To Wheel Brake

To Tank

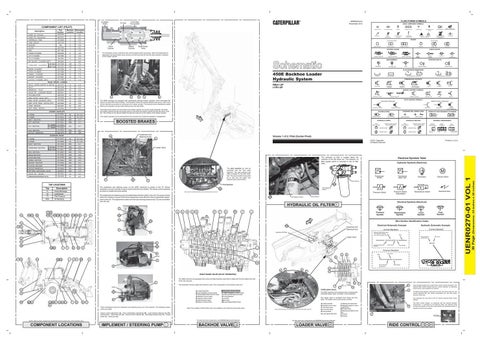

FLUID POWER SYMBOLS

UENR0270-01 November 2012

From Pilot Accumulator

BASIC COMPONENT SYMBOLS

COMPONENT LIST (PILOT) 269-9336

1

B-4

PUMP GP. (Secondary)

280-7873

2

B-3

HYDRAULIC TANK

272-0008

3

A-3

TANK GROUP

245-0169

4

A-3

N/A

5

A-3

FILTER

307-9799

6

B-2

HMU

297-1590

7

A-5

STEER CYLNDER

238-5285

8

A-6

LIFT CYLNDER

125-7895

9

C-8

TILT CYLNDER

100-7844

10

B-8

MP BUCKET CYLNDER (OPT)

226-5540

11

B-8

Left Hand

270-7290

12A

F-3

Right Hand

270-7291

12B

F-7

BOOM CYLINDER

270-7285

13

F-6

STICK CYLNDER

270-7286

14

F-5

SWING

CYLNDER

297-4896

15

F-5

BUCKET CYLNDER

270-7287

16

F-4

E-STICK CYLNDER (OPT).

270-7288

17

F-4

COOLER

STABILIZER CYLINDERS

223-4715

18

C-5

PILOT

267-2758

19

C-4

MANIFOLD - PILOT

268-0094

20

C-6

VALVE GP - CUSHION RELIEF

283-6331

21

F-4

ACCUMULATOR

226-0420

22

E-7

RIDE CNTRL VALVE (OPT)

245-8780

23

D-8

RIDE CNTRL ACCMLTR (OPT)

162-3960

24

D-8

RIDE CNTR PRES. SWTCH (OPT)

304-5696

25

D-8

TEMP. SENSOR

246-4297

26

B-3

DIFF. PRES. SWITCH

134-0404

27

B-3

Slave Cylinder

Master Cylinder

Boost Brake Valve

450E Backhoe Loader Hydraulic System

A

271-0520

28A

C-7

LIFT SECTION

271-0521

28B

C-7

28D

B-7

28E

28E

E

D

C

29

F-7, F-2

8 BANK

271-0528

29

F-7, F-2

INLET SECTION

341-4726

29A

E-7

271-0541

29B

E-3

Right Hand 271-0541

29B

E-7

AUX SECTION

271-0547

29C

E-6

BOOM SECTION

271-0542

29D

E-6

STICK SECTION

341-8185

29E

E-5

SWING SECTION

271-0544

29F

E-5

BUCKET SECTION

271-0545

29G

E-4

E-STICK SECTION

271-0546

29H

E-3

OUTLET MANIFOLD

271-0539

29J

E-2

PATTERN SWITCHING VALVE

299-9072

29K

E-5

VALVE GP - RELIEF

260-3022

30

E-2

PRESSURE REUDCING VALVE

300-0430

31

E-7

MANUAL SHUTOFF

GAS CHARGED

FIXED DISPLACEMENT

LINES CROSSING

SINGLE ACTING

LINES JOINING

FIXED DISPLACEMENT

UNIDIRECTIONAL

BIDIRECTIONAL

BIDIRECTIONAL

DOUBLE ACTING

INTERNAL PASSAGEWAYS

VARIABLE DISPLACEMENT NON-COMPENSATED

UNIDIRECTIONAL

CROSS FLOW

PARALLEL FLOW

FLOW IN ONE DIRECTION

TWO POSITION

THREE POSITION

INFINITE POSITIONING

FLOW ALLOWED IN EITHER DIRECTION

Printed in U.S.A.

The hydraulic oil filter is located below the machine at the left frame rail. The hydraulic oil filter bypass switch is mounted to the oil filter base.

T2

Electrical Symbols Table Hydraulic Symbols (Electrical)

The pilot manifold can also be accessed with the floor plate removed. The pilot pressure tap (T3) is located on the pilot manifold. The pilot manifold routes pilot oil to and from the loader and backhoe pilot control valves.

H

G Transducer (Fluid)

Transducer (Gas / Air)

View of pilot controlled backhoe valve with floor plate removed.

Pressure Switch (Adjustable)

Pressure Switch Temp Sensor

Filter Bypass Switch

SOS

Electrical Symbols (Electrical)

6

N

B

C

D

E

F

G

H

I

J

Pressure Symbol

T2 C

Electrical Wire

Temperature Switch

T

27 26 11

Electric Motor

Filter Bypass Switch

T3

A 5

Generator

SOS

The implement and steering pump is located below the floor plate in the cab. The pump control valve (H) contains a torque control spool adjustment screw (B) and a flow compensator adjustment screw (A). The adjustment screws and the load sensing pressure tap (T2) are accessible from the cab.

8

M

Temp Sensor

The implement and steering pump on the 450E machines is similar to the "D" Series machines, but now includes a torque control solenoid (not visible). The torque control solenoid provides an additional pump setting.

9 10

HYDRAULIC AND PNEUMATIC CYLINDERS

HYDRAULIC MOTORS

VARIABLE DISPLACEMENT NON-COMPENSATED

INTERNAL SUPPLY PRESSURE

COMPLETE

Volume 1 of 2: Pilot (Center Pivot)

Pilot Manifold

4

SIMPLIFIED

Loader Valve

Oil Sampling

3

SPRING

© 2011 Caterpillar All Rights Reserved

Pump Discharge Load Sense Pilot Pressure

25 24 23

PEDAL

A

Description

28 6

PUSH BUTTON

CROSSING AND JOINING LINES

D

12

DETENT

THERMAL

REMOTE SUPPLY PRESSURE

HYDRAULIC PUMPS

HYDRAULIC OIL FILTER 29 22

GENERAL MANUAL

INTERNAL RETURN

SPRING LOADED

TAP LOCATIONS

15

SERVO

SOLENOID and PILOT or MANUAL

SOLENOID and PILOT

ACCUMULATORS

Implement and Steering Pump

C

SOS

RETURN BELOW FLUID LEVEL

PILOT CONTROL SYMBOLS

The master cylinders can be removed from the machine from inside the operator's compartment.

B

271-0527

T1 T2 T3

BIDIRECTIONAL

RELEASED PRESSURE

BOOSTED BRAKES

7 BANK

Tap

UNIDIRECTIONAL

RETURN ABOVE FLUID LEVEL

SOLENOID or MANUAL

PUSH-PULL LEVER

B

The brake boost valves are connected to the master cylinder (A) at each brake pedal (B). Oil enters the master cylinder through the supply hose (C) and exits the master cylinder through the return hose (D). The oil flows to the service brakes through the hoses (E) at the bottom of the master cylinder.

BACKHOE VALVE

Left Hand

SOLENOID

B-7

269-1079

FLOW

COMBINATION CONTROLS

EXTERNAL RETURN

INLET SECTION

271-0523

PILOT CONTROLLED

ROTATING SHAFTS

PRESSURIZED

The 450E machines are equipped with hydraulically assisted master cylinders, which decreases the amount of pedal effort when braking. This illustration shows the boosted brakes valve group, which uses oil from the pilot accumulator to add boost to the master cylinder. The hydraulic force multiplies the pedal effort so the operator can get more braking force with less effort.

A-7, C-7

AUX SECTION

SHUTTLE

SPRING LOADED

BASIC SYMBOL

MANUAL CONTROL SYMBOLS

28

OUTLET MANIFOLD

INFINITE POSITION

TEMPERATURE

VENTED

RBA1-UP LYR1-UP

271-0513

STABILIZER SECTION

P T SHIFTED POSITION

P T NORMAL POSITION

FLUID STORAGE RESERVOIRS

3 BANK

28C

CHECK VALVES

AB

PRESSURE

A-7, C-7

271-0522

FOUR-WAY

THREE-WAY

MEASUREMENT

28

3 BANK

TWO-WAY

THREE POSITION

CONTROL VALVES

This illustration shows a sectional view of the boosted brake valve group. When the brake pedal is depressed, the boost brake valve moves to the left and inlet oil from the pilot manifold is directed to the master cylinder.

271-0512

TILT SECTION

VALVE PORTS

TWO POSITION

ONE POSITION

AB

2 BANK

271-0522

ATTACHMENT

LINE RESTRICTION VARIABLE and PRESSURE COMPENSATED

VALVES

LOADER VALVE (ST)

2 BANK

HYDRAULIC PNEUMATIC ENERGY TRIANGLES

VALVE ENVELOPES

VALVE GROUP ( 2-BANK) PILOT - LEVER W/DTNT & SWTCH

PRESSURE COMPENSATION

LINE RESTRICTION (VARIABLE)

SPRING (ADJUSTABLE)

VARIABILITY

PUMP: VARIABLE and PRESSURE COMPENSATED

2-SECTION PUMP

Flow Symbol

Level Symbol

Temperature Symbol

Wire Number Identification Codes

T1

14

Electrical Schematic Example

SOS

16 15

Implement and Steering Pump

E G

Hydraulic Schematic Example Current Standard

Current Standard

Hydraulic Oil Filter

Harness identification code This example indicates wire 135 in harness "AG".

Wire Circuit Number Identification

Loader Valve

13

Wire Color

325-AG135 PK-14

14

A

12 18 19

1

7

10

9

325-PK Circuit Identification Number

T2

11

Wire Color

Wire Gauge

L Previous Standard

B Drain

14

17 16

18 19

1

3

4

10

5

C

K

Wire Color

Wire

D

B

C

E

A

325-PK-14 B

M Circuit Number Identification

D B

C

D

A

Wire Gauge (EXAMPLE VALVE)

P E

R

EIGHT BANK VALVE (PILOT OPERATED) The 450E machines are equipped with a pilot controlled backhoe valve that is visible with the floor plate at the rear of the cab removed.

F

M This illustration shows a eight bank backhoe valve. The components in the backhoe valve are:

J

Drain

13

(A) Outlet Manifold (B) Left Stabilizer Control Valve (C) Extendable Stick Control Valve (D) Bucket Control Valve (E) Swing Control Valve (F) Stick Control Valve (G) Boom Control Valve

T1

15

E

12

29 22

26 28 6

25 24 23

7

9

8

11

Note: The auxiliary Control Valve (H) is not avalible on the optional seven bank valve.

Torque control adjustment (A), Flow compensator adjustment (B), Load sensing pressure tap (T2), Inlet port (C), Case drain port (D), Torque control solenoid (E), Discharge pressure tap (T1), Torque limiter (F), Outlet port (G) For other bank valve configurations see KENR5488 (Specifications Manual).

NOTE: Alpha numeric numbers are represented by the number only on the machine views.

COMPONENT LOCATIONS

IMPLEMENT / STEERING PUMP

1

BACKHOE VALVE 29

B

N

THREE BANK VALVE:

(H) Auxiliary Control Valve (I) Right Stabilizer Control Valve (J) Pilot On/Off Solenoid Valve (K) Inlet Manifold (L) A Ports (M) B Ports (N) Load Signal Relief Valve

27 These illustrations show the implement and steering pump out of the machine. The following components are visible:

K

F

View of mechanically controlled loader valve with floor plate removed.

A

Travel at high speeds over rough terrain causes bucket movement. The optional Ride Control System acts as a shock absorber by absorbing bucket forces, which stabilize the machine.

The 450E machines are equipped with a mechanically controlled loader valve as shown in this illustration.

The Ride Control System components include; ride control relay (A), ride control solenoids (B), ride control accumulator (C), and ride control pressure switch (D).

The loader valve is accessed from below the floor plate. The loader control valve group contains:

Two solenoids are now used on the "E" Series machines Ride Control System.

(A) Outlet manifold. (B) Auxiliary control valve. (C) Tilt control valve. (D) Lift control valve. (E) Inlet manifold. (F) Load signal relief valve.

(J) Makeup and relief valve. (K) Magnetic detent for return to dig function. (M) Priority Valve. (N) Mechanical detent for the float. (P) A ports. (R) B ports.

D

The Ride Control System, on machines with the optional autoshift transmission, is controlled by the Machine ECM. The Machine ECM monitors the position of the ride control switch and determines when to operate the ride control system.

C

ECM

For other bank valve configurations see KENR5488 (Specifications Manual).

LOADER VALVE 28

RIDE CONTROL 23

24 25

(Dimensions: 39 inches x 28 inches)

PUMP GP. (Primary)

LINE RESTRICTION (FIXED)

RESTRICTION

30 Page

Description

Machine Schematic Location Location

CONTROL VALVES

SPRING

FLUID CONDITIONER

UENR0270-01 VOL 1

Part Number

MAIN AUX.

PUMP or MOTOR