Wire Description

50(1)

41

8 VDC Supply Electrical System Voltage

191

Transmission Output Speed Sensor

247

SAE J1939 Data Link

262

5 VDC Supply

367

Ride Control Switch

50(1)

368

Transmission Auto/Manual Switch

434

Hydraulic Pilot Oil Pressure Sensor

490

Implement Lockout Switch

590

Engine Control Module

153

Warning Level 1

3

3

Description High Voltage Level 1 Event

High Voltage Level 3 Event

High speed directional shift

Activation 1. Start-up delay timer is expired (30 sec) and 2. Engine speed is greater than 800 RPM and 3. System Voltage is greater than 14.8 VDC to activate (less than 14.5 VDC to deactivate) and 4. Debounce status is TRUE. 1. System Voltage is greater than 16 VDC to activate (less than 15.8 VDC to deactivate) and 2. Debounce status is TRUE. 1. Ground speed is greater than 16 km/h (10 mph) and 2. A shift in direction is requested by the operator. A “Shift in Direction” is defined as: 1. Shift from Fwd to Rev

Component Location Schematic Location

Machine Location

Alarm - Accugrade

A-15

B

Antenna

F-13

Block - Diode (XMSN) FNR - Shift Handle

Component

871

“Accugrade” Inclination Front Facing Position Seat Switch

1037

Display Module

1251

Application Location Code

1401

Transmission Solenoid 1

1402

Transmission Solenoid 2

1403

Transmission Solenoid 3

1404

627(1)

797(2)

Transmission Solenoid 4 Transmission Solenoid 5

1406

Transmission Solenoid 6

1482

10 Volt Sensor DC Power Supply Implement Front Auxiliary Quick Coupler Flow Switch

797(1)

1834

Ignition Key Switch

1956

Implement Hoe Bucket Position Sensor

1957

Implement Hoe Stick Position Sensor

1958

Implement Hoe Estick Position Sensor

1959

Boom Cylinder Position

1960

MSS_trm Communication Diag

2108

Dev -- Hoe Swing Sensor

2236

Hoe Auxiliary Valve #1 Port A Solenoid

2237

Hoe Auxiliary Valve #1 Port B Solenoid

2242

Loader Auxiliary Valve Port A Solenoid

2243

Loader Auxiliary Valve Port B Solenoid

2244

Hoe Auxiliary Valve #2 Port A Solenoid

2245

Hoe Auxiliary Valve #2 Port B Solenoid Loader Joystick Thumbwheel Position Sensor

2529

Hoe Left Joystick Thumbwheel Position Sensor

2531

Hoe Right Joystick Thumbwheel Position Sensor

2735

Implement Front Auxiliary Continous flow switch

2736

Hoe Auxiliary Continuous Flow Switch

2977

Low Idle Switch Implement Valve Load Sense Pressure Sensor

3084

2

Machine Driven with Parking Brake ON

The engine coolant temperature is greater than 113 °C (235 °F) for 3 seconds 1. The ground speed is greater than 1 km/h (0.6 mph) in forward or reverse and

1 3

Brake Boost Low Pressure Level 1 Event Brake Boost Low Pressure Level 3 Event

1. Fluid level / pressure for the brake is low and 2. Engine speed is less than 800 RPM. 1. Fluid level / pressure for the brake is low and 2. Engine speed is greater than 800 RPM.

861(1)

1

Machine Synchronize clock Manual Alignment

The SYNC Clock requires Manual Adjustment.

875(1)

1

Low Voltage Level 1 Event

1. Start-up delay timer is expired (30 sec) and 2. Engine speed less than 400 RPM and 3. System Voltage is 12.3 -12.5 VDC and 4. Debounce status is TRUE (8 minute debounce on bench test). OR 1. Start-up delay timer is expired (30 sec) and 2. Engine speed greater than 1300 RPM and 3. System voltage is 12.4 -13 VDC and 4. Debounce status is TRUE.

E-9

A

Suppressor - Front

F-8 F-8

B

Switch - Autoshift Manual

B-14 C-9

Connector Location

101

RD

Bat (+) (Not Application Specific)

945

BR

103

RD

PRM Module #1

973

BR

105 110 111

CST Autoshift- Auto/Manual Switch 2

RD RD RD

Key Switch Flasher Rear Horn Relay

975 976 977

WH OR YL

CST Autoshift- Sol Return Ride Control Solenoid #1 CST Autoshift- Auto/Manual Switch #1

112

PU

PRM Module #2

994

GY

Oil Pressure (Filtered)

115

RD

ACC Power Port

995

BU

Coolant Temperature

996

GN

Engine/Speed Timing (Crankshaft) Throttle Switch 1

875(1)

875(1)

878(1)

2

3

2

Low Voltage Level 2 Event

Low Voltage Level 3 Event

High Hydraulic Oil Temperature Event

Description

Control Circuits (Continued) CAT Data Link -

Schematic Location

Machine Location

116

BR

Rear Flood Lamp

117

YL

Rear Flood Lamp (ATCH)

A755

PK

CONN 1

H-13

1

118

GY

Front Wiper

A756

BU

Throttle Switch 2

B

CONN 2

H-13

1

15

CONN 3

G -13

1

119 121

PK YL

Rear Wiper Backup Alarm To Lamp

A757 A758

GY BR

Throttle Switch 3 Throttle Switch 4

15

CONN 4

E-13

2

122

BU

Heater/AC Switch

C720

BU

Interlock Relay

B

CONN 5

E-13

2

123

WH

Quick Coupler

C743

PK

Parking Brake

A

CONN 6

A-11

3

124

GN

A/C Compressor

C949

YL

Brake Pressure Sensor

A-11

3

126

RD

Grade Check ECM

C967

BU

Inlet Air Temperature

Connector Number

B-9 B-14

A

Switch - AWD

H -9

A

CONN 7

B

Switch - Beacon

C-14

B

CONN 8

C-11

3

127

OR

Laser Grade Check

E455

BR

Hydraulic Oil Filter Switch

Indicator - Lamp (LH)

B-9

A

Switch - Brake (LH)

CONN 9

C-11

3

A-14

B

Switch - Brake (RH)

E-9 E-9

A

Indicator - Wait to Start

A

CONN 10

B -11

3

133 136

OR GN

PHS Solenoid Differential Lock Relay

E540 E543

PK WH

Aux Hydraulic Interlock Aux Hyd. Return Solenoid (Close)

Joystick - Loader

E-3

B

Switch - Control Flow 7-8

D-14

B

CONN 11

C-11

3

D-11

3

143 144

BR GN

Differential Lock/AWS Beacon

E544 E701

GN PK

Aux Hyd. Return Solenoid (Open) Auto Ride Control Switch

Indicator - Assembly (RH)

Machine - ECM

I -7

10

Switch - Control Pattern

I-9

A

CONN 12

Meter - Service

I-9 H-2

A

Switch - Differential Lock

CONN 13

D-11

3

146

GY

PRM Module #1

E750

PU

Body Position Sensor (Load Switch)

B

Switch - Front Work Lamp

F-8 D-14

16

Module - PRM 1

B

CONN 14

D-9

4

150

OR

Batt (+)

E803

YL

Right Ind Steer Solenoid

Module - PRM 2

H-2

B

Switch - Hazard

C-9

A

CONN 15

D-9

4

157

YL

Front Flood Lamp (ATCH)

E804

BU

Left Ind Steer Solenoid

I -4

5

158

BR

Front Flood Lamp

E885

OR

Bucket Dump Exchange

H-1

B

Switch - Horn (Front Console)

G -9

A

CONN 16

Module - PRM (HVAC)

H-1

B

Switch - Horn (Steering Column)

B -8

A

CONN 17

I-4

5

180

GN

Operator Seat

E900

WH

ECPC Trans Output Speed +

Motor - Front Wiper

F-13

11

Switch - Implement Lockout

D-14

B

CONN 18

I-4

5

181

GY

Engine Speed Control (+)

E901

GN

ECPC Trans Output Speed -

Motor - Rear Wiper

F-15

12

Switch - Key

A-15

B

CONN 19

H-4

5

182

PU

H-4

7

Module - PRM (Engine)

Engine Underspeed Control

E917

WH

Implement Lockout Switch To Ground (N.O.)

Ground Circuits

E918

GN

Implement Lockout Switch To Ground (N.C.)

Motor - Seat Group

F -3

13

Switch - Neutral Loader Handle

F-4

B

CONN 20

Power - Port #1

D-12 I-9

B

Switch - Neutral XMSN Handle

F-4

B

CONN 21

G -4

7

200

BK

Main Chassis

E965

BU

Engine Speed/Timing Sensor (Camshaft)

14

Switch - Park Brake

C-12

B

CONN 22

G-4

7

202

BK

XMSN Control

E991

GY

Implement Lock out Switch

Rela y - AWD Brake

C-1

C

Switch - Rear Wiper

A-14

B

CONN 23

G-4

7

207

BK

Start Relay

F420

GN

Warning Lamp

Relay - Backup Alarm

C

Switch - Rear Work Lamp

C-14

B

CONN 24

F -4

3

F702

GN

Throttle Position

Relay - Horn

F-1 F-1

C

Switch - Ride Control

G-9

A

CONN 25

F -4

5

304

WH

Starter Relay No. 1 Output

F711

GN

CAN Link +

Relay - Implement Enable

D-1

C

Switch - Stalk

B-9

A

CONN 26

E-4

5

306

GN

Starter Relay Coil Or Key Switch

F712

GY

CAN Link -

Relay - Position Lamp

F-1

C

Switch - XMSN Lock

H-9

A

Active Ride Control Switch (N.C.)

Power - Port #2

Relay - Ride Control

C-1

B

Relay - Start

G-2

B

Relay - Torque Limiter

G-2

B

Timer - Stabilizer

I-13 H-15

Valve - Stabilizer

17 17

Basic Machine Circuits

CONN 27

E-4

5

307

OR

Key Switch To Shifter

F738

WH

CONN 28

D-4

5

308

BK

Keyswitch Power (+)

F739

GN

Active Ride Control Switch (N.O.)

CONN 29

D-4

5

309

GY

Alternator Regulator Terminal

F748

WH

Ride Control Switch

CONN 30

D-4

5

310

PU

Start Aid Switch To Start Aid Solenoid

G423

PK

Hydraulic Filter Bypass

CONN 31

C-4

5

OR BR

Horn Relay Coil To Switch Backup Alarm Lamp Travel Alarm

G750 G755

BU GY

XMSN Forward Switch To Ground XMSN Reverse Switch To Ground Pilot Cutout Solenoid

Machine locations are repeated for components located close together.

CONN 32

I -2

8

A = Located inside of operator dash.

CONN 50

F -9

4

322

GY

Warning Horn (Forward)

G962

OR

324

BU

Differential Lock Solenoid

H416

GN

Lamp Indicator

331

OR

Backup Alarm Relay Coil

H705

BR

Pump Relay

Relay To Glow Plugs

H707

YL

Impl Cont Pump Torque Solenoid

H730 H731

BR GY

Reverse Output - Shuttle Control Forward Output - Shuttle Control Side Shift Lock Solenoid

The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart.

B = Located inside of right console.

1. Start-up delay timer is expired (30 sec) and 2. Engine is running and 3. Engine speed less than 1300 RPM and 4. System Voltage is 12.4 -13 VDC and 5. Debounce status is TRUE. OR 1. Start-up delay timer is expired (30 sec) and 2. Engine is running and 3. System voltage is 12 -12.3 VDC and 4. Debounce status is TRUE. 1. Start-up delay timer is expired (30 sec) and 2. Engine speed is greater than 800 RPM and 3. System Voltage is 11.5 or 11.8 VDC and 4. Debounce status is TRUE. 1. Hydraulic oil temperature is greater than 110 °C (230. °F) and 2. ON delay timer (3 min) is expired.

(1) logged

AESC Enable Selection Switch

384

BU

A347

GN

403

GN

Alternator (R) Terminal

H771

BR

404

YL

Opr Mon Hydraulic Oil Temperature

H783

GN

AESC Control Indicator Lamp

405 420

GY OR

Opr Mon Oil Pressure (Low) Opr Mon Fuel Filter/Low Accum Pressure

H901 H902

OR YL

LVDT Signal - Boom 1 LVDT Signal - Bucket

432

PK

Opr Mon Brake Pressure (Oil)

H903

PK

LVDT Signal - EStick

439

YL

Water in Fuel Indicator

H904

GY

LVDT Signal - Swing

441

OR

Engine Coolant Temp Gage

H907

GN

LVDT Signal - Stick 2 Bypass

442

GY

Hydraulic Oil Temperature Sensor

J764

BR

Switch/Sensor Return #1

447

PK

Fuel Level Gage

J765

BU

Switch/Sensor Return #2

450 452

YL PU

Tach Sender (+) Torque Converter

J766 J878

PU YL

Switch/Sensor Return #3 Switch/Sensor Return #5

483

BR

Brake Fluid Level

J984

PK

Analog 1

E455 F420

BR GN

Hydraulic Oil Filter Warning Lamp (General)

K753 K754

OR PK

Power Mod Relay (+) Power Mod relay (-)

G423

PK

High Pressure Implement Filter - Rear

K973

PK

Hex Engine Speed Control 1

H416

GN

Lamp Indicator

K974

PU

Hex Engine Speed Control 2

Accessory Circuits

K975

WH

Hex Engine Speed Control 3

MSS Start Condition Indicator Monitoring Circuits

500

BR

Wiper - Front (Park)

L730

OR

Analog Sensor Return (+5V)

501

GN

Wiper - Front (Low)

L731

BR

Analog Sensor Return (+5V)

² The MID is a diagnostic code that indicates which electronic control module diagnosed the fault.

502

OR

Wiper - Front (Hi)

L740

BR

Analog Sensor Return (+5V)(VCM)

503 506

BR PU

Wiper - Rear (Park) Washer - Front

L998 L999

OR GN

Auxiliary Hydraulic Solenoid B Auxiliary Hydraulic Solenoid C Waste Gate Valve (+)

Failure Mode Identifiers (FMI) FMI

1

Failure Description

507

WH

Washer - Rear

M795

WH

PU

Radio Speaker - Left

M936

BR

Flow Control Switch

509

WH

Radio Speaker - Left (Commom)

M937

GN

Flow Control Prox Sw #1

BR

Radio Speaker - Right

M952

BU

LH Joystick

512

GN

Radio Speaker - Right (Common)

M965

GN

RH Joystick

513 515

OR GY

A/C Compressor/Refrigerant Pressure Sw. Blower Motor (HI)

M968 M969

BU YL

Coupler Switch Interconnect Coupler Switch Interconnect

516

GN

Blower Motor (Medium)

N756

PK

Alarm Horn Output

517

BU

Blower Motor (Low)

N939

GN

Ride Control Solenoid

518

OR

Hazard Flasher To Switch

N945

OR

AWD (Signal)

A/C Refrigerant High Pressure

N957

WH

A/C Switch To Thermostat Switch

GN WH

Turn Signal Switch To Flasher Four Wheel Drive Solenoid

PK

520

T

PK

RS-232 RXD - COMM #1

N959

PK

RS-232 RXD - COMM #3

N960 N963

OR OR

RS-232 TXD - COMM #1 RS-232 TXD - COMM #3

Data valid but above normal operating range

1

Data valid but below normal operating range

537 552

2

Data erratic, intermittent or incorrect

564

GY

Rear Wiper Interrupt Switch To Wiper Sw.

N970

YL

RS-232 DTR - COMM #1

568

GN

Parking Brake Warning Buzzer To Diodes

N973

BR

RS-232 DCD - COMM #1

569

PK

A/C Switch Jumper #2

N979

GN

RS-232 Signal Ground - COMM #1

578

BU

Auxiliary Washer

N981

GN

RS-232 Signal Ground - COMM #3

4

Voltage below normal or shorted low

5

Current below normal or open circuit

585

YL

Aux Hydtraulic - Open

N997

WH

PWM - Freq In #1

6

Current above normal or grounded circuit

7

Mechanical system not responding properly

586 597

BR PU

Aux Hydtraulic - Closed A/C High Press. Cutout Switch

P914 P920

GN BR

XMSN Forward Indicator EUI Secondary Engine Speed/Timing

A510

OR

A/C Low Press. Cutout Switch

P993

OR

Auxiliary Hydraulic Select

C506

WH

High Speed Relay

R762

GY

Control Pattern Switch

C510 E528

WH PU

A/C Compressor Relay Switch HVAC On/Off Switch To Blower Switch

R763 R912

BU OR

Control Pattern Switch Hydraulic Pedal Lock Solenoid

E529

YL

Blower Switch Jumper

R954

BK

Discrete Output 1

E540

PK

Aux Hydraulic Interlock

R955

GY

Discrete Output 2

E543

WH

Aux Hydraulic Return Solenoid - Close

R956

BU

Discrete Output 3

E544

GN

Aux Hydraulic Return Solenoid - Open

R956

BK

Discrete Output 3

Lighting Circuits

R957

GY

Discrete Output 4

Abnormal update rate

10

Abnormal rate of change

11

Failure mode not identifiable

12

Bad device or component

13

Out of calibration

9 11

12

15

Data valid but above normal operational range

603

PK

Rotary Beacon

R958

GN

Discrete Output 5

16

Data valid but above normal operational range

17

Data valid but below normal operational range

604 605

OR YL

Stop Lamp Turn Lamp - Left

R997 T901

OR YL

Analog Sensor Power (+5v) MSS Exciter Coil In

18

Data valid but below normal operational range

19

Received network data in error

606 607

GY PK

Turn Lamp - Right Flood Lamp - Front

T902 T904

PK BU

MSS Exciter Coil Out RH Stabilizer Up - Switch To Solenoid

608

GN

Flood Lamp - Rear

T907

GN

LH Stabilizer Down - Switch To Solenoid

614 617

PU BR

Park/Tail/Dash/Lamp Tail/Position Lamp - Left (Road Package)

T969 T970

YL GY

Aux Circuit 1 Stick Extend Solenoid (+)

618 620

YL WH

Tail/Position Lamp - Right (Road Package) Flood Lamp - Front

T971 T972

OR GN

Aux Circuit 3 Stick Extend Solenoid (+)

630

GY

Flood Lamp Rear (ATCH)

T993

BR

Analog Sensor Return

668

BU

Backlight Relay

T997

OR

Analog Sensor Power (+5v)

Control Circuits

X731

BU

Boost Pressure to Controller

4 3 17

C

1

B 14 8

2

15

13 10 7 6

16

5

OR

XMSN Brake Switch LH

X740

BU

Seat Forward to Controller

YL

XMSN Neutral Lock Switch

X750

OR

Fwd/Rev Solenoid Return From Controller

720 751

PU GN

XMSN Brake Switch RH XMSN Shift Solenoid (No. 1 OR 3)

X800 X920

OR BR

+8V Sensor Power Injector 1 Hi Side

752

YL

XMSN Shift Solenoid (No. 2 - Reverse)

X921

PK

Injector 2 Hi Side

754

BU

XMSN Shift Sol (No. 3 Or No. 1 - Forward)

X922

WH

Injector 3 Hi Side

762

YL

Bucket Positioner Solenoid Switch

X923

OR

Injector 4 Hi Side

766

GN

XMSN Disconnect Solenoid

X926

GY

Injector 1 Return

YL

AETA Solenoid - Left

X927

YL

Injector 2 Return

WH

Coupler Engage Solenoid

X928

GN

Injector 3 Return

Ground (Wired): This indicates that the component is connected to a grounded wire. The grounded wire is fastened to the machine.

Sender: A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure. Relay (Magnetic Switch): A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay.

Magnetic Latch Solenoid: A magnetic latch solenoid is an electrical component that is activated by electricity and held latched by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.

Harness and Wire Symbols Wire, Cable, or Harness Assembly Identification: Includes Harness Identification Letters and Harness Connector Serialization Codes (see sample).

Harness Identification Letter(s): (A, B, C, ..., AA, AB, AC, ...)

L-C12 3E-5179

AG-C4 111-7898

799

WH

Sensor Power

X929

BU

Injector 4 Return

852

GN

Continuious Flow Sensor (signal)

Y794

OR

Expanded CAN Data Link +

892

BR

Cat Data Link (-)

Y795

GN

Expanded CAN Data Link -

893

GN

Cat Data LInk (+)

Y946

BU

Fuel Rail Pressure

900

PU

XMSN Shift Sol No. 5 Or 4

Y947

BR

Analog Sensor Return

902

BR

XMSN Shift Sol No. 7

Y948

BR

Analog Sensor Return

903

GY

XMSN Shift Sol No. 8

Y950

YL

Fuel Pump Solenoid (+)

911

YL

AWD Mode Relay Switch Jumper

Y951

PU

Fuel Pump Solenoid (-)

944

OR

CAT Data Link +

L-C12 3E-5179

Harness Connector Serialization Code: The "C" stands for "Connector" and the number indicates which connector in the harness (C1, C2, C3, ...).

1

Part Number: for Connector Plug

Part Number: for Connector Receptacle

2 Plug

Receptacle Pin or Socket Number

1 2

Deutsch connector: Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

1 2

Sure-Seal connector: Typical representation of a Sure-Seal connector. The plug and receptacle contain both pins and sockets.

5A Fuse (5 Amps)

Harness identification code: This example indicates wire group 325, wire 135 in harness "AG".

Off Machine Switch Specification Part No. 16

Function

Actuate

Deactuate

Contact Position

207 kPa (30 psi)

Normally Open

134-0404

Hydraulic Bypass Oil Filter

276 ± 27.5 kPa MAX (40 ± 4 psi)

3E-7675

Boosted Brake Pressure

2550 kPa MAX (369.8 psi)

1800 ± 175 kPa (261 ± 25.3 psi)

Normally Closed

304-5696

Ride Control Pressure

3500 kPa MAX (507.6 psi)

3137 ± 175 kPa (455.0 ± 25.4 psi)

A-C, Normally Closed A-B, Normally Open

11

10 1 13

4

17

A

7

C 3

9

6

B 2

15 5

8

Resistor, Sender and Solenoid Specifications Part No.

Component Description

244-3106

Sender:

238-9397

Resistor:

4W-9972

Sender:

9X-1123

Component Part Number

325-AG135 PK-14

14

12

Switch (Normally Closed): A switch that will open at a specified point (temp, press, etc.). No circle indicates that the wire cannot be disconnected from the component.

Solenoid: A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work.

708

779

Switch (Normally Open): A switch that will close at a specified point (temp, press, etc.). The circle indicates that the component has screw terminals and a wire can be disconnected from it.

T

702

774

Circuit Breaker Symbol

Reed Switch: A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

Special Instruction

A

Flow Symbol

Ground (Case): This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine.

14

¹The FMI is a diagnostic code that indicates what type of failure has occurred.

Level Symbol

Fuse: A component in an electrical circuit that will open the circuit if too much current flows through it.

Voltage above normal or shorted high

Abnormal frequency, pulse, or period

Temperature Symbol

Symbols and Definitions

3

9

Printed in U.S.A.

Symbols

Pressure Symbol

0

8

© 2012 Caterpillar, All Rights Reserved

Harness And Wire Electrical Schematic Symbols

511

519

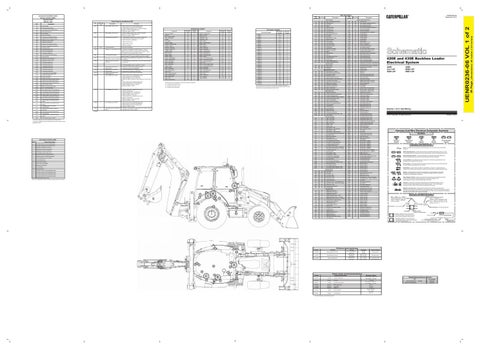

430E: MXB1-UP SWC1-UP

Volume 1 of 2: Cab Wiring

¹ The CID is a diagnostic code that indicates which circuit is faulty.

508

420E and 430E Backhoe Loader Electrical System 420E: DJL1-UP DAN1-UP

320 321

C = Located around of fuse block.

2530

2997

High Engine Coolant Temperature

The engine oil pressure is low enough to activate the engine oil pressure switch for 3 seconds and the engine is not running.

2. The Parking Brake switch is closed for 1 second.

1405

1529

Low Engine Oil Pressure

361

Alternator R-Terminal Signal

1326

360

Suppressor - Arc

A-14

The air filter is restricted.

1009

A

Indicator - AESC

Neutralizer Switch

“FNR” Lever Diagnostics

A

E-9

D-8 I-2

Switch - AESC

629

702

Shifter - Autoshift

Suppressor - Rear

Indicator - Deluxe

Hydraulic Oil Filter Bypass Event 1. Hydraulic oil temperature is greater than 42 °C (108 °F) (Temp Limit) or Hydraulic Oil Temp is unknown or Event is previously active and still in hysteresis( 39 °C (102.2 °F)) and 2. The switch for the hydraulic filter is ACTIVE.

9

B

3. Shift out of neutral

2

B

B

Steering / Transmission Lock Switch

282(1)

H-14

C-1

626

Air Inlet Restriction

Resistor - Terminal (#3)

Component

G-2

Hydraulic Oil Temperature Sensor

5 min

Machine Location

Fuse - Block

600

172

Schematic Location

Flasher

2. Shift from Rev to Fwd

Transmission Shift Lever

Wire Color

Description

UENR0236-06 September 2012

Coolant Temperature Excitation Converter Temperature

3E-8620

Solenoid:

RTD Loader Valve

134-2540

Resistor:

Terminating

212-3350

Solenoid:

Loader QC

251-3231

Sender:

Fuel Level (EST)

167-7801

Resistor:

Terminal (Atch)

¹ At room temperature unless otherwise noted.

Resistance (Ohms)¹ 54.4°C (130°F) - 560 to 716 110°C (230°F) - 72 to 82 120 ± 5% 54°C (130°F) - 560 to 716 110°C (230°F) - 72 to 82 21.8 ± 1 120±10% 3.2 ± 7% Empty - 240-250 Full - 28-33 390 ± 5%

Related Electrical Service Manuals Title Electric Starting Motor: Machine Troubleshooting:

Form Number 143-0539

SENR3828 KENR7663

Wire Gauge Wire Color

(Dimensions: 48 inches x 35 inches)

EID

168

668

Wire Color

Power Circuits

Event Codes for the Machine ECM

Component

CID

Wire Number

36 Page,

Machine ECM (MID No. 039)

Wire Number

UENR0236-06 VOL 1 of 2

Component Identifiers (CID¹) Module Identifier (MID²)