Component Identifiers (CID¹) Module Identifier (MID²) ADEM III ECM (MID No. 036)

Wire Number

Wire Color

BATTERY+

727

GN

SEC STR RELAY COIL+

BU

RUNNING LAMP PWR

728

BU

SEC STR INTER RELAY COIL+

YL

PRODUCT LINK PWR (SWITCHED)

751

GN

CLUTCH 1 REVERSE

106

WH

LIFT/TILT POSITION SENSOR PWR

752

YL

CLUTCH 2 FORWARD

109

OR

ALTERNATOR PWR

754

BU

CLUTCH 3 FOURTH

110

GN

ENGINE ECM PWR (SWITCHED)

755

OR

CLUTCH 4 THIRD

Wire Color

101

RD

102 104

Description

Control Circuits cont.

Power Circuits

Component

0001

Fuel Injector Solenoid #1

0002

Fuel Injector Solenoid #2

0003

Fuel Injector Solenoid #3

0004

Fuel Injector Solenoid #4

0005

Fuel Injector Solenoid #5

112

PU

0006

Fuel Injector Solenoid #6

114

0041

ECM 8V DC Supply

129

MAIN RELAY OUTPUT PWR

761

GN

FORWARD HORN PWR

BU

ETHER INJECT PWR

Machine Location

Alarm - Backup

B-18

2

Sensor - Oil Pressure

F-15

8

Alternator

I-16

3

Sensor - Tilt Position

L-10

21

Arc Suppressor

I-14

4

Sensor - Trans. Lube Oil Temperature

F-12

7

Batteries

K-14

5

Sensor - Trans. Output Speed (Leading)

G-13

18

Breaker - ADEM Engine Control

B-14

4

Sensor - Trans. Output Speed (Trailing)

H-13

18

Breaker - Alternator

B-14

4

Sensor - Trans. Oil Temp

H-13

18

FUEL INJECTOR CYLINDER 6

Breaker - Hood

C-14

4

Sensor - Turbo Inlet Pressure

F-13

14

FUEL PRESSURE

Breaker - Main

B-13

4

Solenoid - A/C Clutch

I-14

3

C-14

4

Solenoid - Aux Lift Prop

I-11

19

GY

LIFT POS SENSOR

762

YL

BUCKET/TILT POS SW

779

WH

QUICK COUPLER (ENGAGE SOL)

136

GN

SECONDARY STEERING PWR

A701

GY

FUEL INJECTOR CYLINDER 1

0094

Fuel Pressure Sensor

138

GN

PAYLOAD MONITOR SYSTEM PWR

A702

PU

FUEL INJECTOR CYLINDER 2

0100

Oil Pressure Sensor

150

OR

ENGINE ECM PWR (UNSWITCHED)

A703

BR

FUEL INJECTOR CYLINDER 3

0110

Engine Coolant Temperature Sensor

170

YL

PRODUCT LINK PWR (UNSWITCHED)

A704

GN

FUEL INJECTOR CYLINDER 4

0168

Electrical Power Supply

0172

Inlet Air Temperature Sensor

0174

Fuel Temperature Sensor

0253

Personality Module mismatch

0254

ADEM III ECM

0261 0262

174 175 177 199

PK PK OR OR

UNSWITCHED BUSS PWR

A705

HOOD MOTOR PWR

BU

A706

MAIN CIRCUIT BREAKER PWR

GY

A745

WH

Component Location Schematic Location

Throttle Sensor

0091

RENR4363-03 August 2003

Description

FUEL INJECOTR CYLINDER 5

Component

Schematic Machine Location Location

Component

F713

OR

TURBO INLET PRESS SENSOR

Breaker - Running Lamp

Ground Circuits

F762

GY

ETHER INJECT RELAY COIL+

Breaker - Unswitched Bus (Cab)

C-14

4

Solenoid - Aux Lower Prop

I-11

19

WH

DETENT ENABLE INTERLOCK

Control - ADEM III

D-9

6

Solenoids - Cylinder Head ( 1 - 6)

H-17

22 19

HOOD CONTROL PWR

200

BK

MAIN CHASSIS GND

F766

Engine Speed Sensor

201

BK

OPERATOR MONITOR GND

G764

PK

PARKING BRAKE SW (ON)

Control - Hood Raise / Lower

C-12

4

Solenoid - Dump Prop

I-10

5 Volt Sensor Supply

229

BK

ENGINE ECM GND

H713

PK

LIFT PROPORTIONAL SOL

Control - Product Link

A-6

7

Solenoid - Ether Injection

G-10

23

0267

Engine Shutdown Switch

251

BK

PAYLOAD MONITOR SYSTEM GND

H714

OR

LOWER PROPORTIONAL SOL

Motor - Actuator

B-15

2

Solenoid - Lift Prop

I-10

19

0268

Check Programmable Parameters

A274

BK

PRODUCT LINK ECM GND

H716

WH

IMPLEMENT ECM SOLENOID RETURN

Motor - Fuel Priming Pump

J-15

8

Solenoid - Lower Prop

I-11

19

Motor - Secondary Steer

K-14

9

Solenoid - On / Off Pilot

I-10

19

BUCKET TILT POSITION SENS (SIG)

Motor - Starter

J-12

10

Solenoids - Quick Coupler

G-7

19

G-9

11

Solenoid - Rack Back Prop

I-10

19

K-18

12

Solenoids - Trans. Clutch

H-14

18

0273 0274

Basic Machine Circuits

Turbo Outlet Pressure Sensor 304

Atmospheric Pressure Sensor

WH

H717

STARTER SOL START TERMINAL

BR

H718

GY

PILOT SOLENOID

Engine Cooling Fan Solenoid

306

GN

START RELAY COIL+

H746

YL

VARIABLE SPD FAN SOLENOID+

Motors - Washers

0296

Transmission ECM

308

YL

MAIN POWER RELAY COIL+

H747

BR

VARIABLE SPD FAN SOLENOID-

Relay - Back Up Alarm

0320

Crankshaft Position Sensor

0291

0342 0545

Camshaft Position Sensor Start Aid Relay

B-12

4

Solenoid Valves - Ride Control

J-11

19

A-12, A-14

4

Solenoid - Variable Speed Fan

G-12

15

Relay - Secondary Steering

K-14

4

Switch - A/C Refrigerant

I-14

3

ENGINE RETARDER SOL COMMON

Relay - Secondary Steering Intermediate

L-15

9

Switch - Brake Oil Pressure

G-10

24

PK

TURBO OUTLET PRESSURE SENSOR

Relay - Start

A-14

4

Switch - Disconnect

K-13

25

GY

ATMOSPHERIC PRESSURE SENSOR

Sender - Fuel Level

C-16

13

Switch - Front Axle Temperature

H-10

26

317

YL

ETHER INJECT SOLENOID+

H795

PK

ENGINE ECM (SENSOR/SW RETURN)

Relay - Ether Injection

321

BR

BACKUP ALARM

J700

BR

ENGINE RETARDER SOL CYL 1

Relay - Main

322

GY

FORWARD HORN

J701

GN

ENGINE RETARDER SOL 3

326

PU

FUEL PRIMING PUMP

J702

BK

397

OR

HOOD MOTOR LOWER

R746

398

BU

HOOD MOTOR RAISE

R747

0562

Caterpillar Monitoring System

0617

Air Inlet Heater Relay

1582

Trans Lube Oil Temperature Sensor

A300

GN

HOOD CONTROL LOWER

A893

OR

FUEL PRIMING PUMP MOTOR-

Sender - Torque Converter Oil Temp

C-8

8

Switch - Fuel Priming Pump

I-15

8

1589

Turbo Inlet Air Pressure Sensor

A301

WH

HOOD CONTROL RAISE

G828

WH

SENSOR PRESSURE +5V

Sensor - Atmospheric Pressure

F-15

14

Switch - Ground Level Shutdown

A-15

27

A307

GY

THROTTLE PEDAL POS SENS

Product Link ECM (MID No. 122) CID

Monitoring Circuits

Component

G829

GN

SENSOR PRESSURE COMMON

Sensor - Cam Shaft Speed Timing

E-15

15

Switch - Hood Actuator

B-15

27

G833

PK

ENGINE TEMP SENSOR COMMON

Sensor - Coolant Temperature

F-15

8

Switch - Hydraulic Filter Bypass Pressure

G-10

24

Sensor - Crank Shaft Speed Timing

D-16

16

Switch - Hydraulic Oil Level

G-9

17

Sensor - Fuel Pressure

F-16

8

Switch - Lift Kickout Proximity

L-9

28

Sensor - Fuel Temperature

E-15

8

Switch - Park Brake Pressure

G-10

24

Sensor - Hydraulic Oil Temperature

G-9

17

Switch - Primary Steer

F-10

9

Sensor - Input Speed

H-13

18

Switch - Rear Axle Temp

C-7

29

Sensor - Inlet Manifold Pressure

E-15

14

Switch - Secondary Steering

F-10

9

Sensor - Intake Manifold Air Temp

F-15

8

Switch - Tilt Kickout Proximity

L-11

30

H-11, I-10

19

Switch - Trans Filter Bypass

G-10

24

L-9

20

403

GN

ALTERNATOR (R) TERMINAL

G850

BU

AIR INLET HEATER RELAY COIL+

0168

Electrical Power Supply

416

OR

SEC STR PRESS SW (N/0)

G853

OR

ENGINE INTAKE MANIFOLD AIR TEMP #2

0254

Electronic Control Module (Product Link)

417

GY

PRIMARY STR PRESS SW (N/O)

G856

WH

TDC PROBE+

0269

Sensor Power Supply

419

YL

PARKING BRAKE SW (OFF)

G857

YL

TDC PROBE-

1251

Alternator R-Terminal Signal

426

BR

XMSN FILTER BYPASS SWITCH

J843

BK

ENGINE ECM ANALOG SENSOR RTN

430

BU

AIR FILTER RESTRICTED IND

J844

GY

ENGINE ECM ANALOG SENS 5VOLTS

432

PK

BRAKE OIL PRES SWITCH (ON)

900

PU

CLUTCH 5 SECOND

442

GY

HYD TANK OIL TEMP SENSOR

901

WH

CLUTCH 6 FIRST

443

YL

TC OUTLET TEMP SENSOR

944

OR

CAT DATA LINK+

447

PK

FUEL LEVEL SENSOR

945

BR

CAT DATA LINK-

450

YL

ENGINE ECM (ENGINE SPD)

953

GY

IMPLEMENT ECM SENSOR RTRN

453

PK

SEC STR PRESS SW (N/O)

962

OR

TRANSMISSION ECM SENSOR RTRN

484

YL

PRIMARY STR PRESS SW (N/C)

975

WH

XMSN ECM SOLENOID/INDICATOR RTN

496

WH

HYD TANK OIL LEVEL SENS

976

OR

RIDE CONTROL ON SOLENOID

E416

PU

LIFT CYL HEAD END PRESS SENSOR

994

GY

OIL PRESSURE (FILTERED)

E455

BR

HYDRAULIC FILTER BYPASS SW

995

BU

Coolant Temperature

¹ The CID is a diagnostic code that indicates which component is faulty. ² The MID is a diagnostic code that indicates which electronic control module diagnosed the fault.

Failure Mode Identifiers (FMI)¹ FMI No.

Failure Description

F421

YL

FUEL TEMPERATURE

A982

BR

ENGINE ECM THROTTLE/IND 8VOLTS

G479

WH

SERVICE ENGINE INDICATOR

E900

WH

XMSN OUTPUT SPD SENS LEADING+

G485

BU

FRONT AXLE OIL TEMP SW

E901

GN

XMSN OUTPUT SPD SENS LEADING-

G486

GN

REAR AXLE OIL TEMP SW

E906

OR

XMSN OUTPUT SPD SENS TRAILING+

Accessory Circuits

E907

GY

XMSN OUTPUT SPD SENS TRAILING-

506

PU

FRONT WASHER PUMP+

E908

BR

XMSN INPUT SPD SENSOR+

507

WH

REAR WASHER PUMP+

E909

WH

XMSN INPUT SPD SENSOR-

513

OR

A/C CLUTCH SOLENOID+

E919

YL

AUX LIFT PROPORTIONAL SOL

521

YL

A/C SELECT SW (A/C POSTION)

E920

BR

AUX LOWER PROPORTIONAL SOL

522

WH

A/C CLUTCH SOLENOID-

E921

PK

RACKBACK PROPORTIONAL SOL

C529

GY

LIFT CYL HE PRESS SENS

E922

GN

DUMP PROPORTIONAL SOL

C530

BU

LIFT POSITION SENSOR

E963

BK

CRANK RPM SENSOR-

Lighting Circuits

E964

WH

CRANK RPM SENSOR+

603

PK

ROTARY BEACON

E965

BU

CAM RPM SENSOR-

604

OR

STOP LAMP

E966

YL

CAM RPM SENSOR+

Sensor - Lift Cylinder Head End Pressure Sensor - Lift Position

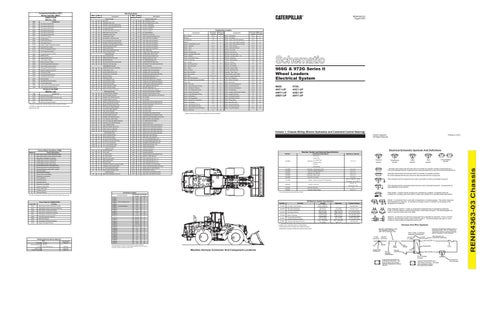

966G & 972G Series II Wheel Loaders Electrical System 966G: ANT1-UP AWY1-UP AWZ1-UP

972G: AXC1-UP AXE1-UP ANY1-UP

Machine locations are repeated for components located close together.

Volume 1: Chassis Wiring (Electro Hydraulics and Command Control Steering)

Part No.

Component Description

Data valid but above normal operational range.

605

YL

LH TURN LAMPS

K933

GN

OPERATOR MONITOR SENSOR PWR

1

Data valid but below normal operational range.

606

GY

RH TURN LAMPS

K977

PK

XMSN OIL TEMP SENSOR

Dump Prop

2

Data erratic, intermittent, or incorrect.

608

GN

REAR FLOOD LAMPS

L983

WH

FUEL INJECTOR RTN CYL 1-2

Lower Prop

3

Voltage above normal or shorted high.

611

PU

HEAD LAMP (HIGH)

L984

OR

FUEL INJECTOR RTN CYL 3-4

4

Voltage below normal or shorted low.

612

GY

BACKUP LAMP

L985

YL

FUEL INJECTOR RTN CYL 5-6

5

Current below normal or open circuit.

614

PU

LICENSE PLATE/RH TAIL/DASH LAMPS

N939

GN

RIDE CONTROL AUTO SOLENOID

6

Current above normal or grounded circuit.

7

Mechanical system not responding properly.

615

YL

FORWARD CAB FLOOD LAMPS

P976

BR

QUICK COUPLER RELEASE SOLENOID

8

Abnormal frequency, pulse width, or period.

617

BR

LH TAIL/CLEARANCE LAMPS

R971

YL

XMSN LUBE OIL TEMP SENSOR

9 10

Abnormal update. Abnormal rate of change.

619

GN

FWD FLOOD/LO BEAM LAMPS

R974

OR

ETHER INJECT SWITCH

11

Failure mode not identifiable.

709

OR

XMSN ECM SENS/IND (+8VOLTS)

12

Bad device or component.

13

Out of calibration.

14

Parameter failures.

15

Parameter failures.

16

X918

PU

GND LEVEL SHUTDOWN SW (N/O)

X919

WH

GND LEVEL SHUTDOWN SW (N/C)

138-2924

Sensor supply fault.

19

Condition not met.

20

24

5 36

2

Connector Number CONN 1 CONN 2 CONN 3 CONN 4 Timing / Calibration Probe CONN 5 CONN 6 CONN 7 Aux. Start Receptacle CONN 8 CONN 9 CONN 10 CONN 11 CONN 12 CONN 13

High Engine Coolant Temperature Derate

E017

High Engine Coolant Temperature Warning

E025

High Inlet Air Temperature Derate

E027

High Inlet Air Temperature Warning

E039

Low Engine Oil Pressure Derate

E095

Fuel Filter Restriction Warning

CONN 14

E096

High Fuel Pressure

E100

Low Engine Oil Pressure Warning

E190

Engine Overspeed Warning

CONN 15 CONN 16 CONN 17 CONN 18 CONN 19 CONN 20 CONN 21 CONN 22 CONN 23 CONN 24 CONN 25 CONN 26 CONN 27 CONN 28 CONN 29 CONN 30 CONN 31 CONN 32

Related Electrical Service Manuals Title 165-4619

Consist:

(Delco 42MT type 400)

Form Number SENR4130

SENR3581

ADEM III ECM

RENR1285

Product Link System

SEBU7351

Machine Location

I-17 G-15 F-15 E-15 D-15 I-14 J-14 L-13 A-12 C-10 H-10, I-8 J-9 J-9 H-3, J-3, J-9, L-3 H-3, J-9 H-3, K-9 K-9, I-3 K-9, I-3 L-8, L-10 I-5, K-7, L-5 G-7 C-7 B-5 H-9 K-1 J-2 I-3

12 22 8 8 16 8 1 9 4 6 19 19 20

8

29

G-2 G-2 F-2 E-2 D-2

Circuit Breaker Symbol

Flow Symbol

Level Symbol

Temperature Symbol

26

30

Solenoid: Variable Speed Fan

5.0 ± 0.3

152-6761

Solenoid: On / Off Pilot

32.6 ± 1.6

152-8340

Solenoids: Ride Control

32.6 ± 1.6

163-0872

Solenoid: A/C Clutch

Normally open switch that will close with an increase of a specific condition (temp-press-etc.). The circle indicates that the component has screw terminals and a wire can be disconnected from it. Normally closed switch that will open with an increase of a specific condition. No circle indicates that the wire cannot be disconnected from the component.

17.6 ± 0.6

This indicates that the component has a wire connected to it that is connected to ground.

560 to 716 @ 54ºC (130ºF)

Sender: Torque Converter Oil Temperature

220-8214

21

Full: 28 - 33

Sender: Fuel Level

This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine.

Empty: 240 - 250

20

27

8.15 ± 0.6

148-2350

72 to 82 @ 110ºC (230ºF)

33

31

Solenoids: Transmission Clutch

19

34

7 32

6

1

45

18

3E-6332

Solenoid: Start Aid

6

3E-8575

Solenoid: Quick Coupler

24.9 ± 0.4

¹ At room temperature unless otherwise noted.

Reed Switch - A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

Sender - A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure.

Off Machine Switch Specification Part No.

14

23 7

3

32

22 12 2 5

4 16 8 1 25 15 13 27

36

31 10

6

33

30

35 17 9

11

Actuate

Deactuate

Contact Position

T

Relay (Magnetic Switch) - A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay. Solenoid - A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work.

Harness And Wire Symbols

³ Specifications represent a differential pressure measurement.

24

18 29

28 34 45 20

Function

275 to 1750 kPa¹ 114-5333 A/C (High / Low) Pressure Normally Open² (39.9 to 253.8 psi) 125 ± 3.0°C 117°C Min Rear Axle Temperature Normally Closed 155-8999 (257 ± 37.4°F) (242.6°F Min) Front Axle Temperature A-B, Normally Open 8270 kPa MAX 6890 ± 345 kPa 174-4312 Park Brake Pressure A-C, Normally Closed (1200 psi MAX) (1000 ± 50 psi) 10700 kPa MAX 8960 ± 537 kPa A-B, Normally Open 175-3244 Brake Oil Pressure A-C, Normally Closed (1550 psi MAX) (1300 ± 79 psi) Primary Steering Pressure 1200 kPa MAX 700 ± 100 kPa A-B Normally Open 3E-6450 (174.0 psi MAX) (102 ± 14.5 psi) Secondary Steering Pressure A-C Normally Closed 110.3 - 137.9 kPa³ 86.2 - 103.4 kPa³ 7X-8549 Hydraulic Filter Bypass Pressure Normally Open (16 - 20 psi) (12.5 - 15) ¹ A hysteresis band exists: with increasing pressure the closed condition can be maintained up to 2800 kpa (405 psi), with decreasing pressure the closed condition can be maintained down to 170 kpa (25psi). ² Contact position at the contacts of the harness connector.

20 20 34 34 34 34 33 31 36 32 35 34 34 45 32 32 32 32 32

Pressure Symbol

7.75 ± 1.0

147-5399

175-3088

Connector Location

E015

Electric Starting Motor:

35

11 17

Condition

185-5294

15 16

28

23

22 13 4

Event Codes For ADEM III ECM

Alternator:

10

12

¹The FMI is a diagnostic code that indicates what type of failure has occurred.

Event Code

9 14

3

Schematic Location

Aux Lower Prop

Aux Lift Prop

25

Parameter failures.

T

Lift Prop

Module not responding.

18

Solenoid:

Resistance (Ohms)¹

Rackback Prop

Parameter not available.

17

Electrical Schematic Symbols And Definitions

Resistor, Sender and Solenoid Specifications

0

Control Circuits

Printed in U.S.A.

© 2003 Caterpillar All Rights Reserved

19

Harness identification code This example indicates wire 135 in harness "AG".

21

26

* * AG-C3 C-C4 130-6795 130-6795 325-A135 PK-14

The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart.

Socket

Pin

Machine Harness Connector And Component Locations

Single Wire Connector

Wire Color

Ground Circuit Connection Number Identification

* Harness identification letter(s) and a serializing code. The "C" stands for connector and the number indicates which connector in the harness.

Wire, Cable, or Harness Assembly Identification Part Number For L-C12* AG-C4* Connector Assembly 3E-5179 111-7898 325-A135 PK-14 1 Wire Gauge

Receptacle Plug 2

200-L32 BK-14 Pin or Socket Number

1 2

Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

Fuse

1 2

Typical representation of a Sure-Seal connector. The plug and receptacle contain both pins and sockets.

105-9344 Component Part Number

RENR4363-03 Chassis

CID

Wire Description Wire Number