5 minute read

Oil Filter Housing

FUEL FILTER HOUSING

2. Connect fuel lines (2) and (3) to the fuel filter housing.

Advertisement

3. Install tube (4) on the engine.

4. Fill the cooling system to the correct level.

5. Open the fuel supply to the engine.

DISASSEMBLE FUEL FILTER HOUSING 1262-15

Tools Needed A 1P1855 Pliers 1

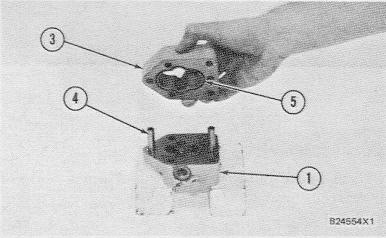

start by: a) remove fuel filter housingB43366X1

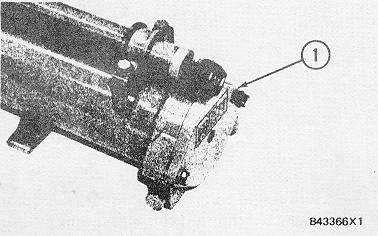

1. Remove cover (I) from the end of the filter housing.

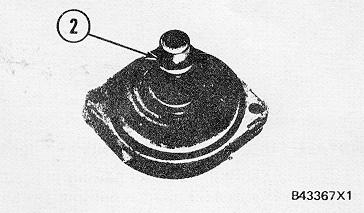

2. Use tool (A) to remove ring (2) from the cover.

280

FUEL FILTER HOUSING

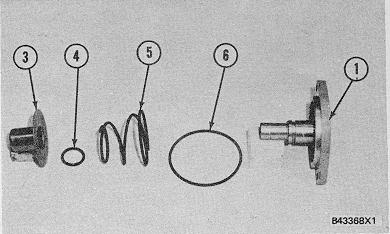

3. Remove retainer (3), O-ring seal (4), spring (5) and O-ring seal (6) from cover (1).

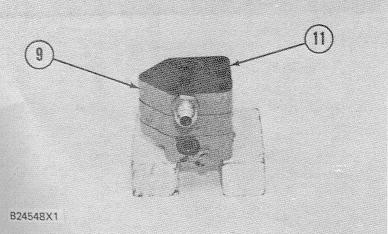

4. Remove the five filter elements (7) from the filter housing.

5. Disconnect fuel line (9) from cover (8). Remove cover (8) from the filter housing and remove the O-ring seal from the cover.

ASSEMBLE FUEL FILTER HOUSING1262-16

Tools Needed A 1P1855Pliers 1

1. Install O-ring seal (2) on cover (1) and put clean engine oil on the seal.

2. Install cover (1) on the end of the filter housing. Connect fuel line (3) to the cover.

281

FUEL FILTER HOUSING

3. Install the five filter elements (4) in the filter housing.

4. Put O-ring seal (6), spring (7) and retainer (5) in position on cover (9).

5. Use tool (A) to install ring (10) on the cover.

6. Install O-ring seal (8) on cover (9) and put clean engine oil on it. Install cover (9) on the end of the filter housing. end by: a) install fuel filter housing

282

FUEL PRIMING PUMP, FUEL TRANSFER PUMP

REMOVE FUEL PRIMING PUMP 1258-11

1. Close the fuel supply line to the engine.

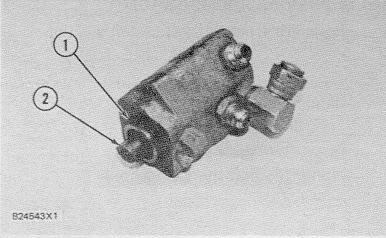

2. Remove the bolts and clamp (1) from the pump.

3. Remove bolts (2) and remove fuel priming pump (3) and the gasket from the fuel filter housing.

INSTALL FUEL PRIMING PUMP 1258-12

1. Put priming pump (1) and the gasket in position and install the clamp and bolts to hold it.

2. Open the fuel supply line to the engine.

REMOVE FUEL TRANSFER PUMP 1256-11

1. Close the fuel supply line to the engine.

2. Disconnect fuel lines (2) from fuel transfer pump (1).

3. Remove the four bolts to remove fuel transfer pump (1) from the engine.

INSTALL FUEL TRANSFER PUMP 125612

1. Make a replacement of the O-ring seal on the fuel transfer pump if necessary. Put clean engine oil on the seal.

2. Put fuel transfer pump (1) in position on the engine oil pump. Make sure the drive coupling for the fuel transfer pump is engaged correctly with the engine oil pump shaft.

3. Install the bolts that hold the fuel transfer pump.

4. Connect fuel lines (2) to fuel transfer pump (1).

5. Open the fuel supply line to the engine and use the fuel priming pump to remove (bleed) the air from the system.

283

FUEL TRANSFER PUMP

DISASSEMBLE FUEL TRANSFER.

PUMP 1256-15

start by: a) remove fuel transfer pump

1. Pull drive coupling (2) from the pump shaft.

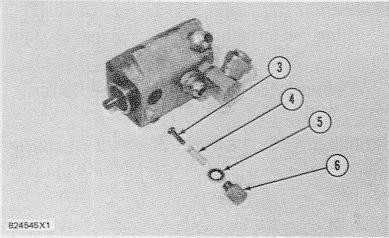

2. Remove O-ring seal (1) from the pump.3x1

3. Remove cap (6), seal washer (5), spring (4) and relief valve poppet (3) from the pump bracket assembly.

4. Remove bolts (7) and remove pump head (8) from plate (9).

5. If necessary, remove check valve (10) from head (8).

6. Remove plate (9) from the pump casing.

7. Remove gasket (11) and the O-ring seal from’ the opposite side of plate (9).

8. If necessary, remove the bearings from plate (9).

284

FUEL TRANSFER PUMP

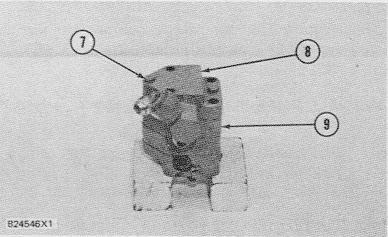

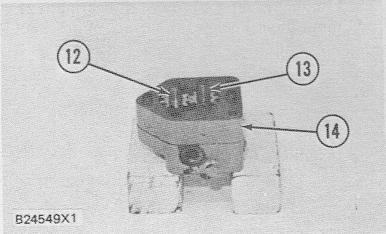

9. Remove gear assembly (12) and shaft assembly (13) from the pump bracket and casing (14).

10. Remove casing (14) and sleeves (15) from pump bracket (16).

11. Remove the O-ring seal from casing (14).

12. Remove outer seal (17) and inner seal (18) from bracket (16).

13. If necessary, remove the two bearings from bracket (16).

l

ASSEMBLE FUEL TRANSFER PUMP1256-16

Tools Needed A 1P510Driver Group 1

1. Use tool group (A) to install the inner and outer lip type seals in bracket (1). Make sure the lips of the seals are in the position shown at assembly. Put clean engine oil on the lips of the seals.

285

FUEL TRANSFER PUMP

2. Use tool group (A) to install bearings (2) 1.5 mm (.06 in.) below the surface of bracket (1).

3. Install sleeves (4) in bracket (1).

4. Install O-ring seal (5) in casing (3) and put casing (3) over sleeves (4) on bracket (1).

5 Install gear assembly (6) and shaft assembly (7) in the bracket and casing.

6. Use tool group (A) to install bearings (8) 1.5 mm (.06 in.) below the surface of plate (9).

7. Install O-ring seal (10) in plate (9) and put plate (9) in position on the pump casing.