513

BR GN OR BR YL BU PU WH PU WH BR GN OR

Actuator - Hood As.

A-14

116-6844

1

Sensor - Engine Speed

C-14

6V-2455

21

Actuator - Water Valve

H-11

126-5610

56

Sensor - Input Speed

B-13

3E-8848

26

CONN 4

F-15,I-15

53

Alarm - Action

E-10

3E-6328

C

Sensor - Lift Cyl Head End Press

D-1

124-4672

23

CONN 5

D-14

44

Alarm - Backup

C-15

123-6449

2

Sensor - Lift Linkage Rotary Position

F-1

161-8904

24

CONN 6

A-13

C

Alternator

C-15

107-7977

3

Sensor - Tilt Lever Pos

F-7

106-4437

E

CONN 7

B-13

C

26

CONN 8

F-12

45

CONN 9

E-12

45

CONN 10

D-12

45

CONN 11

C-12

45

CONN 12

C-11

C

CONN 13 HVAC Unit

G-10

56

CONN 14 Service Tool

F-10

C

CONN 15 Monitor Harness

Batteries

F-15

115-2422

4

Sensor - Torque Conv Output Speed

B-13

3E-8848

Breaker - Alt

A-14

9S-4693

5

Sensor - Tran Intermediate Speed Sensor 1

B-13

3E-8848

26

Breaker - Engine Shutdown

B-14

6T-3643

5

Sensor - Tran Intermediate Speed Sensor 2

B-13

3E-8848

26

Breaker - Hood

B-13

6T-3644

5

Sensor - Tran Output Speed Sensor 1

C-13

3E-8848

26

Breaker - Main

B-14

9S-4693

5

Sensor - Tran Output Speed Sensor 2

B-13

3E-8848

26

Breaker - Running Lamp

B-14

3T-2662

5

Sensor - Trans Oil Temp

B-13

100-3055

26

Breakers - 15A

D-11

6T-3643

C

Solenoid - A/C Clutch

B-15

3E-1906

27

E-5

155-1615

A

Solenoid - Start Aid

I-5

3E-6332

C

Control - Power Train ECM

I-10

160-1758

57

Solenoid - Shutdown

D-14

110-6465

15

Control - Water Valve/Blend Door

G-11

126-6010

A

Solenoid Valves - Ride Control

D-1

3E-8574

31

Control - Cat Monitoring System

H-9,l-13

C

CONN 16 Service Mode

H-9

C

CONN 17

E-8

57

CONN 18

E-8

57

Control - WLPCS ECM

C-4

112-1572

59

Solenoids - Clutch Modulating Valve

C-13

159-0932

26

H-5

119-1733

B

Stud - Terminal

D-11

9G-8451

C

E-11

103-5526

C

Suppressors - Arc

E-6

106-8704

A 27

CONN 19

D-8

57

Converter - Voltage

CONN 20

D-8

57

Dimmer - Control

CONN 21 Option Code Plug

I-7

C

Flasher

F-10

120-4537

C

Switch - A/C Refrigerant

D-15

114-5333

CONN 22

F-6

A

Fuses

A-13

3K-8782

5

Switch - AIH

G-5

112-6169

A

CONN 23

I-4

C

Fuses - 10A

D-11

3K-8782

C

Switch - Auto Ride Control

B-5

103-6333

D

CONN 24

G-4

A

Fuses - 15A

D-11

8M-8948

C

Switch - Auto/Manual

B-6

123-6383

D

CONN 25 Customer Data

C-4

C

Gauge - Quad

E-4

100-5895

A

Switch - Beacon

B-9

9X-9639

D

CONN 26

B-4

D

Ground - Cab

A-8

D

Switch - Blower

B-9

3E-7156

D

CONN 27

A-3

46

Ground - Cab

F-10

57

Switch - Brake Oil Pressure

I-4

3E-7693

34

CONN 28

A-3

46

Ground - Cab

H-8

57

Switch - Bucket Positioner

F-1

164-3583

35

57

Switch - Dimmer

C-3

2H-1855

58

CONN 29

B-3

62

Ground - Cab

H-10

CONN 30

E-3

61

Ground - Left Frame Boss

E-14

6

Switch - Disconnect

B-15

7N-0718

36

CONN 31

F-3

61

Ground - Left Front

H-5

C

Switch - Engine Oil

B-14

9X-0378

37

CONN 32

I-3

34

Ground - Right Rear Frame

A-15

7

Switch - Forward Horn

G-4

21-3360

A

A

Switch - Front Axle Temp

D-1

155-8999

39

8

Switch - Front Wiper

B-4

110-7886

D

9

Switch - Hazard lamp

G-9

112-6167

B

CONN 33

I-2,I-1,H-1,G-2

60

CONN 34

I-2,I-1,H-1,G-2

60

CONN 35

H-2,G-2,D-2

47

CONN 36

D-2

31

CONN 37

D-1

23

Ground - Steer Column

CONN 38 F-1 35 ¹ The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart.

E-5

Ground - Strap Frame to Cab

G-12

Ground - To Engine

C-15

Ground - To Engine Block

D-14

8X-5804

10

Switch - Hood Actuator

A-14

146-0240

40

Horn - Forward

I-2

4Y-7882

1

Switch - Hyd Oil Level

A-2

123-2993

19

Horns - Forward

F-1

7T-0970

12

Switch - Key Start

D-5

9G-7641

A

Horns - Forward

I-1

7T-0970

12

Switch - Neutralizer

C-3

105-6118

58

Keypad - WLPCS

B-4

129-0419

59

Switch - Park Brake Oil Pressure

I-4

3E-6452

42

Motor - Actuator

A-14

117-1557

1

Switch - Primary Steer

I-3

3E-6450

C

Motor - Blower

G-11

3E-6392

56

Switch - Rear Axle Temp

C-14

155-8999

33

Motor - Front Wiper

D-5

147-7973

A

Switch - Rear Wiper

C-9

112-6174

D

Motor - Rear Wiper

F-10

137-8709

C

Switch - Run/Work/Panel/Tail

C-8

108-3320

D

Motor - Sec Steer

H-4

154-2563

C

Switch - Sec Steer Test

H-8

143-3001

B

Motor - Starter

D-14

6V-5227

15

Switch - Secondary Steer

I-3

3E-6450

C

Motors - Washers

A-3

7T-8890

16

Switch - Selector AC/Heat

B-9

3E-7155

D

Relay - Backup Lamp

I-15

4Y-6135

25

Switch - Service Brake Pedal As.

B-3

110-8029

58

Relay - Front Flood

E-10

3E-5239

C

Switch - Start Aid

G-5

3E-7176

A

Relay - Hood Raise Lower

A-14

149-2612

5

Switch - Start Aid Coolant

B-15

3E-6425

22

Relay - Main

A-14

101-7740

5

Switch - Stop Lamp

B-3

3E-5520

60

Relay - Rear Flood

E-11

3E-5239

C

Switch - Tach/Speedo/Serv Meter

G-5

112-6171

A

Relay - Sec Steering Intermediate

F-11

3E-5239

C

Switch - Temp Selector

B-9

127-4540

D

Relay - Start Magnetic Switch

B-14

125-1302

5

Switch - Thermostat

G-11

3E-5464

56

Resistor - Blower

G-11

9G-1950

56

Switch - Tran Neutralizer Override

B-5

112-6156

D

Sender - Engine Coolant Temp

B-15

7N-8532

A

Switch - Turn Signal

F-6

134-9569

A

Sender - Fuel Level

C-15

134-3033

2

Tach/Speedometer

E-4

153-8061

A

Sender - Hyd Temp

A-3

4W-9972

19

Machine locations are repeated for components located close together.

53

C = Operator Compartment - Relay/Fuse Panel

B = Operator Compartment - Left Overhead Console

D = Operator Compartment - Right Overhead Console

515 516 517 518 521 522 537 538 539 540 A513 A523 A524 A525 A526 A527 A541 A592 A593 A594 A595 A596 C529 C530

GY GN BU OR YL WH GN BR BU WH PK PU BR GN PK BU PU BU OR WH GN YL GY BU

603 604 605 606 608 610 611 612 614 615 617 619 633 646 647 661 662 663 691 692

PK OR YL GY GN OR PU GY PU YL BR GN BU OR GN GN YL GY GY YL

709 720 727 728 751 752 754 755 761 762 795 E701 E702 E707 E708 E735 F781 F783 F784 G750 G755 G761 G762 G763 G764 G766 G767 H713 H714 H715 H716 H717 818 819 900 901 910 944 945 973 975 976 977 E900 E901 E902 E903 E904 E905 E906 E907 E908 E909 E917 E918 E919 E920 E921 E922 E923 E924 E925 E926 E927 E928 E930 E936 E955 G939 K933 K977 N939 P910

OR PU GN BU GN YL BU OR GY YL YL PK OR GN PK PU BR GN YL BU GY YL BR PU PK GN WH PK OR PU WH BR BR GY PU WH YL OR BR BR WH OR YL WH GN PU YL BR BU OR GY BR WH WH GN YL BR PK GN PK YL OR BU GN WH BU WH OR PK GN PK GN BR

Power Circuits Bat(+) Hd Lmp Key Start Sw Eng Shut-Down Fire Suppr Aux Ckt Alt Output (+) Term. Main Power Rly Output Opr Mon Panel VMIS B+ Switched Warning Horn (Forward) Aux Ckt Aux Ckt Aux Ckt Aux Ckt A/C Xmsn Ctrl Aux Ckt Aux Ckt Aux Ckt Aux Ckt Aux Ckt Aux Ckt Aux Ckt Sec Ster Auto Lube Pump To Payload Mon Aux Ckt Aux Ckt Aux Ckt Aux Ckt Aux Ckt Aux Ckt Main Brkr Aux Ckt Aux Ckt Ground Circuits Main Chassis Operator Monitor Return XMSN Ctrl Payload Mon - Customer Gnd Payload Mon - System Gnd CMS Ident Code 0 CMS Ident Code 1 CMS Ident Code 2 CMS Ident Code 3 CMS Ident Code 4 CMS dent Code 5 CMS Service CMS Clear WTL Impl Ctrl Gnd WTL Impl Ctrl Serv Mode SW to GND WTL Impl Ctrl Clear Fault SW to GND WTL Impl Ctrl ID Code 3 WTL Impl Ctrl ID Code 4 WTL Impl Ctrl ID Code 5 ETAC Ctrl Gnd Impl Ctrl BTrans Ctrl BBasic Machine Circuits Starter Relay No. 1 Output Starter Relay Coil To Neut Start SW Or Key Start SW Key Start SW To Neutral Start SW Main Power Relay Coil Start Aid SW To Start Aid Sol Start Aid Sol To Temp SW Backup Alarm Lamp Travel Alarm Warning Horn (Forward) Key Start SW “C” Term. Shutdown Solenoid Start Aid Sol #2 Start Aid Switch To Timer Hood Raise Motor Hood Raise Motor Hood Raise Relay Coil Hood Raise Relay Coil Monitoring Circuits Alternator (R) Term. Opr Mon Oil Press. (Low Setting) Opr Mon Action Alarm Opr Mon Master Sec Star SW Primary Ster SW Opr Mon Parking Brake Opr Mon Brake Press. (Oil) Eng Coolant Temp Gauge Hyd System Temp Gauge Power Train Temp Gauge Fuel Level Gauge Tach Sender (+) Sec Ster Action Lamp Primary Ster Lamp Opr Mon Panel Hyd Oil Level Opr Mon Implement Oil Filter Display Data Display Load PMS Lift Cyl Press Sensor Opr Mon Front Brake Temperature Opr Mon Rear Brake Temperature Accessory Circuits Wiper - Front (Park) Wiper - Front (Low) Wiper - Front (HI) Wiper - Rear (Park) Wiper - Rear (Low) Wiper - Rear (HI) Washer - Front Washer - Rear Radio Speaker - Left Radio Speaker - Left (Common) Radio Speaker - Right Radio Speaker - Right (Common) A/C Compressor/Refrigerant Pressure SW

3

22 2

9

54

27

10

36

A

26

C 5

20

12

62

21

7

35

E

45 57

1

39

60

D 61

46

23 31

59

40

Failure Mode Identifiers (FMI)¹

24 16

59

A

E

35 3

5

C

27 8

37

54

58

61

62

26 31

47 6

1

34

42

36

55

24

48

44

15 10

53

57 60

21

2

12

56

45

9

20 23

7

Switch (Normally Closed): A switch that will open at a specified point (temp, press, etc.). No circle indicates that the wire cannot be disconnected from the component. Ground (Wired): This indicates that the component is connected to a grounded wire. The grounded wire is fastened to the machine. Ground (Case): This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine. Reed Switch: A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

966G and 972G Wheel Loader Electrical System 966G: AAH1-UP 3ZS1-UP 9RS1-UP

19

972G: 7LS1-UP 1EW1-UP AAW1-UP

Harness and Wire Symbols Wire, Cable, or Harness Assembly Identification: Includes Harness Identification Letters and Harness Connector Serialization Codes (see sample).

Electro Hydraulics and Command Control Steering

Component Identifiers (CID¹) and Module Identifier (MID²) For Power Train ECM (MID No. 081) Component

Machine Code

966G

18,20,42

972G

19,21

CID

Component

+8 Volts Sensor Supply

0168

0070

Parking Brake Switch

0248

Data Link

0149

Ride Control Solenoid #2

0270

Caterpillar Monitoring System Harness Code

0168

Electrical System Voltage

0296

Powertrain Electronic Control Module

0177

Transmission Oil Temperature Sensor

0350

Rotary Position Sensor (Lift Linkage)

0190

Engine Speed Sensor

0352

Position Sensor (Lift Lever)

0270

Cat Monitor System Harness Code

0353

Position Sensor (Tilt Lever)

0363

Ride Control Solenoid

0354

Solenoid Valve (Lift Linkage Raise)

Electrical System Voltage

0562

Unable To Communicate With Cat Monitor System

Voltage above normal or shorted high.

0585

Transmission Output Speed Sensor 1

4

Voltage below normal or shorted low.

0621

Downshift Switch

5

Current below normal or open circuit.

0622

Up Shift Switch

6

Current above normal or grounded circuit.

0623

Direction Switch

7

Mechanical system not responding properly.

0631

8

Abnormal frequency, pulse width, or period.

0632

9

Abnormal update.

0633

10

Abnormal rate of change.

11

Failure mode not identifiable.

Module not responding.

18

Sensor supply fault.

19

Condition not met.

20

Parameter failures.

E72059

Sales Model

Component Identifiers (CID¹) and Module Identifier (MID²) For Implement ECM (MID No. 082)

Data erratic, intermittent, or incorrect.

17

Code

Fault

16800

Battery Voltage Too High

16801

Battery Voltage Too low

25413

PCS Not Calibrated

35001

Position Sensor Out of Range

35002

Loss of Position Sensor Signal

36401

Pressure Sensor Out of Range

36402

Loss of Pressure Sensor Signal

76901

Pressure Sensor Out of Range

76902

Loss of Pressure Sensor Signal

81704

Backup Battery Error

81708

Real Time Clock Not Running

82002

Loss Of Keypad Data Link

1 2

Sure-Seal connector: Typical representation of a Sure-Seal connector. The plug and receptacle contain both pins and sockets.

5A 9X-1123

Fuse (5 Amps)

Component Part Number

Harness identification code: This example indicates wire group 325, wire 135 in harness "AG".

Wire Gauge Wire Color

Printed in U.S.A.

Off Machine Switch Specifications

3

Parameter not available.

Deutsch connector: Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

Part No.

2

16

1 2

© 2012 Caterpillar All Rights Reserved

Data valid but below normal operational range.

Parameter failures.

Receptacle Pin or Socket Number

325-AG135 PK-14

1

15

Part Number: for Connector Receptacle

Plug

Solenoid Valve (Lift Linkage Dump)

Parameter failures.

L-C12 3E-5179

Harness Connector Serialization Code: The "C" stands for "Connector" and the number indicates which connector in the harness (C1, C2, C3, ...).

2

Start Relay

14

L-C12 3E-5179

1

Part Number: for Connector Plug

0444

Out of calibration.

Harness Identification Letter(s): (A, B, C, ..., AA, AB, AC, ...)

AG-C4 111-7898

0357

Solenoid Valve (Tilt Linkage Tiltback)

0358

Solenoid Valve (Pilot Pressure Supply)

0359

Detent Coil (Lift Lever Raise)

0360

Detent Coil (Lift Lever Lower)

0361

Detent Coil (Tilt Lever Tiltback)

0365

Switch (Kickout Set)

0487

Position Sensor (Auxiliary Lever)

Transmission Clutch #1 Solenoid

0489

Switch (Function Select)

Transmission Clutch #2 Solenoid

0490

Switch (implement Lockout)

0491

Solenoid Valve (Auxiliary Lever Forward)

Transmission Clutch Solenoid #3

Function

Actuate

Deactuate

Contact Position

38 ± 3°C 27 °C MIN Normally Closed (100.4° ± 5.4°F) (80.6°F MIN) Primary Steering Oil Pressure 1200 kPa MAX 700 ± 100 kPa A-C, Normally Closed 3E-6450 Secondary Steering Oil Pressure (175 psi MAX) (100 ± 15 psi) A-B, Normally Open 8270 kPa MAX 6890 ± 345 kPa A-C, Normally Closed 3E-6452 Park Brake Oil Pressure (1200 psi MAX) (1000 ± 50 psi) A-B, Normally Open 10700 kPa MAX 8960 ± 345 kPa A-B, Normally Open 3E-7693 Service Brake Oil Pressure (1550 psi MAX) (1300 ± 50 psi) A-C, Normally Closed 62.0 kPa MAX 38.0 ± 20.0 kPa Normally Open 9X-0378 Engine Oil Pressure (9.0 psi MAX) (5.5 ± 3.0 psi) 275 to 1750 kPa ¹ 114-5333 Refrigerant Pressure (AC) Normally Open ² (40 to 255 psi) Rear Axle Temperature 125 °C ± 3 117 °C Min 155-8999 Normally Closed Front Axle Temperature (257.0 °F) (242.6 °F) Min ¹ A hysteresis band exists: with increasing pressure the closed condition can be maintained up to 2800 kPa (405 psi), with decreasing pressure the closed condition can be maintained down to 170 kPa (25psi). ² Contact position at the contacts of the harness connector. 3E-6425

Coolant Temperature (Start Aid)

Resistor, Sender and Solenoid Specifications

0634

Transmission Clutch Solenoid #4

0492

Solenoid Valve (Auxiliary Lever Rearward)

0635

Transmission Clutch Solenoid #5

0596

Harness Code Incorrect

0636

Transmission Clutch Solenoid #6

0668

Transmission Shift Lever

0672

Torque Converter Output Speed Sensor

Part No.

Component Description

Resistance (Ohms)¹

3E-1906

Solenoid - A/C Clutch

3E-6332

Solenoid Valve - Start Aid

17.6 ± 0.6

3E-8574

Solenoid Valve - Ride Control

34.3 ± 1.7

3E-9366

53.3 ± 2.7

6.0

0673

Transmission Output Speed Sensor

9G-1950

Solenoid - Bucket Lift,Lower,Tilt Detent Sender - Hydraulic Oil Temperature Engine Coolant Temp Torque Converter Temp Resistor - A/C, Heater Blower Motor

0674

Transmission Intermediate Speed Sensor 1

110-6465

Solenoid - Engine Shutdown

5.12 ± .26

0675

Transmission Intermediate Speed Sensor 2

121-4298

7.75 ± 1.0

0793

Primary Steering Pressure Switch

0794

Secondary Steering Pressure Switch

0795

Secondary Steering Intermediate Relay

Solenoid - Clutch Modulating Valves Sender - Fuel Level Full: Empty:

0687 Option Code incorrect ¹ The CID is a diagnostic code that indicates which component is faulty. ² The MID is a diagnostic code that indicates which electronic control module diagnosed the fault.

Component Identifiers (CID¹) and Module Identifier (MID²) For Caterpillar Monitoring System (MID No. 030)

¹ The CID is a diagnostic code that indicates which component is faulty. ² The MID is a diagnostic code that indicates which electronic control module diagnosed the fault.

Mode of Operation Normal Harness Code

CID

Component

0084

Ground Speed Sensor

0096

Fuel Level Sensor

0100

Engine Oil Pressure Sensor

0110

Engine Coolant Temperature Sensor

0177

Torque Converter Oil Temperature Sensor

0248

Data Link

Mode Number

0263

8 Volt Sensor Power Supply

0

0271

Action Alarm

0324

Action Lamp

0523

Engine Speed Sensor Hydraulic Oil Temperature Sensor

Monitoring System Mode

Payload Control Fault Codes

Machine Codes

Magnetic Latch Solenoid: A magnetic latch solenoid is an electrical component that is activated by electricity and held latched by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.

Solenoid Valve (Lift Linkage Lower)

33

Machine Harness Connector And Component Locations

Solenoid: A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work.

0356

¹The FMI is a diagnostic code that indicates what type of failure has occurred.

39

Relay (Magnetic Switch): A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay.

0355

Bad device or component.

Sender: A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure.

T

Transmission AUTO/MAN Switch

13

Circuit Breaker Symbol

Flow Symbol

Switch (Normally Open): A switch that will close at a specified point (temp, press, etc.). The circle indicates that the component has screw terminals and a wire can be disconnected from it.

Ride Control Switch

12

Level Symbol

Fuse: A component in an electrical circuit that will open the circuit if too much current flows through it.

0368

Failure Description

Temperature Symbol

Symbols and Definitions

0367

0

B D

22

T

Data valid but above normal operational range.

FMI No.

19

55

Symbols

Pressure Symbol

0041

47

33 37

58

56

15

Accessory Circuits (Continued) Blower Motor (HI) Blower Motor (Medium) Blower Motor (Low) Hazard Flasher To SW A/C SW To Refrigerant SW A/C Clutch To Thermostat SW Turn Signal SW To Flasher Hazard Indicator Turn Signal Indicator Basic/Right Turn Signal Indicator Left DC/DC Converter Memory Output Temp Potentiometer Pos 1 Temp Potentiometer Pos 2 Temp Potentiometer Pos 3 Electronic Water Valve Actuator Electronic Water Valve Actuator Flasher To Indicator Lights Blend Door Motor (A) Blend Door Motor (B) Blend Door Position Feedback (+) Blend Door Position Feedback (Signal) Blend Door Position Feedback (-) Lift Press Sensor Lift Position Sensor Lighting Circuits Rotary Beacon Stop Lamp Turn Lamp - Left Turn Lamp - Right Flood Lamp - Rear Head Lamp Basic Head Lamp Hi Backup Lamp Park/Tail/Dash/Lamp Cab Flood Lamp/Rops Tail/Position Lamp - Left (Road Pkg)/Width Head Lamp Lo Attach Lighting Ckt Light SW To Front Flood Relay Light SW To Rear Flood Relay Tachometer Lamp Speedometer Lamp Gauge Lamps Warning Lights To Bkr Flasher Bkr To Flasher Control Circuits Sensor Power Supply XMSN Brake SW Sec Ster Motor Relay Sec Star Cont SW XMSN Shift Sol No. 1 Or 3 XMSN Shift Sol No. 2 XMSN Shift Sol No. 3 Or 1 XMSN Shift Sol No. 4 Or 5 Lift Kickout Sol SW Bucket Positioner Sol SW Dual Hp Sol Auto Ride Cntl SW Auto Ride Cntl SW Display +V Display Clock Tack/Serv Mtr/Odometer Select Downshift SW (N.O.) Upshift SW (N.C.) Downshift SW (N.C.) XMSN Cont Fwd SW To Gnd XMSN Cont Rev SW To Gnd XMSN Cont Speed 3 SW To Gnd XMSN Cont Speed 4 SW To Gnd XMSN Cont Neut SW To Gnd XMSN Cont PK Brk Lever SW To Gnd Impl Cont SW To Gnd N.O. Impl Cont SW To Gnd N.C. Impl Cont Lift Proportional Sol Impl Cont Lower Proportional Sol Impl Cont Lower Kickout Sol Impl Cont Sol Return Impl Cont Pilot Press Sol Serial Data (Transmit) Serial Data (Receive) XMSN Shift Sol No. 5 or 4 XMSN Shift Sol No. 6 XMSN Neutizer Override Indicator Data Link + (CAT) Data Link - (CAT) CST Autoshift- Auto/Manual SW 2 CST Autoshif t- Sol Return Ride Cont Solenoid 1 CST Autoshift- Auto/Manual SW 1 ECPC Trans Output SPD + ECPC Trans Output SPD ECPC Trans Intermediate SPD + ECPC Trans Intermediate SPD ECPC Trans Intermediate SPD Q+ ECPC Trans Intermediate SPD QECPC Trans Output SPD Q+ ECPC Trans Output SPD QECPC Trans Input SPD + ECPC Trans Input SPD Implement Lockout SW To GND (N.O.) Implement Lockout SW To Gnd (N.C.) Aux Lower Proportional Sol Aux Lift Proportional Sol Rackback Proportional Sol Dump Proportional Solenoid ETAC Front Left Wheel Proportional Solenoid ETAC Front Right Wheel Proportional Solenoid ETAC Rear Left Wheel Proportional Solenoid ETAC Rear Right Wheel Proportional Solenoid ETAC Test Mode SW (N/C) ETAC Test Mode SW (N/O) ETAC Front Axle Pilot Solenoid ETAC Solenoid Return WLPMS PHII Keypad Data Switch Return Stick 2 Bypass Sol ECPC Trans Oil Temp Sensor Ride Control Solenoid 2 Secondary Steering Test Sw Input

Harness And Wire Electrical Schematic Symbols

RENR2174-02 April 2012

Description

CID

B

44 6

4 40

Wire Color

8

25

25

Wire Number

34

42 4

E = Operator Compartment - Right Console

A = Operator Compartment - Dash Console

Description

1

Parameter Display

2

0600

Service

3

0601

Brake Air Pressure Sensor

Tattletale

4

0819

Display Data Link

Units

5

0821

9 Volt Display Power Supply

0830

Brake Oil Temperature Sensor

Calibration

6,7,8

¹ The CID is a diagnostic code that indicates which component is faulty. ² The MID is a diagnostic code that indicates which electronic control module diagnosed the fault.

4W-9972

134-3033

54°C (130°F) - 560 to 716 110°C (230°F) - 72 to 82 Overall 2.0 ± .1; Tap 1.0 ± .05

27.5 - 39.5 240 - 260

¹ At room temperature.

Related Electrical Service Manuals Title

Form No.

Alternator: 107-7977

SENR4757

Caterpillar Monitoring System Electric Starting Motor: 6V-5227 Consist: 106-8552 Consist: 6V-5537 Consist: 6V-5538 Payload Control System

SENR1394

Power Train ECM 966G and 972G Wheel Loader Hyd. System System Operation Testing And Adjusting

SENR3536 SENR3581 SENR4975 SENR6614 SENR1380 RENR2114 RENR2148

(Dimensions: 39 inches x 24 inches)

Schematic Location

20 Page,

Connector Number

RENR2174-02

Connector Location ¹