2 minute read

Fuel Setting

FUEL SYSTEM

Either too much fuel or not enough fuel for combustion can be the cause of a problem in the fuel system.

Advertisement

Many times work is done on the fuel system when the problem is really with some other part of the engine. The source of the problem is difficult to find, especially when smoke comes from the exhaust. Smoke that comes from the exhaust can be caused by a bad fuel injector, but it can also be caused by one or more of the reasons that follow:

a. Not enough air for good combustion. b. An overload at high altitude. c. Oil leakage into combustion chamber. d. Not enough compression.

FUEL SYSTEM INSPECTION

A problem with the components that send fuel to the engine can cause low fuel pressure. This can decrease engine performance.

1. Check the fuel level in the fuel tank. Look at the cap for the fuel tank to make sure the vent is not filled with dirt.

2. Check the fuel lines for fuel leakage. Be sure the fuel supply line does not have a restriction or a bad bend.

3. Install new fuel filters. Clean the primary fuel filter.

4. Inspect the fuel pressure relief valve in the fuel transfer pump to see that there is no restriction to good operation.

CHECKING ENGINE CYLINDERS SEPARATELY

Temperature of an exhaust manifold port, when the engine runs at low idle speed, can be an indication of the condition of a fuel injector. Low temperature at an exhaust manifold port is an indication of no fuel to the cylinder. This can possibly be an indication of an injector with a defect. Extra high temperature at an exhaust manifold port can be an indication of too much fuel to the cylinder, also caused by an injector with a defect.

FUEL INJECTOR TESTING

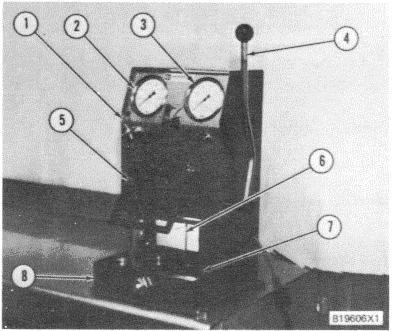

Tools Needed: 6V4022 Injector Tester. 6V4172 Injector Sleeve. 6V6068 Calibration Fluid 19 liters (5 U.S. gal.) -or6V6067 Calibration Fluid 208 liters (55 U.S. gal.)

NOTICE Be sure to use clean SAE J967 Calibration Fluid when tests are made. Dirty test fluid will damage components of the fuel injectors. The temperature of the test fluid must be 18 to 24OC (65 to 75OF) for good test results.