Periodic Maintenance/Tune-Up Tighten all nuts, bolts, and cap screws. Care must be taken that all calibrated nuts, bolts, and cap screws are tightened to specifications. It is advisable to lubricate certain components periodically to ensure free movement. Apply light oil to the components using the following list as reference. KC147

A. Throttle Lever Pivot/Cable Ends

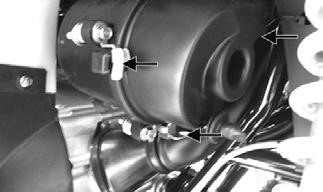

2. Remove the foam filter element from the air filter housing and separate the foam element from the spring.

B. Brake Lever Pivot/Cable Ends C. Auxiliary Brake Cable Ends SPECIAL TOOLS

A number of special tools must be available to the technician when performing service procedures in this section. Refer to the current Special Tools Catalog for the appropriate tool description. NOTE: When indicated for use, each special tool

will be identified by its specific name, as shown in the chart below, and capitalized. Description Compression Tester Kit

p/n 0444-213

Oil Filter Wrench

0644-389

Tachometer

0644-275

Timing Light

0644-296

Valve Clearance Adjuster

0444-178

KC148

NOTE: Special tools are available from the Textron Off Road Service Department.

Air Filter CLEANING AND INSPECTING FILTER

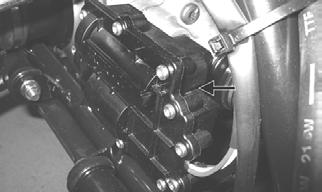

1. Rotate the three locking tabs free of the lugs on the air filter cover; then rotate the cover forward and away from the filter housing.

KC143

3. Place the element in a pan larger than the element and spray both sides generously with cleaning solvent. Let sit approximately three minutes. 4. In a pan larger than the element and with a mild detergent (dish soap) and water, wash all the dirt and oil off by squeezing the element, not twisting it (wringing out or twisting the filter can cause damage). 5. Rinse off any remaining soap. 6. Remove any excess water from the element by pressing with a towel. 7. Allow the element to dry completely.

KC0056A

8. Spray oil generously onto the air filter and work the oil into the element. NOTE: Foam Air Filter Cleaner and Foam Air Filter Oil are available.

6