Suspension The following suspension system components should be inspected periodically to ensure proper operation: A. Shock absorber rods bent, pitted, or damaged. B. Reservoirs damp or leaking.

NOTE: Before attempting to adjust the suspension, clean dirt and debris from the sleeve and remove load from the suspension by using a jack to lift the frame and allow the shock to fully extend. Loosen each preload lock adjustment ring; then use an appropriate spanner wrench to adjust the preload adjustment ring to the desired position.

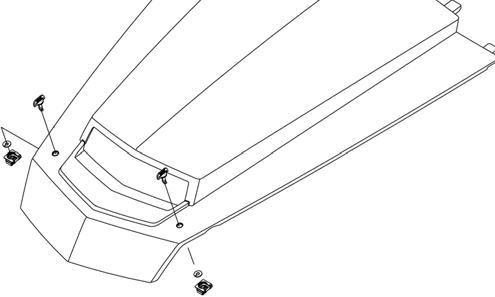

1. Measure from the ground to the bottom of the frame tube in the locations shown behind the front lower A-arms. Measurement should be 14 in. (35.6 cm).

C. Shock absorber body damaged, punctured, or leaking. D. Shock absorber eyelets broken, bent, or cracked. E. Shock absorber eyelet bushings worn, deteriorated, cracked, or missing. F. Shock absorber spring broken or sagging. G. Sway bar mountings tight and bushings secure. H. Proper preload and damping for conditions. SPECIAL TOOLS

A number of special tools must be available to the technician when performing service procedures in this section. Refer to the current Special Tools Catalog for the appropriate tool description. NOTE: When indicated for use, each special tool will be identified by its specific name, as shown in the chart below, and capitalized. Description

p/n

Shaft Bullet Tool

0644-404

Inflation Needle

0644-604

Piston Location (IFP) Tool

0644-575

Gas Shock Rod/Body Clamping Tool

0644-425

XX258

2. If measurement is not as specified, use a jack positioned under the front of the frame to lift and fully extend the front shocks. With a spanner wrench, loosen the preload lock adjustment ring located above the preload adjustment ring; then use an appropriate spanner wrench to rotate the preload adjustment ring in the desired directions shown. Adjust the left- and right-side springs equally as required. Tightening the springs will increase ground clearance, loosening the springs will decrease ground clearance. Secure the preload lock adjustment ring when correct ride height is achieved.

NOTE: Special tools are available from the Textron Off Road Service Department.

Shock Absorbers CHECKING/ADJUSTING RIDE HEIGHT

! WARNING Always ensure the vehicle is adjusted to the specified ride height. Failure to do so can result in adverse changes to the vehicle’s ride and handling, which could cause accidents or overturns.

XX130

NOTE: The preload collars MUST maintain contact with the spring at all times. Do not remove so much preload that the collar loses contact with the spring and allows the spring to “float” between the upper and lower spring collars. NOTE: Ensure the vehicle is on level ground, the tires are properly inflated. 14 psi (96.5 kPa) for the front tires and 22 psi (151.7 kPa) for the rear tires. This is for an average operating load in the vehicle.

143