2 minute read

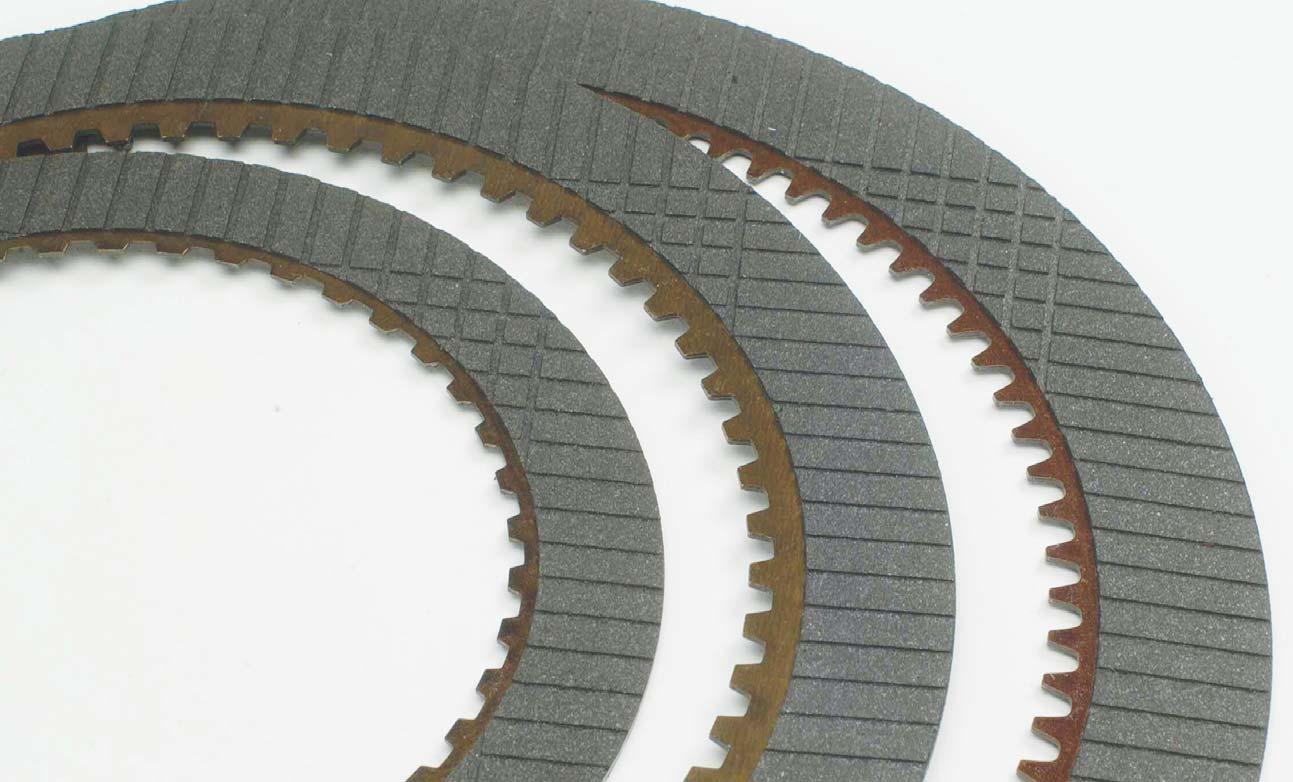

Clutch Plates

Oil grooves appear shallow or worn away measure plate thickness and groove depth. Spline teeth battered and worn - may be an indication of driveline issues.Replace clutch plates and check driveline. D. Spline Teeth

A. Contact Surface

C. Oil

Groove

Depth

A. Inspect friction plate contact faces and splines for excessive wear, damage and coning. Inspect the plates for burrs, pitted faces, cracks, distortion and damaged spline teeth.

B. Measure friction plate

thickness and coning. Reference the Service Manual SM3191EN for minimum thickness and maximum coning specifications. Do not reuse friction plates that do not meet published specifications. If reused plates are slightly coned (within specification), make sure each plate is stacked with the cone facing the same direction.

C. Measure friction plate oil

groove depth. Replace any plates that are not within Service Manual SM3191EN minimum groove depth specification. D. Inspect spline teeth for excessive wear and battering. Replace the clutch plate if damage cannot be repaired using a soft stone or crocus cloth. Replace the clutch plate if spline teeth are broken or missing. NOTE: Anti-freeze (glycol) and/or water will adversely affect the bonding agent between the friction material and steel core. Replace any friction plates which have been exposed to water and/or glycol.Reference SIL 18-TR-98, Rev. A, for details.

(continued)

B. Clutch Plate

Thickness and

Coning Coned Plate

Flat Plate Check Using Feeler Gauge

(continued) CLUTCHPLATES

C. Tangs Acceptable discoloration reuse plates.

Excessive scoring replace plates.

Broken tangs replace plates.

B. Thickness & Coning (see prior page graphic)

A. Contact Surfaces

A. Inspect reaction plates for excessive wear, warping, coning and surface damage. Replace any plate with wear exceeding service limits or with damage which cannot be repaired using a soft stone or crocus cloth.. B. Measure reaction plate thickness and coning. Reference the Service Manuals for minimum thickness and maximum coning specifications. Do not reuse plates that do not meet published specifications. If reused plates are slightly coned (within specification), make sure each plate is stacked with the cone facing the same direction.

C. Inspect reaction plate tangs for damage. Replace the plate if damage cannot be repaired using a soft stone or crocus cloth.