SERVICE MANUAL

SAW CHAIN

Saw Chain, Guide Bars and Sprockets SAW CHAIN

CHAIN TYPES

CHAIN NOMENCLATURE

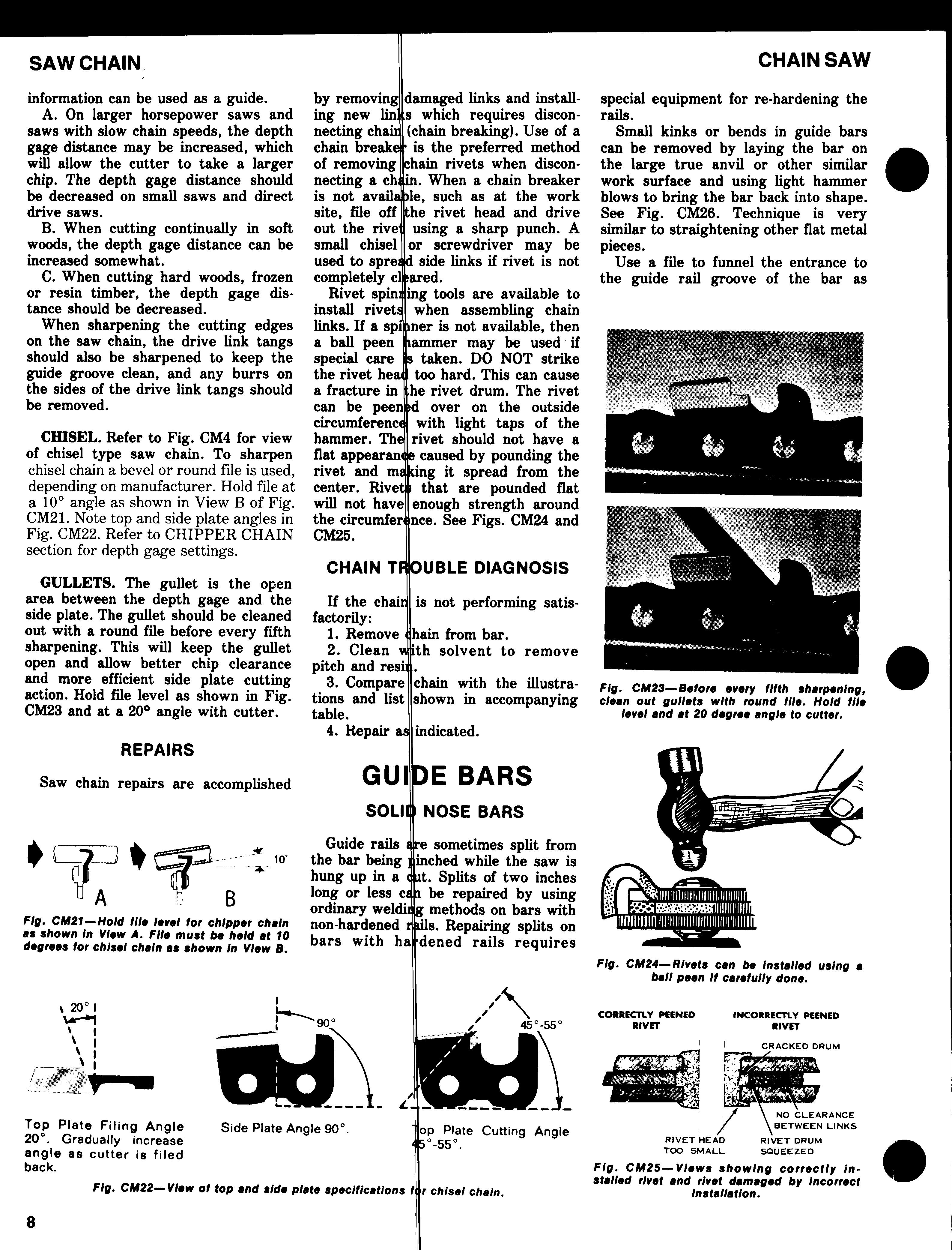

The two common types of chain cutters are chipper and chisel. Note in Fig. CM4 that cutting edge of chipper cutter is round while cutting edge of chisel cutter is square. Different configurations of chisel and chipper cutters may be used to meet specific cutting requirements. Refer to subsequent CHAIN SHARPENING section for procedures and tools used when sharpening chipper and chisel chain types. Anti-kickback saw chain uses drive links or side links which extend as they travel around tip of bar thereby preventing contact between cutter link and wood. Refer to Fig. CM5. Possibility of saw kickback is lessened if cutter contact is prevented as chain travels around bar nose.

Note component parts of chain shown in Fig. CM1 exploded view. The cutters remove material being sawed while saw chain is driven by engagement of drive links with engine sprocket. Side links connect drive links and ride against bar. Special chain types such as anti-kickback or ripping chain may use components designed as a safety feature or for specialized cutting. CHAIN SIZE Saw chain size is determined by chain pitch and gage. Pitch is the distance between alternate chain rivets divided by half as shown in Fig. CM2. Common pitch sizes are lk, 3/8, 0.404, 7/16 and Vz inch. Gage is the drive link thickness measured at the tang as shown in Fig. CM3. Common gage sizes are 0.050, 0.058 and 0.063 inch. Chain size must be matched with engine drive sprocket and bar sprocket, if so equipped. Mismatching chain and sprocket will result in damage to both components as well as possible damage to engine should chain break.

SIDt LINK

CHIVE IINK

5. Recheck tension until chain is fully broken in. 6. Keep chain well lubricated when in use. 7. Keep chain sharp. 8. Correct chain tension, especially on bar lengths of 32 inches and over, is important to prevent the chain jumping the bar and causing damage to the equipment and loss of time to the operator.

CHAIN BREAK IN, TENSION AND LUBRICATION BREAKING IN A NEW CHAIN. As

with any machine or accessory containing moving parts, the first hour or so of operation can make a great difference to the length of life. Careful attention to the instructions for breaking in and making tension adjustments can greatly add to the- life of the chain. The following instructions are important and will add to the life of saw chain: 1. If possible, soak chain in oil bath before use and between uses. 2. Install chain properly with recommended chain tension. 3. Run chain at slow speed for about 5 minutes, giving it plenty of oil. 4. Stop engine and readjust chain tension.

Fig. CM4—Vlew of chipper and chisel cutters.

Fig. CM1 — Exploded view of typical section of saw chain.

Pitch" = this distance divided by

oo the drive link

Fig. CM2— Chain pitch Is measured between rivet pins as shown above.

Fig. CM3—Saw chain gage size Is thickness of drive link tang (T).

Fig. CMS—Protruding drive links of antlklckback chain prevent cutter contact with wood as cutters travel around bar nose.