2 minute read

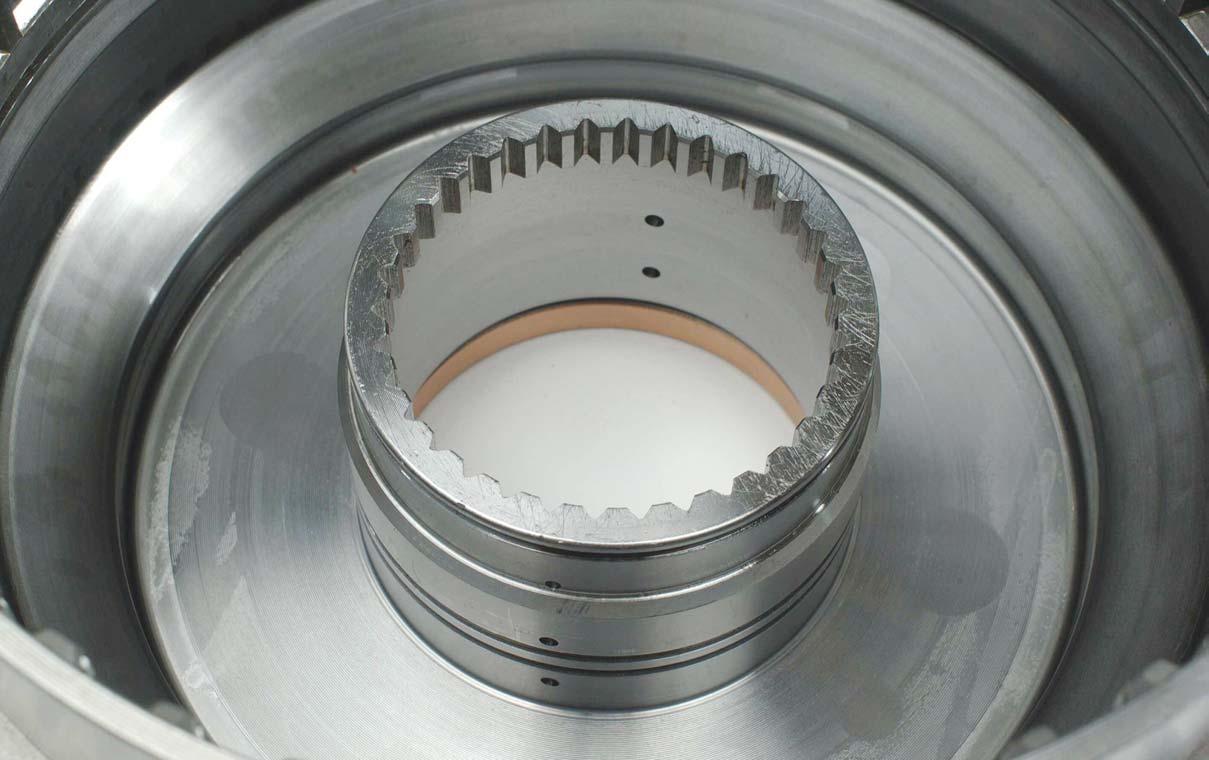

Rotating Clutch Housing

Inspect the internal splines where the C2 reaction plates index.

A. Rotating Clutch Housing E. Turbine Shaft

C. Bushing

B. PTO Drive Gear

Splines

A. Inspect the rotating clutch housing. Replace the housing if it is cracked, dented or has damage which cannot be repaired using a soft stone or crocus cloth.

Inspect the internal splineswhere the C2 reaction plates index for step wear, twisting, chips, burrs and signs of battering. Replace the housing if damage cannot be repaired using a soft stone or crocus cloth.

Inspect the surface just below the

bushing where the three front

support sealrings ride for cracks,

D. Speed

Sensor

Tone

Wheel F. P1 Sun Gear

pitting, grooves and scoring. Replace the housing if damage cannot be repaired using a soft stone or crocus cloth.

Inspect the C1/C2 piston housing snap ring and sealring grooves for burrs, chips and cracks. Replace the housing if damage cannot be repaired using a soft stone or crocus cloth.

NOTE: Use the appropriate special tools during C2 clutch piston snap ring removal and installation to avoid damaging the C1 clutch sealring area. Reference Service Manual SM3191 for procedures. B. Inspect the PTO drive gear teeth for chips, cracks and abnormal wear. Replace the rotating clutch housing assembly if damage cannot be repaired using a soft stone or crocus cloth, or if the gear is missing teeth or loose on the housing. C. Inspect the rotating clutch housing bushing. Replace the bushing if it has any damage which cannot be repaired using a soft stone or crocus cloth. Maximum allowable bushing inside diameter is 78.170mm (3.0776 inches).

(continued)

C1/C2 piston housing C1/C2 piston housing snap ring and sealring snap ring and sealring grooves. grooves.

C2 Clutch C2 Clutch Feed Feed C1 C1 Clutch Clutch Feed Feed

Front Support Front Support Sealring Area Sealring Area

C1 Return Spring C1 Return Spring C1 Return Spring Retaining Ring Retaining Ring Retaining Ring Groove Groove Groove

C2 Snap C2 Snap Ring Groove Ring Groove

(Top Groove) (Top Groove)

C1 Sealring Groove C1 Sealring Groove

(Bottom Groove) (Bottom Groove) C1 Balance C1 Balance C1 Balance Piston Feed Piston Feed Piston Feed

D. Replace the speed sensor tone wheel if it is deeply scratched, scored, dented, out-of-round or shows signs of impact damage. Any of these conditions can cause an erratic turbine speed sensor signal. E. Reference the "Inspection and

Analysis of the Turbine Shaft"

section of this manual for details. F. Inspect the P1 sun gear for chipped, broken, pitted and missing teeth. Replace the gear if damage cannot be repaired using a soft stone or crocus cloth.

The PTO gear must be securely attached to the rotating clutch housing.