CHAIN SAW

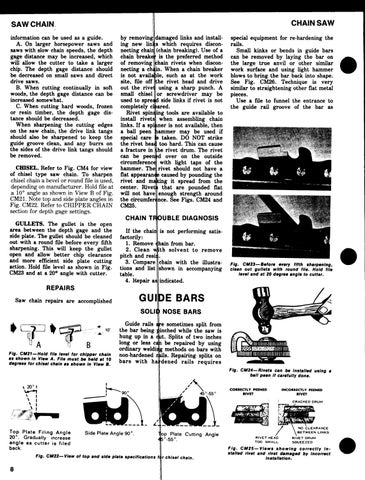

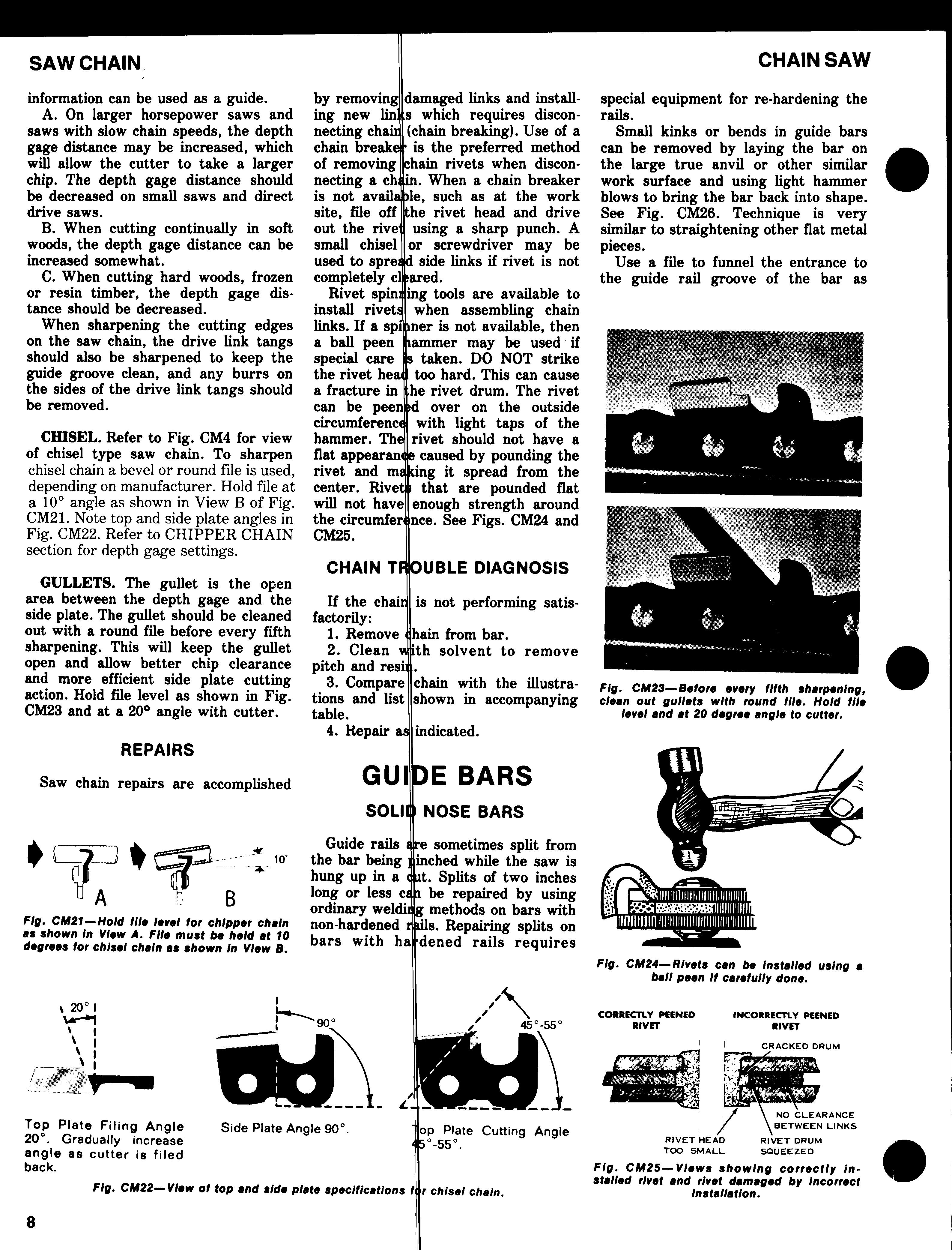

SAW CHAIN by removingl damaged Links and installing new links which requires disconnecting chain (chain breaking). Use of a chain breaker is the preferred method of removing llchain rivets when disconnecting a chain. When a chain breaker is not available, such as at the work site, file off lithe rivet head and drive out the riven using a sharp punch. A small chisel or screwdriver may be used to spread side links if rivet is not completely cleared. Rivet spinning tools are available to install rivets when assembling chain links. If a spinner is not available, then a ball peen hammer may be used if special care Is taken. DO NOT strike the rivet heaa too hard. This can cause a fracture in ihe rivet drum. The rivet can be peened over on the outside circumference with light taps of the CHISEL. Refer to Fig. CM4 for view hammer. The rivet should not have a of chisel type saw chain. To sharpen flat appearance caused by pounding the chisel chain a bevel or round file is used, rivet and making it spread from the depending on manufacturer. Hold file at center. Rivets that are pounded flat a 10° angle as shown in View B of Fig. will not have enough strength around CM21. Note top and side plate angles in the circumference. See Figs. CM24 and Fig. CM22. Refer to CHIPPER CHAIN CM25. section for depth gage settings. CHAIN TFflOUBLE DIAGNOSIS GULLETS. The gullet is the open area between the depth gage and the If the chain] is not performing satisside plate. The gullet should be cleaned factorily: out with a round file before every fifth 1. Remove dhain from bar. sharpening. This will keep the gullet 2. Clean wjith solvent to remove open and allow better chip clearance pitch and resii and more efficient side plate cutting 3. Compare I chain with the illustraaction. Hold file level as shown in Fig. tions and list||shown in accompanying CM23 and at a 20° angle with cutter. table. 4. Repair as|| indicated. REPAIRS information can be used as a guide. A. On larger horsepower saws and saws with slow chain speeds, the depth gage distance may be increased, which will allow the cutter to take a larger chip. The depth gage distance should be decreased on small saws and direct drive saws. B. When cutting continually in soft woods, the depth gage distance can be increased somewhat. C. When cutting hard woods, frozen or resin timber, the depth gage distance should be decreased. When sharpening the cutting edges on the saw chain, the drive link tangs should also be sharpened to keep the guide groove clean, and any burrs on the sides of the drive link tangs should be removed.

special equipment for re-hardening the rails. Small kinks or bends in guide bars can be removed by laying the bar on the large true anvil or other similar work surface and using light hammer blows to bring the bar back into shape. See Fig. CM26. Technique is very similar to straightening other flat metal pieces. Use a file to funnel the entrance to the guide rail groove of the bar as

Fig. CM23—Before every fifth sharpening, clean out gullets with round file. Hold file level and at 20 degree angle to cutter.

GUIDE BARS

Saw chain repairs are accomplished

SOLID NOSE BARS 10°

Fig. CM21—Hold file level for chipper chain as shown In View A. File must be held at 10 degrees for chisel chain as shown In View B.

Guide rails sometimes split from the bar being (inched while the saw is hung up in a it. Splits of two inches long or less c« be repaired by using ordinary welc methods on bars with non-hardened ils. Repairing splits on bars with hardened rails requires Fig. CM24—Rivets can be Installed using a ball peen If carefully done.

/\

c

CORRECTLY PEEKED RIVET

INCORRECTLY PEENED RIVET CRACKED DRUM

Top Plate Filing Angle 20°. Gradually increase angle as cutter is filed back.

Side Plate Angle 90°.

op Plate Cutting Angle 5°-55°.

Fig. CM22—Vlew of top and side plate specifications t r chisel chain.

NO CLEARANCE BETWEEN LINKS RIVET HEAD TOO SMALL

RIVET DRUM SQUEEZED

Fig. CM2S—Views showing correctly Installed rivet and rivet damaged by Incorrect Installation.