UENR6237-01 November 2017

56

CONN 11

54 CONN 3

85

46

93

94 25

49

220 CONN 9

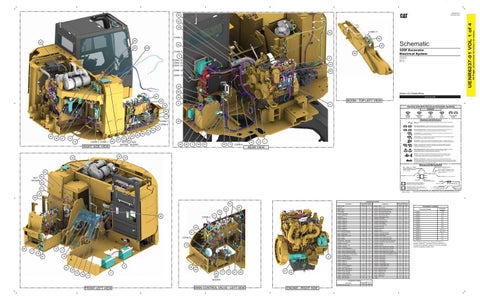

325F Excavator Electrical System

86

5

XAA10001-UP YCA10001-UP NDJ1-UP RBW1-UP

8

CONN 15 CONN 14 CONN 10

32

CONN 12

65

CONN 13

38 89 84

Volume 1 of 4: Chassis Wiring

53

BOOM - TOP LEFT VIEW

59 9

6

72

Harness And Wire Electrical Schematic Symbols Symbols

82 T

Pressure Symbol

71 CONN 7 CONN 8

Temperature Symbol

22

Fuse: A component in an electrical circuit that will open the circuit if too much current flows through it. Switch (Normally Open): A switch that will close at a specified point (temp, press, etc.). The circle indicates that the component has screw terminals and a wire can be disconnected from it. Switch (Normally Closed): A switch that will open at a specified point (temp, press, etc.). No circle indicates that the wire cannot be disconnected from the component.

50 45

44 40

47

19 12

CONN 2 CONN 1

48

RIGHT SIDE VIEW

43

80

Ground (Wired): This indicates that the component is connected to a grounded wire. The grounded wire is fastened to the machine. Ground (Case): This indicates that the component does not have a wire connected to ground. It is grounded by being fastened to the machine.

57

27

66

NOT NOT SHOWN SHOWN

14 24

26

7

36

37

55

73

13

Reed Switch: A switch whose contacts are controlled by a magnet. A magnet closes the contacts of a normally open reed switch; it opens the contacts of a normally closed reed switch.

1

35

Sender: A component that is used with a temperature or pressure gauge. The sender measures the temperature or pressure. Its resistance changes to give an indication to the gauge of the temperature or pressure.

CONN 6 T

REAR VIEW

33

Circuit Breaker Symbol

Flow Symbol

Symbols and Definitions

51 58

Level Symbol

Relay (Magnetic Switch): A relay is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close the switch part of the relay. Solenoid: A solenoid is an electrical component that is activated by electricity. It has a coil that makes an electromagnet when current flows through it. The electromagnet can open or close a valve or move a piece of metal that can do work.

34

Magnetic Latch Solenoid: A magnetic latch solenoid is an electrical component that is activated by electricity and held latched by a permanent magnet. It has two coils (latch and unlatch) that make electromagnet when current flows through them. It also has an internal switch that places the latch coil circuit open at the time the coil latches.

Harness and Wire Symbols Wire, Cable, or Harness Assembly Identification: Includes Harness Identification Letters and Harness Connector Serialization Codes (see sample).

23 NOT SHOWN

Harness Identification Letter(s): (A, B, C, ..., AA, AB, AC, ...)

L-C12 3E-5179

AG-C4 111-7898

1

Part Number: for Connector Plug

92

L-C12 3E-5179

Harness Connector Serialization Code: The "C" stands for "Connector" and the number indicates which connector in the harness (C1, C2, C3, ...).

Part Number: for Connector Receptacle

2 Plug

20

Receptacle Pin or Socket Number

1 2

Deutsch connector: Typical representation of a Deutsch connector. The plug contains all sockets and the receptacle contains all pins.

1 2

Sure-Seal connector: Typical representation of a Sure-Seal connector. The plug and receptacle contain both pins and sockets.

5A 9X-1123

Fuse (5 Amps)

Component Part Number

325-AG135 PK-14

91

© 2017 Caterpillar All Rights Reserved

Harness identification code: This example indicates wire group 325, wire 135 in harness "AG".

CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow”, and the POWER EDGE trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

39 69 Component Location

62

Component

81

76 74

Schematic Location

Machine Location

Alarm - Travel

D-13

1

Sensor - Soot

Alternator

I-13

2

Sensor - Squeeze Atch

Batter - Front

I-5

3

CONN 4

31

CONN 5

68

10 17 18 67

16

2

4

30

64 63

29 79

78

3 15

88

77

75

61

83

21

90

NOT SHOWN

Sensor - Stick Out Control Pressure

B-6

51

Sensor - Tank Coolant Diverter Valve

I-7

52

CONN 1

J-16

6

Sensor - UREA Tank Header Unit

I-7

53

CONN 2

C-16

J-7

7

Sensor - Viscus Clutch Atch

I-13

54

CONN 3

I-11

H-16

8

Sensor - Water Separator Level

A-13

55

Ground - Chassis 2

I-3

9

Solenoid - A/C Clutch

H-13

56

CONN 4

B-7

Ground - Chassis A

E-11

10

Solenoid - Boom 2 Up Atch

C-10

57

CONN 5

B-7

Connector Number

Ground - Chassis B

A-9

11

Solenoid - Boom Down Atch

C-7

58

CONN 6

G-7

Ground - Chassis C

E-13

12

Solenoid - Boom Regen

D-4

59

Ground - Chassis D

I-13

13

Solenoid - Fine Swing Atch

G-7

60

CONN 7

E-6

Ground - Chassis F

H-14

14

Solenoid - Heavy Lift

C-4

61

CONN 8

D-6

Ground - Chassis G

F-10

15

Solenoid - Hyd Lock

D-4

62

CONN 9

G-3

Ground - Chassis H

A-9

16

Solenoid - NFC 1

E-6

63

CONN 10

F-3, F-1

Horn - Forward Warning LH

E-5

17

Solenoid - NFC 2

D-4

64

Horn - Forward Warning RH

E-5

18

Solenoid - Power Shift Pressure

A-13

65

CONN 11

D-3, C-3

Motor - Lifting Pump

B-16

19

Solenoid - QC Bypass Cut Atch

C-10

66

CONN 12

E-1

Motor - Refueling Pump Atch

A-10

20

Solenoid - Quick Coupler

A-6

67

CONN 13

F-1

Motor - Starter

J-13

21

Solenoid - Quick Coupler Hold To Run

A-6

68

CONN 14

G-1

Motor - Washer

H-4

22

Solenoid - Quick Coupler Unlock Atch

D-11

69

Potentiometer - Boom Atch

B-10

23

Solenoid - Smart Boom Down ELE Check Atch

C-7

70

CONN 15

J-1

Resistor - Can J1939 (DEF)

J-7

24

Solenoid - Smart Boom Up ELE Check Atch

C-7

71

A-15

25

Solenoid - Snubber

E-4

72

J-7

26

Solenoid - Start Aid

D-13

73

Sender - Fuel Level

A-13

27

Solenoid - Stem 1 Extend Sol X1 (Tool-20)

C-6

74

Sensor - Air Inlet Temperature

I-10

28

Solenoid - Stem 1 Retract Sol X1 (Tool-20)

C-6

75

Sensor - Boom Cylinder Head Pressure

F-6

29

Solenoid - Stem 2 Extend Sol X (Tool-20)

C-6

76

Sensor - Boom Cylinder Rod Pressure

F-6

30

Solenoid - Stem 2 Retract Sol X1 (Tool-20)

B-6

77

Sensor - Bucket Cylinder Head Pressure

B-6

31

Solenoid - Stem 3 Extend Atch (Medium Circuit)

F-7

78

Sensor - Charge Air Cool Out Temperature

G-16

32

Solenoid - Stem 3 Retract Atch (Medium Circuit)

F-7

79

Sensor - Def Fluid Injector

A-16

33

Solenoid - Stick In Atch

D-7

80

Sensor - DOC IN Temperature

A-16

34

Solenoid - Swing Brake

D-4

81

Sensor - DPF IN Temperature

82

A-16

35

Solenoid - Swing Priority

E-4

Sensor - Heater 1m

I-7

36

Solenoid - Travel Speed

C-4

83

Sensor - Heater 2m

I-7

37

Solenoid - Travel Straight

D-4

84

Sensor - Heater 3m

H-7

38

Solenoid - Variable Relief 1 Atch

C-1, D-1

85

Sensor - Hyd Oil Temperature

B-10

39

Solenoid - Variable Relief 2 Atch

C-1, D-1

86

Sensor - ID Module (DEF)

B-16

40

Switch - Air Cleaner Pressure

I-10

87

Sensor - NFC 1 Pilot Pressure

D-4

41

Switch - Bucket In Pressure

B-6

88

Sensor - NFC 2 Pilot Pressure

E-4

42

Switch - Dual Disconnect

I-4

89

Sensor - Pump 1 Pressure

D-4

43

Switch - Engine Oil Level

G-16

90

Sensor - Pump 2 Pressure

C-4

44

Switch - Hyd Oil Filter

B-10

91

Sensor - SCR IN Temperature

A-16

45

Switch - Refueling Atch

A-10

92

J-10

93

I-4

94

Sensor - SCR Inlet NOX

B-16

46

Switch - Shunt Tank

Sensor - SCR Outlet NEX

B-16

47

VLPM

Schematic Location A-6

Machine Location

Component Location

ENGINE - RIGHT SIDE

50

4

Camera - Side View (Atch)

MAIN CONTROL VALVE - LEFT SIDE

C-7

5

Component

FRONT LEFT VIEW

Sensor - Stick In Control Pressure Atch

Connector Location

I-5

Resistor - Can Soot 1 (DEF

11

48 49

J-4

Resistor - Can Soot 1

70

B-13 C-1, D-1

Box - Breaker

Glow Plug

41

Machine Location

Batter - Rear

Control - XNOX ACU

42

Schematic Location

Schematic Location C-16

Control - Engine ECM

60

Component

220

Wire Gauge Wire Color

The connectors shown in this chart are for harness to harness connectors. Connectors that join a harness to a component are generally located at or near the component. See the Component Location Chart.

(Dimensions: 56 inches x 35 inches)

28

42 Page,

UENR6237-01 VOL 1 of 4

87