METRIC AND INCH (SAE) FASTENERS

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

SAFETY PRECAUTIONS MAINTENANCE

AND REPAIR

• The Service Manuals are updated on a regular basis, but may not reflect recent design changes to the product. Updated technical service information may be available from your local authorized Yale® dealer. Service Manuals provide general guidelines for maintenance and service and are intended for use by trained and experienced technicians. Failure to properly maintain equipment or to follow instructions contained in the Service Manual could result in damage to the products, personal injury, property damage or death.

• When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load.

•Do not lift heavy parts by hand, use a lifting mechanism.

•Wear safety glasses.

• Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section.

•Keep the unit clean and the working area clean and orderly.

•Use the correct tools for the job.

•Keep the tools clean and in good condition.

• Always use YALE ® APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer.

• Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to remove parts.

• Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs.

•Be sure to follow the WARNING and CAUTION notes in the instructions.

• Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable. Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems.

• Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area. Make sure the area is well ventilated.

NOTE: The following symbols and words indicate safety information in this manual:

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury and property damage.

On the lift truck, the WARNING symbol and word are on orange background. The CAUTION symbol and word are on yellow background.

WARNING

Installing improper electrical accessories or installing an electrical accessory incorrectly can increase the risk of equipment damage, personal injury and fire. DO NOT install electrical accessories to the truck unless you have been trained and authorized to do so. Personnel installing the electrical accessories must document the changes made to the truck. DO NOT install accessories which affect the truck’s compliance with standard EN 1175:2020.

WARNING

California Proposition 65 - Operating, servicing and maintaining a powered industrial truck can expose you to chemicals including engine exhaust, carbon monoxide, phthalates, and lead, which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov.

General

THREADED FASTENERS

Threaded fasteners, like bolts, nuts, cap screws, and studs, are made to specifications that describe the mechanical strength and hardness of the fastener. A fastener used in a design application is selected according to its specifications. Yale® Company buys parts from many countries. Parts that are purchased must be to Yale® Company standards. There are several standards used by these countries in the manufacture of threaded fasteners. Many of these fasteners are similar, but cannot be used as a direct replacement. To make sure that you have the correct fastener, order fasteners and parts through the Yale® Parts Depot.

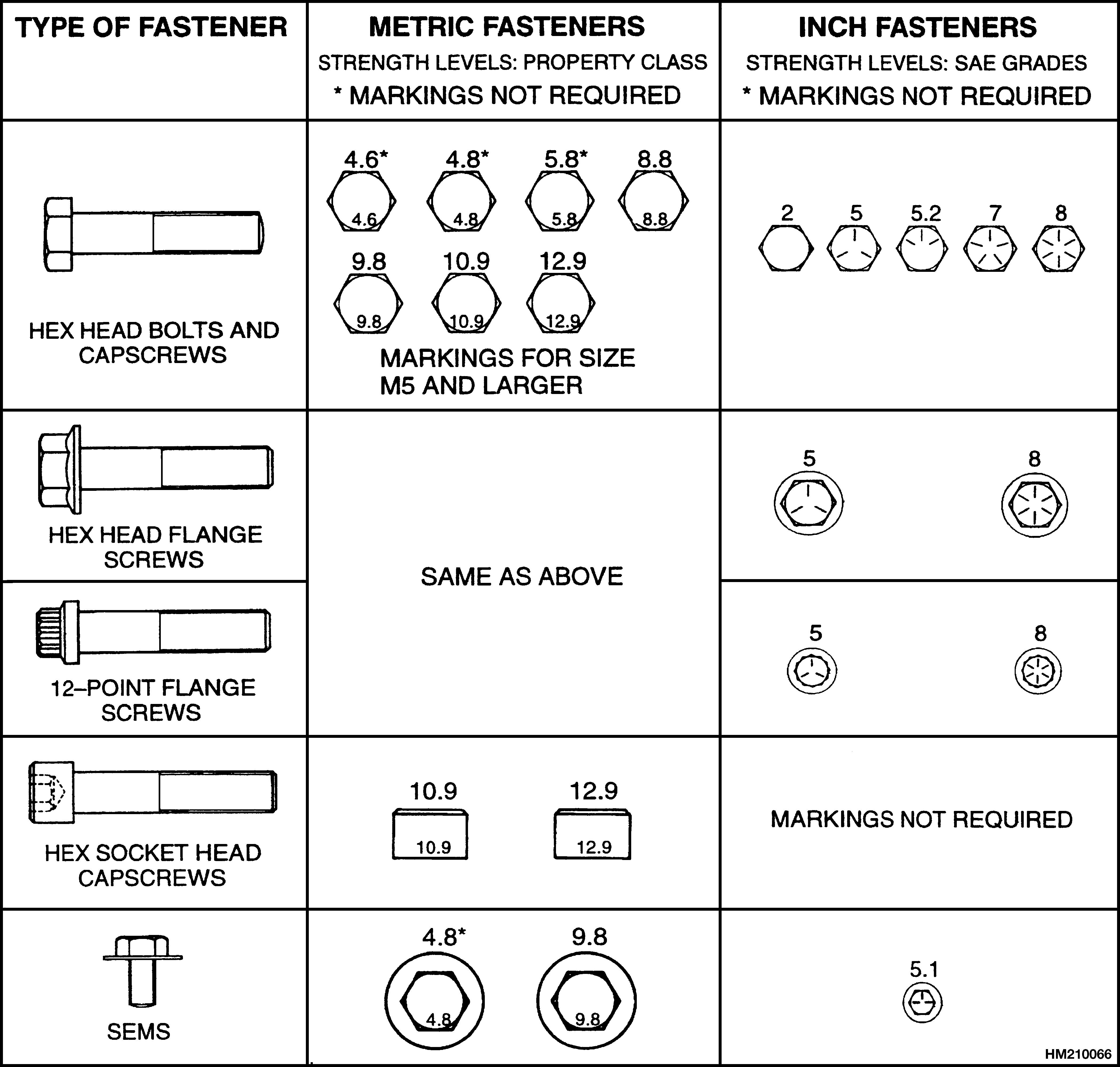

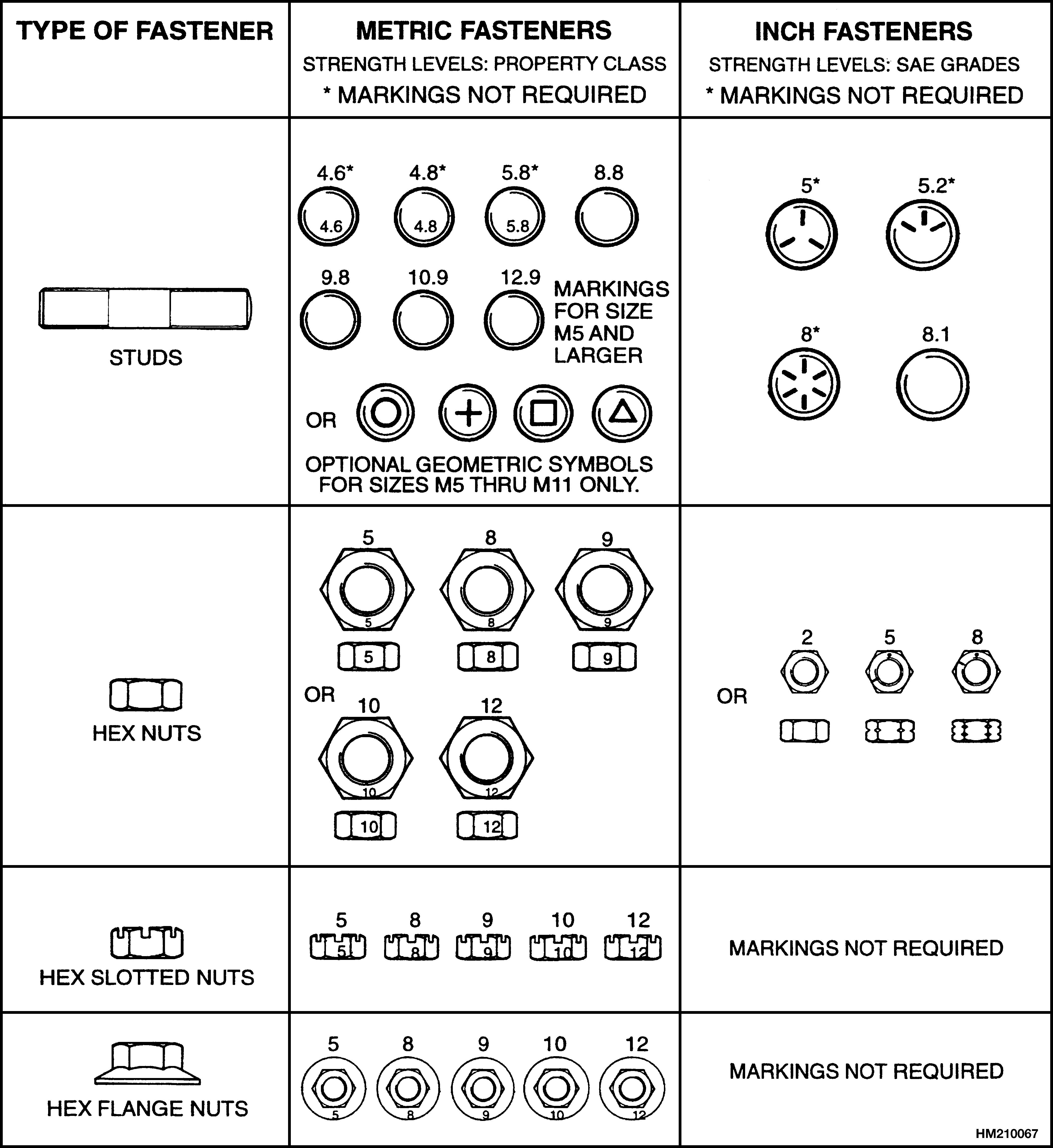

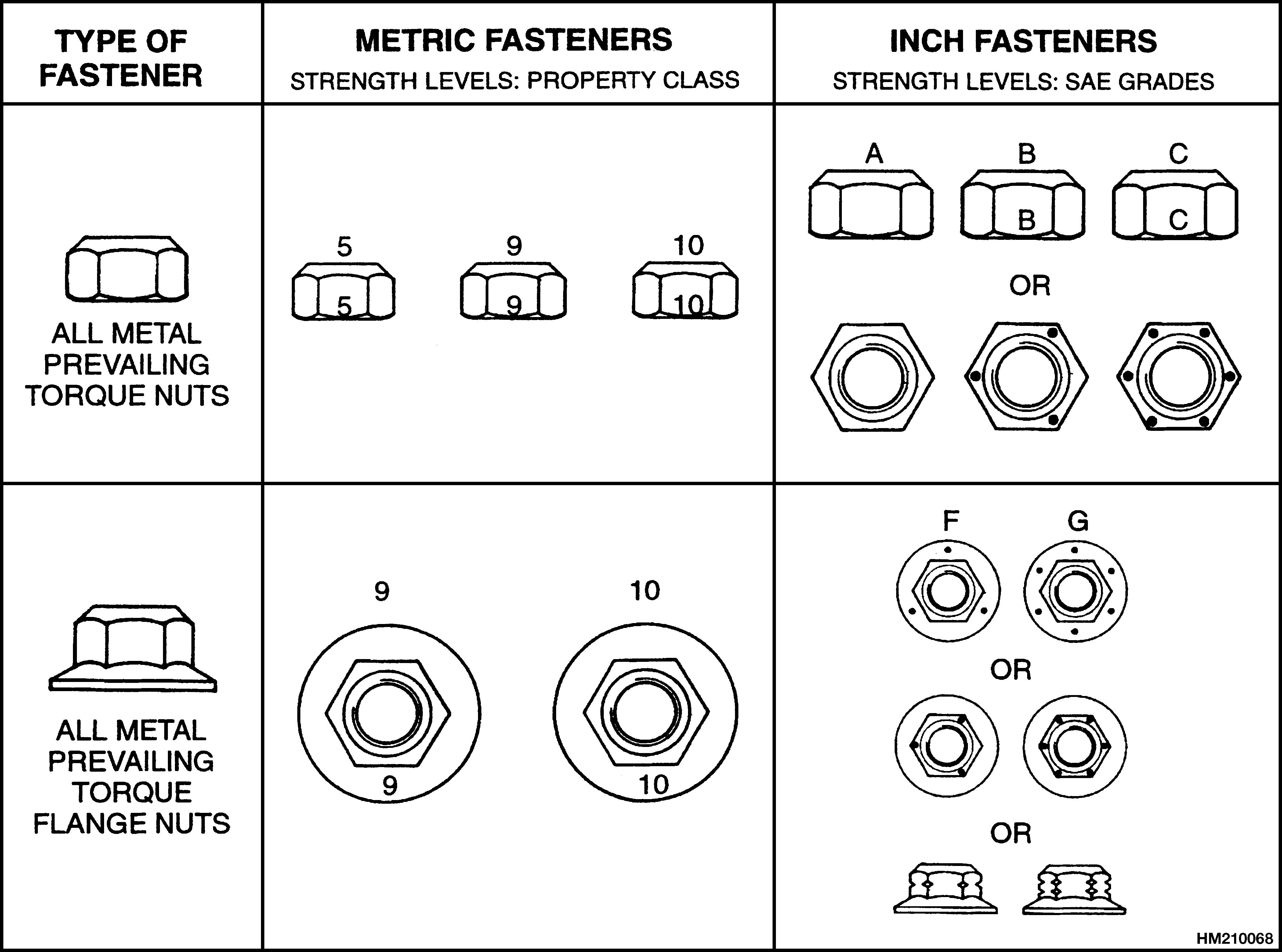

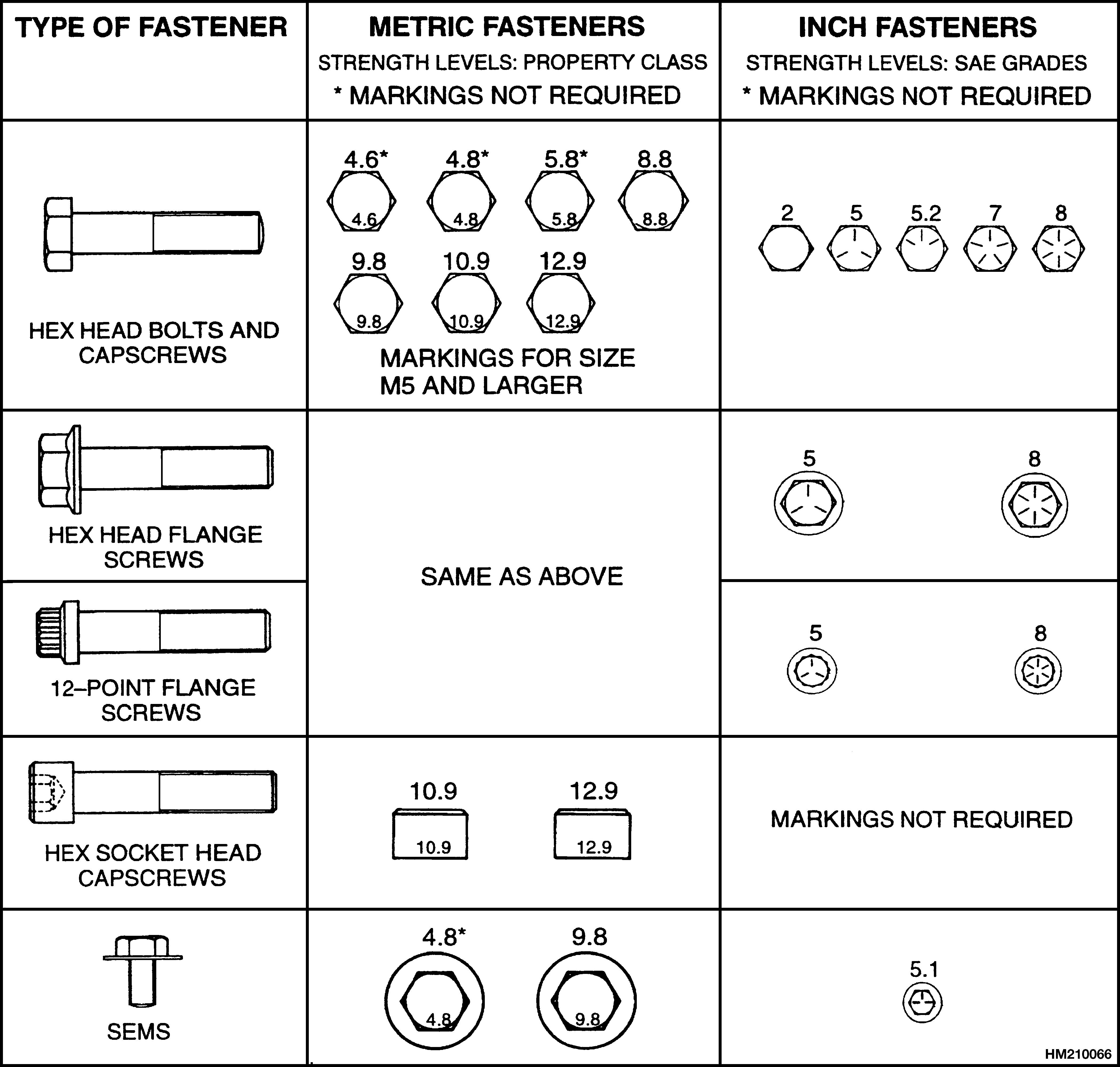

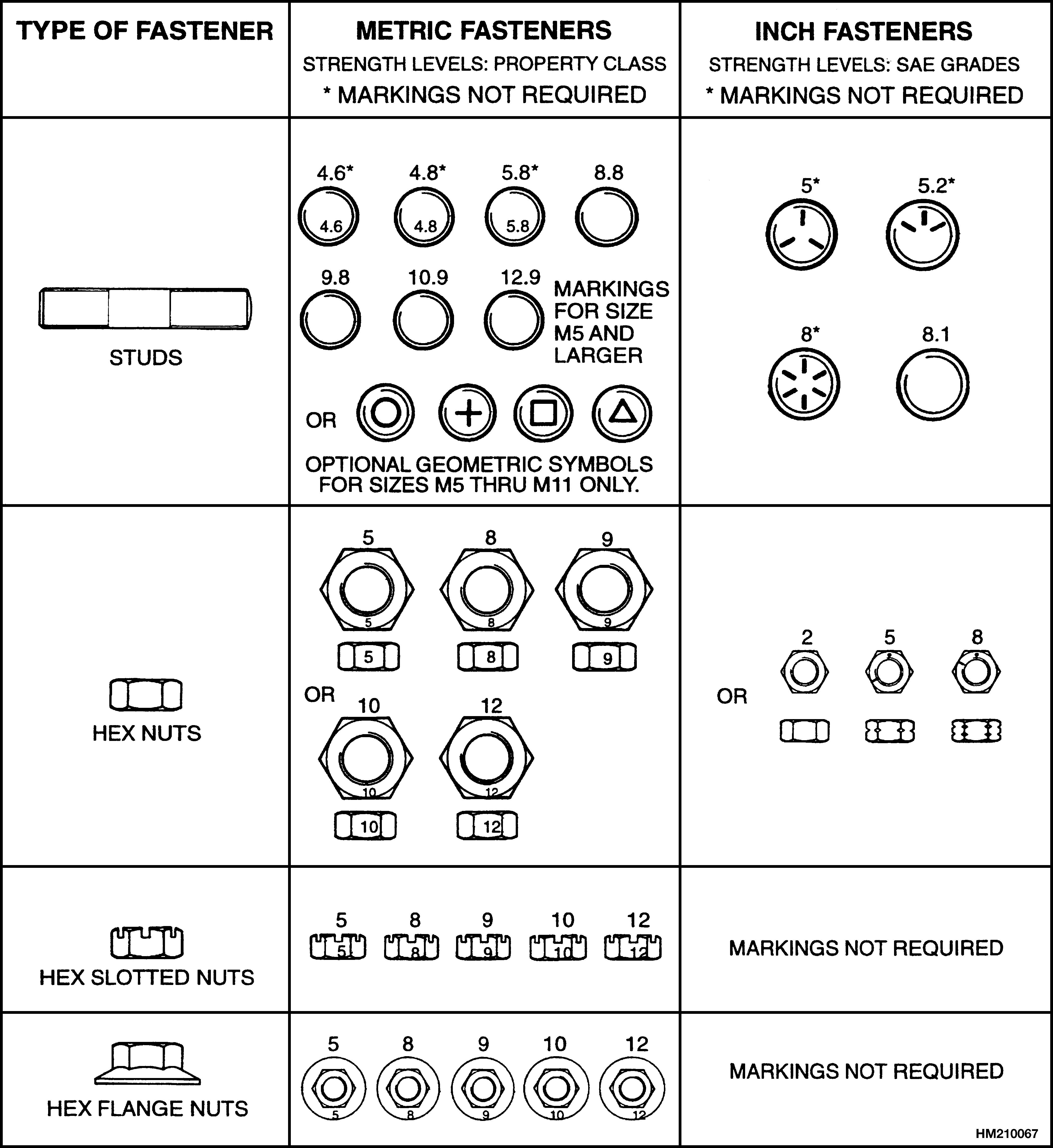

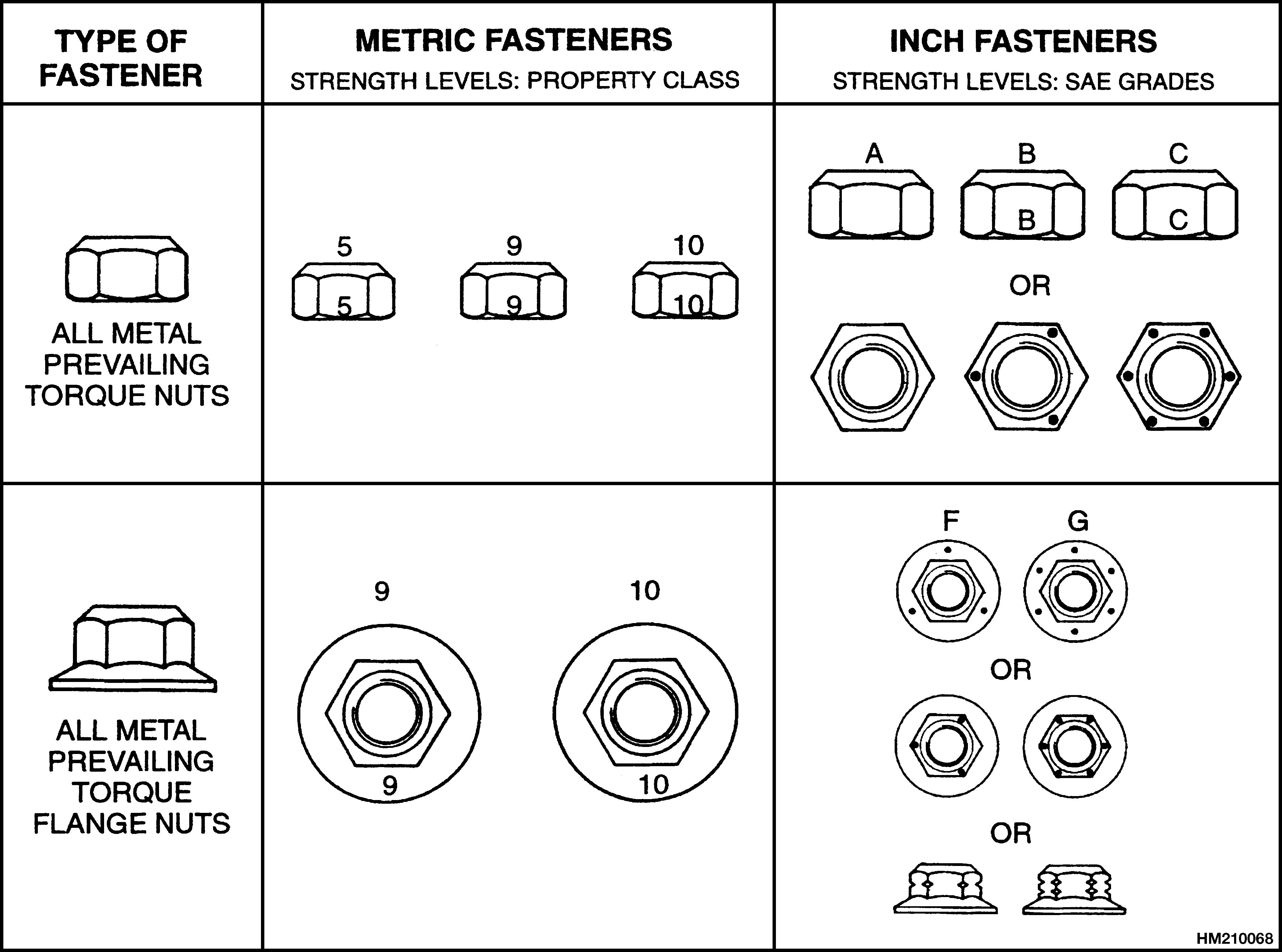

Service persons must use replacement fasteners that have the same specifications. Fasteners made to each specification have identification marks for that specification. This specification is commonly called "Grade" for SAE standards and "property class" for metric standards. This section describes the identification of some common fasteners.

The metric system used by Yale® Company is described as SI (Le Systeme d'Unites or the International System of units, also called SI in all languages). The SI System of measurement is described in ISO Standard 1000, 1973. A conversion table of common measurements is shown in Table 7.

NOMENCLATURE, THREADS

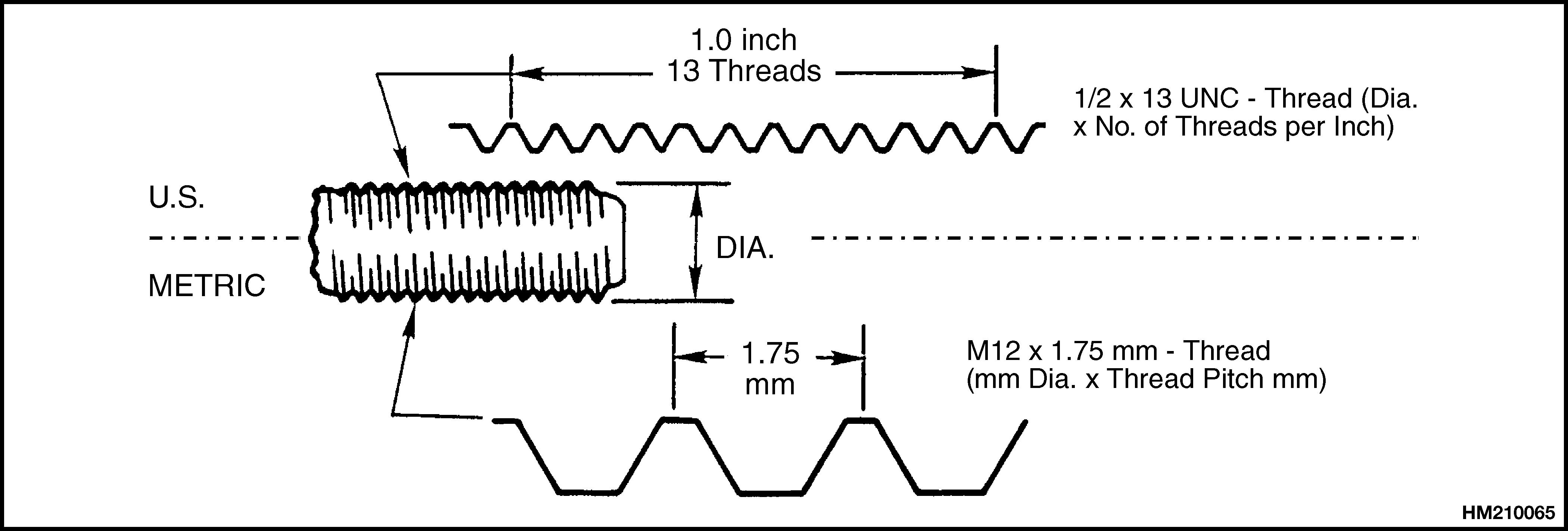

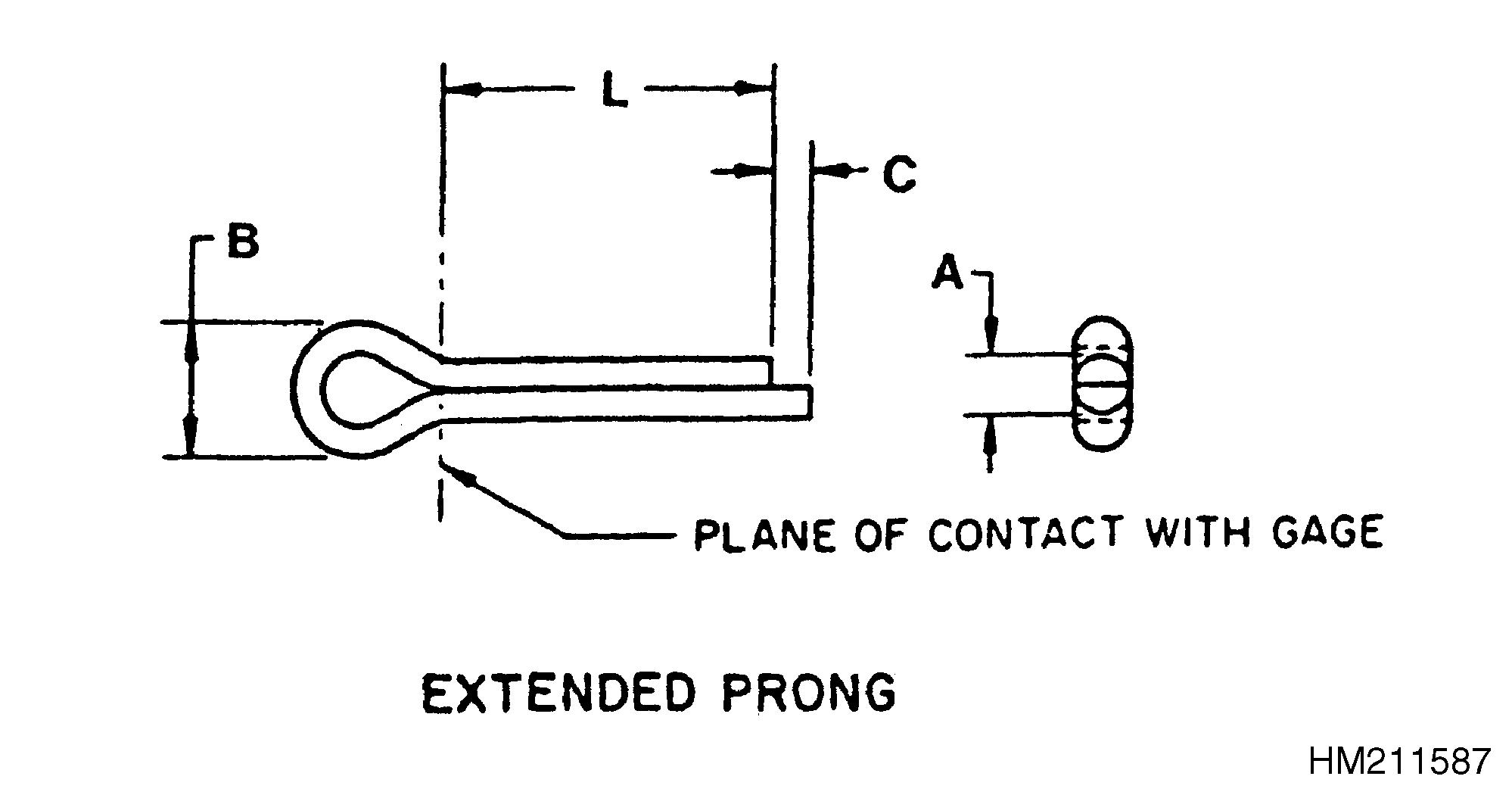

The thread design is specified by a series of numbers and letters for inch and metric fasteners. See Figure 1.

The diameter of the shank of the fastener is shown first in the series [M12 = 12 mm, M20 = 20 mm (1/2 = 1/2 in., 3/4 = 3/4 in.)].

The number of threads per inch is normally not shown for inch nomenclature and only the UNC (Unified National Coarse) or UNF (Unified National Fine) is shown. This number of threads per inch is not shown because a UNC or UNF fastener has a standard number of threads per inch for a specific diameter. Metric fasteners show the number of threads per millimeter.

The length of the shank is often indicated as part of the description of a fastener. This length is shown in inches for inch fasteners and in millimeters for metric fasteners.

A cap screw will have the following description:

Metric Inch

M12 × 1.75 × 50 1/2 × 13 UNC × 1-1/2

A B C A B C D

A = Thread Size A = Shank Diameter

B = Pitch

C = Length

B = Number of Threads Per Unit of Length

C = type of Thread

D = Shank Length

STRENGTH IDENTIFICATION

CAUTION

When fasteners must be replaced, the new fasteners must be of the same strength or greater than the original fasteners. The new fasteners must also be the correct size.

NOTE: Identification marks are according to bolt strength. The higher the number or the increase in the number of marks indicates increased bolt strength.

The most common property classes for metric fasteners are 8.8 and 10.9. The property class is marked with a number on the head of the cap screw or on a nut. Property classes less than 8.8 are often not marked. Grades for inch bolts go from 2 to 8. Grade 2 fasteners normally do not have any marks. The following tables show the marks that identify the grades and property classes for different fasteners.

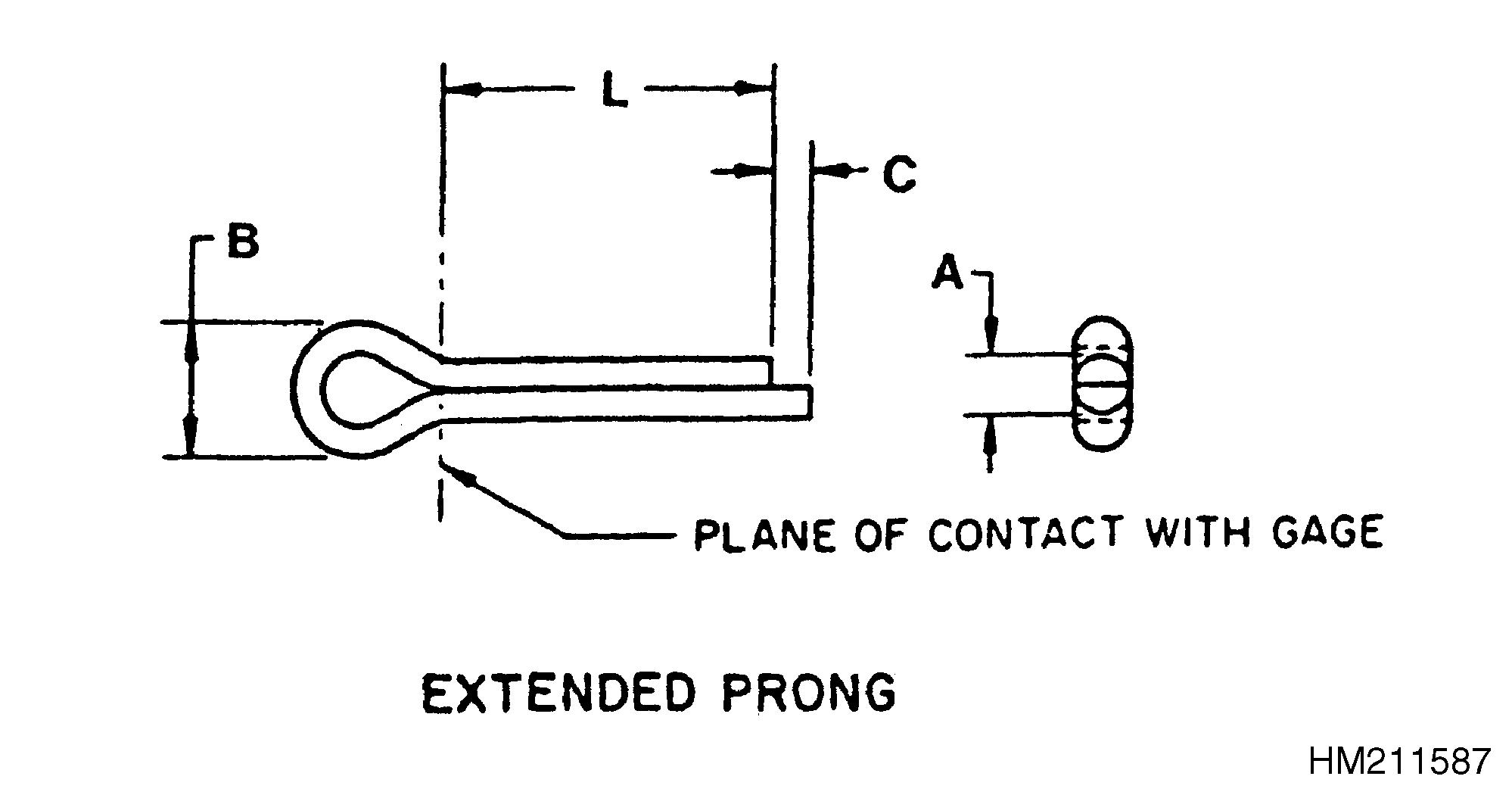

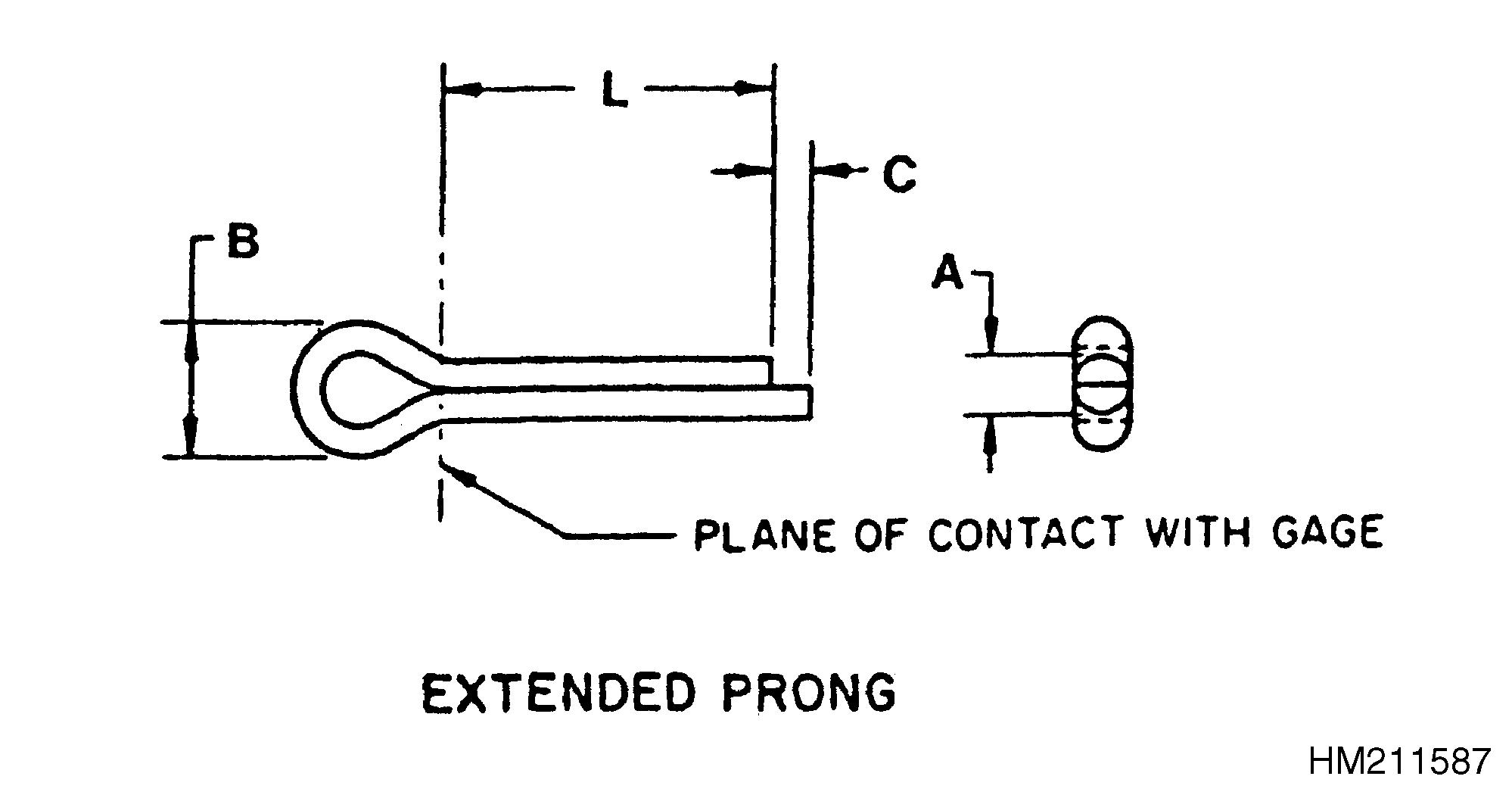

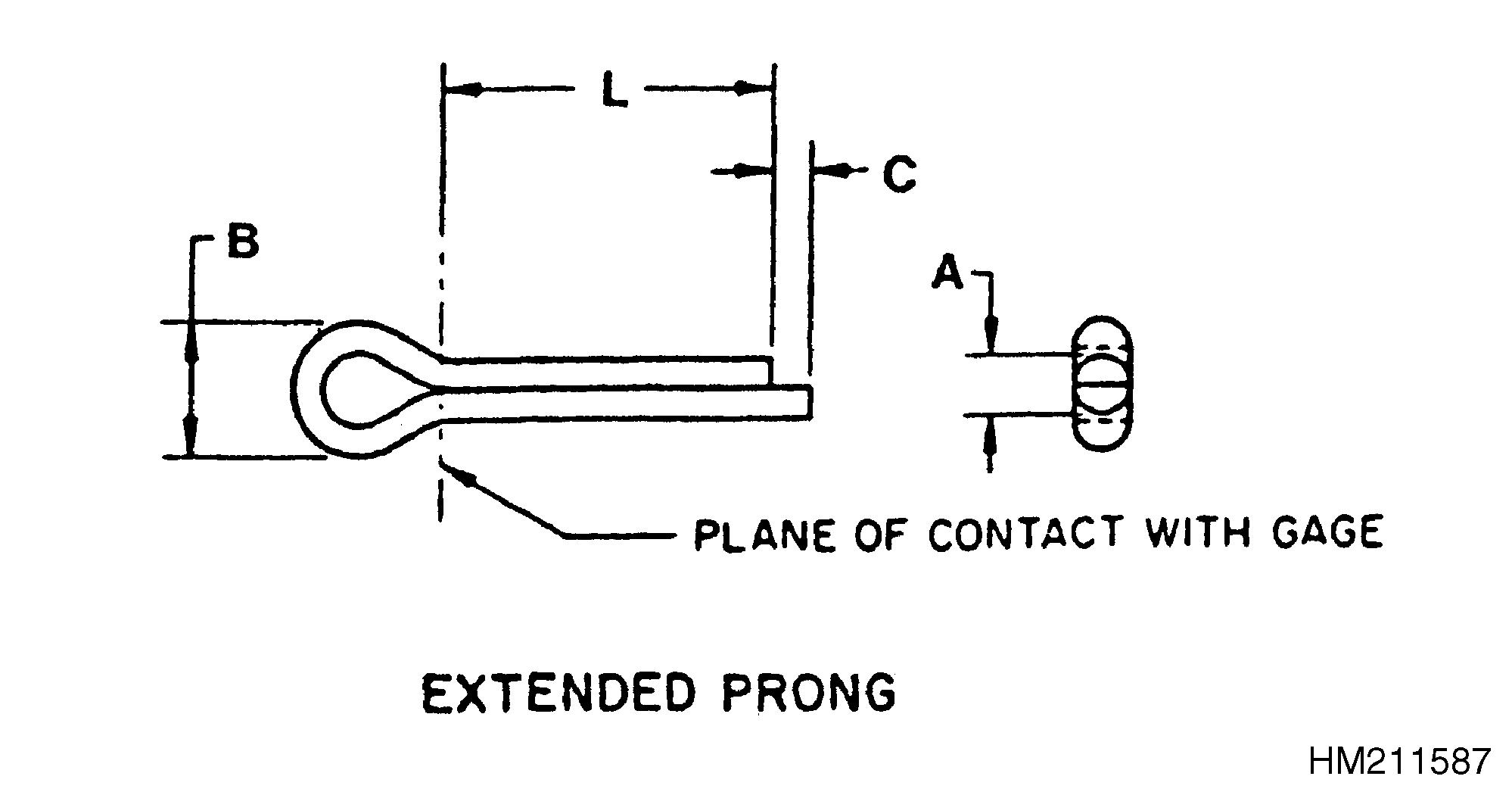

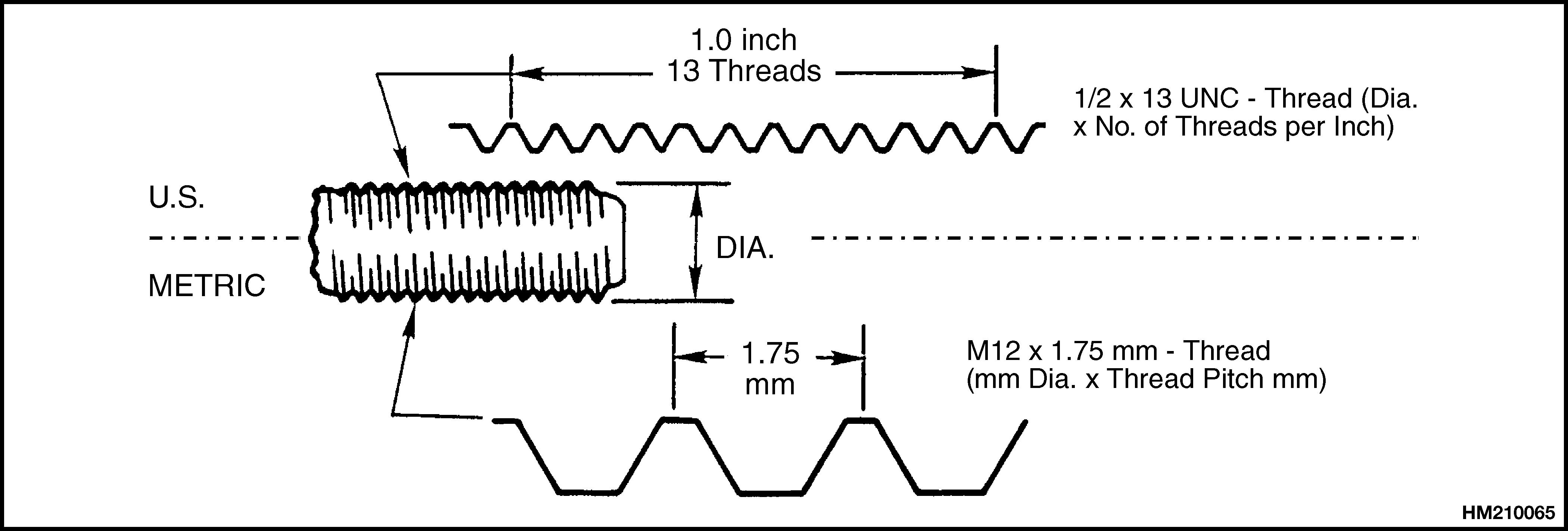

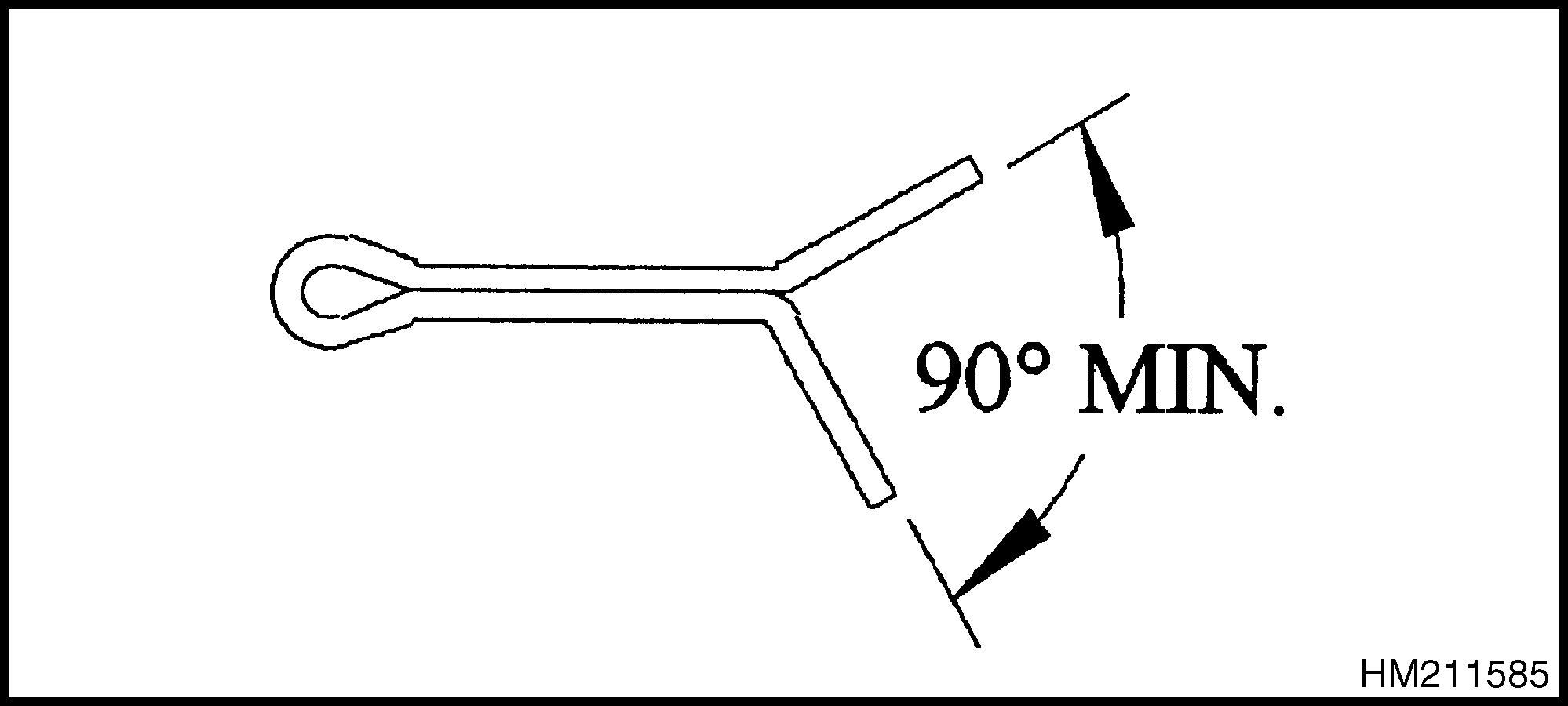

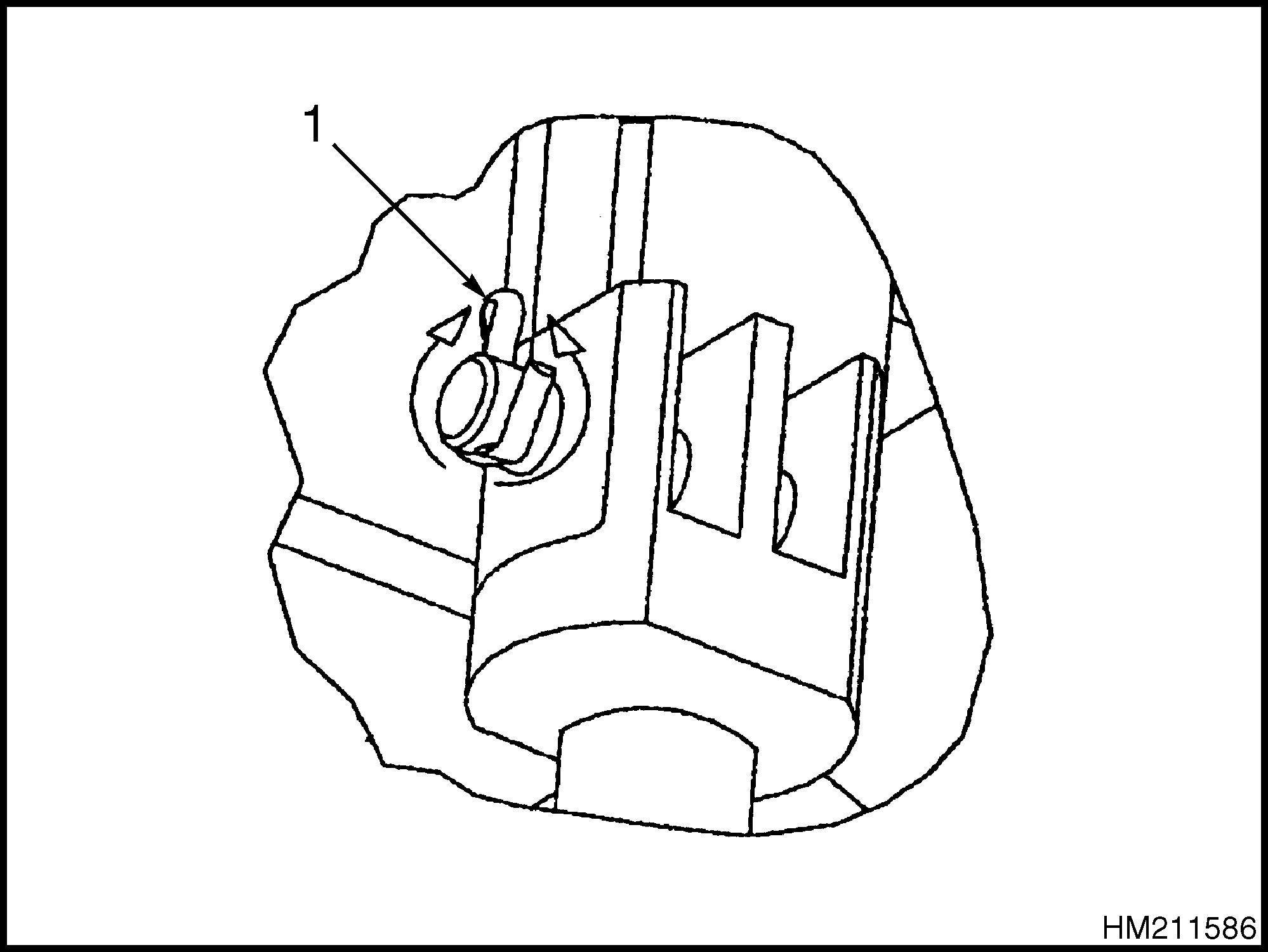

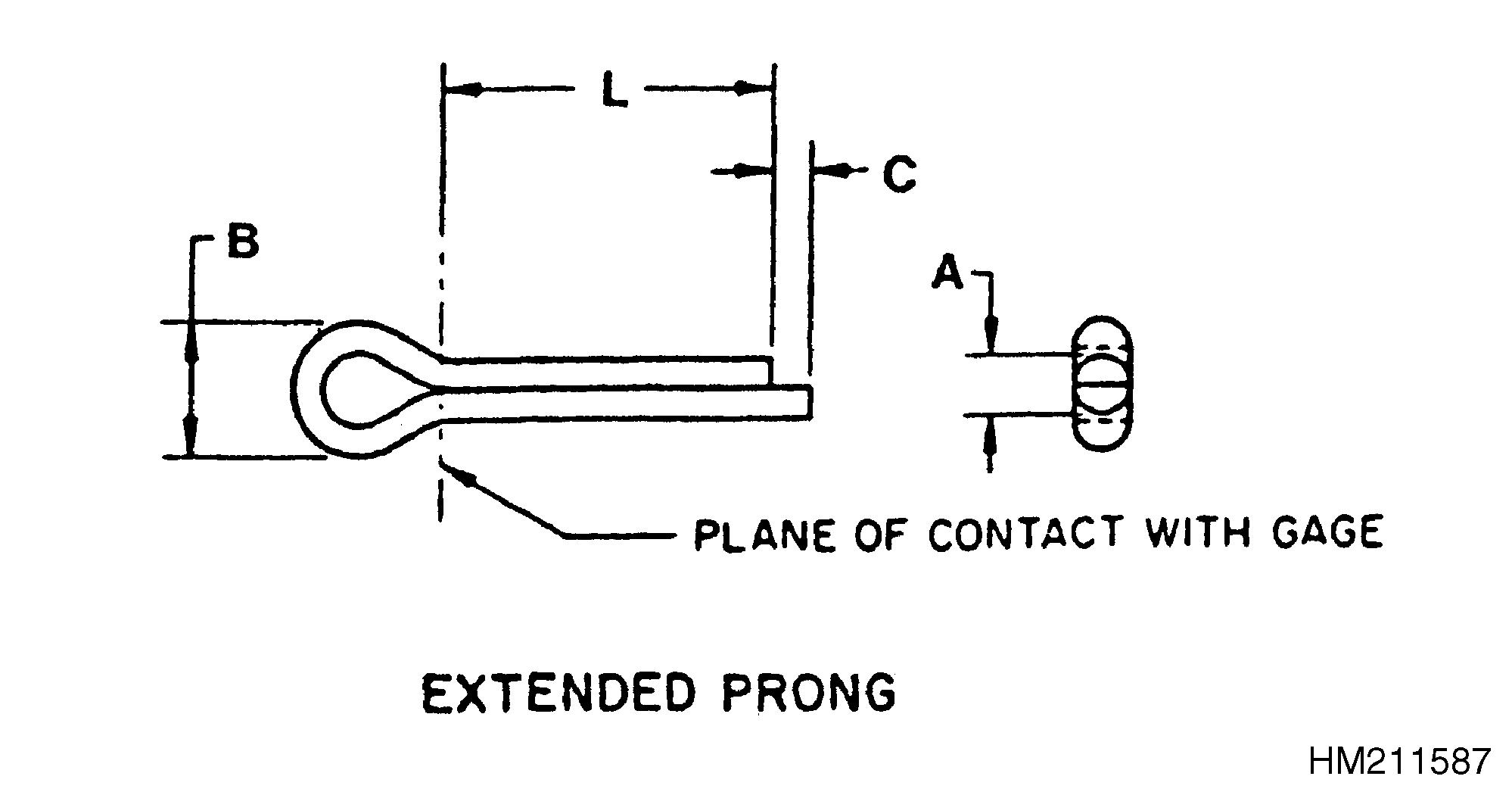

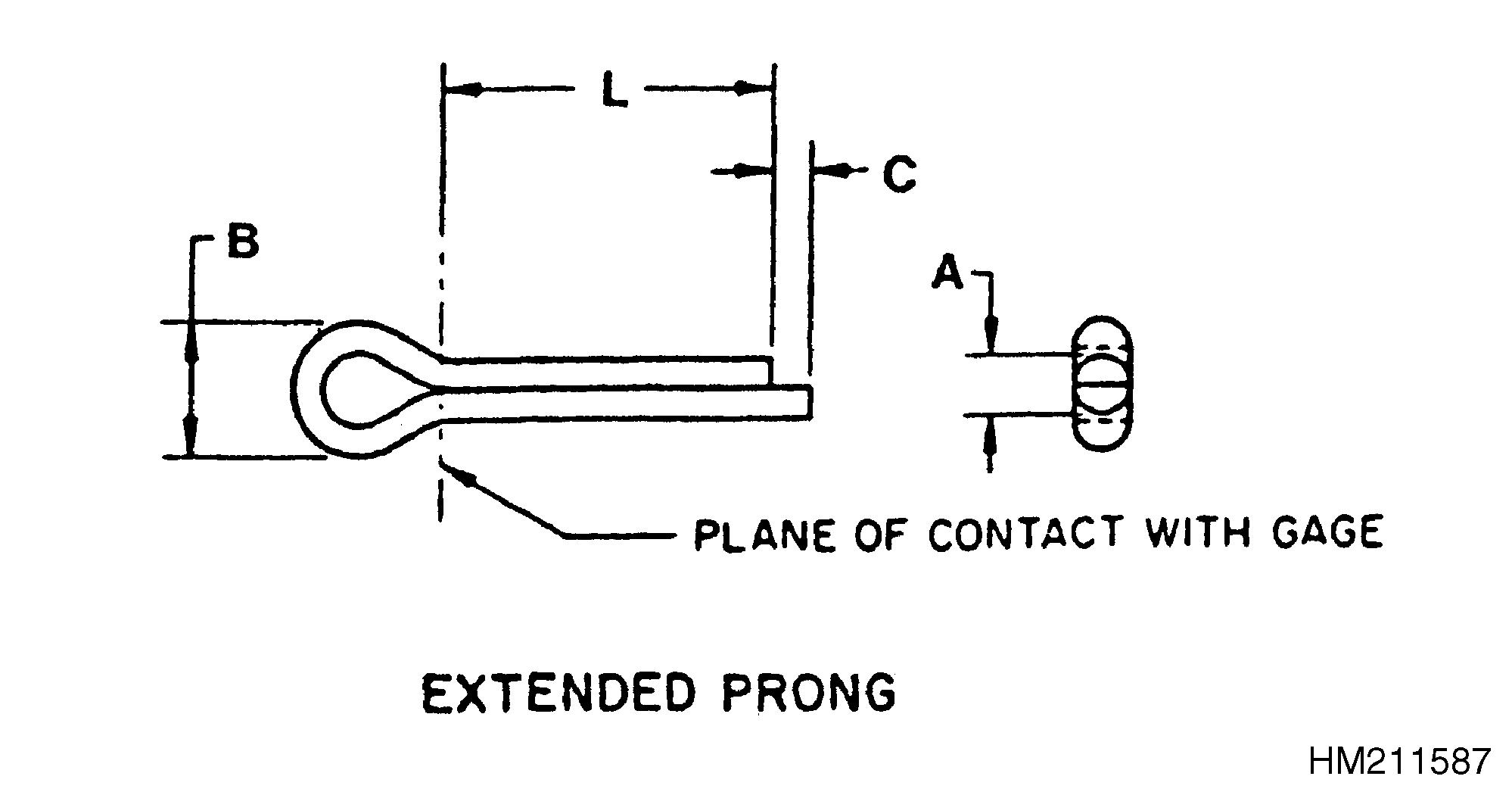

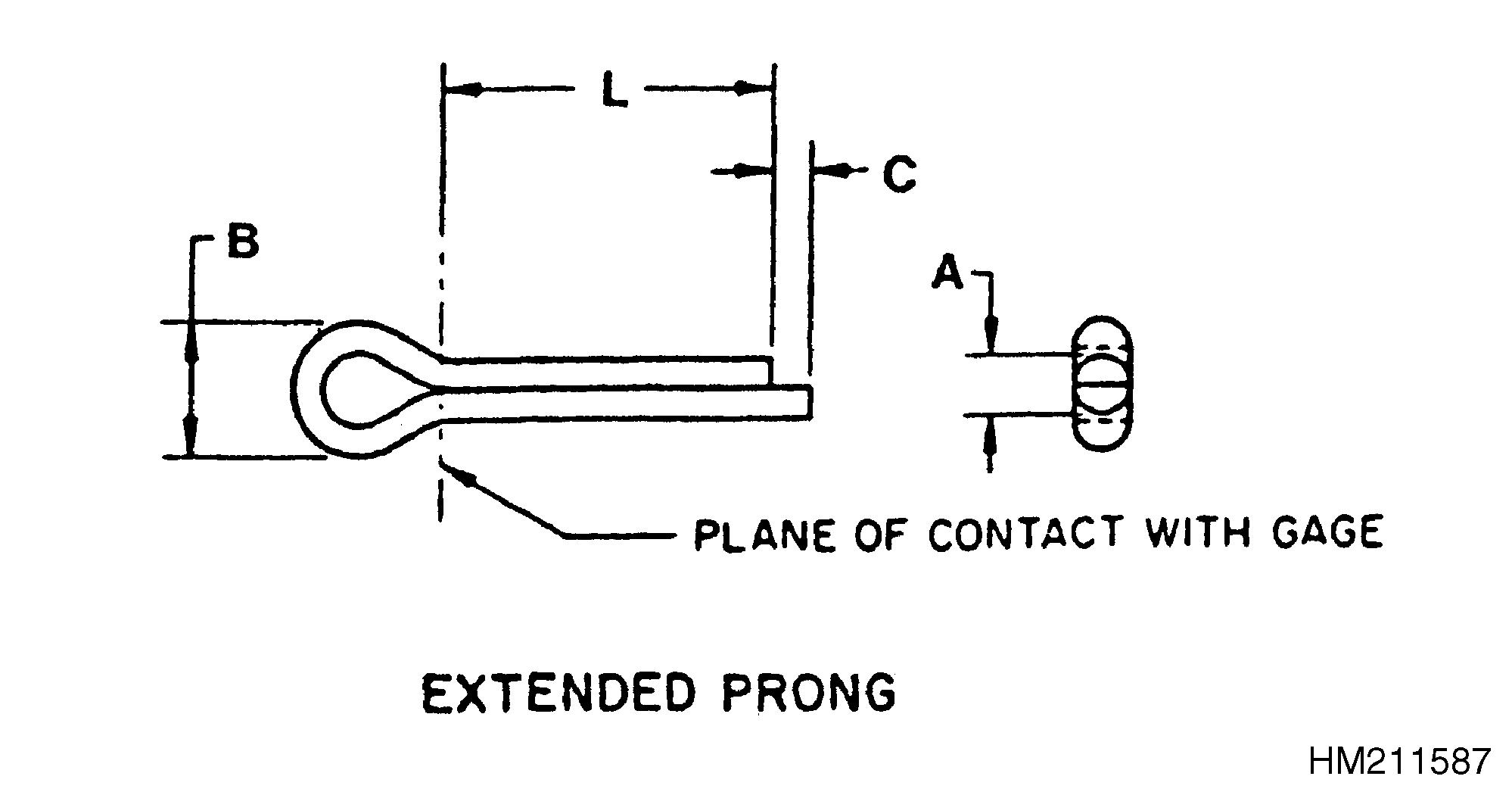

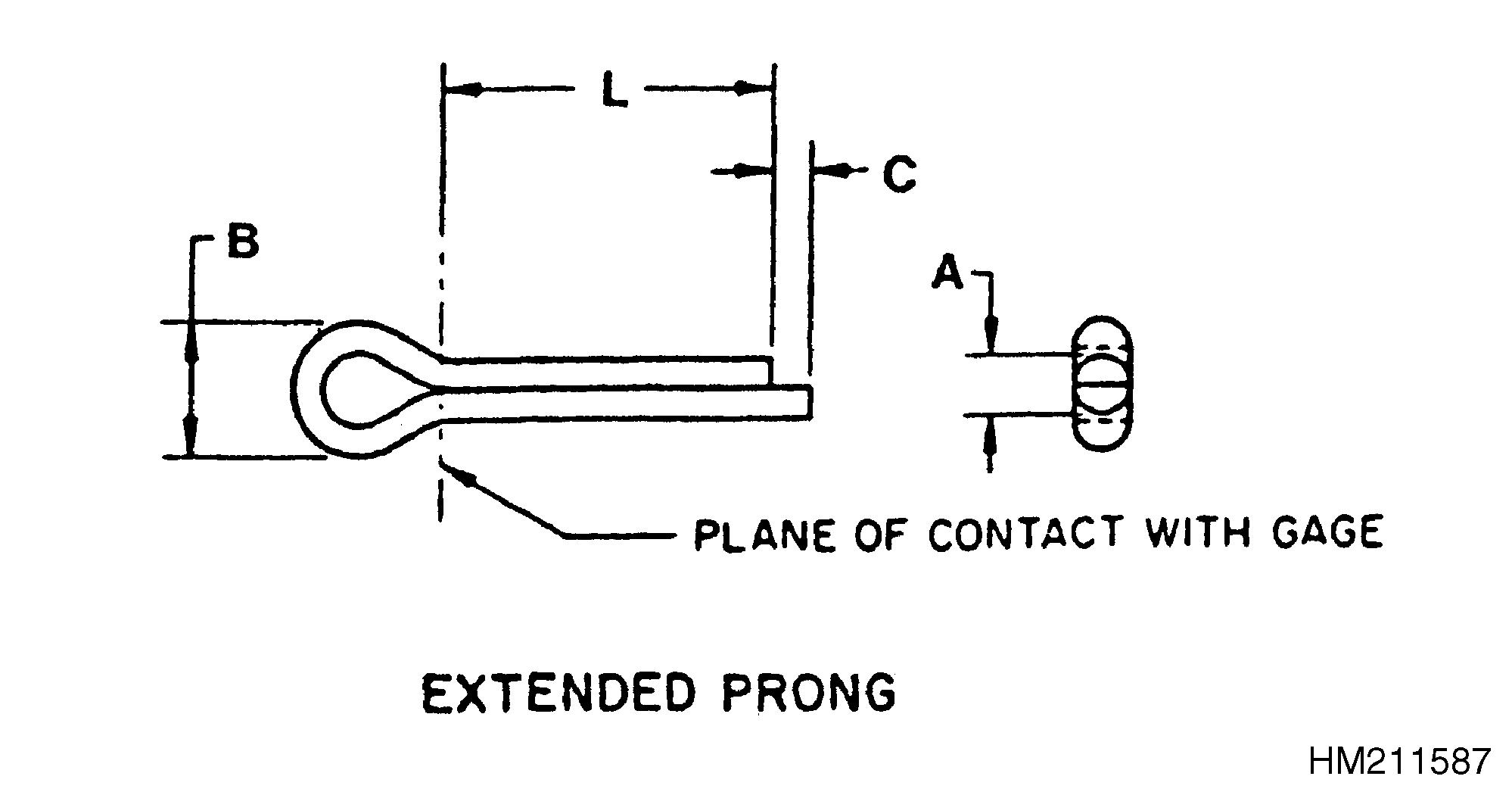

COTTER (SPLIT) PINS

Cotter (split) pins are used in many applications on your forklift. They are typically used to retain parts such as pins and nuts. Cotter (split) pins are typically not used as load-bearing members. Service personnel must use new cotter (split) pins. Do not reuse a cotter (split) pin. Replacement cotter (split) pin must be of the correct size. See Table 8.

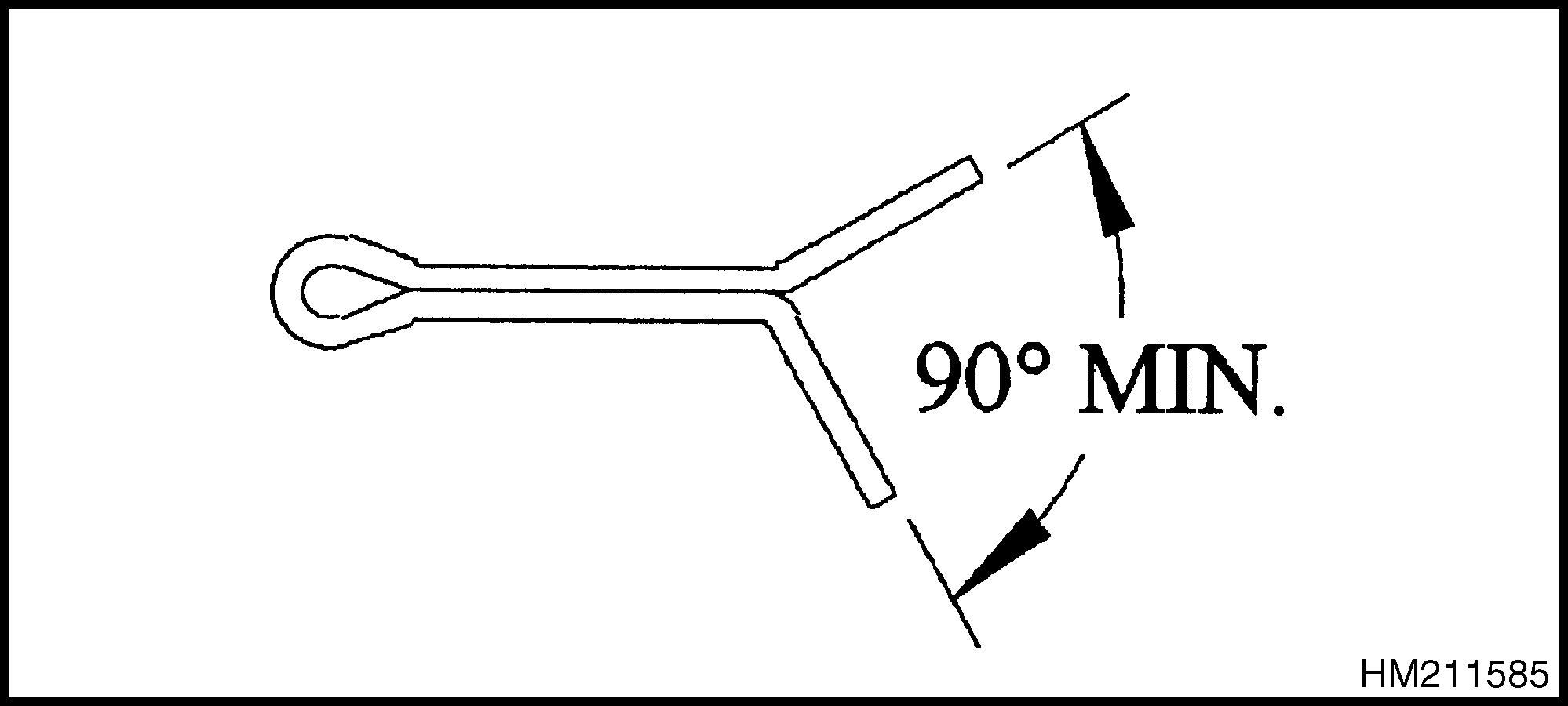

The legs of a cotter (split) pin are bent for the following reasons:

• To retain the cotter (split) pin in the part

• To provide clearance between the cotter pin legs and other parts or members. One or both cotter (split) pin legs must be bent to provide a minimum 90° angle between the legs. See Figure 2.

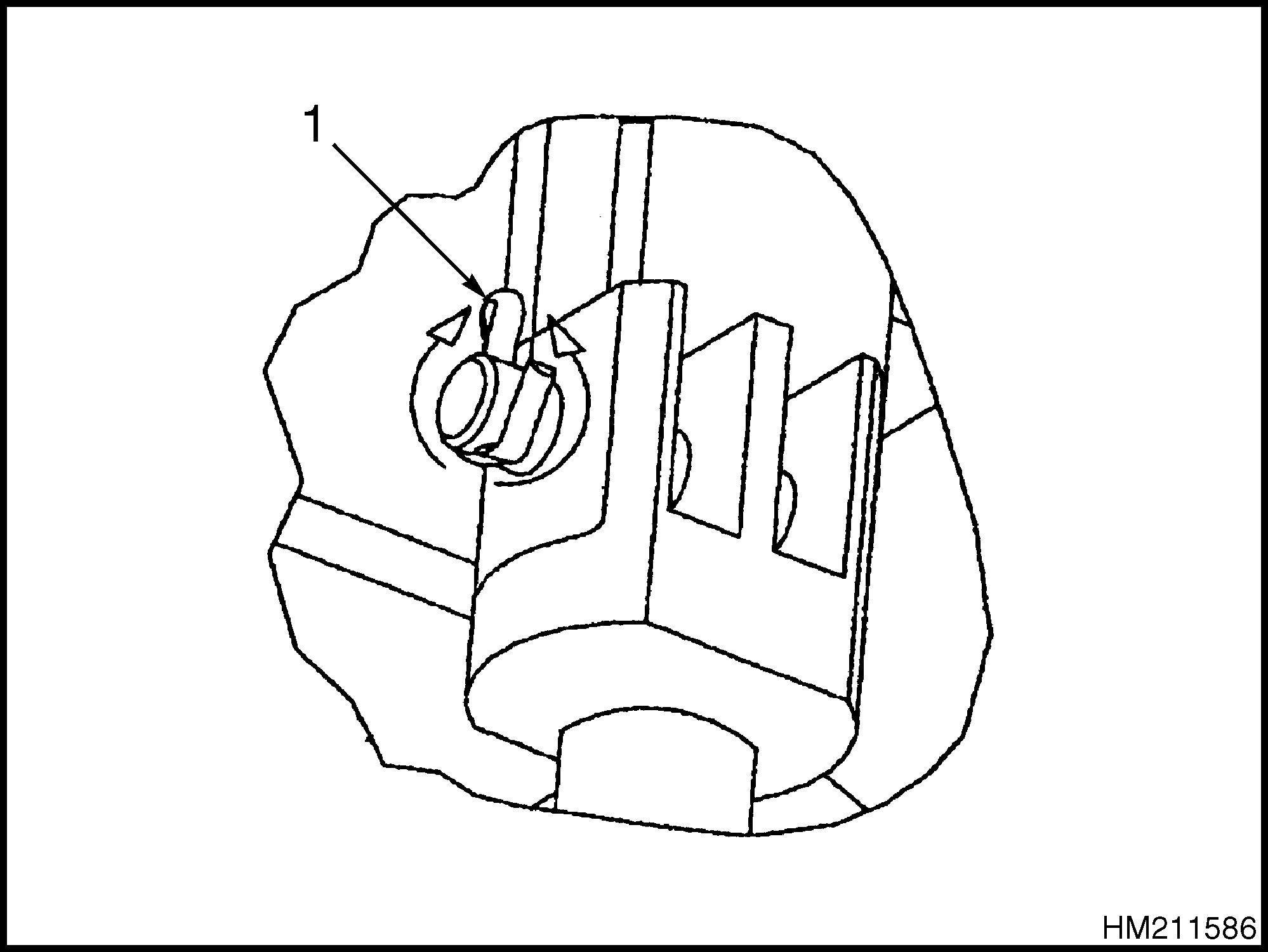

Unless otherwise specified, the legs of chain anchor cotter (split) pins are to be bent against the pin. See Figure 3.

Figure 2. Minimum Angle Between Cotter Pin Legs

1.COTTER PIN

Figure 2. Minimum Angle Between Cotter Pin Legs

1.COTTER PIN

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

FASTENER TORQUE TABLES

M42 × 4.5 M42 × 3 M45 × 4.5 M45 × 3 M48 × 5

* Unless otherwise specified 1 Approximately equal to Grade 2 2 Approximately equal to Grade 5 3 Approximately equal to Grade 8

and Pitch

* Unless otherwise specified 1 Approximately equal to metric Property Class 5.8 2 Approximately

Table 6. Torque Values for Inch Fasteners* (Continued)

CONVERSION TABLE

Table 7. Conversion Table for Metric and English units

Multiply By To Get

Multiply By To Get

Area

inches 2 (in. 2) × 6.452 = centimeters 2 (cm 2) centimeters 2 (cm 2) × 0.155 = inches 2 (in. 2)

feet 2 (ft 2) × 0.093 = meters 2 (m 2) meters 2 (m 2) × 10.764 = feet 2 (ft 2)

Linear

inches (in.) × 25.4 = millimeters (mm) millimeter (mm) × 0.039 = inches (in.)

feet (ft) × 0.305 = meters (m) meter (m) × 3.281 = feet (ft)

yards (yd) × 0.914 = meters (m) meter (m) × 1.094 = yards (yd) miles (mi) × 1.609 = kilometers (km) kilometer (km) × 0.621 = miles (mi)

ounces (oz) × 28.35 = grams (g)

Mass

grams (g) × 0.035 = ounces (oz) pounds (lb) × 0.454 = kilograms (kg) kilograms (kg) × 2.205 = pounds (lb)

tons (2,000 lb) × 907.18 = kilograms (kg) kilograms (kg) × 0.001 = tons (2,000 lb)

tons (2,000 lb) × 0.907 = metric ton (t) metric ton (t) × 1.102 = tons (2,000 lb)

Power

horsepower (hp) × 0.746 = kilowatts (kW) kilowatts (kW) × 1.34 = horsepower (hp)

Pressure

pounds/in. 2 (psi) × 6.895 = kilopascal (kPa) kilopascals (kPa) × 0.145 = pounds/in. 2 (psi) pounds/in. 2 (psi) × 0.007 = megapascal (MPa) megapascals (MPa) × 145.04 = pounds/in. 2 (psi)

Temperature

(°Fahrenheit−32) × 0.56 = °Celsius (C) (°Celsius × 1.8) +32 = °Fahrenheit

Torque

pound inches (lbf in.) × 0.113 = Newton meter (N•m) Newton meter (N•m) × 8.851 = pound inches (lb f in.)

pound feet (lbf ft) × 1.356 = Newton meter (N•m) Newton meter (N•m) × 0.738 = pound feet (lb f ft)

Velocity

miles/hour (mph) × 1.609 = kilometer/hour (km/h) kilometer/hr (km/h) × 0.621 = miles/hour (mph)

Volume

inches 3 (in. 3) × 16.387 = centimeters 3 (cm 3) centimeters 3 (cm 3) × 0.061 = inches 3 (in. 3) inches 3 (in. 3) × 0.016 = liters (l) liters (l) × 61.024 = inches 3 (in. 3)

quarts, U.S. (qt) × 0.946 = liters (l) liters (l) × 1.057 = quarts, U.S. (qt) quarts, U.S. (qt) × 0.83 = quarts, Imp. (qt) quarts, Imp. (qt) × 1.205 = quarts, U.S. (qt) gallons, U.S. (gal) × 3.785 = liters (l) liters (l) × 0.264 = gallons, U.S. (gal) gallons, U.S. (gal) × 0.83 = gallons, Imp. (gal) gallons, Imp. (gal) × 1.205 = gallons, U.S. (gal) ounces (oz) × 29.57 = milliliters (ml) milliliters (ml) × 0.034 = ounces (oz)

1.00 mm (0.031 in.)

mm (0.047 in.)

2.00 mm (0.062 in.)

2.50 mm (0.094 in.)

in.)

mm (0.035 in.)

Table 8. Cotter Pin Dimensional Data

mm (0.091 in.)

(0.120 in.)

in.)

in.) 4.00 mm (0.156 in.) 3.80 mm (0.150 in.)

mm (0.138 in.)

in.) 5.00 mm (0.188 in.)

in.)

mm (0.312 in.)

mm (0.295 in.)

in.)

6.35 mm (0.250 in.)

mm (0.375 in.)

mm (0.280 in.)

mm (0.413 in.)

mm (0.500 in.) 13.5 mm (0.530 in.)

19.05 mm (0.750 in.)

mm (1.000 in.)

mm (1.250 in.)

mm (1.500 in.)

mm (2.000 in.)

mm (0.807 in.)

mm (1.060 in.)

Table 9. Cotter Pin Dimensional Data

mm (0.217 in.)

mm (0.345 in.)

mm (0.453 in.)

mm (0.720 in.)

mm (0.940 in.)

mm (1.610 in.)

mm (2.060 in.)

57.15 mm (2.250 in.) 58.7 mm (2.310 in.)

mm (2.500 in.)

mm (2.560 in.)

mm (2.750 in.) 72.1 mm (2.840 in.)

mm (1.940 in.)

mm (2.170 in.)

in.)

mm (2.690 in.)

76.2 mm (3.000 in.) 81.3 mm (3.200 in.) 74.7 mm (2.940 in.)

88.9 mm (3.500 in.) 91.4 mm (3.600 in.)

mm (3.440 in.)

101.6 mm (4.000 in.)

mm (5.000 in.)

mm (6.000 in.)

mm (4.460 in.)

mm (5.060 in.)

mm (3.060 in.)

Table 9. Cotter Pin Dimensional Data (Continued)

6.35 mm (0.250 in.)

mm (0.280 in.)

mm (3.890 in.)

mm (4.870 in.)

mm (138.7 in.)

Table 10. Cotter Pin Dimensional Data

mm (0.217 in.)

9.525 mm (0.375 in.) 10.5 mm (0.413 in.) 8.80 mm (0.345 in.)

12.7 mm (0.500 in.) 13.5 mm (0.530 in.) 11.5 mm (0.453 in.)

19.05 mm (0.750 in.)

mm (0.807 in.)

mm (0.720 in.)

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

25.4 mm (1.000 in.)

mm (1.250 in.)

38.1 mm (1.500 in.)

44.45 mm (1.750 in.)

50.8 mm (2.000 in.)

mm (2.250 in.)

(2.500 in.)

mm (2.750 in.)

mm (3.000 in.)

mm (1.060 in.)

Table 10. Cotter Pin Dimensional Data (Continued)

(0.940 in.)

mm (1.610 in.)

mm (1.440 in.)

mm (2.060 in.)

mm (1.940 in.)

mm (3.200 in.)

mm (2.940 in.)

88.9 mm (3.500 in.) 91.4 mm (3.600 in.) 87.4 mm (3.440 in.)

mm (4.000 in.)

mm (5.000 in.)

mm (4.460 in.)

mm (5.060 in.)

(3.890 in.)

mm (4.870 in.)

152.4 mm (6.000 in.) 153.9 mm (3.060 in.) 5.460 mm (138.7 in.)

mm (0.750 in.)

mm (1.00 in.)

mm (1.250 in.)

mm (1.750 in.)

mm (2.000 in.)

Table 11. Cotter Pin Dimensional Data

152.4 mm (6.000 in.) 153.9 mm (3.060 in.) 138.7 mm (5.460 in.)

METRIC AND INCH (SAE) FASTENERS

SAFETY PRECAUTIONS MAINTENANCE

AND REPAIR

• When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load.

•Do not lift heavy parts by hand, use a lifting mechanism.

•Wear safety glasses.

• DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift trucks. Disconnect the battery ground cable on internal combustion lift trucks.

• Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section.

•Keep the unit clean and the working area clean and orderly.

•Use the correct tools for the job.

•Keep the tools clean and in good condition.

• Always use APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer.

• Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to remove parts.

• Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs.

•Be sure to follow the WARNING and CAUTION notes in the instructions.

• Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable. Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems.

• Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area. Make sure the area is well ventilated.

NOTE: The following symbols and words indicate safety information in this manual:

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury and property damage.

On the lift truck, the WARNING symbol and word are on orange background. The CAUTION symbol and word are on yellow background.

General

THREADED FASTENERS

Threaded fasteners, like bolts, nuts, capscrews, and studs, are made to specifications that describe the mechanical strength and hardness of the fastener. A fastener used in a design application is selected according to its specifications. Yale® Company buys parts from many countries. Parts that are purchased must be to Yale® Company standards. There are several standards used by these countries in the manufacture of threaded fasteners. Many of these fasteners are similar, but cannot be used as a direct replacement. To make sure that you have the correct fastener, order fasteners and parts through the Yale® Parts Depot.

Service persons must use replacement fasteners that have the same specifications. Fasteners made to each specification have identification marks for that specification. This specification is commonly called "Grade" for SAE standards and "property class" for metric standards. This section describes the identification of some common fasteners.

The metric system used by Yale® Company is described as SI (Le Systeme d'Unites or the International System of units, also called SI in all languages). The SI System of measurement is described in ISO Standard 1000, 1973. A conversion table of common measurements is shown in Table 7.

NOMENCLATURE, THREADS

The thread design is specified by a series of numbers and letters for inch and metric fasteners. See Figure 1.

The diameter of the shank of the fastener is shown first in the series [M12 = 12 mm, M20 = 20 mm (1/2 = 1/2 in., 3/4 = 3/4 in.)].

The number of threads per inch is normally not shown for inch nomenclature and only the UNC (Unified National Coarse) or UNF (Unified National Fine) is shown. This number of threads per inch is not shown because a UNC or UNF fastener has a standard number of threads per inch for a specific diameter. Metric fasteners show the number of threads per millimeter.

The length of the shank is often indicated as part of the description of a fastener. This length is shown in inches for inch fasteners and in millimeters for metric fasteners.

A capscrew will have the following description:

Metric Inch

M12 × 1.75 × 50 1/2 × 13 UNC × 1-1/2

A B C

A B C D

A = Thread Size A = Shank Diameter

B = Pitch

C = Length

B = Number of Threads Per Unit of Length

C = type of Thread

D = Shank Length

STRENGTH IDENTIFICATION

CAUTION

When fasteners must be replaced, the new fasteners must be of the same strength or greater than the original fasteners. The new fasteners must also be the correct size.

NOTE: Identification marks are according to bolt strength. The higher the number or the increase in the number of marks indicates increased bolt strength.

The most common property classes for metric fasteners are 8.8 and 10.9. The property class is marked with a number on the head of the capscrew or on a nut. Property classes less than 8.8 are often not marked. Grades for inch bolts go from 2 to 8. Grade 2 fasteners normally do not have any marks. The following tables show the marks that identify the grades and property classes for different fasteners.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

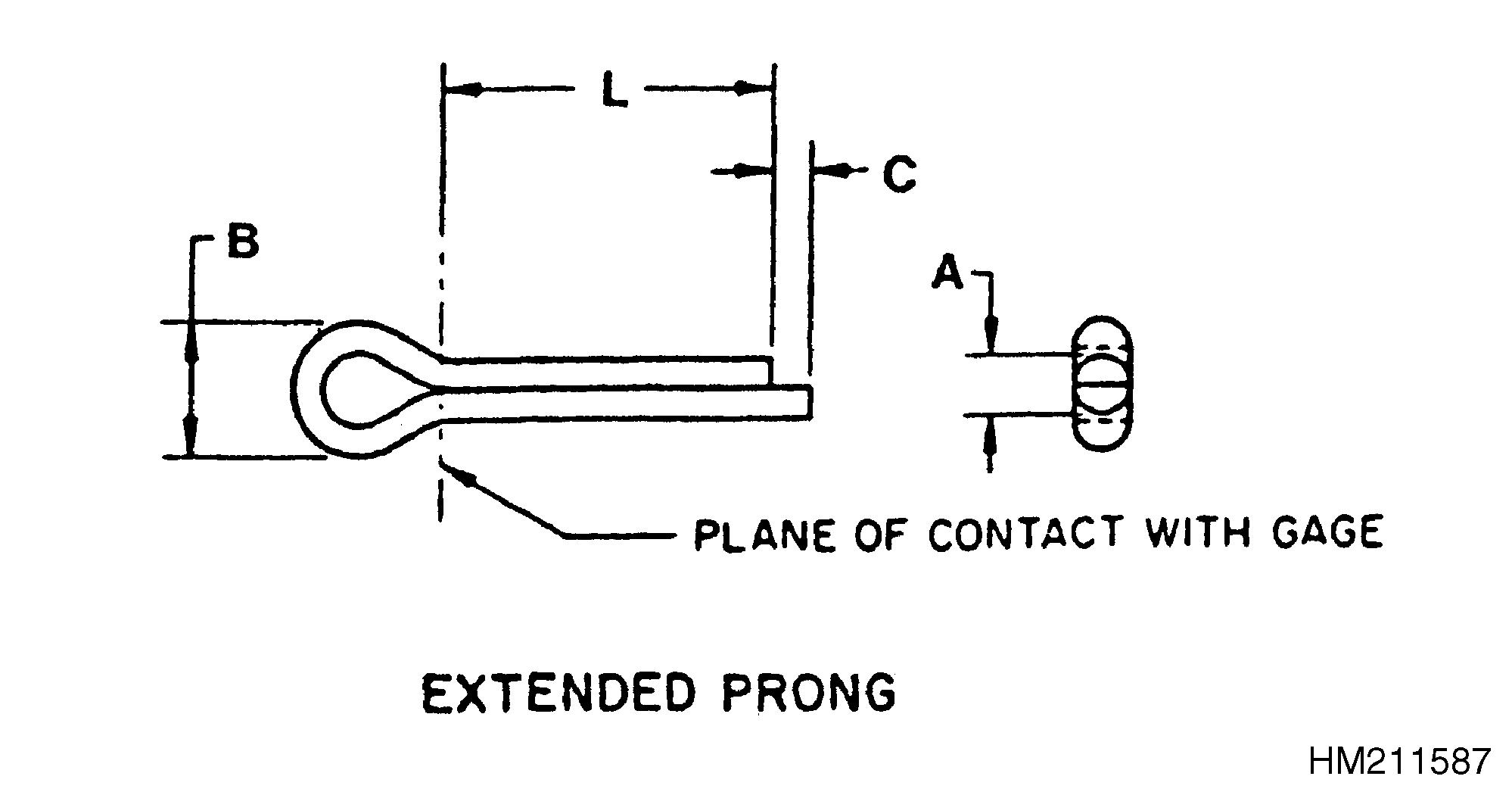

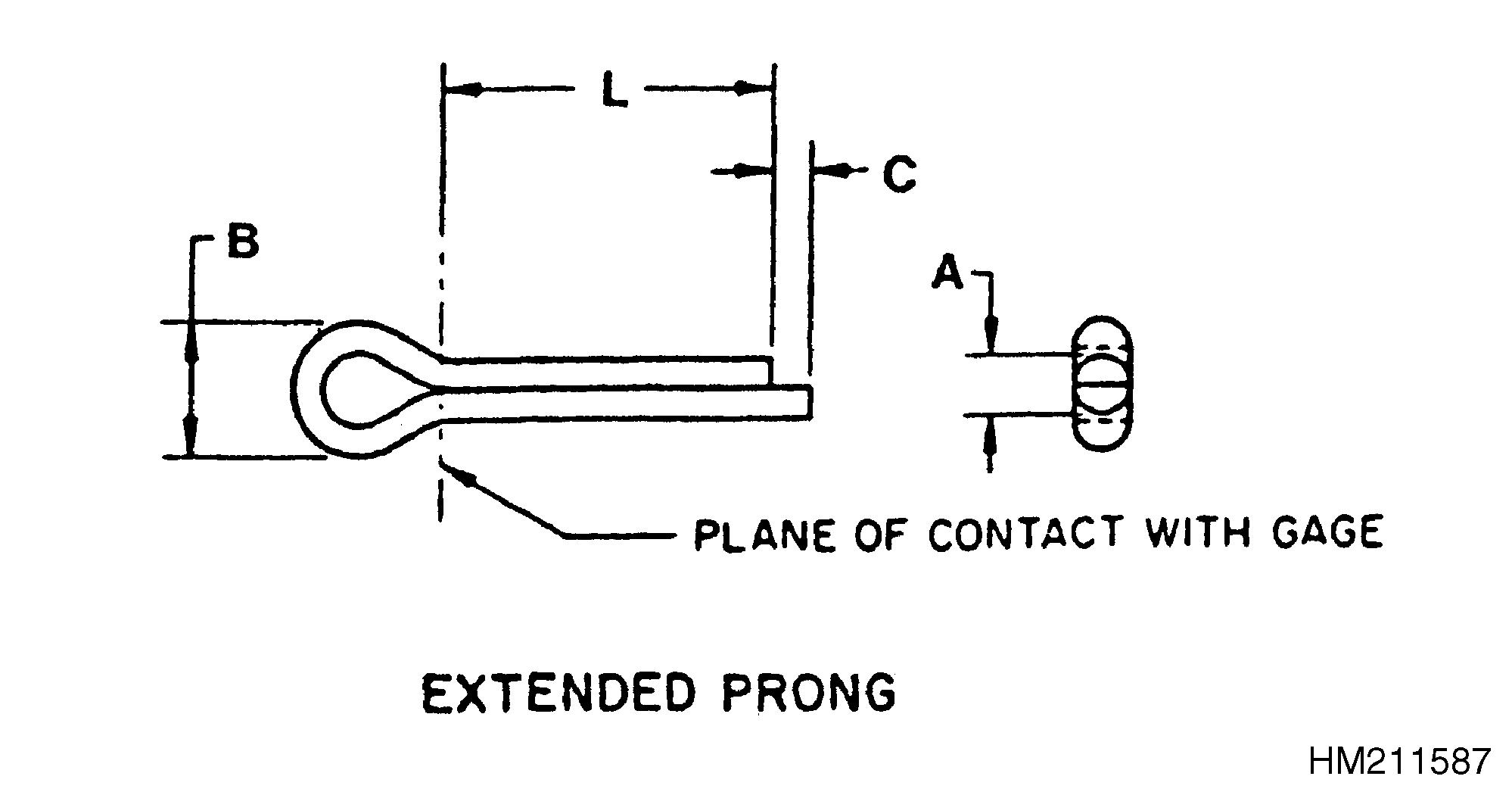

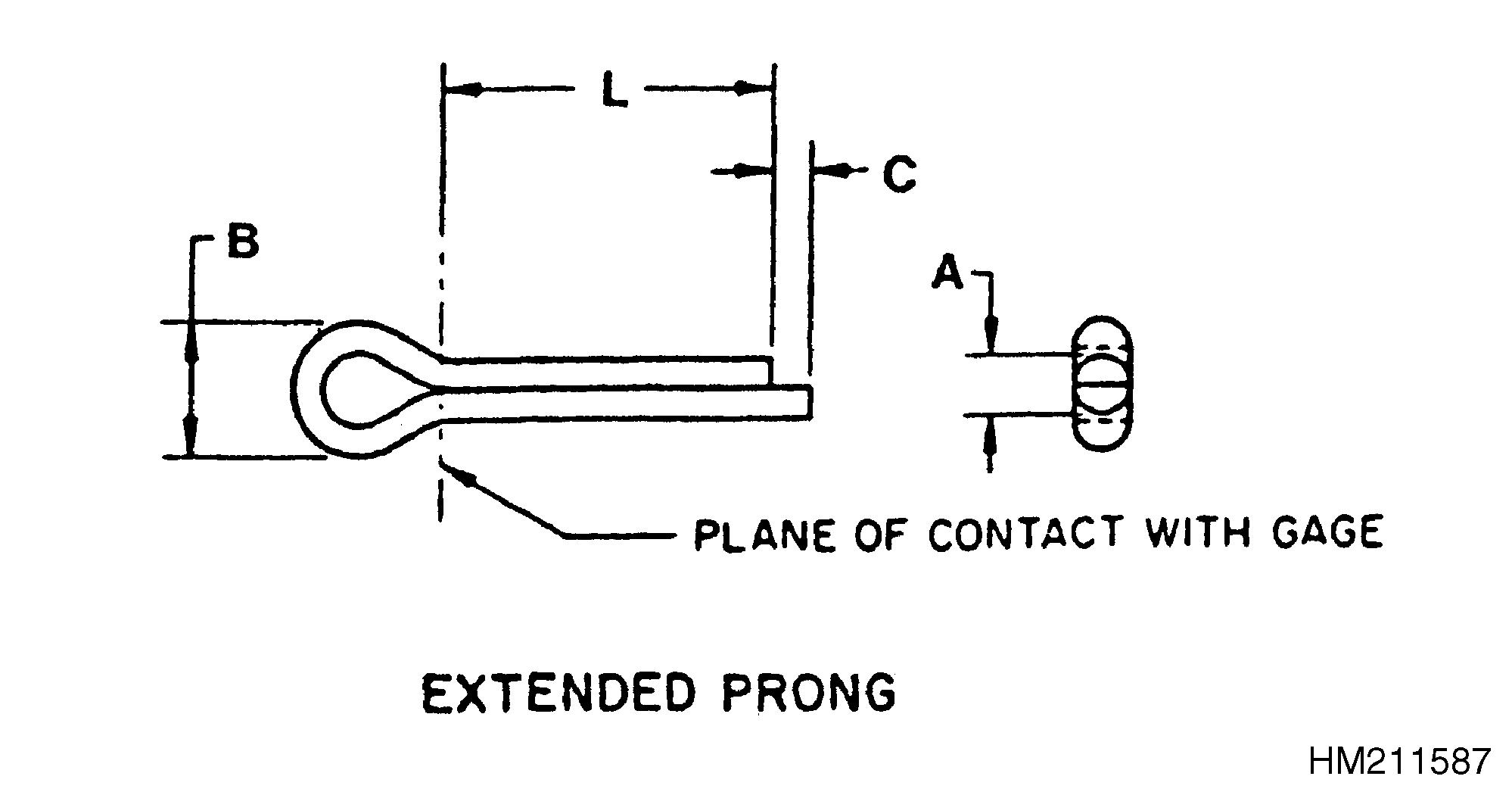

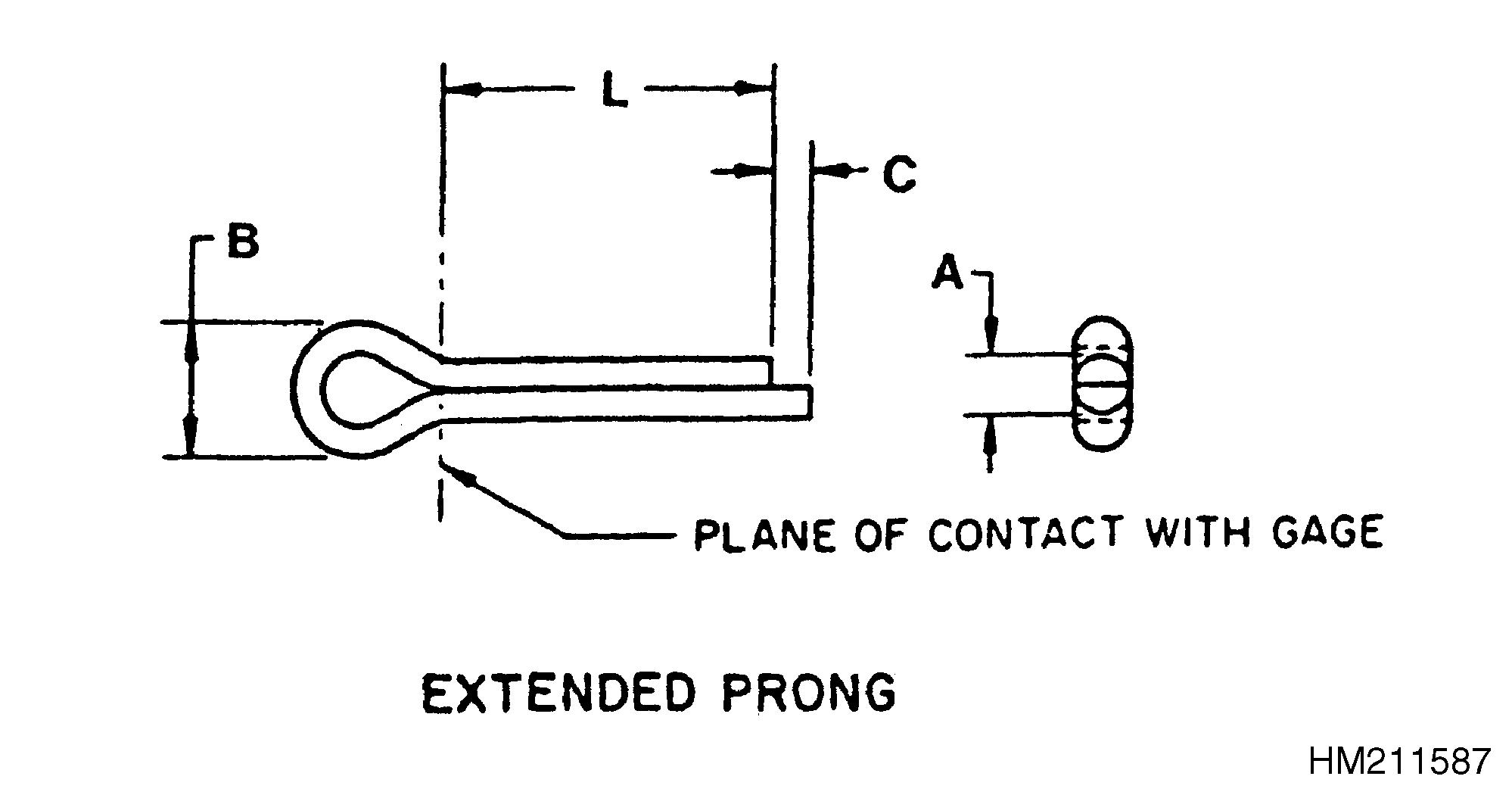

COTTER (SPLIT) PINS

Cotter (split) pins are used in many applications on your forklift. They are typically used to retain parts such as pins and nuts. Cotter (split) pins are typically not used as load-bearing members. Service personnel must use new cotter (split) pins. Do not reuse a cotter (split) pin. Replacement cotter (split) pin must be of the correct size. See Table 8.

The legs of a cotter (split) pin are bent for the following reasons:

• To retain the cotter (split) pin in the part

• To provide clearance between the cotter pin legs and other parts or members. One or both cotter (split) pin legs must be bent to provide a minimum 90° angle between the legs. See Figure 2.

Unless otherwise specified, the legs of chain anchor cotter (split) pins are to be bent against the pin. See Figure 3.

Figure 2. Minimum Angle Between Cotter Pin Legs

1.COTTER PIN

Figure 2. Minimum Angle Between Cotter Pin Legs

1.COTTER PIN

FASTENER TORQUE TABLES

M42 × 4.5 M42 × 3 M45 × 4.5

5,060 * Unless otherwise specified 1 Approximately equal to Grade 2 2 Approximately equal to Grade 5 3 Approximately equal to Grade 8

Table 6. Torque Values for Inch Fasteners*

CONVERSION TABLE

Table 7. Conversion Table for Metric and English units

Multiply By To Get

Multiply By To Get

Area

inches 2 (in. 2) × 6.452 = centimeters 2 (cm 2) centimeters 2 (cm 2) × 0.155 = inches 2 (in. 2)

feet 2 (ft 2) × 0.093 = meters 2 (m 2) meters 2 (m 2) × 10.764 = feet 2 (ft 2)

Linear

inches (in.) × 25.4 = millimeters (mm) millimeter (mm) × 0.039 = inches (in.)

feet (ft) × 0.305 = meters (m) meter (m) × 3.281 = feet (ft)

yards (yd) × 0.914 = meters (m) meter (m) × 1.094 = yards (yd) miles (mi) × 1.609 = kilometers (km) kilometer (km) × 0.621 = miles (mi)

ounces (oz) × 28.35 = grams (g)

Mass

grams (g) × 0.035 = ounces (oz) pounds (lb) × 0.454 = kilograms (kg) kilograms (kg) × 2.205 = pounds (lb)

tons (2,000 lb) × 907.18 = kilograms (kg) kilograms (kg) × 0.001 = tons (2,000 lb)

tons (2,000 lb) × 0.907 = metric ton (t) metric ton (t) × 1.102 = tons (2,000 lb)

Power

horsepower (hp) × 0.746 = kilowatts (kW) kilowatts (kW) × 1.34 = horsepower (hp)

Pressure

pounds/in. 2 (psi) × 6.895 = kilopascal (kPa) kilopascals (kPa) × 0.145 = pounds/in. 2 (psi) pounds/in. 2 (psi) × 0.007 = megapascal (MPa) megapascals (MPa) × 145.04 = pounds/in. 2 (psi)

Temperature

(°Fahrenheit−32) × 0.56 = °Celsius (C) (°Celsius × 1.8) +32 = °Fahrenheit

Torque

pound inches (lbf in.) × 0.113 = Newton meter (N•m) Newton meter (N•m) × 8.851 = pound inches (lb f in.)

pound feet (lbf ft) × 1.356 = Newton meter (N•m) Newton meter (N•m) × 0.738 = pound feet (lb f ft)

Velocity

miles/hour (mph) × 1.609 = kilometer/hour (km/h) kilometer/hr (km/h) × 0.621 = miles/hour (mph)

Volume

inches 3 (in. 3) × 16.387 = centimeters 3 (cm 3) centimeters 3 (cm 3) × 0.061 = inches 3 (in. 3) inches 3 (in. 3) × 0.016 = liters (l) liters (l) × 61.024 = inches 3 (in. 3)

quarts, U.S. (qt) × 0.946 = liters (l) liters (l) × 1.057 = quarts, U.S. (qt) quarts, U.S. (qt) × 0.83 = quarts, Imp. (qt) quarts, Imp. (qt) × 1.205 = quarts, U.S. (qt) gallons, U.S. (gal) × 3.785 = liters (l) liters (l) × 0.264 = gallons, U.S. (gal) gallons, U.S. (gal) × 0.83 = gallons, Imp. (gal) gallons, Imp. (gal) × 1.205 = gallons, U.S. (gal) ounces (oz) × 29.57 = milliliters (ml) milliliters (ml) × 0.034 = ounces (oz)

1.00 mm (0.031 in.)

mm (0.047 in.)

2.00 mm (0.062 in.)

2.50 mm (0.094 in.)

in.)

mm (0.035 in.)

Table 8. Cotter Pin Dimensional Data

mm (0.091 in.)

(0.120 in.)

in.)

in.) 4.00 mm (0.156 in.) 3.80 mm (0.150 in.)

mm (0.138 in.)

in.) 5.00 mm (0.188 in.)

in.)

mm (0.312 in.)

mm (0.295 in.)

in.)

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

6.35 mm (0.250 in.)

mm (0.375 in.)

mm (0.280 in.)

mm (0.413 in.)

mm (0.500 in.) 13.5 mm (0.530 in.)

19.05 mm (0.750 in.)

mm (1.000 in.)

mm (1.250 in.)

mm (1.500 in.)

mm (2.000 in.)

mm (0.807 in.)

mm (1.060 in.)

Table 9. Cotter Pin Dimensional Data

mm (0.217 in.)

mm (0.345 in.)

mm (0.453 in.)

mm (0.720 in.)

mm (0.940 in.)

mm (1.610 in.)

mm (2.060 in.)

57.15 mm (2.250 in.) 58.7 mm (2.310 in.)

mm (2.500 in.)

mm (2.560 in.)

mm (2.750 in.) 72.1 mm (2.840 in.)

mm (1.940 in.)

mm (2.170 in.)

in.)

mm (2.690 in.)

76.2 mm (3.000 in.) 81.3 mm (3.200 in.) 74.7 mm (2.940 in.)

88.9 mm (3.500 in.) 91.4 mm (3.600 in.)

mm (3.440 in.)

101.6 mm (4.000 in.)

mm (5.000 in.)

mm (6.000 in.)

mm (4.460 in.)

mm (5.060 in.)

mm (3.060 in.)

Table 9. Cotter Pin Dimensional Data (Continued)

6.35 mm (0.250 in.)

mm (0.280 in.)

mm (3.890 in.)

mm (4.870 in.)

mm (138.7 in.)

Table 10. Cotter Pin Dimensional Data

mm (0.217 in.)

9.525 mm (0.375 in.) 10.5 mm (0.413 in.) 8.80 mm (0.345 in.)

12.7 mm (0.500 in.) 13.5 mm (0.530 in.) 11.5 mm (0.453 in.)

19.05 mm (0.750 in.)

mm (0.807 in.)

mm (0.720 in.)

25.4 mm (1.000 in.)

mm (1.250 in.)

38.1 mm (1.500 in.)

44.45 mm (1.750 in.)

50.8 mm (2.000 in.)

mm (2.250 in.)

(2.500 in.)

mm (2.750 in.)

mm (3.000 in.)

mm (1.060 in.)

Table 10. Cotter Pin Dimensional Data (Continued)

(0.940 in.)

mm (1.610 in.)

mm (1.440 in.)

mm (2.060 in.)

mm (1.940 in.)

mm (3.200 in.)

mm (2.940 in.)

88.9 mm (3.500 in.) 91.4 mm (3.600 in.) 87.4 mm (3.440 in.)

mm (4.000 in.)

mm (5.000 in.)

mm (4.460 in.)

mm (5.060 in.)

(3.890 in.)

mm (4.870 in.)

152.4 mm (6.000 in.) 153.9 mm (3.060 in.) 5.460 mm (138.7 in.)

mm (0.750 in.)

mm (1.00 in.)

mm (1.250 in.)

mm (1.750 in.)

mm (2.000 in.)

Table 11. Cotter Pin Dimensional Data

152.4 mm (6.000 in.) 153.9 mm (3.060 in.) 138.7 mm (5.460 in.)

SAFETY PRECAUTIONS MAINTENANCE

AND REPAIR

• When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load.

•Do not lift heavy parts by hand, use a lifting mechanism.

•Wear safety glasses.

• DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift trucks. Disconnect the battery ground cable on internal combustion lift trucks.

• Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section.

•Keep the unit clean and the working area clean and orderly.

•Use the correct tools for the job.

•Keep the tools clean and in good condition.

• Always use APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer.

• Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to remove parts.

• Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs.

•Be sure to follow the WARNING and CAUTION notes in the instructions.

• Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable. Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems.

• Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area. Make sure the area is well ventilated.

NOTE: The following symbols and words indicate safety information in this manual:

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury and property damage.

On the lift truck, the WARNING symbol and word are on orange background. The CAUTION symbol and word are on yellow background.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

Series Code / Model Designation Reference Table

This table consists of the following Series Codes used in this manual.

Series Code

European Model Americas Model

A909 GLP/GDP80VX, GLP/GDP80VX9, GLP/ GDP90VX

B878 BDP60-70CA

B879 N/A

B909 GLP/GDP80VX, GLP/GDP80VX9, GLP/ GDP90VX

C878 GLP60-70VX

C879 GLC60-70VX

C909 GLP/GDP80VX, GLP/GDP80VX9, GLP/ GDP90VX

D818 N/A

D878 GLP60-70VX

D879 GLC60-70VX

D909 GLP/GDP80VX, GLP/GDP80VX9, GLP/ GDP90VX

E813 GLP/GDP3.5-5.5LJ/MJ

E818 GLC40-45-55VX, GLC55SVX

E878 GLP60-70VX

E879 GLC/GDC60-70VX

F813 GLP/GDP50-55VX, GLP/GDP40VX5, GLP/GDP40VX6, GLP/GDP45VX5, GLP/ GDP45VX6

F818 GLC40-45-55VX, GLC55SVX

F878 GLP/GDP60VX, GLP/GDP70VX

F879 GLC/GDC60-70VX

G813 GLP/GDP50-55VX, GLP/GDP40VX5, GLP/GDP40VX6, GLP/GDP45VX5, GLP/ GDP45VX6

G878 GLP/GDP60VX, GLP/GDP70VX, GP70VXS6, GP70VXS9

H813 GLP/GDP50-55VX, GLP/GDP40VX5, GLP/GDP40VX6, GLP/GDP45VX5, GLP/ GDP45VX6

GLP/GDP170VX, GLP/GDP175VX36, GLP/ GDP190VX

GP/GLP/GDP135-155CA

GC/GLC135-155CA

GLP/GDP170VX, GLP/GDP175VX36, GLP/ GDP190VX

GP/GLP135-155VX

GC/GLC135-155VX

GDP170VX, GDP175VX36, GDP190VX

GC070-120LJ/MJ

GP/GLP135-155VX

GC/GLC135-155VX

GDP170VX, GDP175VX36, GDP190VX

GP/GLP/GDP70-120LJ/MJ

GC/GLC80VX, GC/GLC80VX-BCS, GC/GLC100VX, GC/GLC100VX-BCS, GC/GLC120VX, GC/ GLC120SVX, GC/GLC120VXPRS

GP/GLP135-155VX

GC/GLC/GDC135-155VX

GP/GLP/GDP80VX, GP/GLP/GDP90VX, GP/GLP/ GDP100VX, GP/GLP/GDP110VX, GP/GLP/ GDP120VX

GC/GLC80VX, GC/GLC80VX-BCS, GC/GLC100VX, GC/GLC100VX-BCS, GC/GLC120VX, GC/ GLC120SVX, GC/GLC120VXPRS

GP/GLP/GDP135VX, GP/GLP/GDP155VX

GC/GLC/GDC135-155VX

GP/GLP/GDP80VX, GP/GLP/GDP90VX, GP/GLP/ GDP100VX, GP/GLP/GDP110VX, GP/GLP/ GDP120VX

GP/GLP/GDP135-155VX, GP155VXS

GP/GLP/GDP80VX, GP/GLP/GDP90VX, GP/GLP/ GDP100VX, GP/GLP/GDP110VX, GP/GLP/ GDP120VX

J813

K813

GLP/GDP50-55VX, GLP/GDP40VX5, GLP/GDP40VX6, GLP/GDP45VX5, GLP/ GDP45VX6

GLP/GDP50-55VX, GLP/GDP40VX5, GLP/GDP40VX6, GLP/GDP45VX5, GLP/ GDP45VX6

GP/GLP/GDP80VX, GP/GLP/GDP90VX, GP/GLP/ GDP100VX, GP/GLP/GDP110VX, GP/GLP/ GDP120VX

GP/GLP/GDP80VX, GP/GLP/GDP90VX, GP/GLP/ GDP100VX, GP/GLP/GDP110VX, GP/GLP/ GDP120VX

Description

DISTRIBUTOR IGNITION (DI) SYSTEM

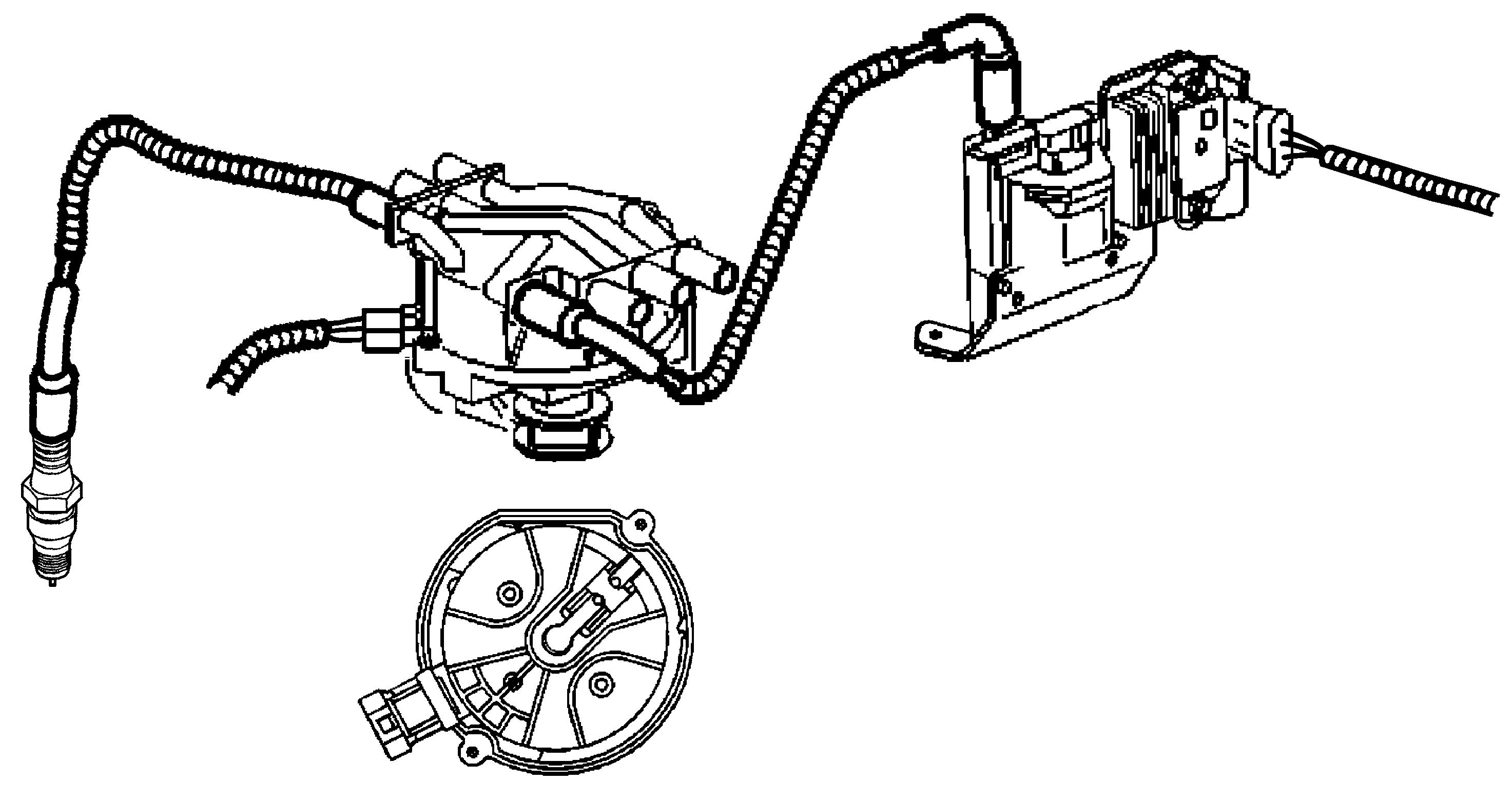

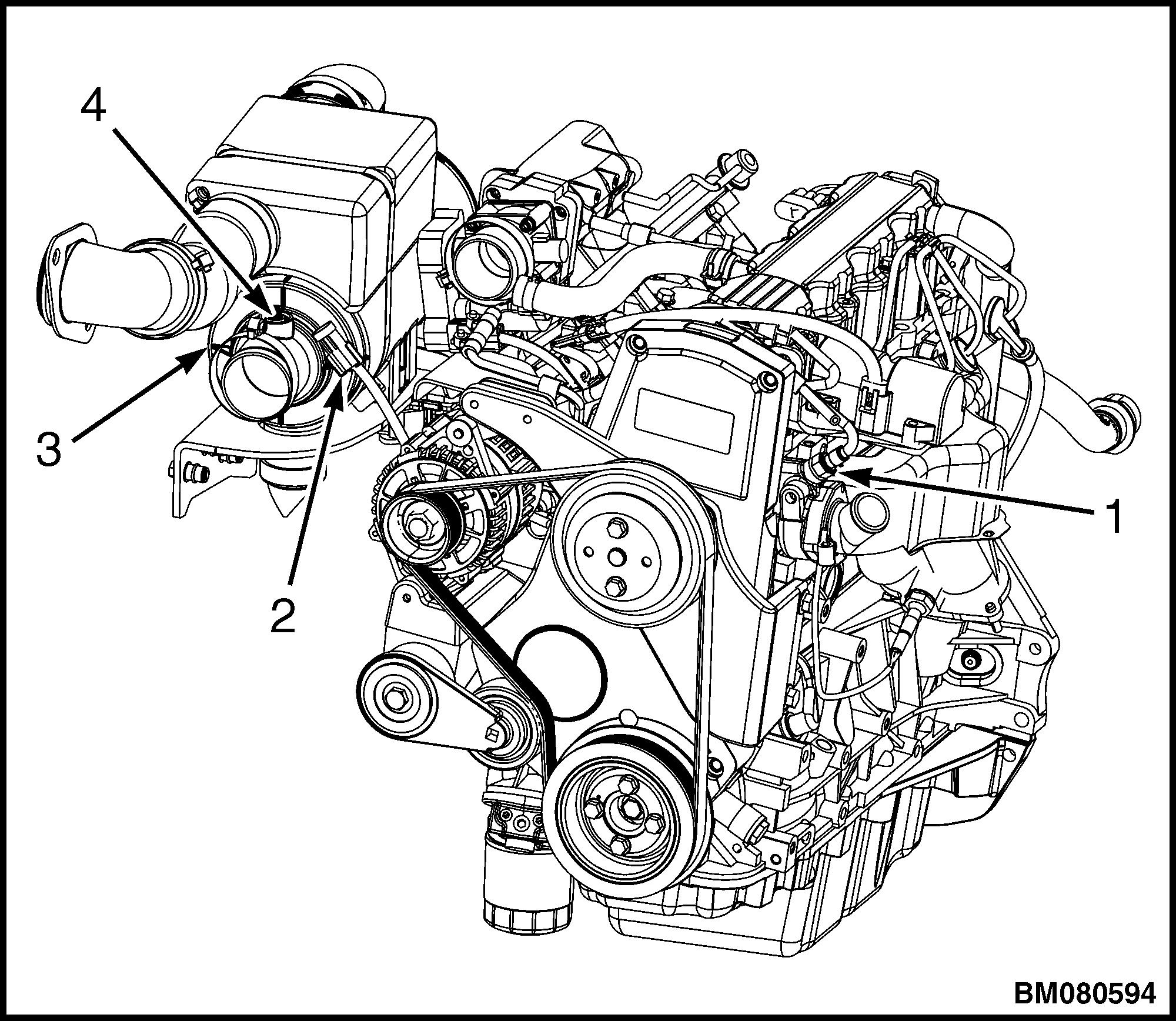

The distributor ignition (DI) system is responsible for producing and controlling a high energy secondary spark. This spark is used to ignite the compressed air/ fuel mixture at precisely the correct time. This provides optimal performance, fuel economy, and control of exhaust emissions. This ignition system consists of a single ignition coil and ignition control module (ICM). Spark energy is delivered via a distributor cap, rotor, and secondary spark plug wires. The driver module within the ICM is commanded to operate the coil by the electronic control module (ECM), that has complete control over spark timing. The DI system consists of a Crankshaft Position (CKP) Sensor, Camshaft Position (CMP) Sensor, Ignition Coil and Ignition Control Module (ICM), and Secondary Ignition Components.

CRANKSHAFT POSITION (CKP) SENSOR

The CKP sensor is a three-wire sensor based on the magneto-resistive principle. A magneto-resistive sensor uses two magnetic pickups between a permanent magnet. As an element such as a reluctor wheel passes the magnets, the resulting change in the magnetic field is used by the sensor electronics to produce a digital output pulse. The ECM supplies a 5volt, low reference and signal circuit to the CKP sensor. The sensor returns a digital ON/OFF pulse 3 times per crankshaft revolution. The CKP sensor reads the crankshaft mounted reluctor wheel to identify pairs of cylinders at top dead center (TDC).

CAMSHAFT POSITION (CMP) SENSOR

The CMP sensor is a hall-effect sensor located in the ignition distributor base, and uses the same type of circuits as the CKP sensor. The CMP sensor signal is a digital ON/OFF pulse, output once per revolution of the camshaft. The CMP sensor information is used by the ECM to determine the position of the valve train relative to the CKP.

IGNITION COIL AND IGNITION CONTROL MODULE (ICM)

The ICM is connected to the ECM by an ignition control (IC) circuit. The ICM also has a ground circuit and shares an ignition 1 voltage supply with the ignition coil. The coil driver in the ICM controls current through the ignition coil based on signal pulses from the ECM. There is no backup or bypass function in the ICM.

SECONDARY IGNITION COMPONENTS

The distributor is only used as a means to operate the CMP sensor and to distribute spark in the correct sequence. Since the distributor has no influence on base timing, the distributor is not adjustable. The spark is distributed through conventional carbon core wires to the spark plugs.

Spark Plugs and Wires

SPARK PLUG WIRE INSPECTION

Spark plug wire integrity is vital for proper engine operation. A thorough inspection will be necessary to accurately identify conditions that may affect engine operation. Inspect for the following conditions:

1. Correct routing of the spark plug wires. Incorrect routing may cause cross-firing.

2. Any signs of cracks or splits in the wires.

3. Inspect each boot for the following conditions:

• Tearing

• Piercing

• Arcing

• Carbon tracking

• Corroded terminal

If corrosion, carbon tracking, or arcing are indicated on a spark plug wire boot or on a terminal, replace the wire and the component connected to the wire.

SPARK PLUG WIRE REPLACEMENT

Remove

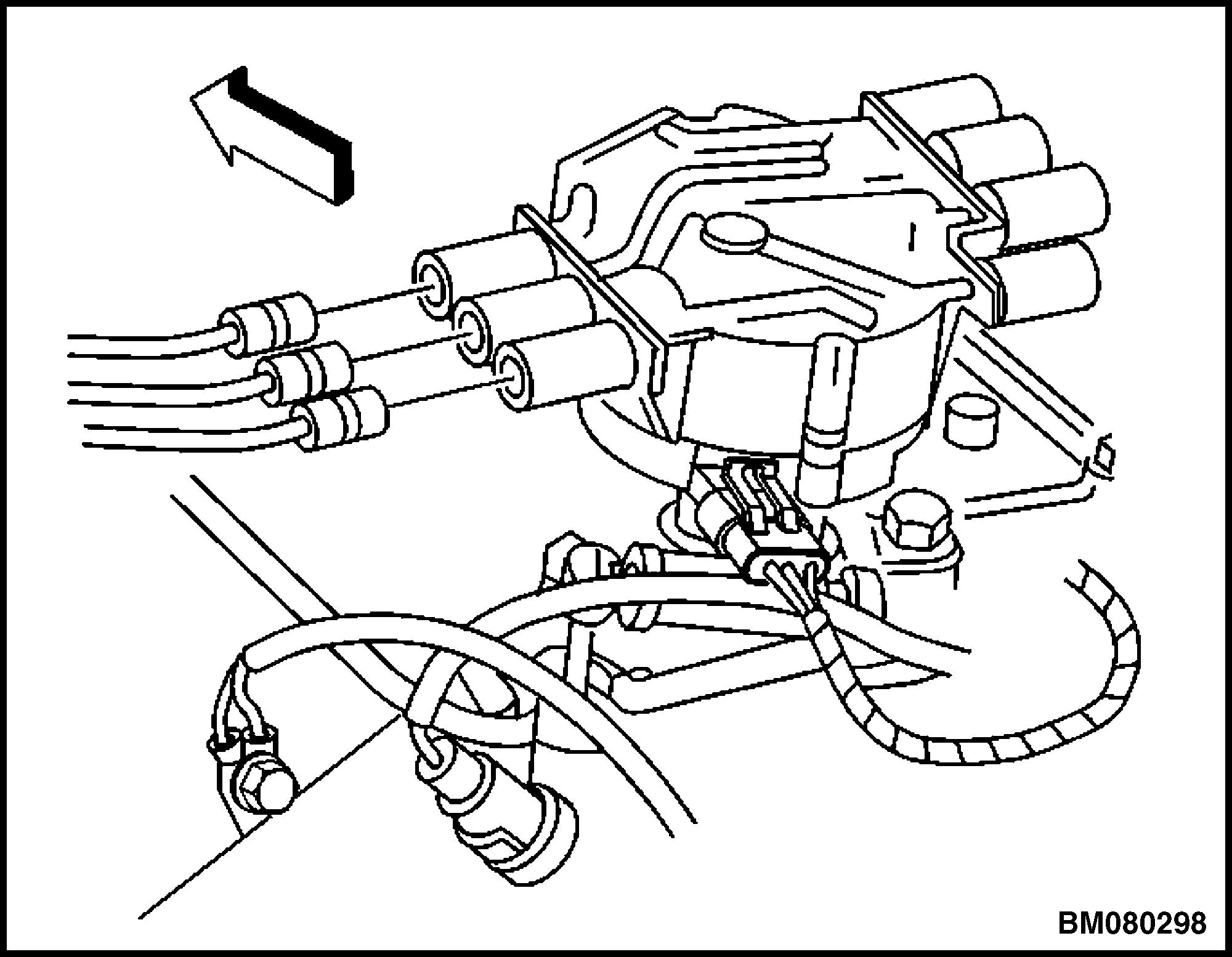

1. Disconnect the spark plug wire at each spark plug. See Figure 1.

a. Twist the boots 1/2 turn before removing the boots.

b. Pull only on the boot or use a tool designed for this purpose in order to remove the wire from each spark plug.

1.SPARK PLUG WIRES

Figure 1. Spark Plug Wire Removal/Installation

2. Disconnect the spark plug wire from the distributor.

a. Twist each spark plug boot 1/2 turn.

b. Pull only on the boot or use a tool designed for this purpose in order to remove the wires from the distributor.

Install

NOTE: If the boot-to-wire movement has occurred, the boot will give a false visual impression of being fully seated. Ensure that the boots have been properly assembled by pushing sideways on the installed boots. Failure to properly seat the terminal onto the spark plug will lead to wire core erosion and result in an engine misfire or crossfire condition and possible internal damage to the engine.

1. Install the spark plug wires at the distributor.

2. Install the spark plug wire to each spark plug. See Figure 1.

3. Inspect the wires for proper installation:

a. Push sideways on each boot in order to inspect the seating.

b. Reinstall any loose boot.

c. Wire routing must be kept intact during service and followed exactly when wires have been disconnected or when replacement of the wires is necessary. Failure to route the wires properly can lead to radio ignition noise and cross firing of the plugs or shorting of the leads to the ground.

d. Any time the spark plug wires or boots are installed on the spark plugs, new dielectric grease needs to be applied inside the boot.

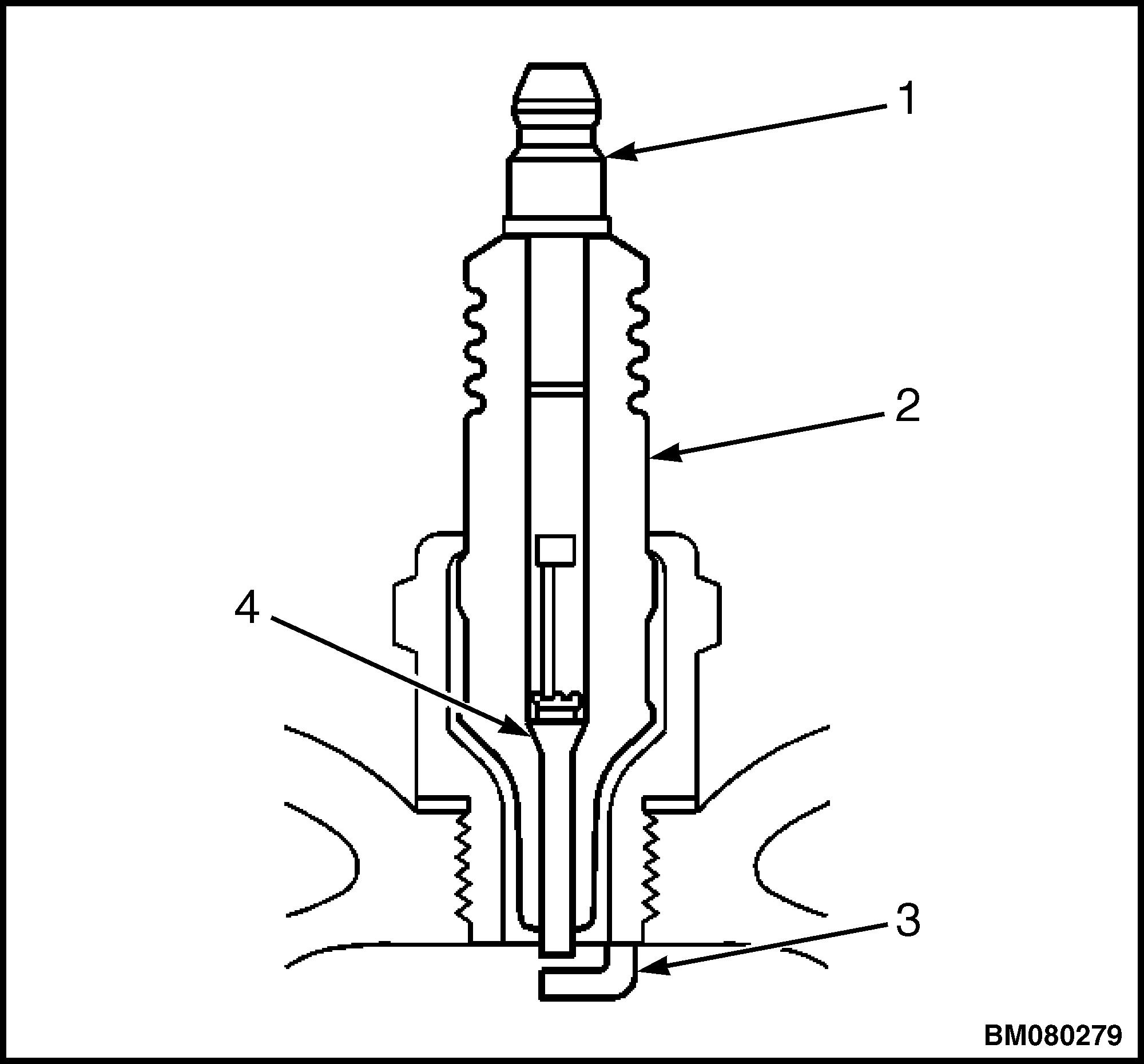

SPARK PLUG INSPECTION

Usage

1. Ensure that the correct spark plug is installed. An incorrect spark plug causes driveability conditions. Refer to Table 1 for the correct spark plug.

2. Ensure that the spark plug has the correct heat range. An incorrect heat range causes the following conditions:

• Spark plug fouling - Colder plug

• Pre-ignition causing spark plug and/or engine damage - Hotter plug

Inspection

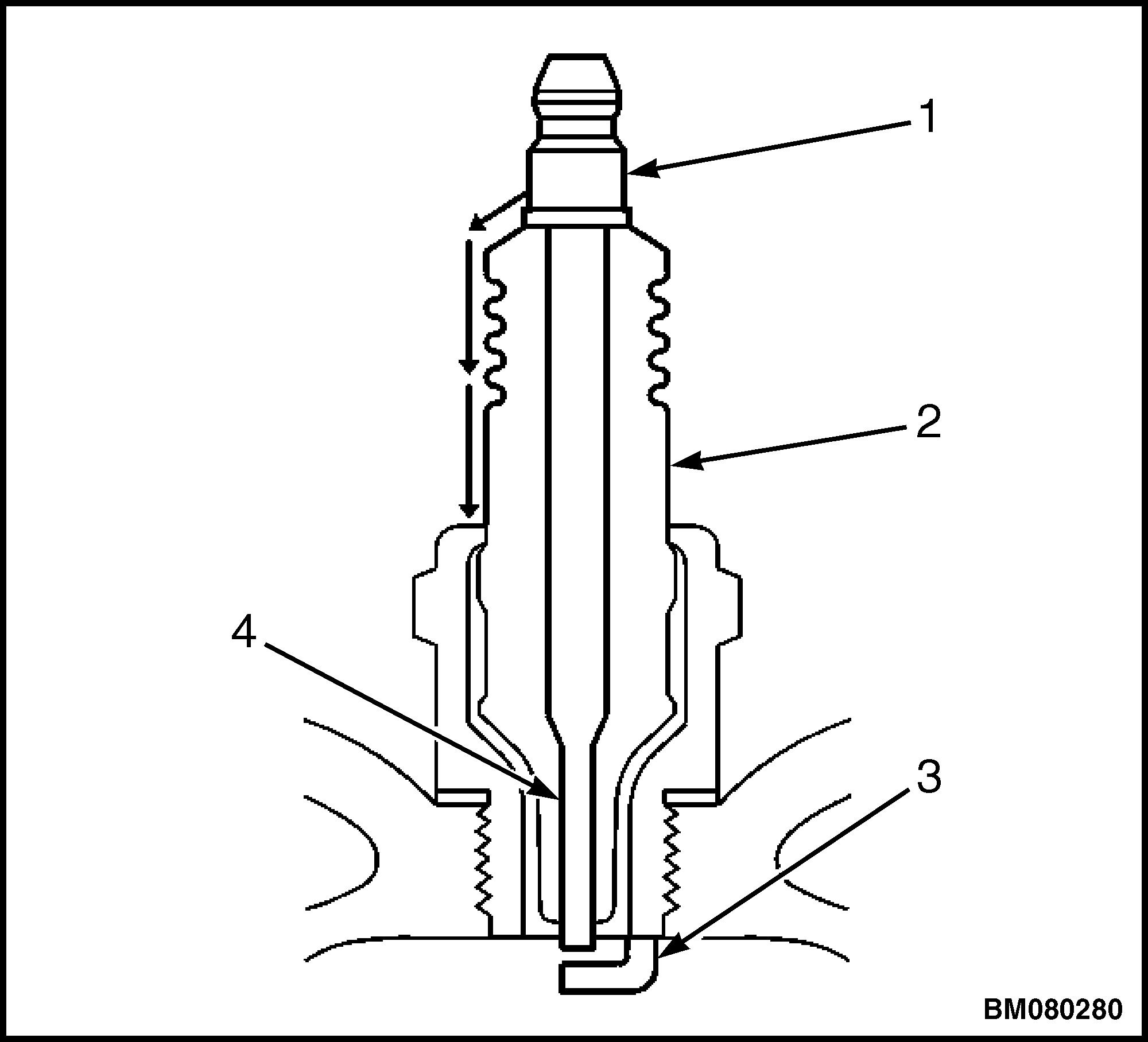

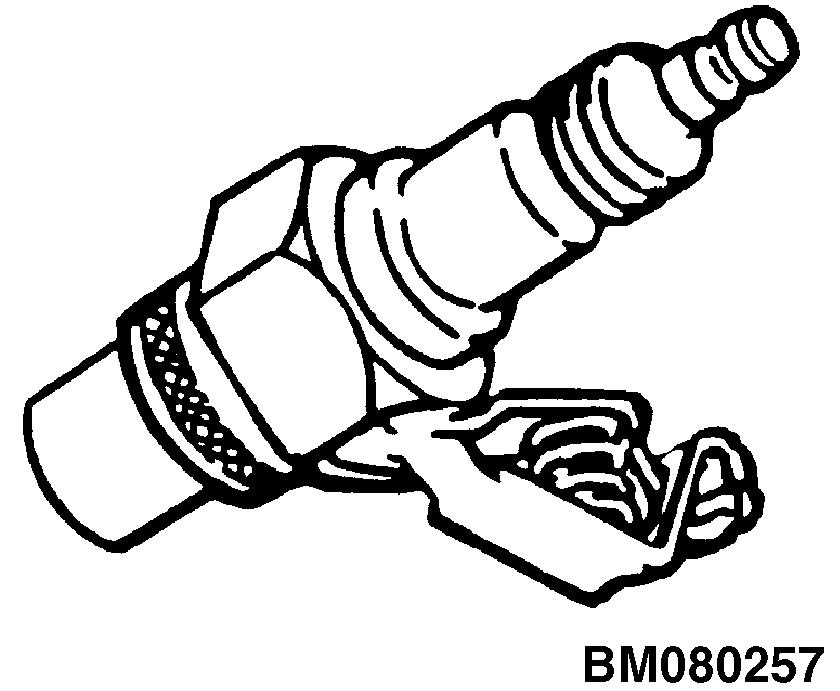

1. Inspect the terminal post for damage. See Figure 2.

a. Inspect for a bent or broken terminal post.

1.TERMINAL POST 2.INSULATOR 3.ELECTRODE 4.ELECTRODE

Figure 2. Spark Plug

b. Test for a loose terminal post by twisting and pulling the post. The terminal post should NOT move.

2. Inspect the insulator for flashover or carbon tracking, soot. See Figure 3. This is caused by the electrical charge traveling across the insulator between the terminal post and ground. Inspect for the following conditions:

1.TERMINAL POST 2.INSULATOR 3.ELECTRODE 4.ELECTRODE

Figure 3. Spark Plug With Flashover or Carbon Tracking

a. Inspect the spark plug boot for damage.

b. Inspect the spark plug recess area of the cylinder head for moisture, such as oil, coolant, or water. A spark plug boot that is saturated causes arcing to ground.

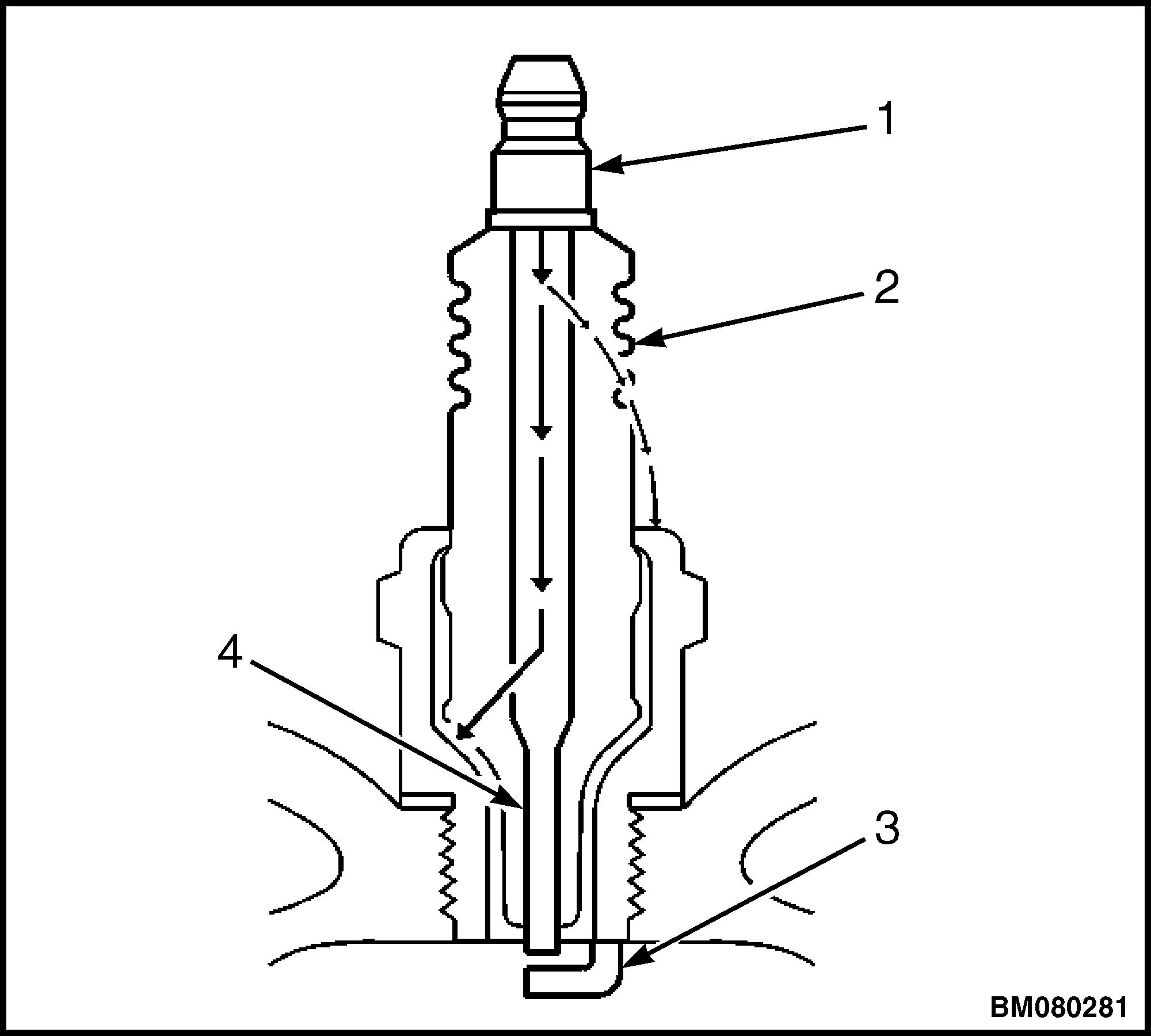

3. Inspect the insulator for cracks. All or part of the electrical charge may arc through the crack instead of the electrodes. See Figure 4.

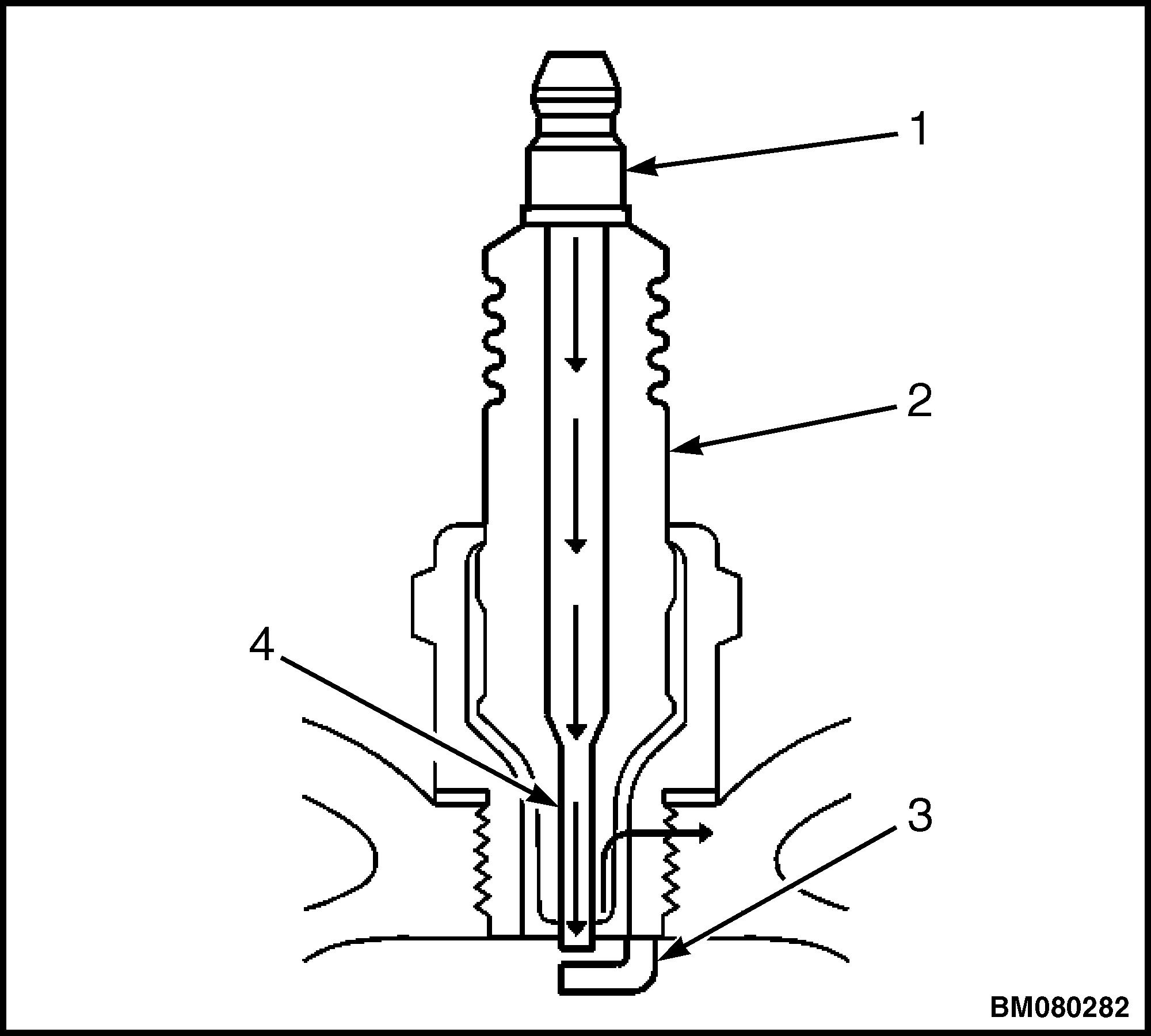

4. Inspect for evidence of improper arcing. See Figure 5.

a. Measure the gap between the center electrode (4) and the side electrode (3) terminals. An excessively wide electrode gap can prevent correct spark plug operation.

b. Inspect for the correct spark plug torque. Refer to Table 1. Insufficient torque can prevent correct spark plug operation. An over-torqued spark plug causes the insulator to crack.

1.TERMINAL POST 2.INSULATOR 3.ELECTRODE 4.ELECTRODE

Figure 4. Spark Plug Arcing Through a Crack

1.TERMINAL POST 2.INSULATOR 3.ELECTRODE 4.ELECTRODE

Figure 5. Spark Plug Arcing Improperly

c. Inspect for signs of tracking that occurred near the insulator tip instead of the center electrode (4).

d. Inspect for a broken or worn side electrode (3).

e. Inspect for a broken, worn, or loose center electrode (4) by shaking the spark plug.

(1) A rattling sound indicates internal damage.

(2) A loose center electrode (4) reduces the spark intensity.

f. Inspect for bridged electrodes (3, 4). Deposits on the electrodes (3, 4) reduce or eliminate the gap.

g. Inspect for worn or missing platinum pads on the electrodes (3, 4) if equipped.

h. Inspect for excessive fouling.

5. Inspect the spark plug recess area of the cylinder head for debris. Dirty or damaged threads can cause the spark plug not to seat correctly during installation.

Visual Inspection

1. Normal operation - Brown to grayish-tan with small amounts of white powdery deposits are normal combustion by-products from fuels with additives.

2. Carbon fouled - Dry, fluffy black carbon, or soot caused by the following conditions:

• Rich fuel mixtures

• Leaking fuel injectors

• Excessive fuel pressure

• Restricted air filter element

• Incorrect combustion

• Reduced ignition system voltage output

• Weak coils

• Worn ignition wires

• Incorrect spark plug gap

• Excessive idling or slow speeds under light loads can keep spark plug temperatures so low that normal combustion deposits may not burn off.

3. Deposit Fouling - Oil, coolant, or additives that include substances such as silicone, very white coating, reduces the spark intensity. Most powdery deposits will not effect spark intensity unless they form into a glazing over the electrode.

SPARK PLUG REPLACEMENT

Remove

1. Remove the spark plug wires. Refer to Spark Plug Wire Replacement.

2. Loosen each spark plug 1 or 2 turns.

3. Brush or air blast away any dirt from around the spark plugs.

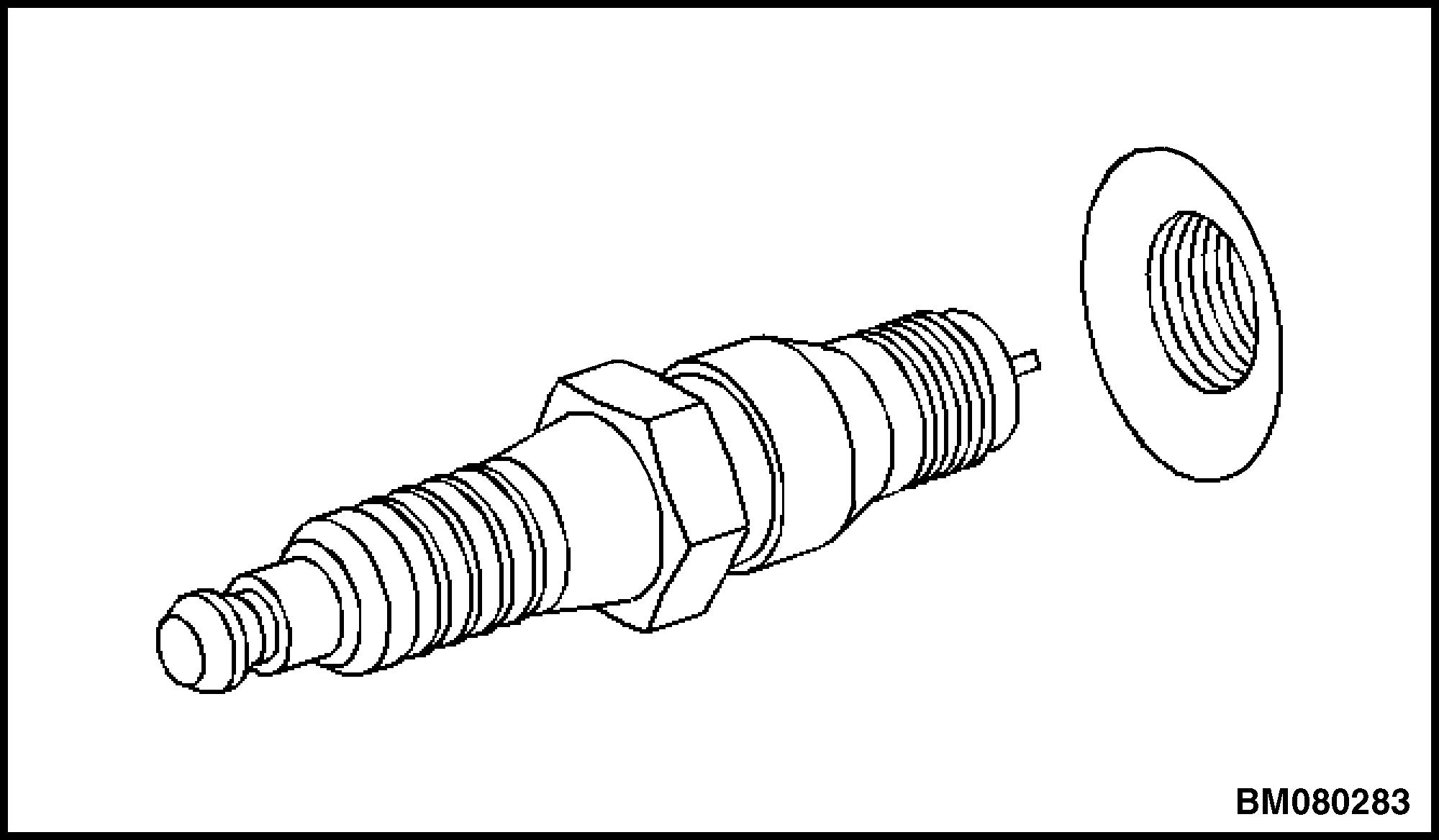

4. Remove the spark plugs one at a time. Place each plug in a tray marked with the corresponding cylinder numbers. See Figure 6.

Install

1. Properly position each spark plug washer.

2. Inspect each spark plug gap. Adjust each plug as needed. See Table 1.

CAUTION

Late model engines use a combination of standard and metric fasteners. The components affected are the starter motor, engine mounts, and flywheel housing mounting. Other components may also have a combination of fasteners. Always verify that the proper fasteners are used whenever removing or replacing any components.

3. Hand start the spark plugs in the corresponding cylinders. See Figure 6.

4. Tighten the spark plugs.

a. For used heads, tighten the spark plugs to 15 N•m (11 lbf ft).

Figure 6. Spark Plug Removal/Installationb. For new aluminum heads, tighten the spark plugs to 20 N•m (15 lbf ft).

INSPECT

c. For new iron heads, tighten the spark plugs to 30 N•m (22 lbf ft).

Distributor Repair

6. Install the engine cover. Refer to the Frame section for your lift truck.

1. Remove the engine cover. Refer to the Frame section for your lift truck.

NOTE: Discoloration of the cap and some whitish buildup around the cap terminals is normal. Yellowing of the rotor cap, darkening, and some carbon buildup under the rotor segment is normal. Replacement of the cap and the rotor is not necessary unless there is a driveability concern.

2. Inspect the cap for cracks, tiny holes, or carbon tracks between the cap terminal traces. Diagnose the carbon tracks using the following procedure:

a. Remove the cap. Refer to Distributor, Replace.

b. Place 1 lead from the DMM on a cap terminal.

c. Use the other lead in order to probe all other terminals and the center carbon ball.

d. Move the base lead to the next terminal. Probe all other leads.

e. Continue this procedure until you test all the secondary terminals.

f. If there are any non-infinite readings, replace the cap.

3. Inspect the cap for excess buildup of corrosion on the terminals. Scrape clean the terminals. Replace the cap if the corrosion is excessive. Some buildup is normal.

4. Inspect the rotor segment for excess wear. Replace the rotor if excess looseness in the rotor segment is present. See Figure 8.

5. Inspect the shaft for shaft-to-bushing looseness:

a. Inspect the housing for cracks or damage.

b. Insert the shaft in the housing.

c. If the shaft wobbles, replace the housing assembly.

OVERHAUL

Disassemble

1. Remove the engine cover. Refer to the Frame section for your lift truck.

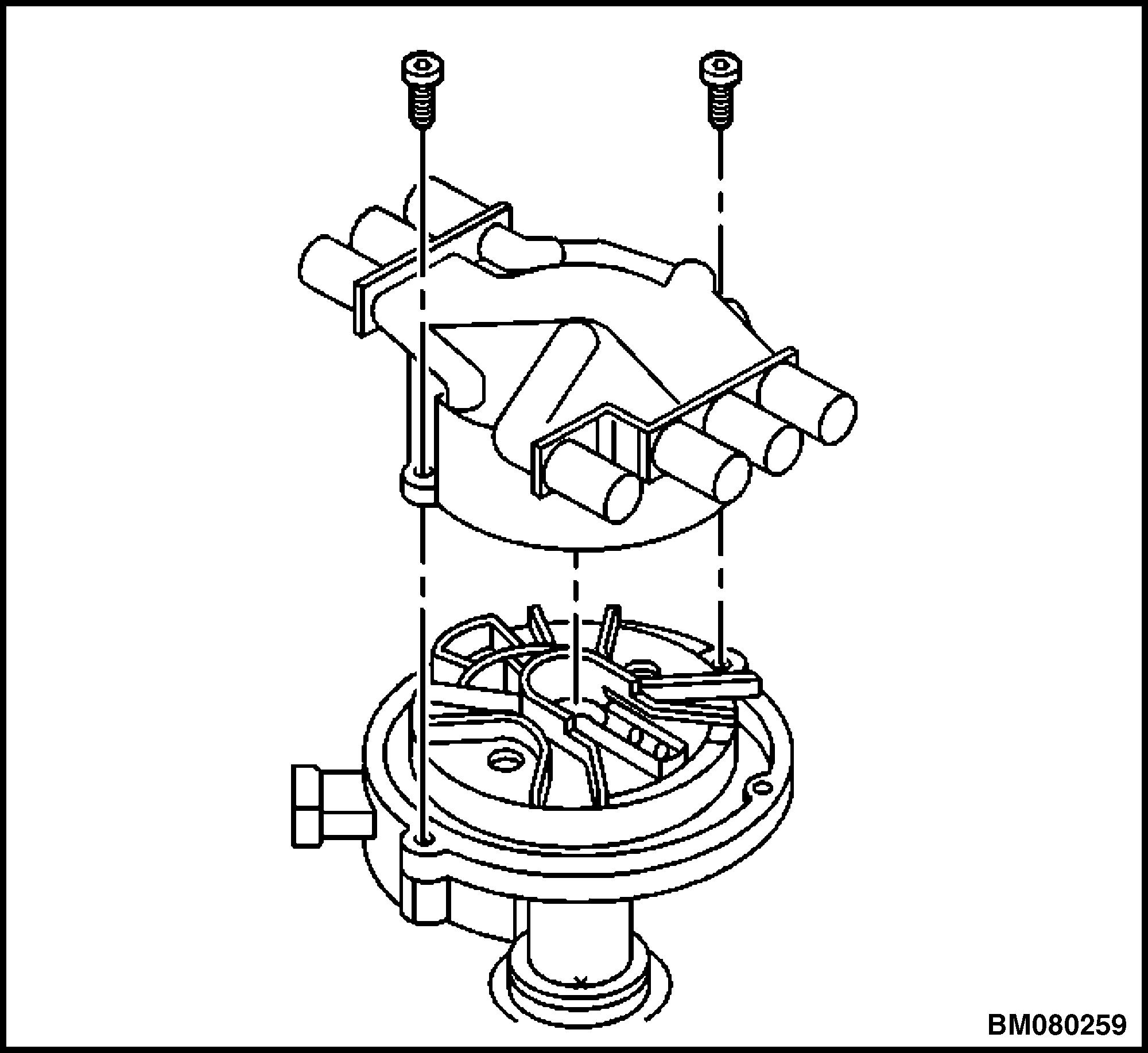

NOTE: The ignition system distributor driven gear and rotor may be installed in multiple positions. In order to avoid mistakes, mark the distributor on the following components in order to ensure the same mounting position upon reassembly:

• Distributor driven gear

• Distributor shaft

• Rotor holes

Installing the driven gear 180 degrees out of alignment, or locating the rotor in the wrong holes, will cause a no-start condition. Premature engine wear or damage may result.

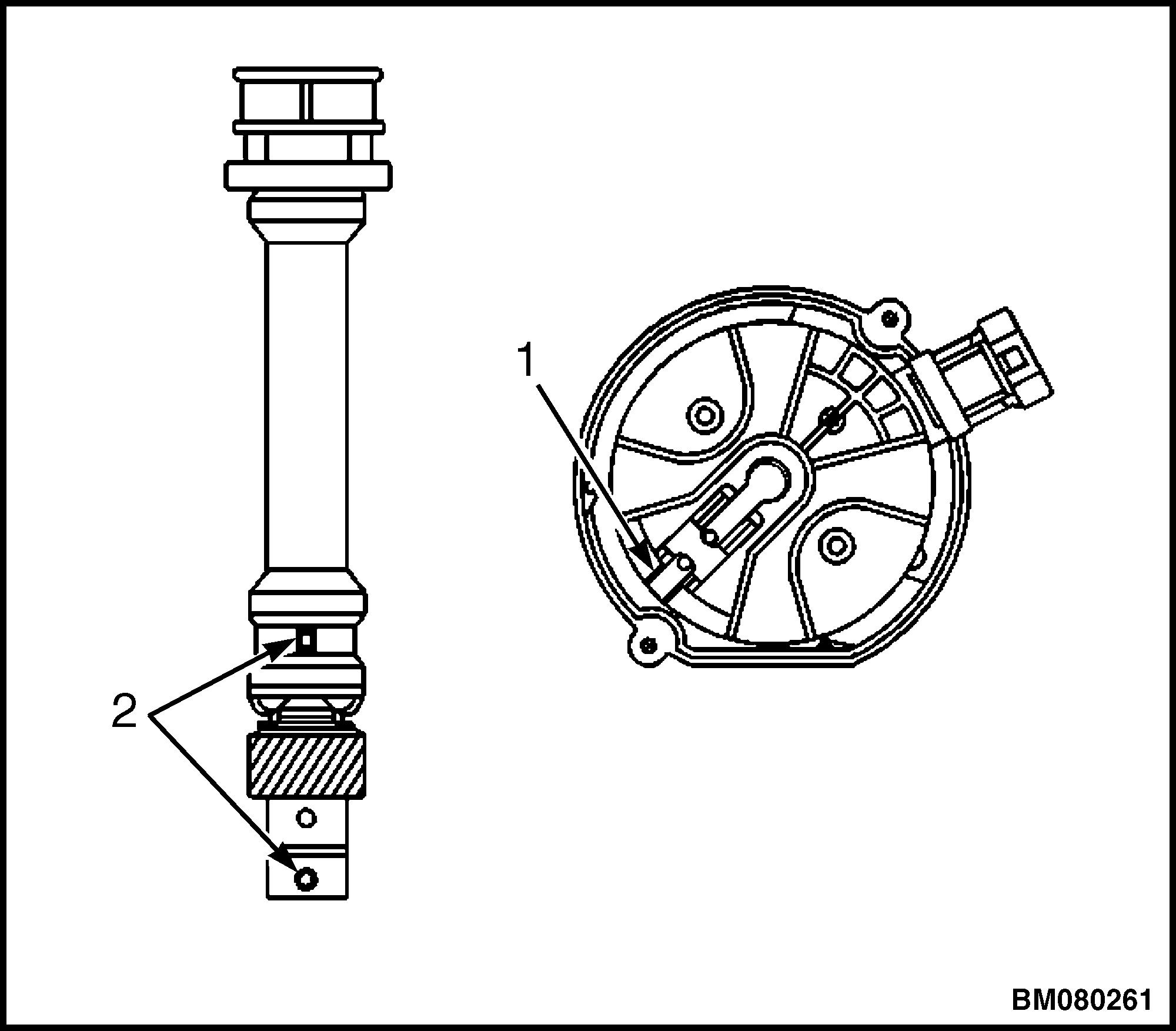

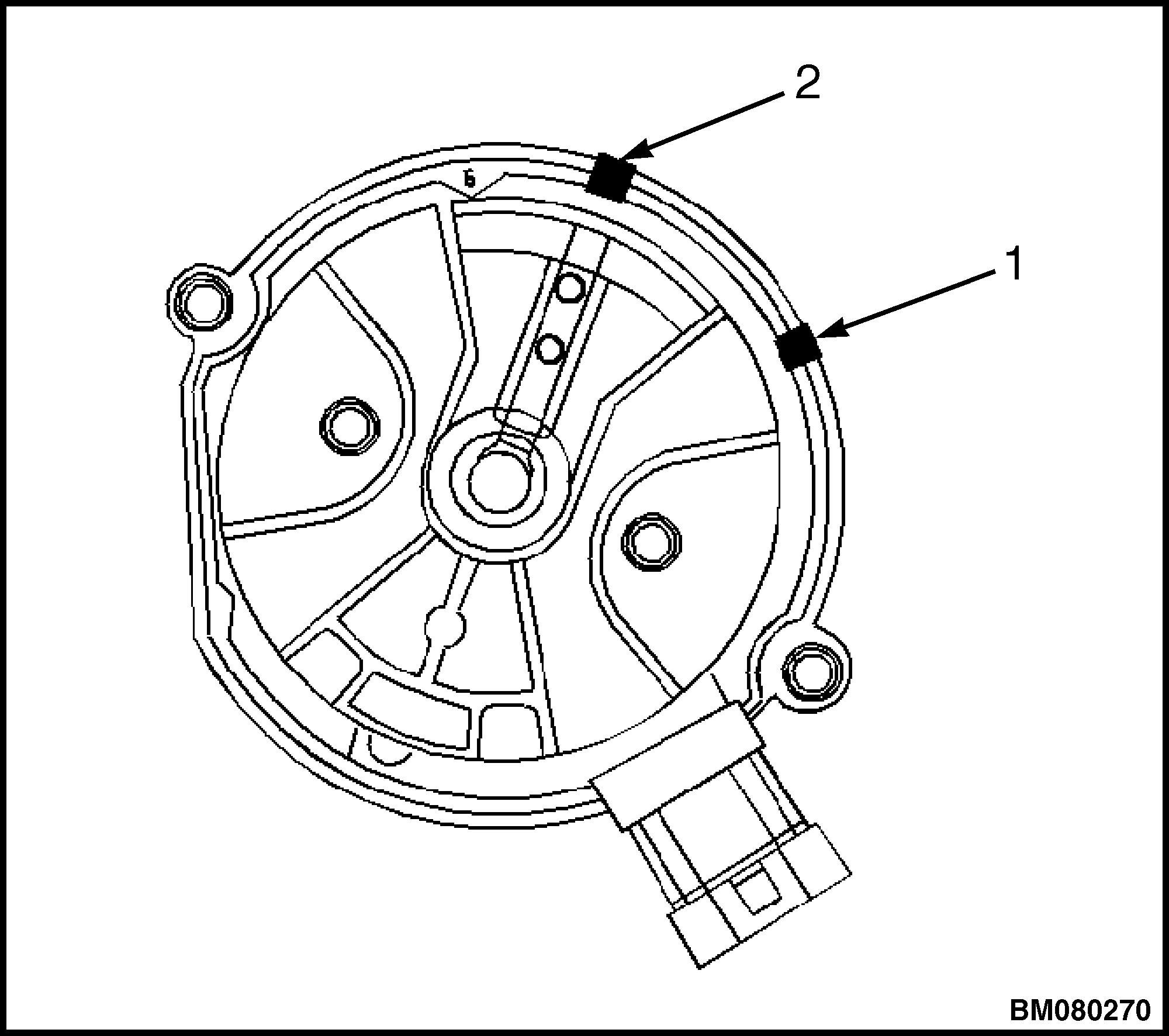

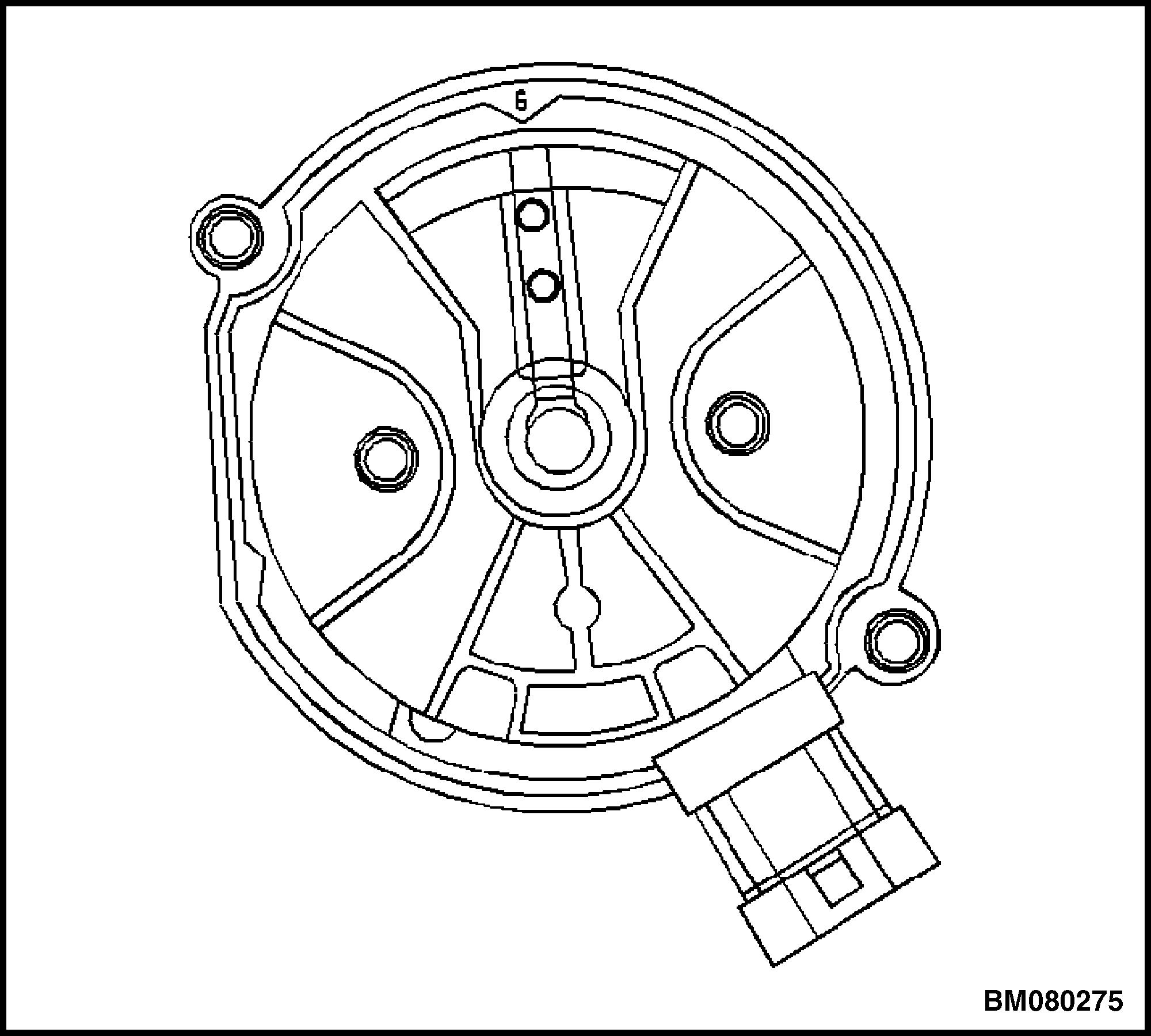

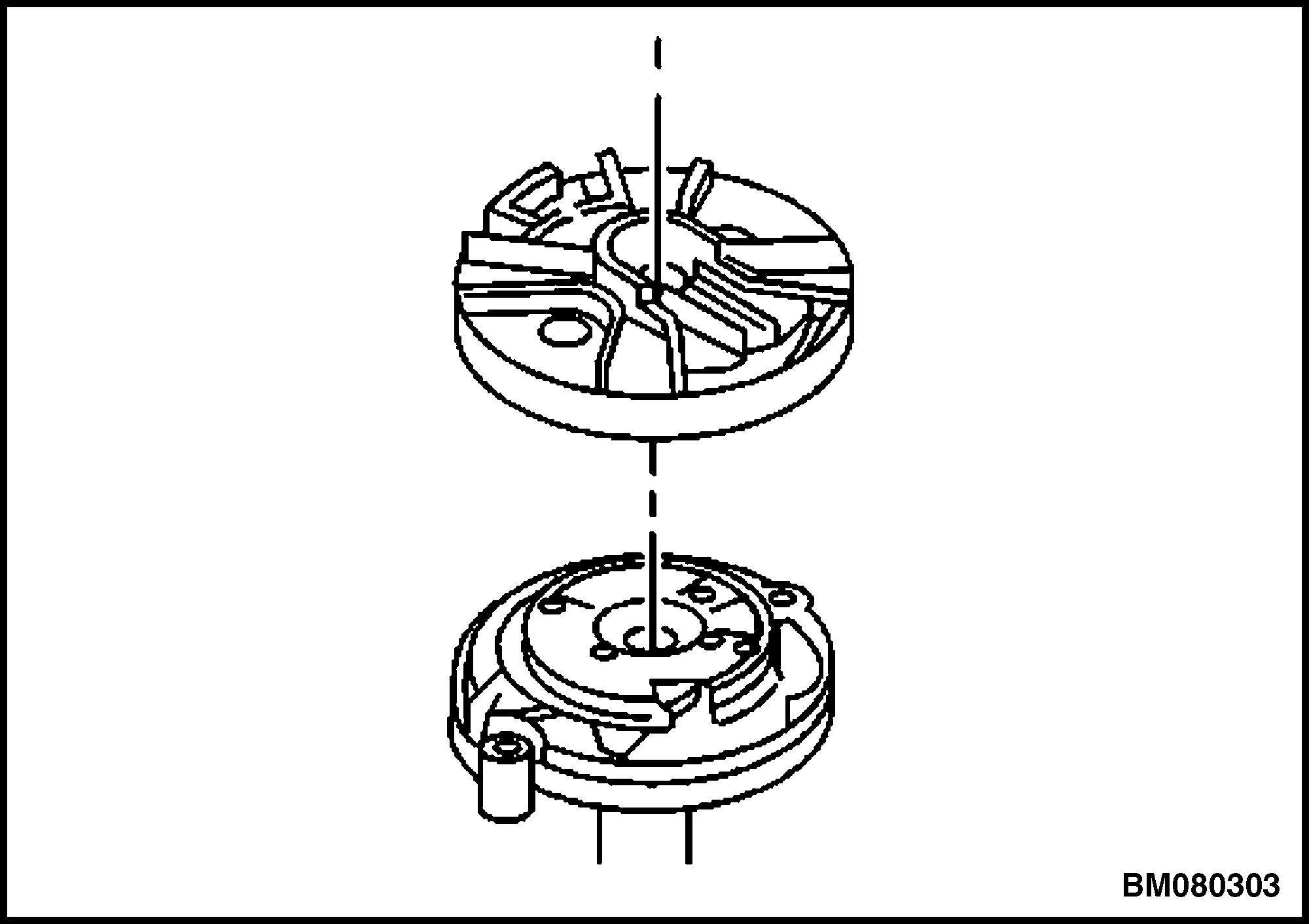

2. Align white paint mark on the bottom stem of the distributor and the pre-drilled indent hole in the bottom of the gear. See Figure 7.

Legend for Figure 7.

1.ROTOR SEGMENT POSITIONING

2.INDENT HOLE IN BOTTOM OF GEAR

3. With the gear in this position, the rotor segment should be positioned as shown in Figure 7. If not, replace the distributor.

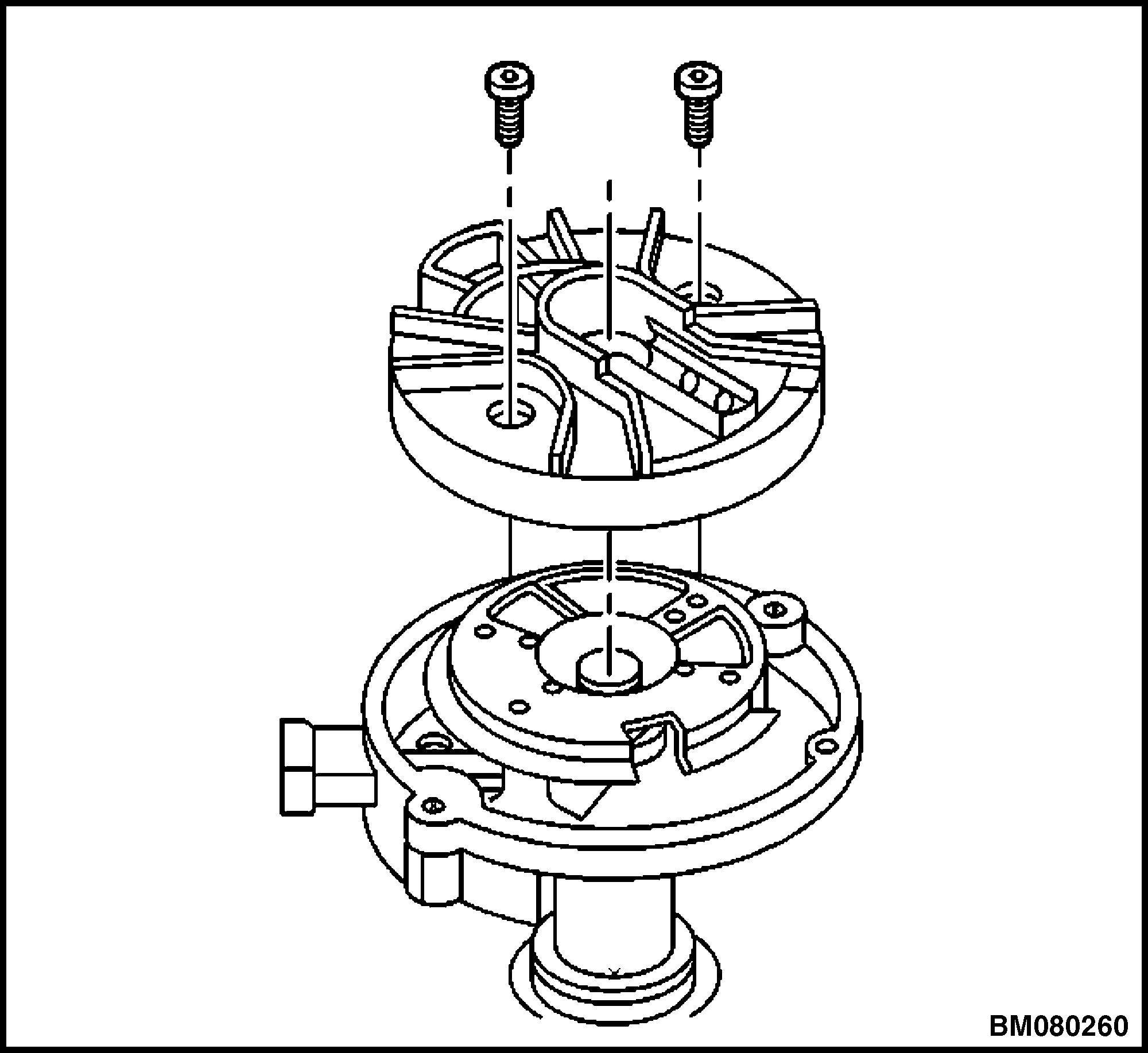

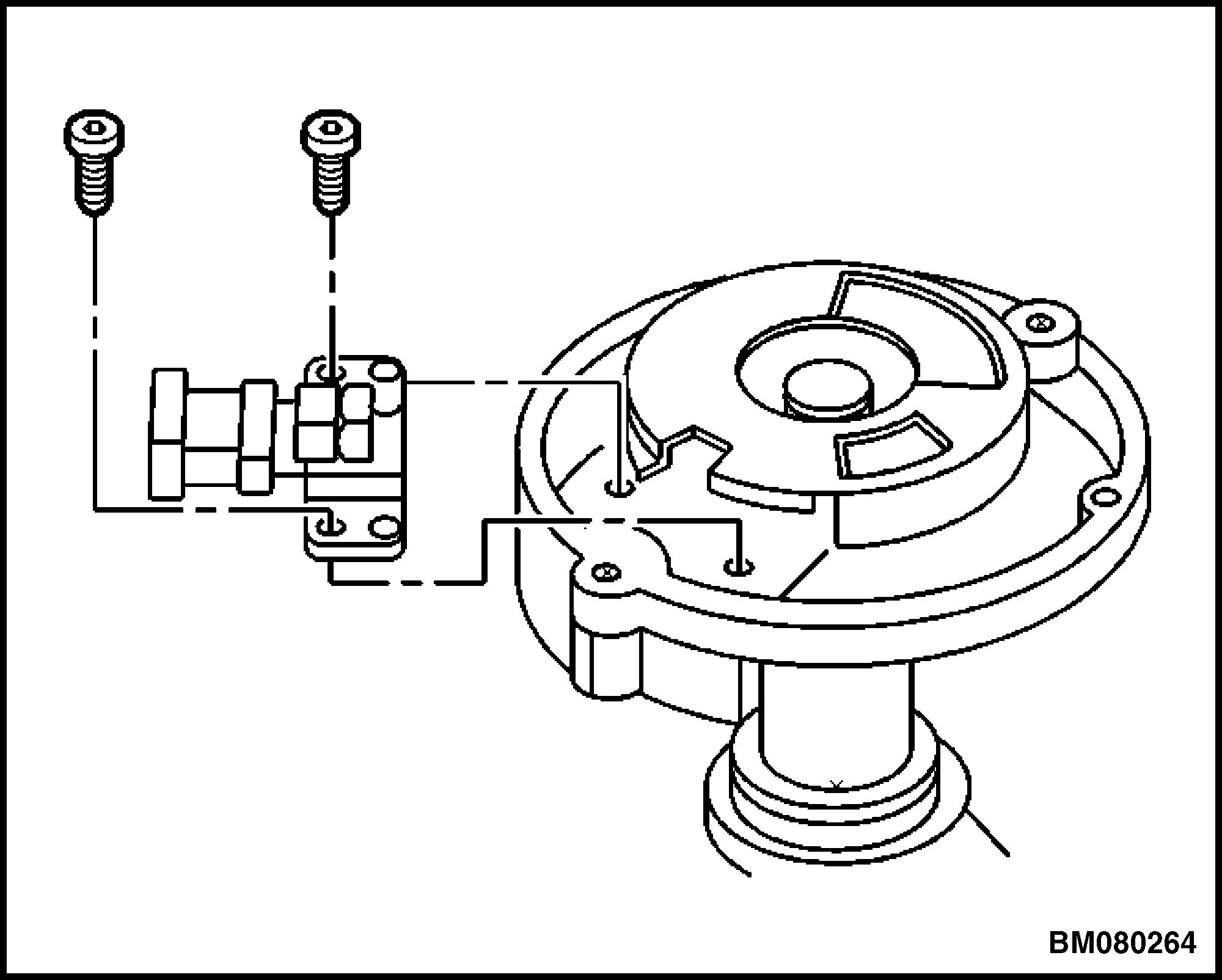

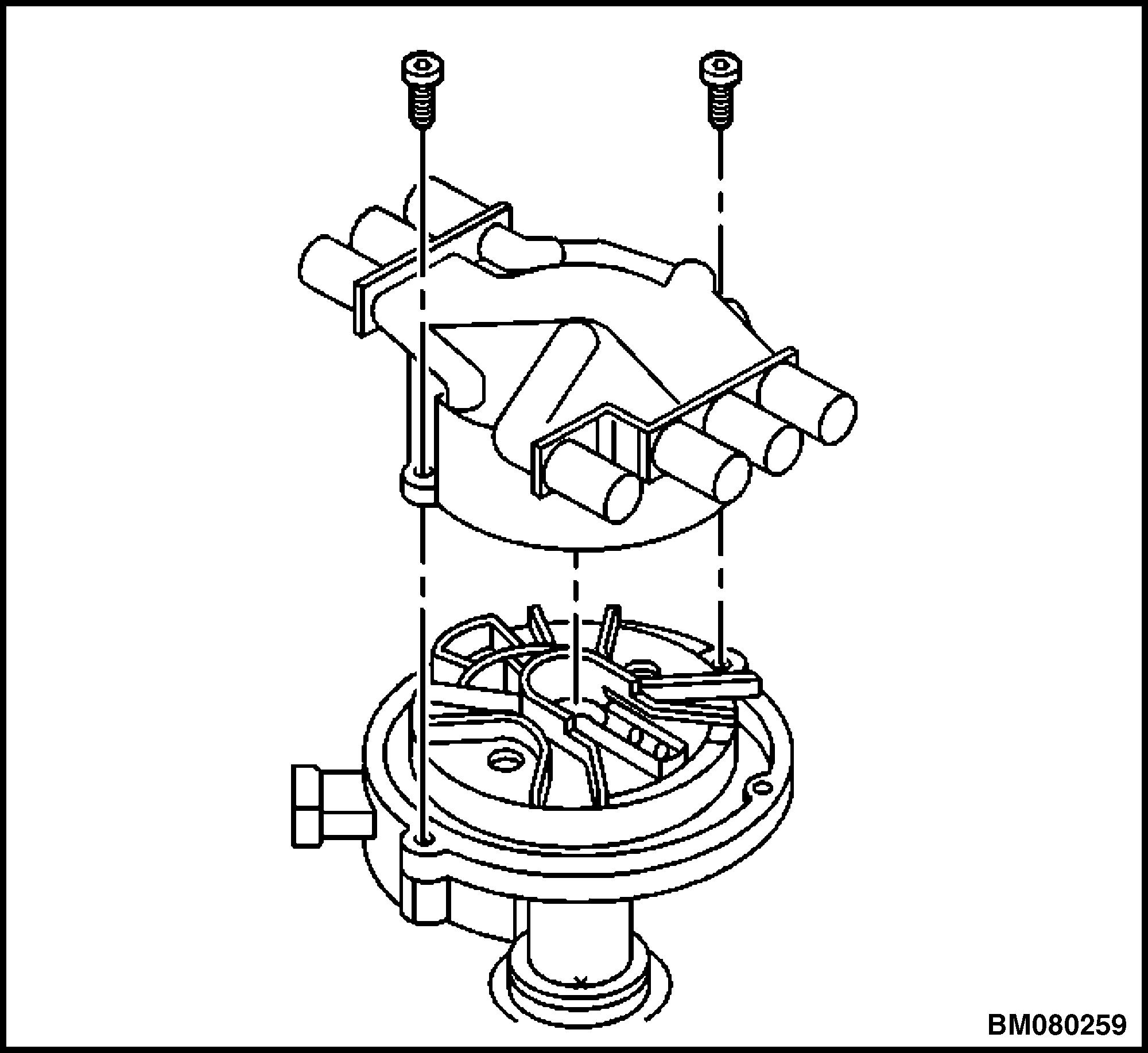

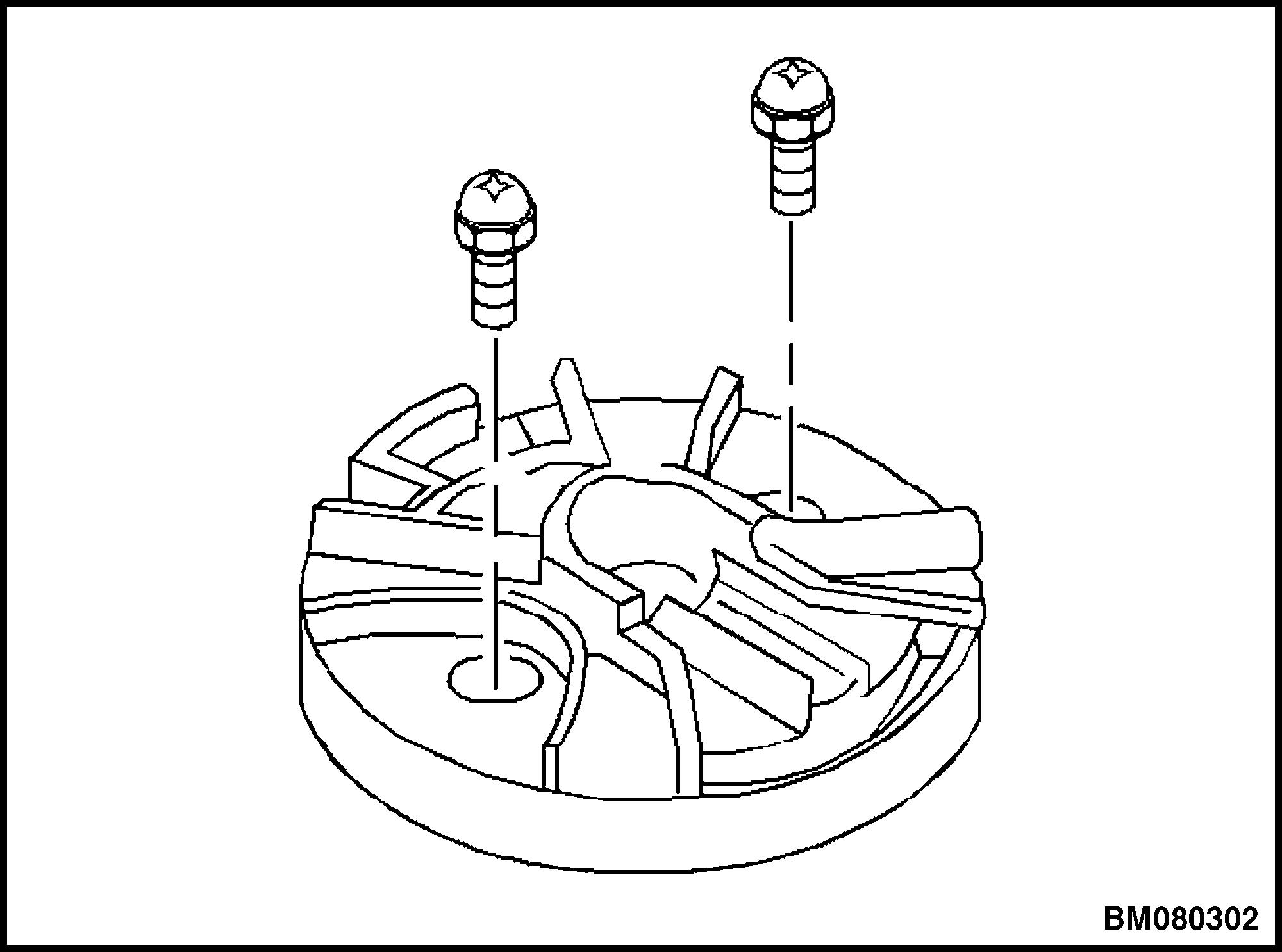

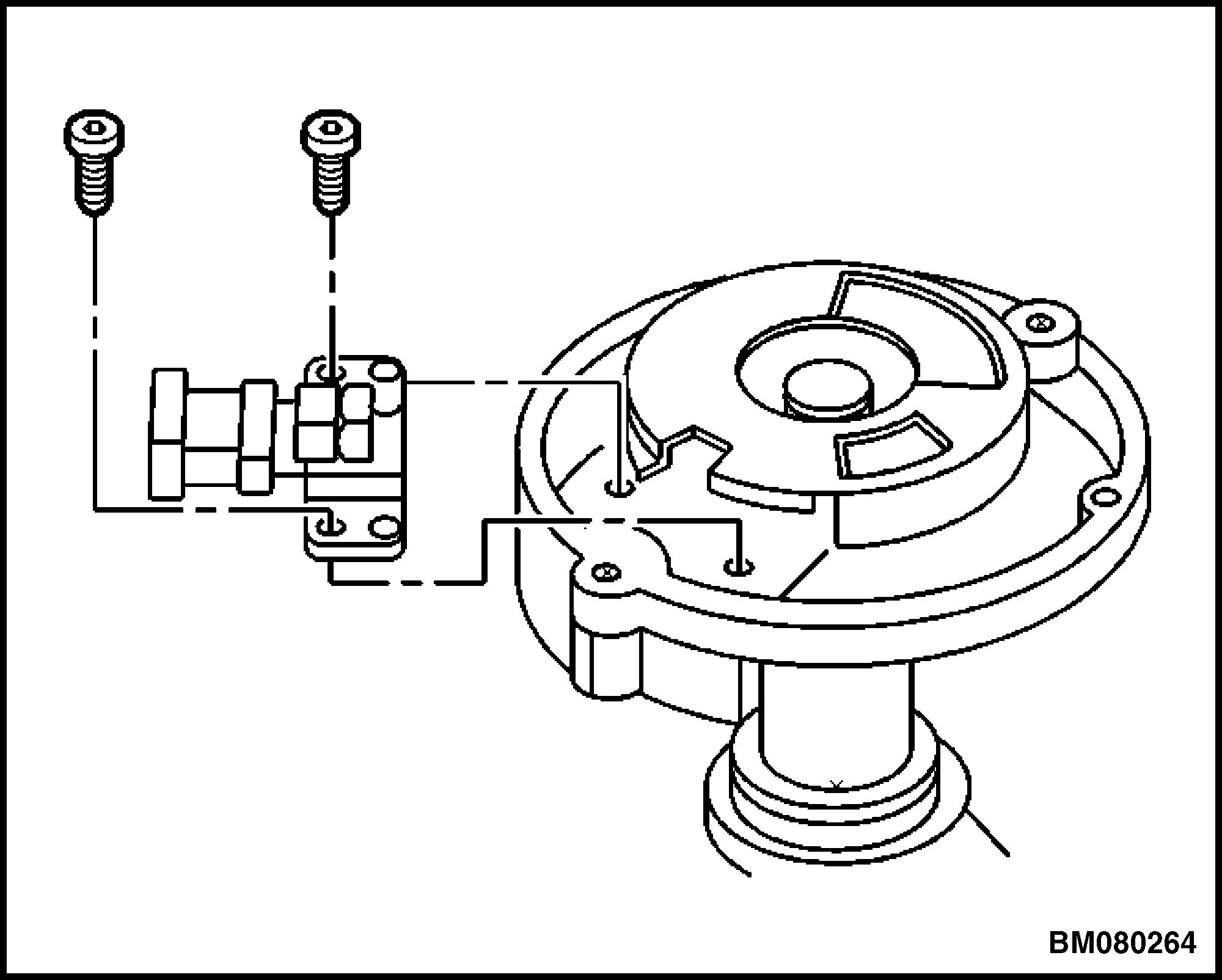

4. Remove the two screws from the rotor. See Figure 8.

5. Remove the rotor.

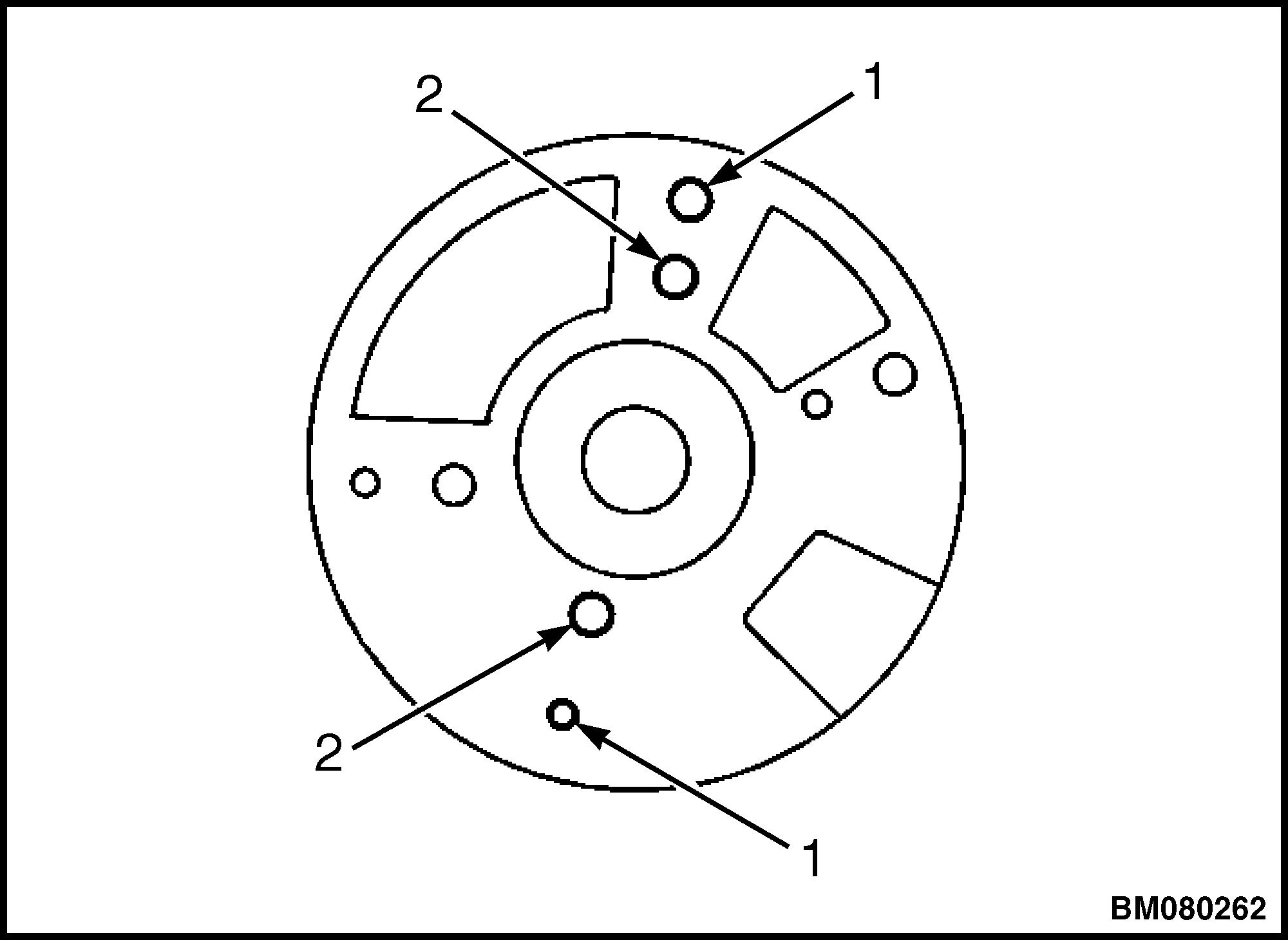

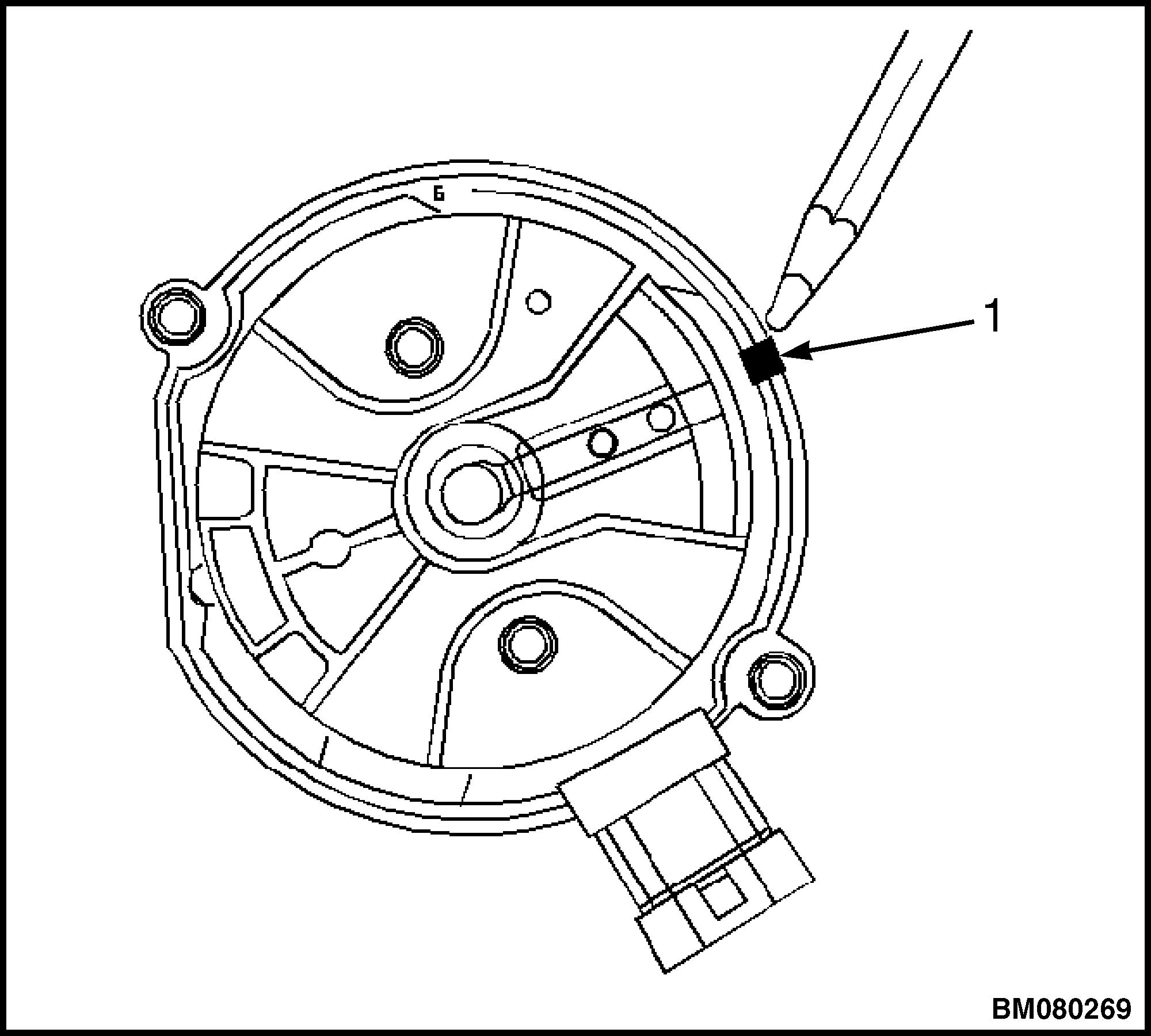

6. Note the locating holes that the rotor was removed from (see Figure 9):

• Rotor screw holes (1)

• Rotor locator pin holes (2)

1.ROTOR SCREW HOLE

2.ROTOR LOCATOR PIN HOLE

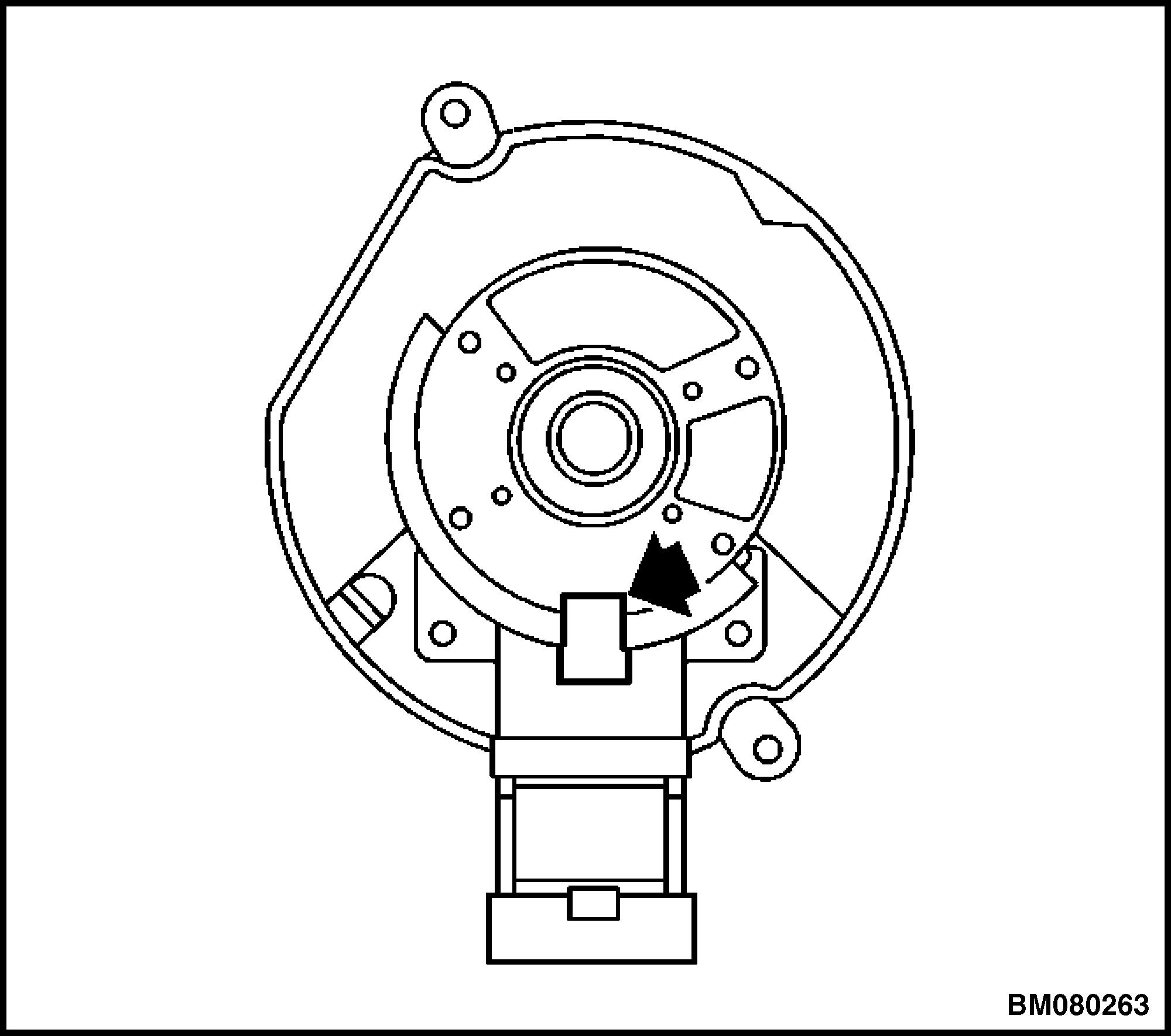

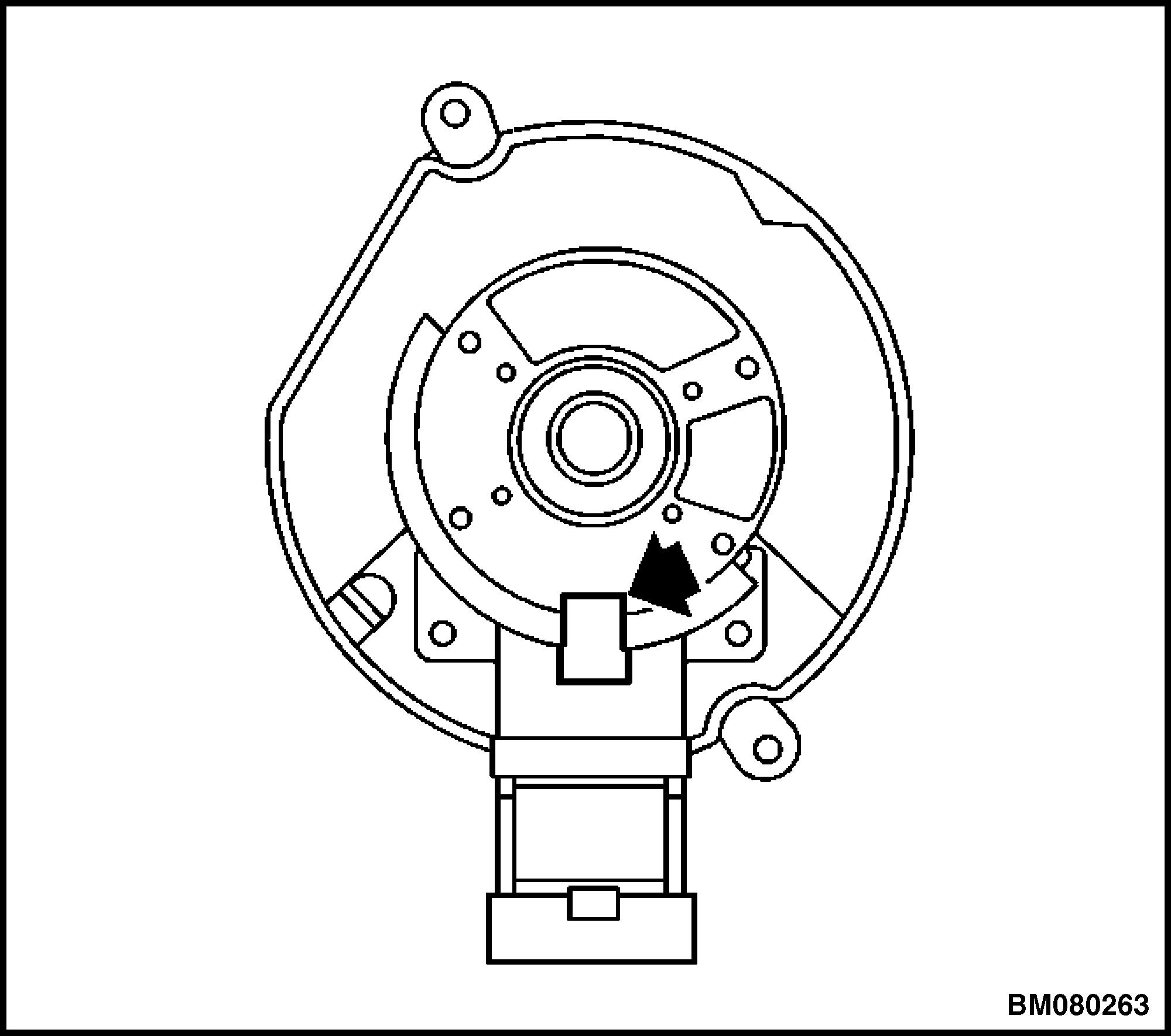

7. Line up the square-cut hole in the vane wheel with the camshaft position (CMP) sensor. See Figure 10.

Figure 8. Rotor

Figure 9. Rotor Mounting Holes

Figure 8. Rotor

Figure 9. Rotor Mounting Holes

8. Remove the two screws that hold the CMP sensor. See Figure 11.

11. Camshaft Position (CMP) Sensor Mounting Screws

9. Discard the screws.

10. Remove the CMP sensor. See Figure 12.

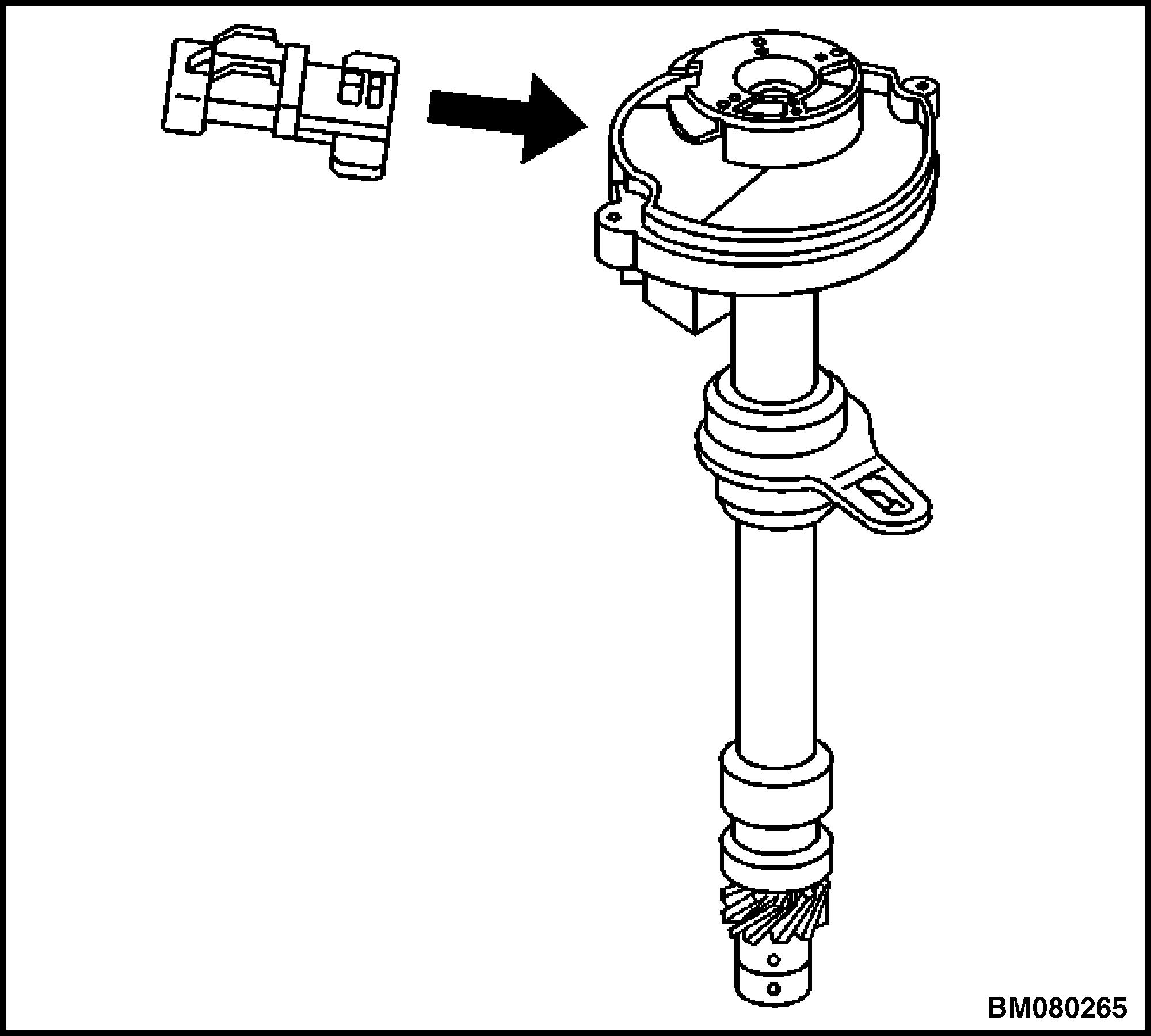

11. Note the dimple located below the roll pin hole on one side of the gear. The dimple will be used to properly orient the gear onto the shaft during reassembly.

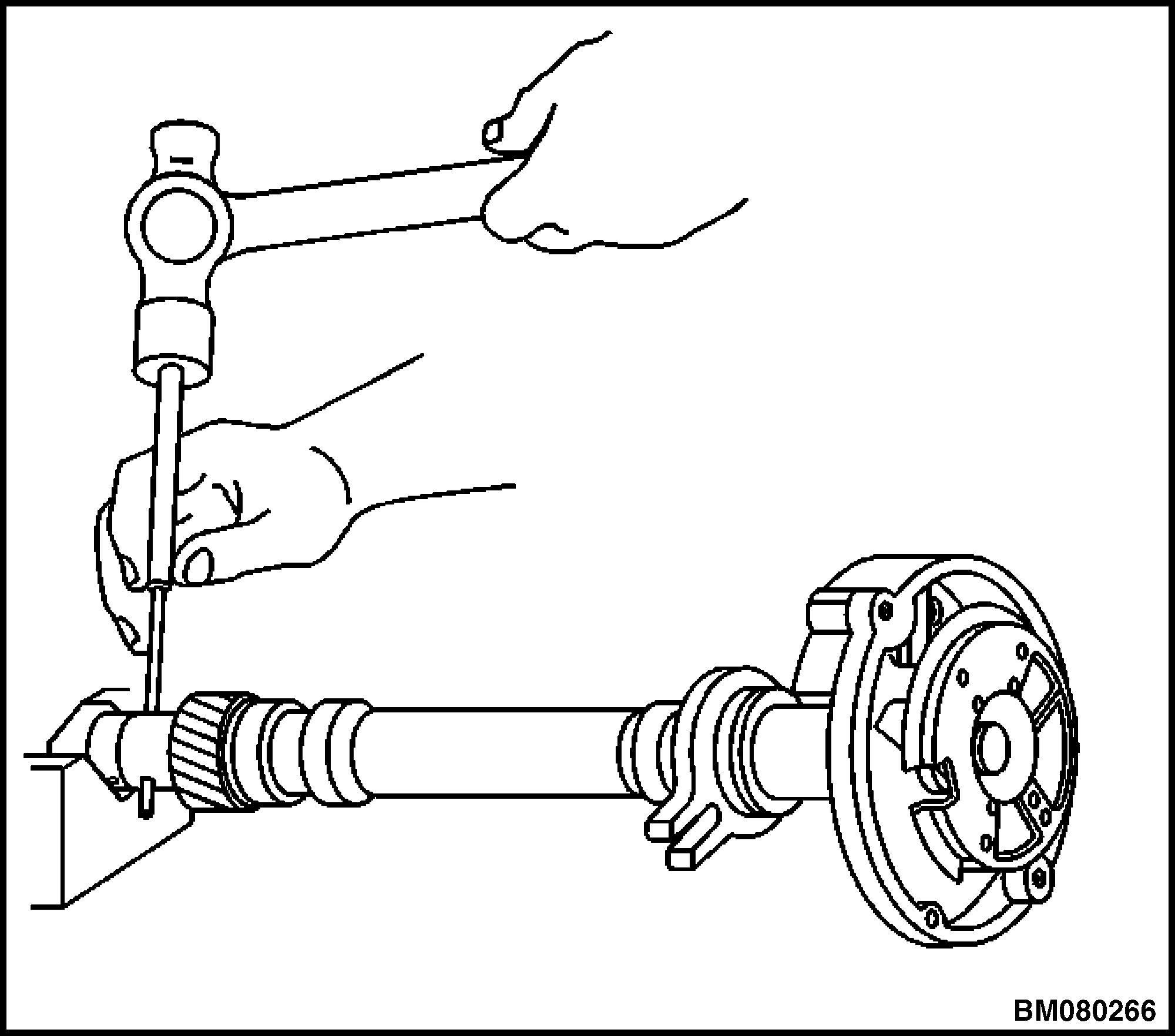

12. Support the distributor drive gear in a V-block or similar fixture.

WARNING

To prevent serious eye injury, always wear safe eye protection when performing vehicle maintenance or service.

13. Drive out the roll pin with a suitable punch. See Figure 13.

14. Remove the driven gear from the distributor shaft.

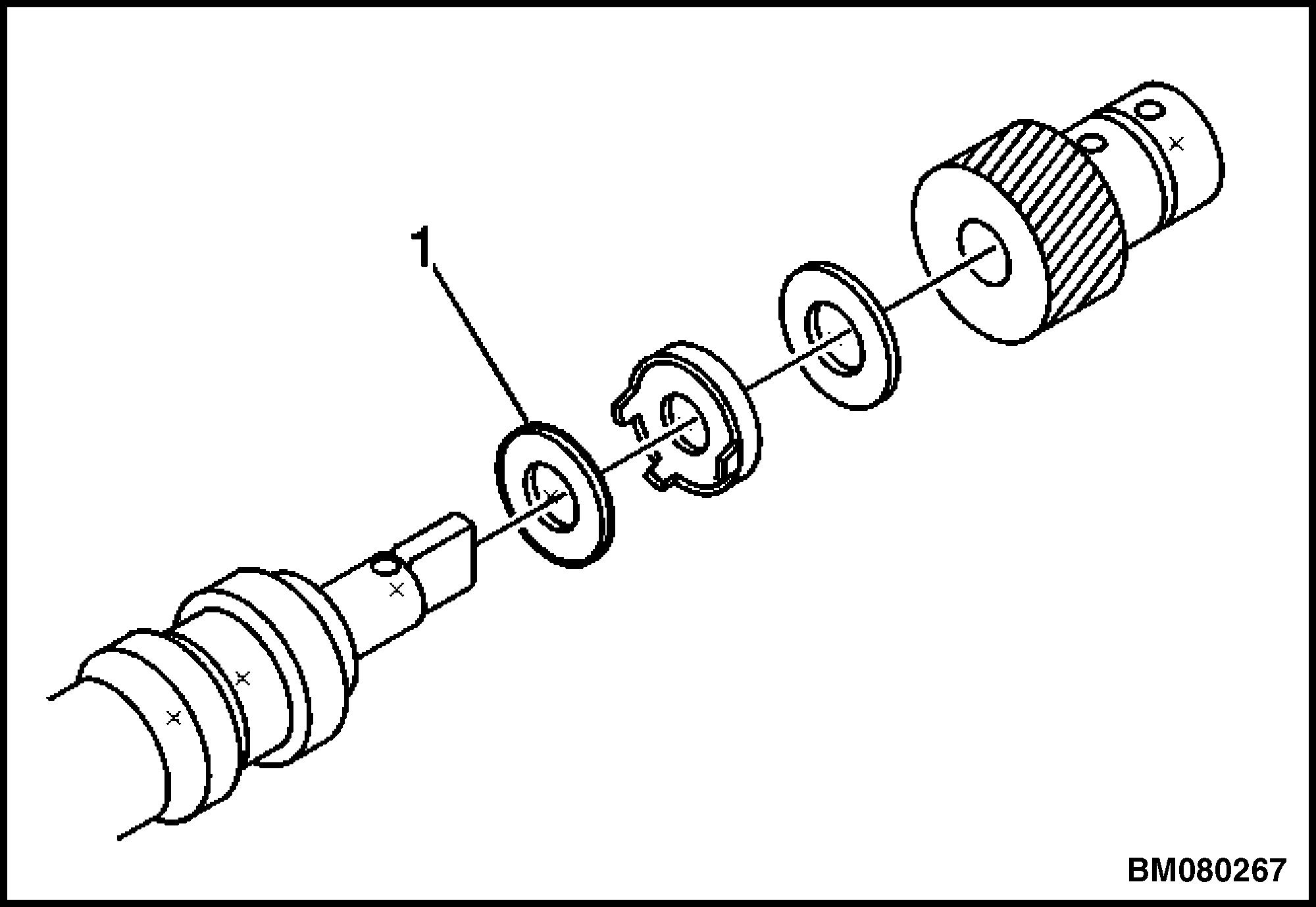

15. Remove the round washer.

16. Remove the tang washer.

17. Remove the shim washer. See Figure 14.

Figure Figure 12. Camshaft Position (CMP) Sensor Figure 13. Roll Pin LocationCLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

1.SHIM WASHER

Figure 14. Shim Washer Location

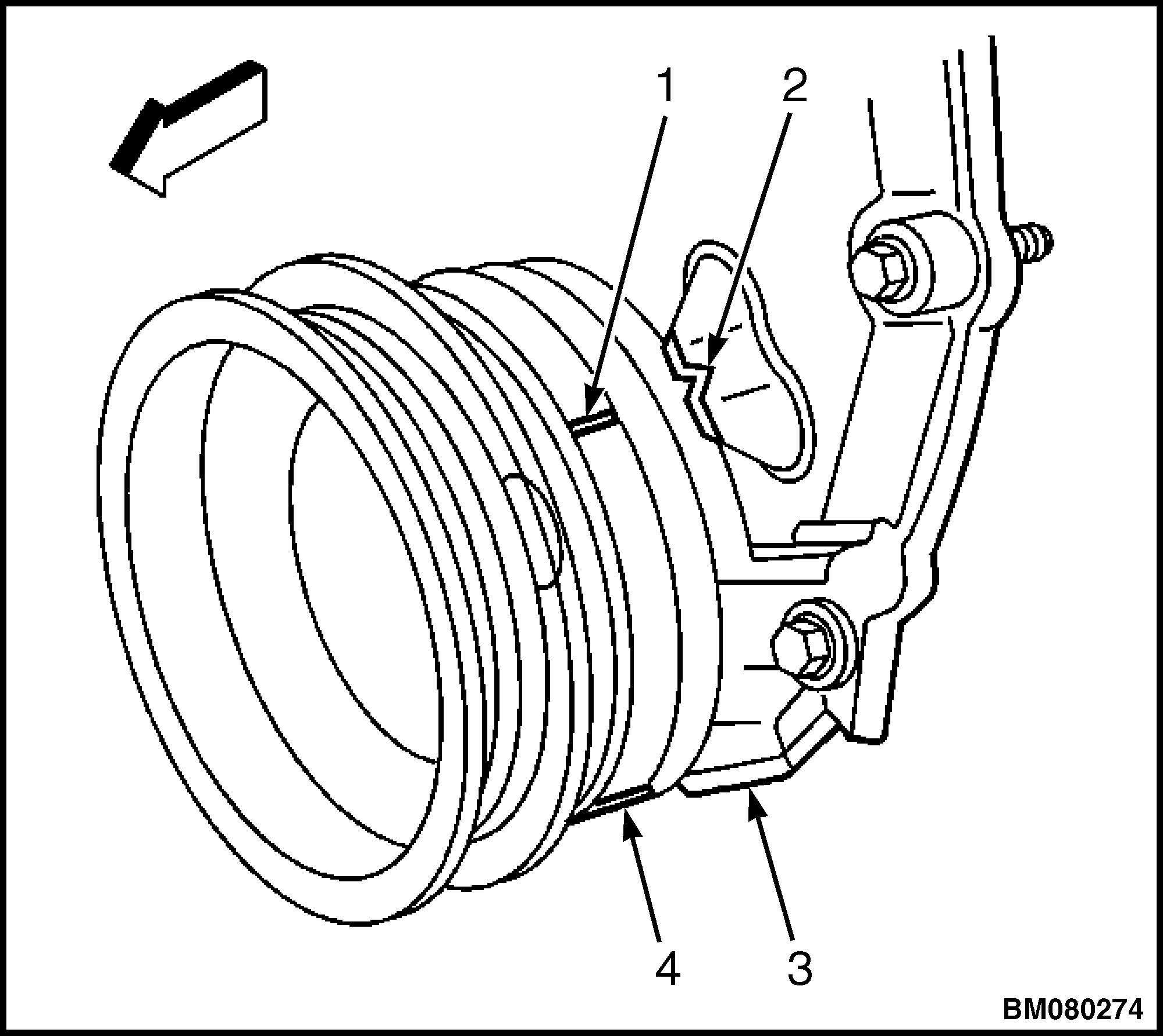

18. Remove the old oil seal. See Figure 15.

Figure 15. Oil Seal Removal/Installation

Assemble

CAUTION

Installing the driven gear 180 degrees out of alignment or locating the rotor in the wrong holes, will cause a no-start condition. Premature engine wear or damage may result.

1. Line up the square-cut hole in the vane wheel for the CMP sensor. See Figure 10.

2. Insert the sensor into the housing. See Figure 12.

CAUTION

Late model engines use a combination of standard and metric fasteners. The components affected are the starter motor, engine mounts, and flywheel housing mounting. Other components may also have a combination of fasteners. Always verify that the proper fasteners are used whenever removing or replacing any components.

3. Install two new screws for the CMP sensor. Tighten the screws to 2.2 N•m (19 lbf in). See Figure 11.

4. Identify the correct rotor mounting position (see Figure 9):

• At the rotor screw holes (1)

• At the rotor locator pin holes (2)

5. Install the distributor rotor according to the index marks.

6. Install two rotor hold down screws. Tighten the screws to 1.9 N•m (17 lbf in). See Figure 8.

7. Install the shim washer on the bottom of the distributor shaft. See Figure 14.

8. Install the tang washer.

9. Install the round washer.

10. Install the driven gear according to the index marks.

11. Align the rotor segment as shown in Figure 7.

12. Install the gear and align white paint mark on the bottom stem of the distributor and the pre-drilled indent hole in the bottom of the gear.

13. Check to see if the driven gear is installed incorrectly. On an incorrectly installed driven gear, the dimple will be approximately 180 degrees opposite the rotor segment when the gear is installed in the distributor.

14. Support the distributor drive gear in a V-block or similar fixture.

WARNING

To prevent serious eye injury, always wear safe eye protection when performing vehicle maintenance or service.

15. Install the roll pin with a suitable punch and hammer in order to hold the driven gear in the correct position. See Figure 13.

16. Install the new oil seal under the mounting flange of the distributor base. See Figure 15.

17. Install the distributor.

18. Install the engine cover. Refer to the Frame section for your lift truck.

REPLACE

Remove

NOTE: There are two procedures available to install the distributor.

Use Install Procedure 1 when the crankshaft has NOT been rotated from the original position.

Use Install Procedure 2 when any of the following components are removed:

• Intake manifold

• Cylinder head

• Camshaft

• Timing chain or sprockets

• Complete engine

If the malfunction indicator lamp (MIL) turns on and DTC P1345 sets after installing the distributor, this indicates an incorrectly installed distributor.

Engine damage or distributor damage may occur. Use Install Procedure 2 in order to install the distributor.

1. Turn OFF the ignition.

2. Remove the engine cover. Refer to the Frame section for your lift truck.

3. Remove air cleaner assembly.

4. Remove the air intake resonator assembly.

5. Remove the ignition coil wire. Note the correct orientation of the wire boot. See Figure 16.

NOTE: V-6 SHOWN, V-8 SIMILAR.

1.COIL WIRE 2.COIL

3.DISTRIBUTOR

Figure 16. Ignition Coil Wire

6. Remove the spark plug wires from the distributor cap.

a. Twist each spark plug 1/2 turn.

b. Pull only on the wire boot in order to remove the wire from the distributor cap.

7. Remove the electrical connector from the base of the distributor.

8. Remove the two screws that retain the distributor cap to the housing. See Figure 17.

Figure 17. Distributor Cap Removal/Installation

Legend for Figure 17.

NOTE: V-6 SHOWN, V-8 SIMILAR.

9. Discard the screws.

10. Remove the distributor cap from the housing.

11. Use a grease pencil in order to mark the position of the rotor in relation to the distributor housing shown in Figure 18.

18. Rotor Position Mark

Legend for Figure 18.

1.MARK SHOWING POSITION OF ROTOR IN RELATION TO DISTRIBUTOR HOUSING

12. Mark the distributor housing and the intake manifold with the grease pencil.

13. As the distributor is being removed from the engine, watch the rotor move in a counterclockwise direction about 42 degrees. This will appear as slightly more than one o'clock position. See Figure 19.

1.MARK SHOWING POSITION OF ROTOR IN RELATION TO DISTRIBUTOR HOUSING

2.MARK ON BASE OF DISTRIBUTOR

Figure 19. Rotor Position in Distributor Housing

14. Note the position of the rotor segment.

15. Place a second mark on the base of the distributor.

This will aid in achieving the proper rotor alignment during the distributor installation.

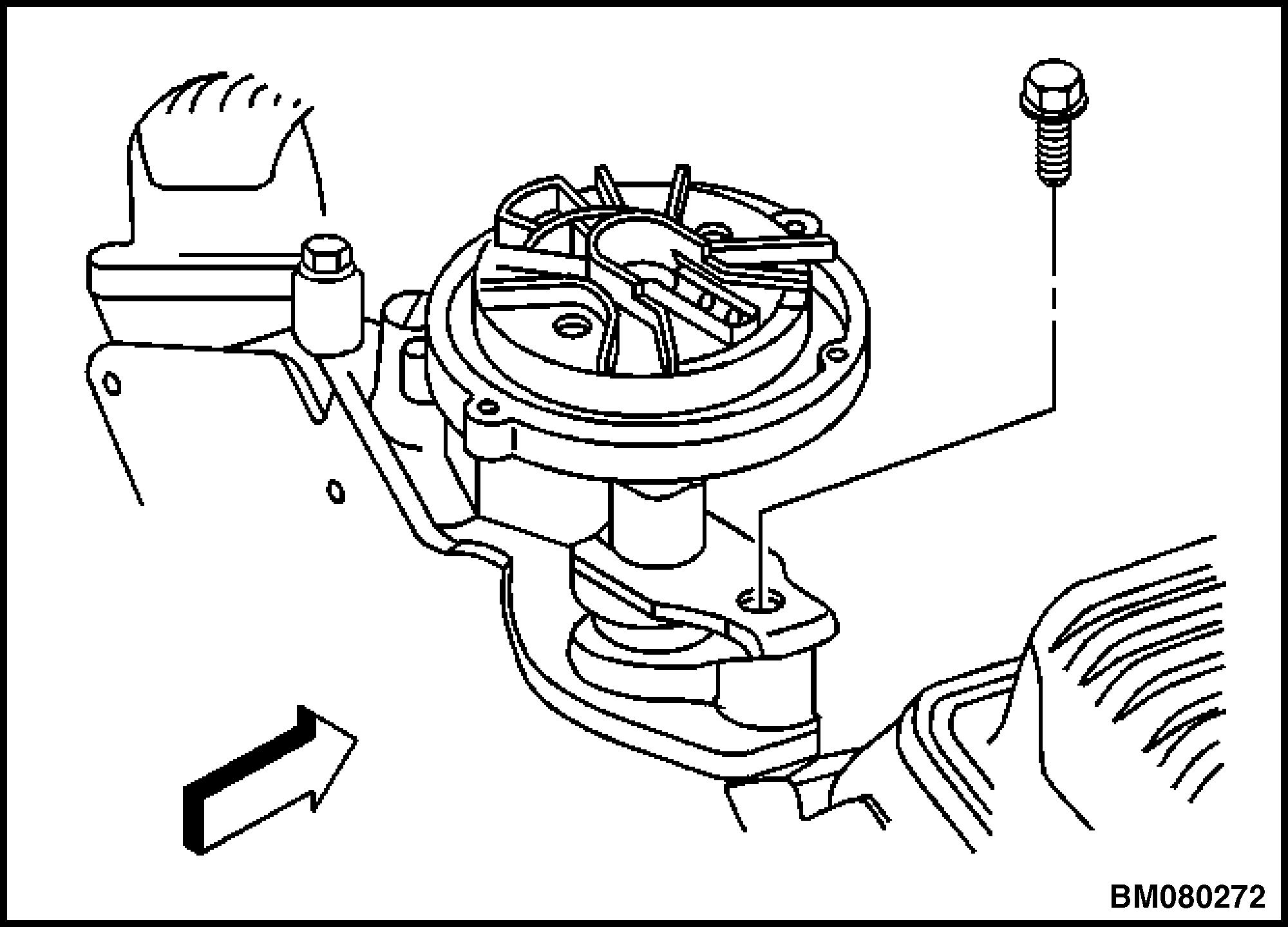

16. Remove the mounting clamp holddown bolt. See Figure 20.

Figure

Figure 20. Distributor Mounting Clamp Bolt

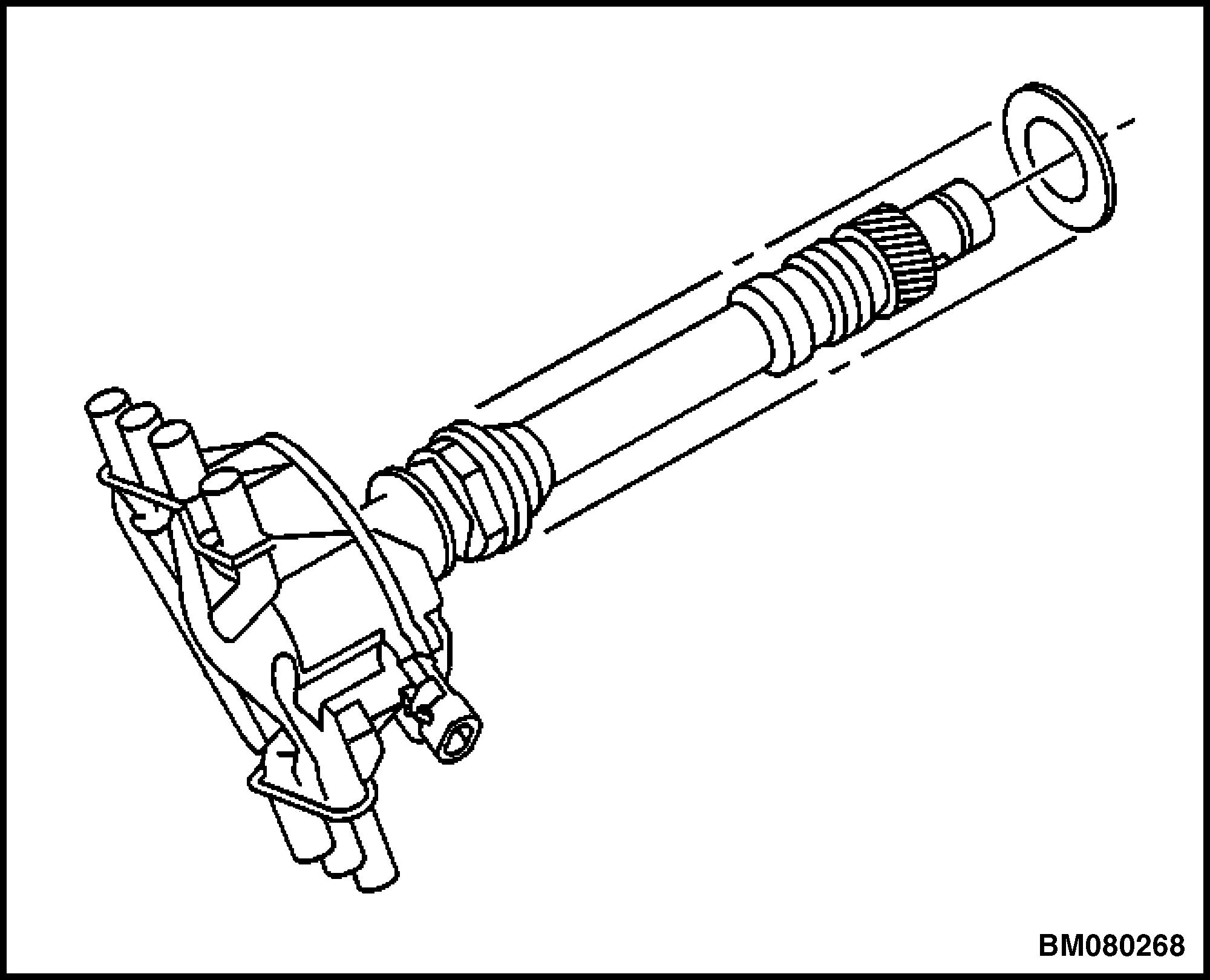

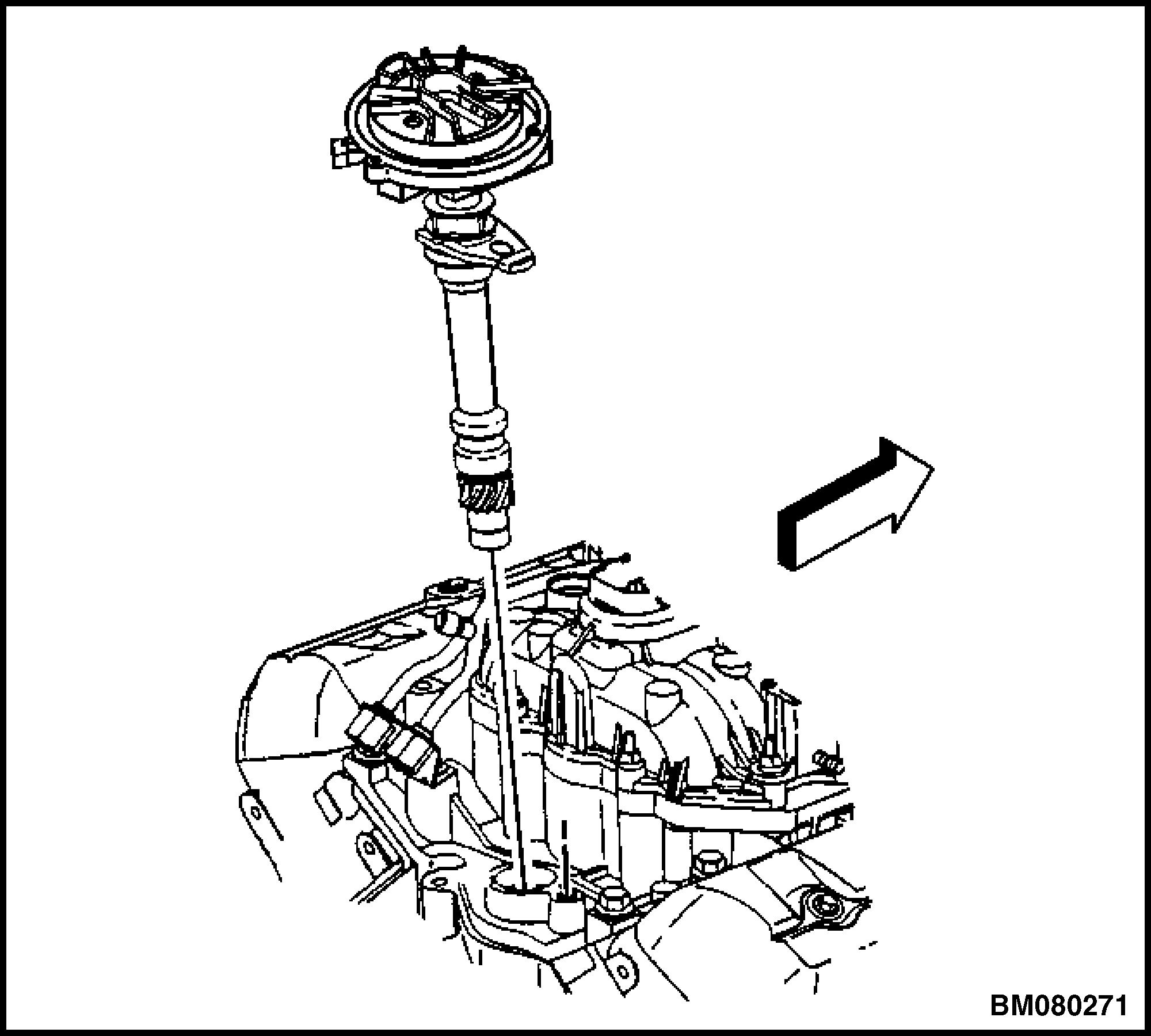

17. Remove the distributor. See Figure 21.

Figure 21. Distributor Removal/Installation

Install Procedure 1

1. If installing a new distributor assembly, place two marks on the new distributor housing in the same location as the marks on the original housing. See Figure 19.

2. Remove the new distributor cap if necessary.

3. Align the rotor with the second mark.

4. Guide the distributor into the engine. See Figure 21.

5. Align the hole in the distributor holddown base over the mounting hole in the intake manifold.

6. As the distributor is being installed, observe the rotor moving in a clockwise direction about 42 degrees. See Figure 18.

7. Once the distributor is completely seated, the rotor segment should be aligned with the mark on the distributor base.

• If the rotor segment is not aligned with the mark, the driven gear teeth and the camshaft have meshed one or more teeth out of alignment.

• In order to correct this condition, remove and reinstall the distributor.

CAUTION

Late model engines use a combination of standard and metric fasteners. The components affected are the starter motor, engine mounts, and flywheel housing mounting. Other components may also have a combination of fasteners. Always verify that the proper fasteners are used whenever removing or replacing any components.

8. Install the distributor mounting clamp bolt. Tighten the bolt to 25 N•m (18 lbf ft). See Figure 20.

9. Install the distributor cap. See Figure 17.

10. Install the new distributor capscrews. Tighten the capscrews to 2.4 N•m (21 lbf in).

11. Install the electrical connector to the distributor.

12. Install the spark plug wires to the distributor cap.

13. Install the ignition coil wire. Note the correct orientation of the wire boot. See Figure 16.

CAUTION

If the malfunction indicator lamp illuminates after installing the distributor and DTC P1345 is set, the distributor has been installed incorrectly.

14. Refer to Install Procedure 2 if the malfunction indicator lamp illuminates after installing the distributor.

15. Install the engine cover. Refer to the Frame section for your lift truck.

Install Procedure 2

NOTE: Rotate the number 1 cylinder to top dead center (TDC) of the compression stroke. The engine front cover has two alignment tabs and the crankshaft balancer has two alignment marks spaced 90 degrees apart which are used for positioning the number 1 piston at TDC. See Figure 22. With the piston on the compression stroke and at TDC, the crankshaft balancer alignment mark (1) must align with the engine front cover tab (2) and the crankshaft balancer alignment mark (4) must align with the engine front cover tab (3).

1. Rotate the crankshaft balancer clockwise until the alignment marks on the crankshaft balancer are aligned with the tabs on the engine front cover and the number 1 piston is at TDC of the compression stroke. See Figure 22.

1.CRANKSHAFT BALANCER ALIGNMENT MARK

2.ENGINE FRONT COVER TAB

3.ENGINE FRONT COVER TAB

4.CRANKSHAFT BALANCER ALIGNMENT MARK

NOTE: The ignition system distributor driven gear and rotor may be installed in multiple positions. In order to avoid mistakes, mark the distributor on the following components in order to ensure the same mounting position upon reassembly:

• Distributor driven gear

• Distributor shaft

• Rotor holes

Installing the driven gear 180 degrees out of alignment or locating the rotor in the wrong holes, will cause a no-start condition. Premature engine wear or damage may result.

3. With the gear in this position, the rotor segment should be positioned as shown in Figure 7.

4. Use a long screw driver in order to align the oil pump drive shaft to the drive tab of the distributor.

5. Guide the distributor into the engine. See Figure 21.

Ensure the flat portion of the distributor housing is facing toward the front of the engine.

6. Once the distributor is fully seated, the rotor segment should be aligned with the pointer cast into the distributor base. See Figure 23.

2. Align the white paint mark on the bottom stem of the distributor and the pre-drilled indent hole in the bottom of the gear. See Figure 7.

Figure 22. Crankshaft Balancer and Engine Front Cover Alignment Marks

Figure 22. Crankshaft Balancer and Engine Front Cover Alignment Marks

If the rotor segment does not come within a few degrees of the pointer, repeat the procedure in order to achieve the proper alignment.

CAUTION

Late model engines use a combination of standard and metric fasteners. The components affected are the starter motor, engine mounts, and flywheel housing mounting. Other components may also have a combination of fasteners. Always verify that the proper fasteners are used whenever removing or replacing any components.

7. Install the distributor mounting clamp bolt. Tighten the bolt to 25 N•m (18 lbf ft). See Figure 20.

8. Install the distributor cap.

9. Install the new distributor capscrews. Tighten the screws to 2.4 N•m (21 lbf in). See Figure 17.

REMOVE

10. Install the electrical connector to the distributor.

11. Install the spark plug wires to the distributor cap.

12. Install the ignition coil wire. Note the correct orientation of the wire boot. See Figure 16.

CAUTION

If the malfunction indicator lamp illuminates after installing the distributor and DTC P1345 is set, the distributor has been installed incorrectly.

13. Repeat Install Procedure 2 if the malfunction indicator lamp illuminates after installing the distributor.

14. Install the engine cover. Refer to the Frame section for your lift truck.

Ignition Coil Replacement

CAUTION

1. Remove the engine cover. Refer to the Frame section for your lift truck.

2. Disconnect the electrical connectors.

3. Remove the ignition coil wire to the distributor. See Figure 24.

4. Remove the studs holding the bracket and the ignition coil to the intake manifold. See Figure 25.

5. Remove the bracket and the ignition coil.

6. Drill and punch out the two rivets holding the ignition coil to the bracket.

7. Remove the ignition coil from the bracket.

INSTALL

NOTE: A replacement ignition coil kit comes with two screws in order to attach the ignition coil to the bracket.

1. Install the ignition coil to the bracket with the two screws.

Late model engines use a combination of standard and metric fasteners. The components affected are the starter motor, engine mounts, and flywheel housing mounting. Other components may also have a combination of fasteners. Always verify that the proper fasteners are used whenever removing or replacing any components.

2. Install the ignition coil and the bracket to the intake manifold with studs. Tighten the studs to 11 N•m (97 lbf in). See Figure 25.

3. Install the ignition coil wire. See Figure 24. The wire must not touch anything like the dipstick. Rubbing will make a ground or short after time of use.

4. Install the electrical connectors.

5. Install the engine cover. Refer to the Frame section for your lift truck.

NOTE: V-6 SHOWN, V-8 SIMILAR.

1.COIL WIRE

2.COIL

3.DISTRIBUTOR

Figure 24. Ignition Coil Wire

NOTE: V -6 SHOWN, V-8 SIMILAR.

1.COIL

2.MOUNTING BOLTS

Figure 25. Ignition Coil

Ignition Control Module Replacement

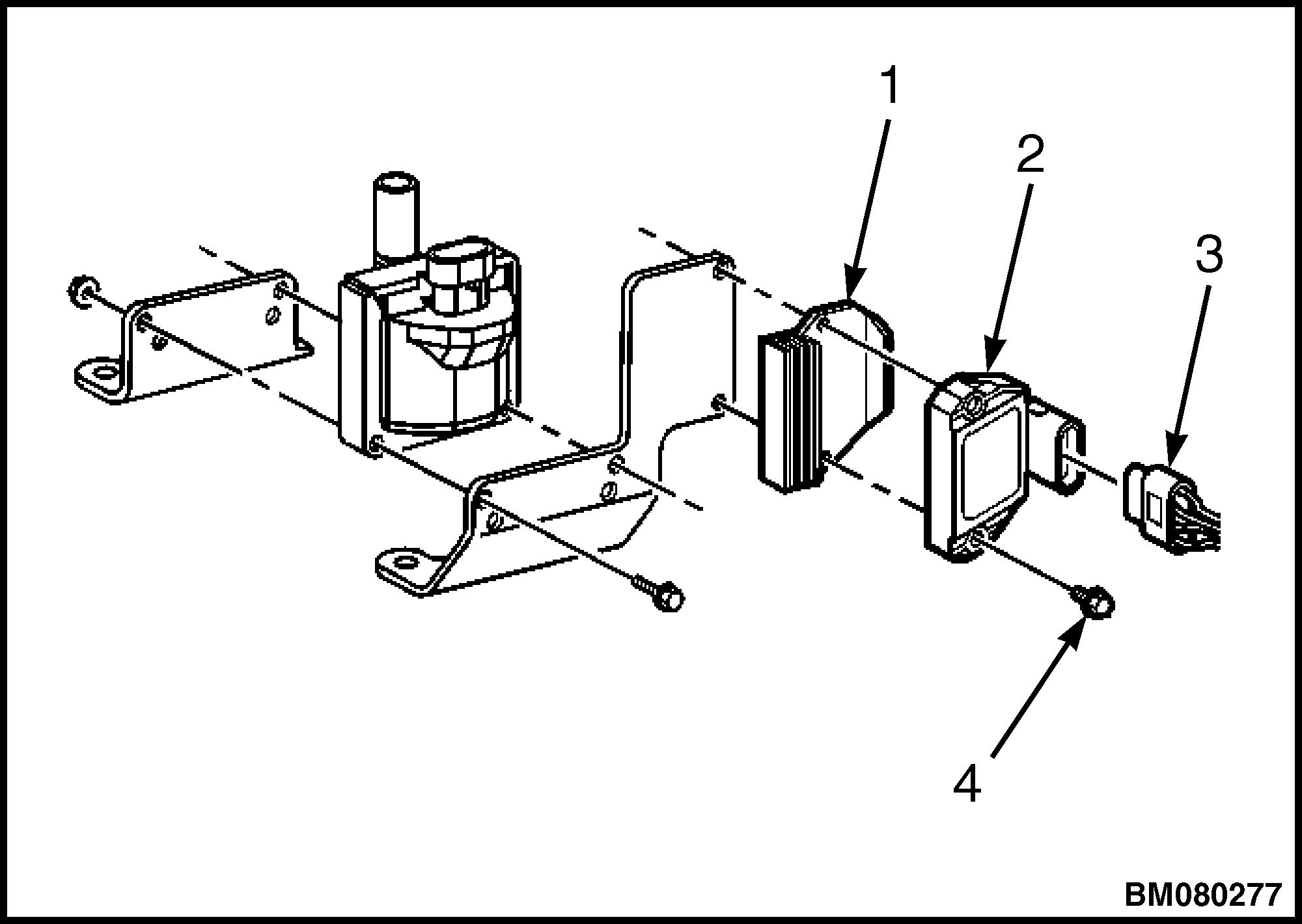

REMOVE

1. Remove the engine cover. Refer to the Frame section for your lift truck.

2. Disconnect the electrical connector. See Figure 26.

3. Remove the screws holding the ignition control module and the heat sink to the bracket.

4. Remove the ignition control module and the heat sink.

1. Install the ignition control module and the heat sink on the bracket with the screws. Tighten the screws to 3.5 N•m (31 lbf in). See Figure 26.

2. Reconnect the electrical connectors.

3. Install the engine cover. Refer to the Frame section for your lift truck.

INSTALL CAUTION

Late model engines use a combination of standard and metric fasteners. The components affected are the starter motor, engine mounts, and flywheel housing mounting. Other components may also have a combination of fasteners. Always verify that the proper fasteners are used whenever removing or replacing any components.

1.HEAT SINK

Legend for Figure 26.

2.IGNITION CONTROL MODULE

3.ELECTRICAL CONNECTOR

4.SCREW

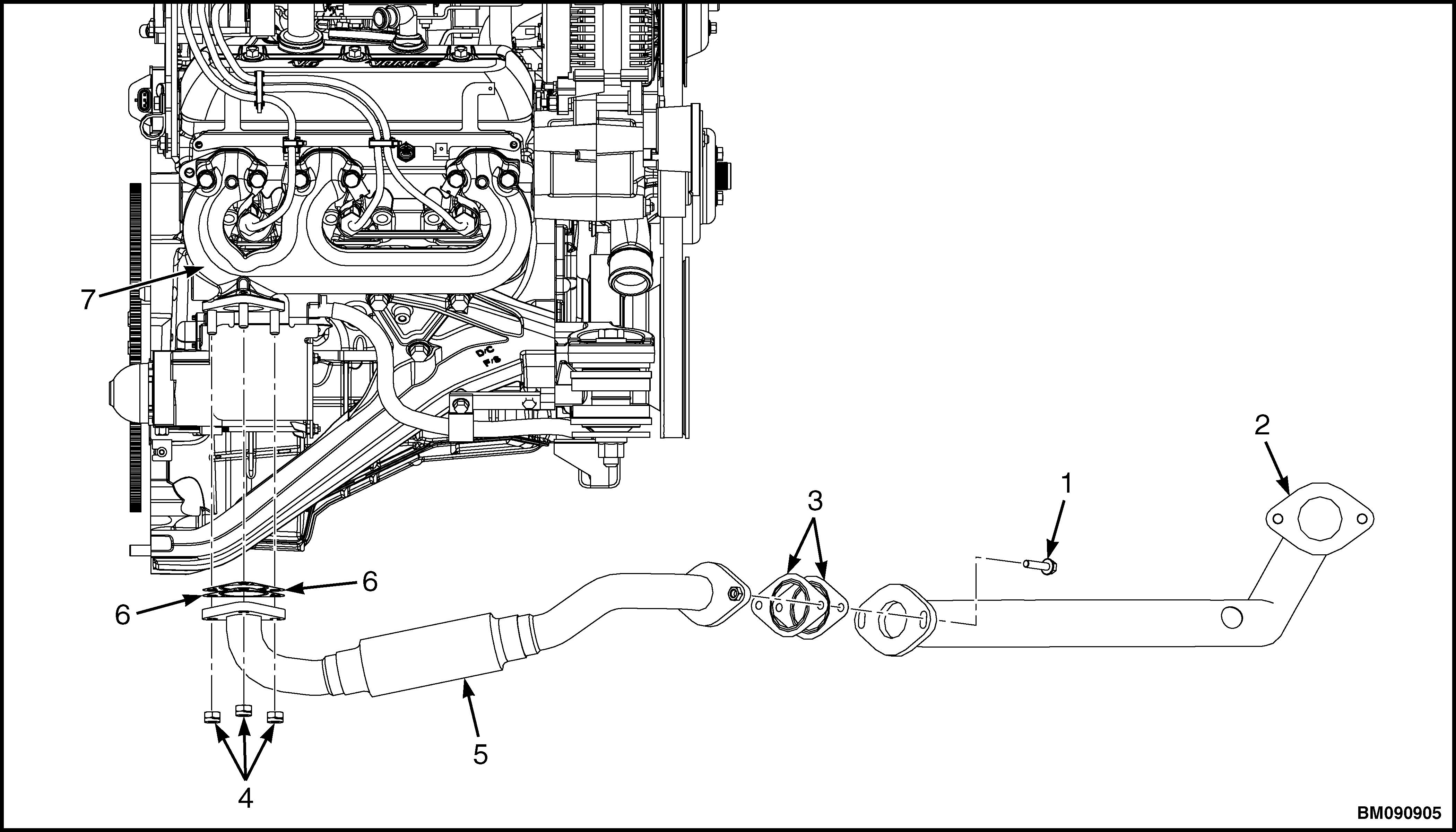

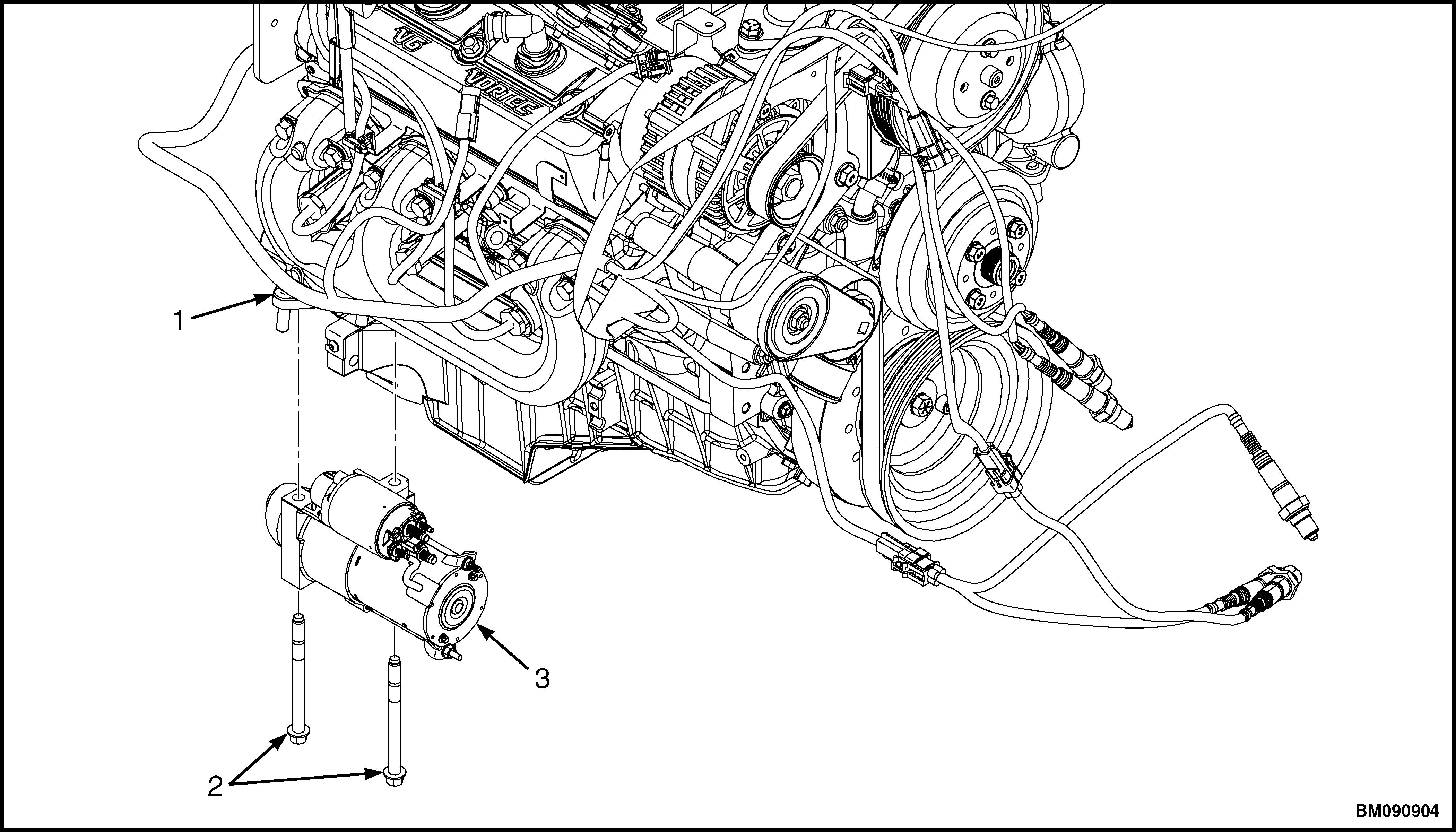

Starter Replacement

REMOVE

1. Remove three locknuts, exhaust pipe (5), and two gaskets from exhaust manifold. See Figure 27.

1.CAPSCREW

2.EXHAUST PIPE

3.GASKET

4.LOCKNUT

5.EXHAUST PIPE

6.GASKET

7.EXHAUST MANIFOLD

2. Remove two capscrews, exhaust pipe (5), and two gaskets from exhaust pipe (2). See Figure 27.

3. Disconnect positive (B+) battery cable from starter motor. See Figure 28.

1.CAPSCREW 2.LEFT SIDE ENGINE MOUNT

3.POSITIVE (B+) BATTERY CABLE 4.ENGINE

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

4. Remove six capscrews and left side enging mount from engine to access starter motor. See Figure 28.

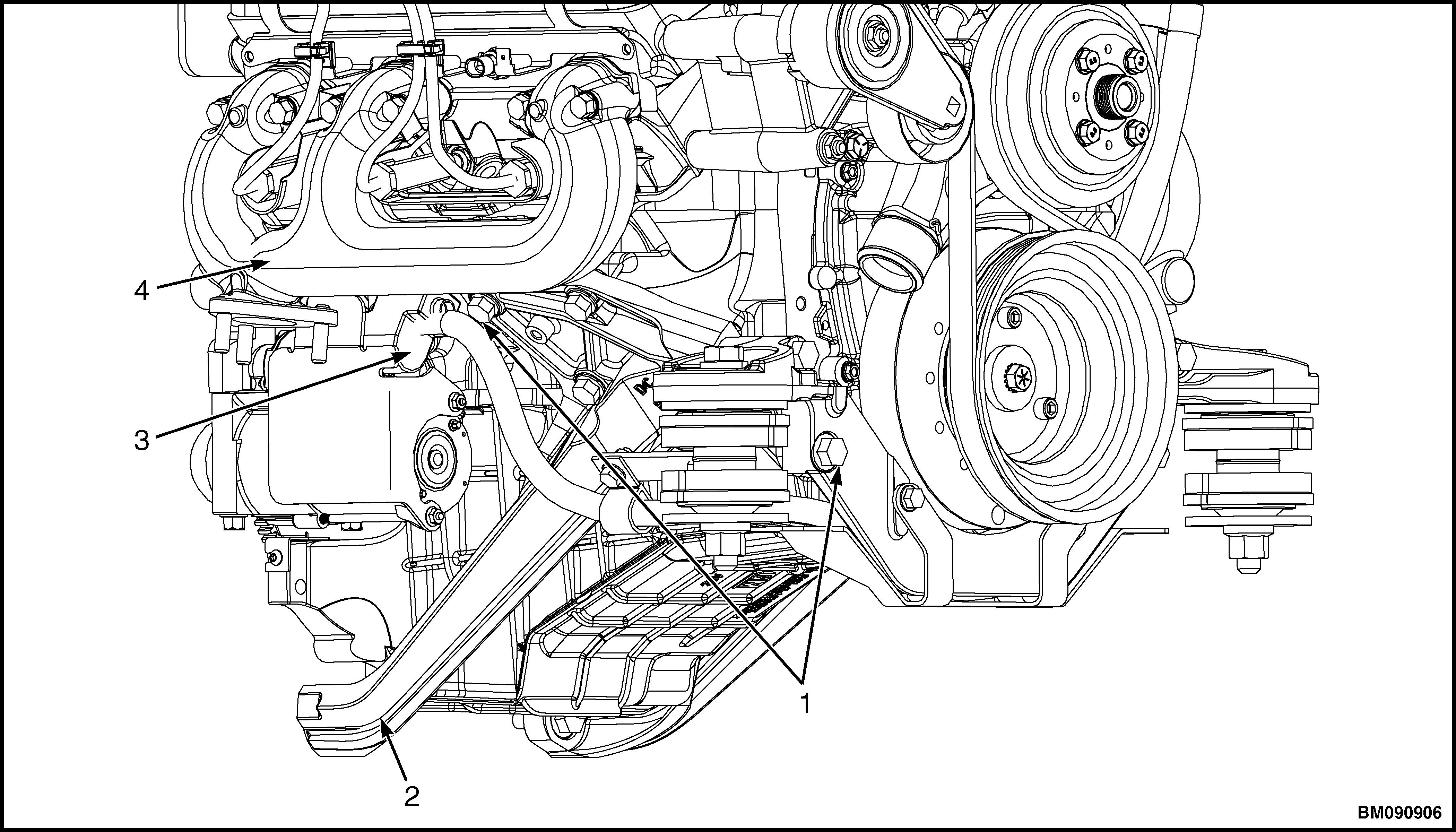

5. Remove two nuts and heat shield from starter . See Figure 29.

1.STARTER

2.HEAT SHIELD

3.NUT

6. Remove two starter bolts and starter form engine block. See Figure 30.

1.ENGINE BLOCK

2.STARTER BOLT

3.STARTER

INSTALL

1. Install starter and two starter bolts on engine block. Tighten bolts to 52 N•m (38 lbf ft). See Figure 30.

2. Install heat shield and two nuts on starter. Tighten nuts to 18 to 24 N•m (159 to 212 lbf in). See Figure 29.

3. Install left side engine mount on engine. Tighten capscrews to 90 N•m (66 lbf ft). See Figure 28.

4. Connect positive (B+) battery cable to starter motor. Tighten terminal nut to 8 to 11 N•m (71 to 97 lbf in). See Figure 28.

5. Install two gaskets, exhaust pipe (5), and two capscrews on exhaust pipe (2). Tighten capscrews to 90 N•m (66 lbf ft). See Figure 27.

6. Install two gaskets, exhaust pipe (5), and three locknuts on exhaust manufold. Tighten capscrews to 39 N•m (29 lbf ft). See Figure 27.

Figure 30. StarterSensors and Switches

GAS AND LPG TRUCKS

Crankshaft Position (CKP) Sensor

Remove

1. Remove the floor mat and floor plate; disconnect the battery for lift truck models

• GLP60-70VX (GP/GLP135-155VX) (C878, D878, E878, F878)

• GLP60-70VX (GLP135-155VX, GP155VXS) (G878)

• GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909)

• GLP80VX, GLP80VX9, GLP90VX (C909)

• GLP80VX, GLP80VX9, GLP90VX (D909)

Raise the hood and disconnect the battery for lift truck models

• GC/GLC135-155CA (B879)

• GLC60-70VX (GC/GLC135-155VX) (C879, D879, E879, F879)

• GC070-120LJ/MJ (D818)

• GLC40-55VX; GLC55SVX; (GC/ GLC080-120VX; GC/GLC080-100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818)

• GDP60-70CA (GP/GLC/GDP135-155CA (B878)

• GLP/GDP3.5-5.5LJ/MJ (GP/GLP/ GDP70-120LJ/MJ) (E813)

• GLP40VX5/VX6; GLP45SVX5, GLP45VX6, GLP50-55VX (GP/GLP080-120VX ) (F813, G813, H813, J813, K813)

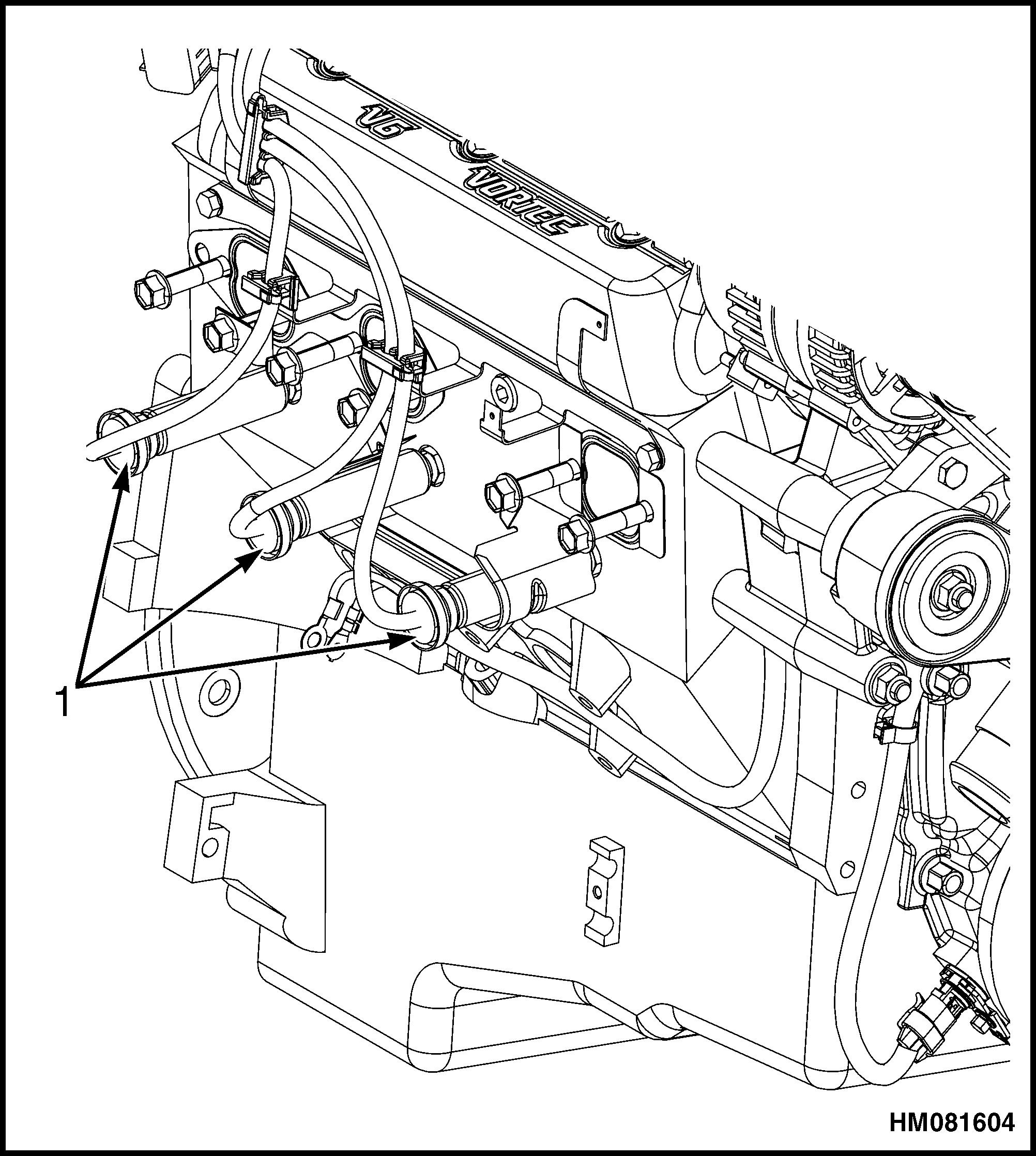

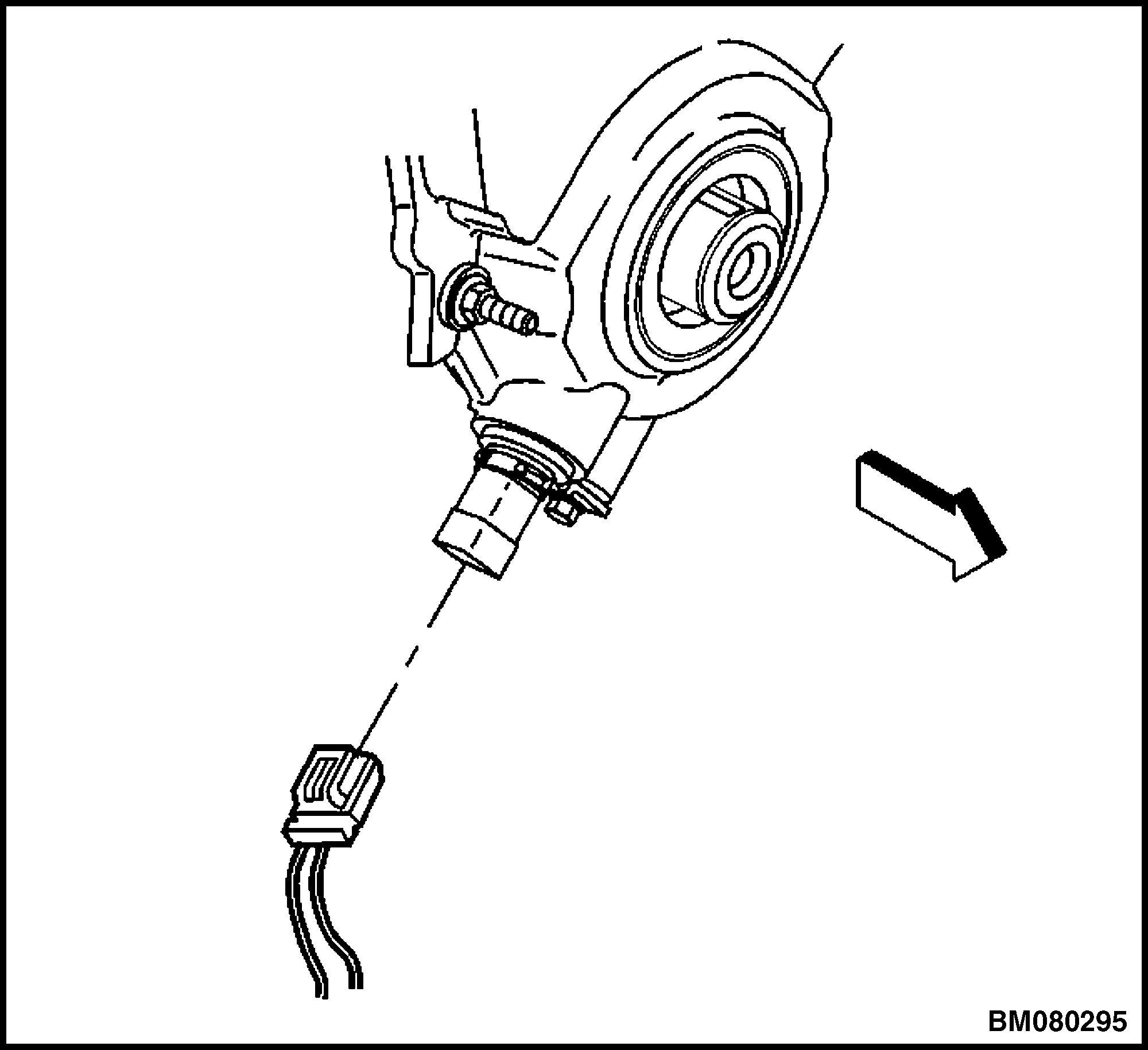

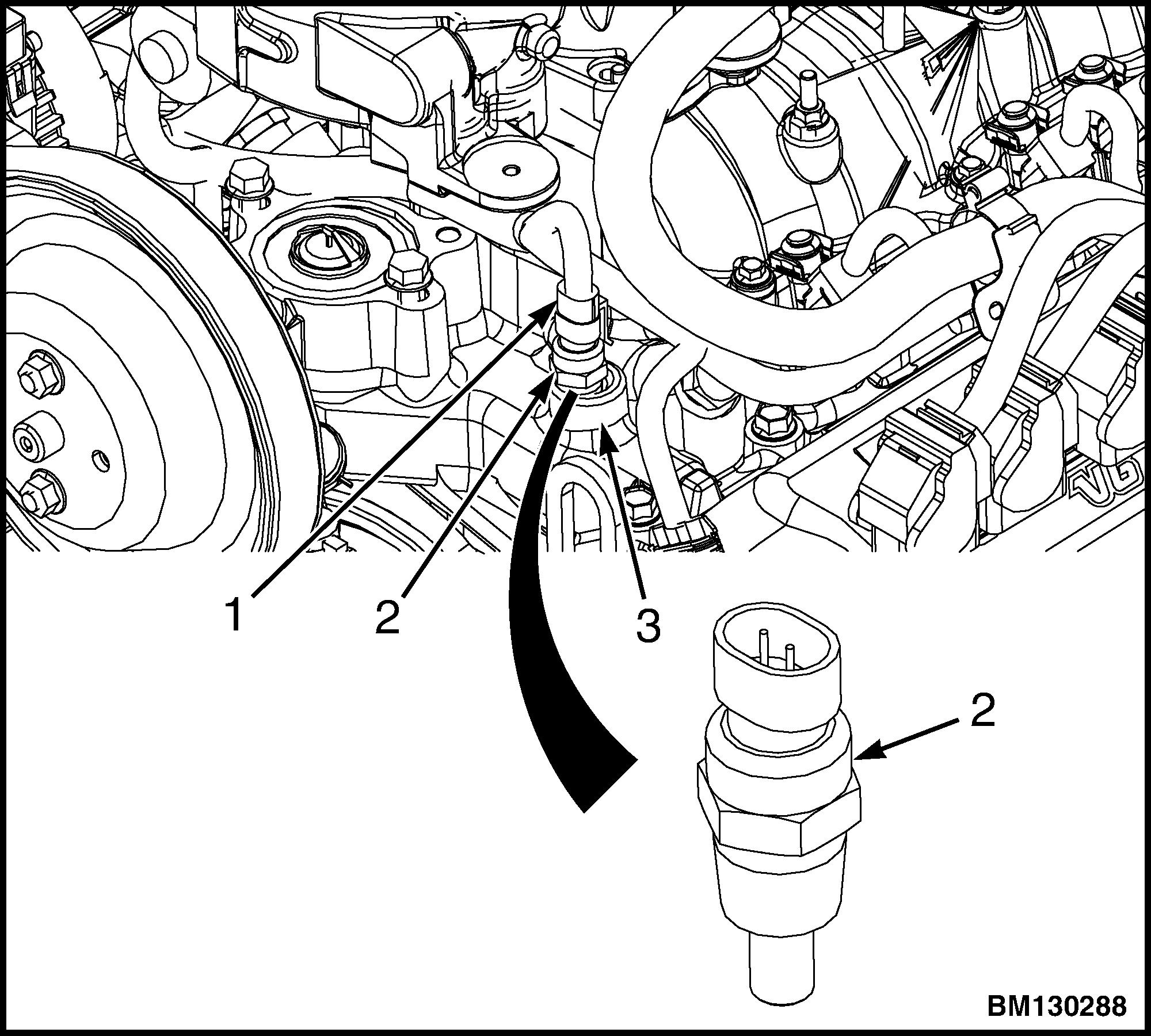

2. Disconnect the crankshaft position (CKP) sensor harness connector. See Figure 31.

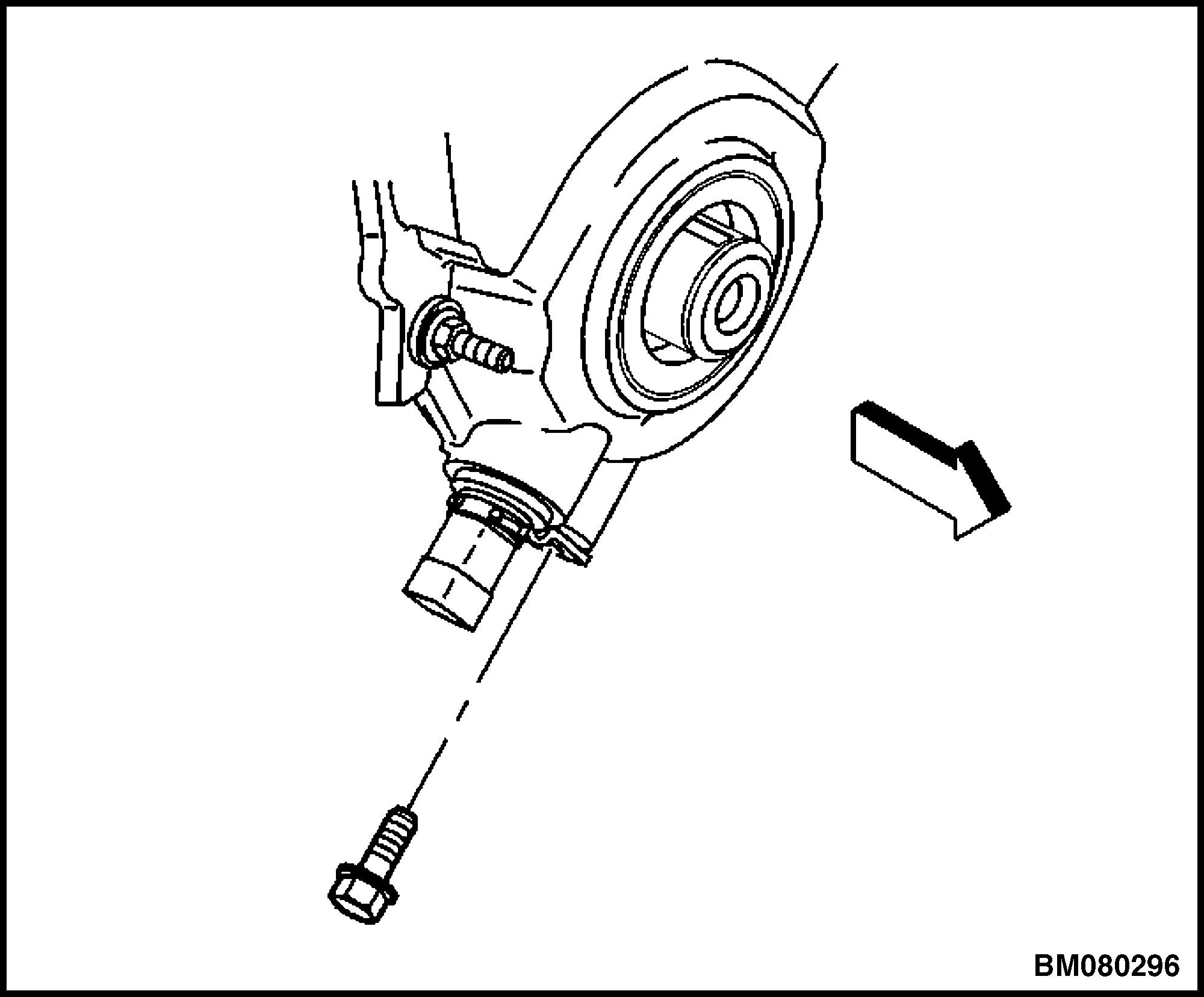

3. Remove the CKP sensor mounting bolt. See Figure 32.

4. Remove the CKP sensor. See Figure 33.

Install

CAUTION

When installing the CKP sensor, make sure the sensor is fully seated before tightening the mounting bolt. A poorly seated CKP sensor may perform erratically and may set false DTCs.

NOTE: Do not reuse the original O-ring.

1. Replace the CKP sensor O-ring.

Figure 31. Crankshaft Position (CKP) Sensor Harness

2. Lubricate the O-ring with clean engine oil before installing the CKP sensor.

NOTE: Make sure the CKP sensor mounting surface is clean and free of burrs.

3. Install the CKP sensor. See Figure 33.

CAUTION

Late model engines use a combination of standard and metric fasteners. The components affected are the starter motor, engine mounts, and flywheel housing mounting. Other components may also have a combination of fasteners. Always verify that the proper fasteners are used whenever removing or replacing any components.

4. Install the CKP sensor mounting bolt and tighten the CKP sensor mounting bolt to 9 N•m (80 lbf in). See Figure 32.

5. Connect the CKP sensor harness connector. See Figure 31.

6.

Connect the battery; install floor plate and floor mat for lift truck models

• GLP60-70VX (GC/GLC135-155VX) (C878, D878, E878, F878)

• GLP60-70VX (GLP135-155VX, GP155VXS) (G878)

• GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909)

• GLP80VX, GLP80VX9, GLP90VX (C909)

• GLP80VX, GLP80VX9, GLP90VX (D909)

Connect the battery and lower the hood for lift truck models

• GC/GLC/GDC135-155CA (B879)

• GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879)

• GC070-120LJ/MJ (D818)

• GLC40-55VX; GLC55SVX; (GC/ GLC080-120VX; GC/GLC080-100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818)

• GDP60-70CA (GP/GLC/GDP135-155CA (B878)

• GLP/GDP3.5-5.5LJ/MJ (GP/GLP/ GDP70-120LJ/MJ) (E813)

• GLP40VX5/VX6; GLP45SVX5, GLP45VX6, GLP50-55VX (GP/GLP080-120VX ) (F813, G813, H813, J813, K813)

1.CRANKSHAFT POSITION SENSOR

2.MOUNTING BOLT

3.CRANKSHAFT SENSOR HARNESS CONNECTOR

Figure 33. Crankshaft Position (CKP) Sensor Removal/Installation

Camshaft Position (CMP) Sensor

Remove

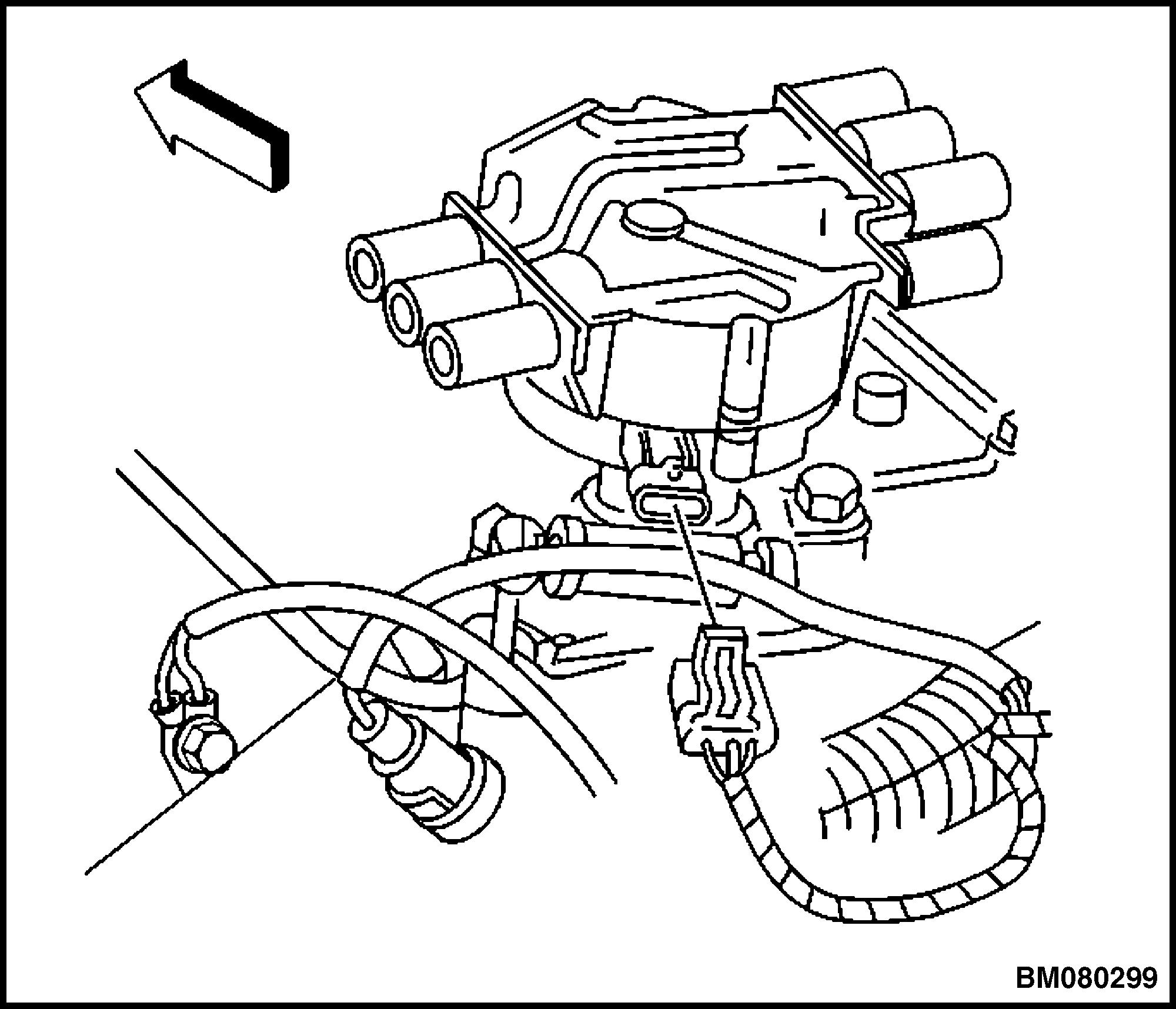

1. Disconnect the spark plug wires and ignition coil wire from the distributor. Refer to Spark Plug Wire Replacement and Figure 34.

2. Disconnect the camshaft position (CMP) sensor harness connector from the distributor. See Figure 35.

3. Remove the capscrews retaining the distributor cap. Remove the distributor cap. See Figure 36.

4. Remove the rotor retaining screws. See Figure 37.

5. Remove the rotor. See Figure 38.

6. Align the square slot in the reluctor wheel with the CMP sensor. See Figure 39.

Figure 32. Crankshaft Position (CKP) Sensor Mounting Bolt

Figure 34. Distributor Cap and Spark Plug Wires

Figure 35. Camshaft Position (CMP) Wire Harness

Figure 36. Distributor Cap Remove/Install

Figure 34. Distributor Cap and Spark Plug Wires

Figure 35. Camshaft Position (CMP) Wire Harness

Figure 36. Distributor Cap Remove/Install

Figure 38. Rotor Remove/Install

Figure 39. Camshaft Position (CMP) Sensor and Reluctor Wheel Alignment

7. Remove the CMP retaining screws. Remove the CMP. See Figure 40.

Install

CAUTION

DO NOT use the old cap, CMP sensor, and rotor screws. Use the replacement screws that have been coated with a thread locking compound.

1. Insert the CMP sensor through the reluctor wheel slot. See Figure 40.

2. Install new CMP mounting screws and tighten to 2.2 N•m (19 lbf in). See Figure 40.

3. Install the rotor onto the reluctor wheel. See Figure 38.

4. Install new rotor retaining screws and tighten to 2 N•m (18 lbf in). See Figure 37.

5. Install the distributor cap and new distributor capscrews. See Figure 36.

6. Connect the CMP sensor harness connector. See Figure 35.

7. Connect the spark plug wires and ignition coil wire. Refer to Spark Plug Wire Replacement and Figure 34.

Figure 40. Camshaft Position Sensor Remove/ Install

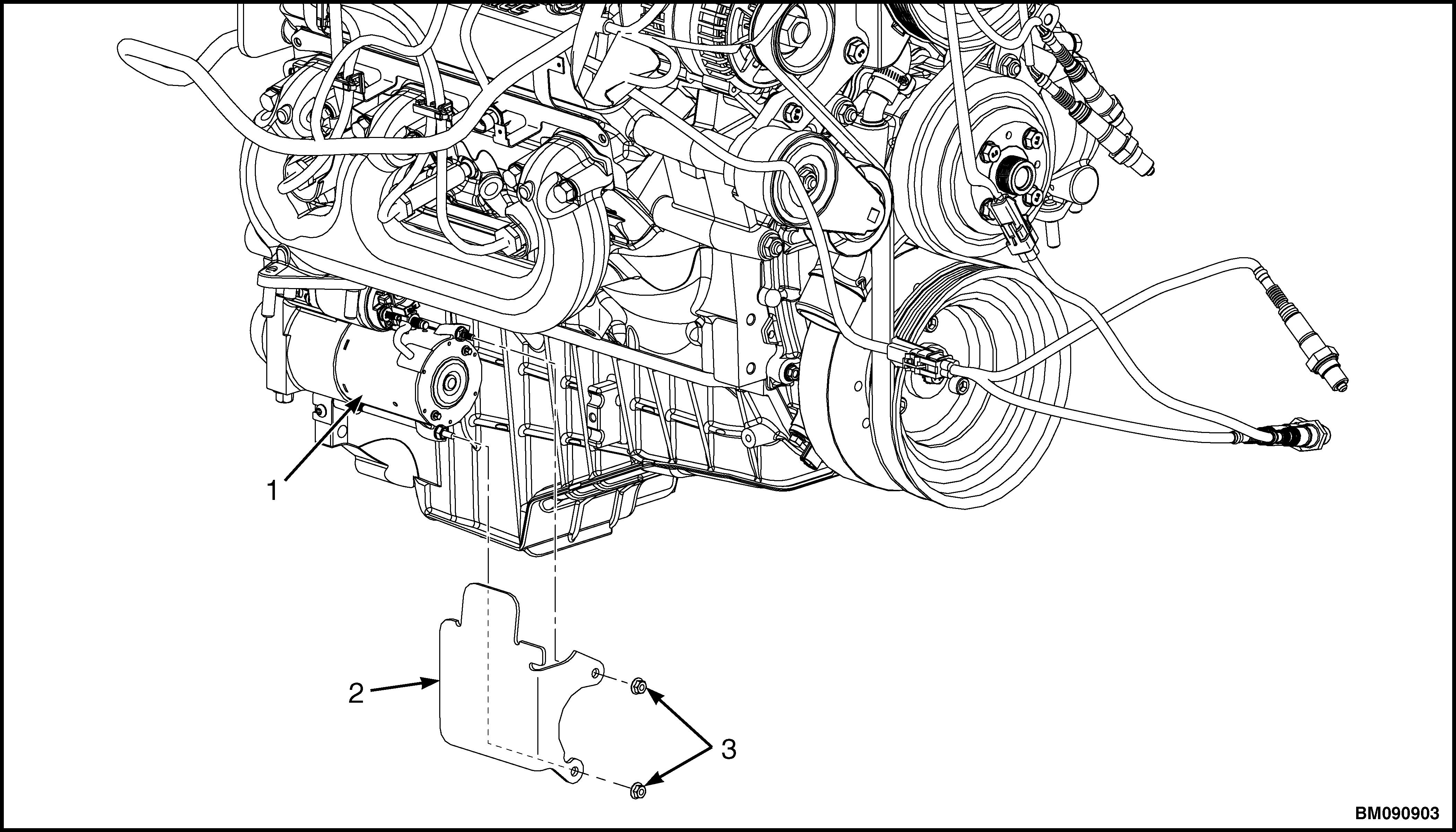

Oil Pressure Sensor

Remove

1. Remove the floor mat and floor plate; disconnect the battery for lift truck models

• GLP60-70VX (GC/GLC135-155VX) (C878, D878, E878, F878)

• GLP60-70VX (GLP135-155VX, GP155VXS) (G878)

• GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909)

• GLP80VX, GLP80VX9, GLP90VX (C909)

• GLP80VX, GLP80VX9, GLP90VX (D909)

Raise the hood and disconnect the battery for lift truck models

• GC/GLC/GDC135-155CA (B879)

• GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879)

• GC070-120LJ/MJ (D818)

• GLC40-55VX; GLC55SVX; (GC/ GLC080-120VX; GC/GLC080-100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818)

• GDP60-70CA (GP/GLC/GDP135-155CA (B878)

• GLP/GDP3.5-5.5LJ/MJ (GP/GLP/ GDP70-120LJ/MJ) (E813)

• GLP40VX5/VX6; GLP45SVX5, GLP45VX6, GLP50-55VX (GP/GLP080-120VX ) (F813, G813, H813, J813, K813)

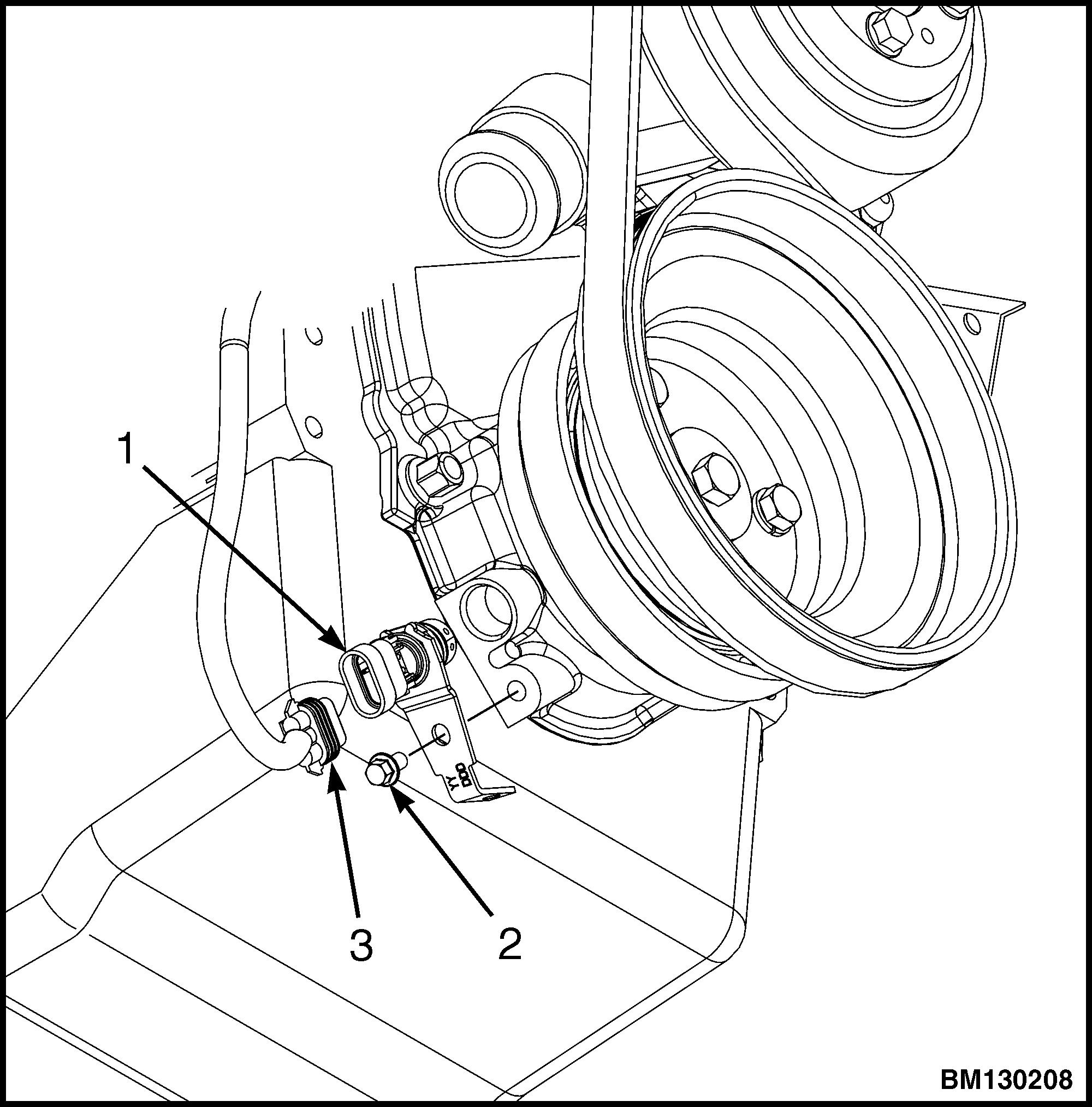

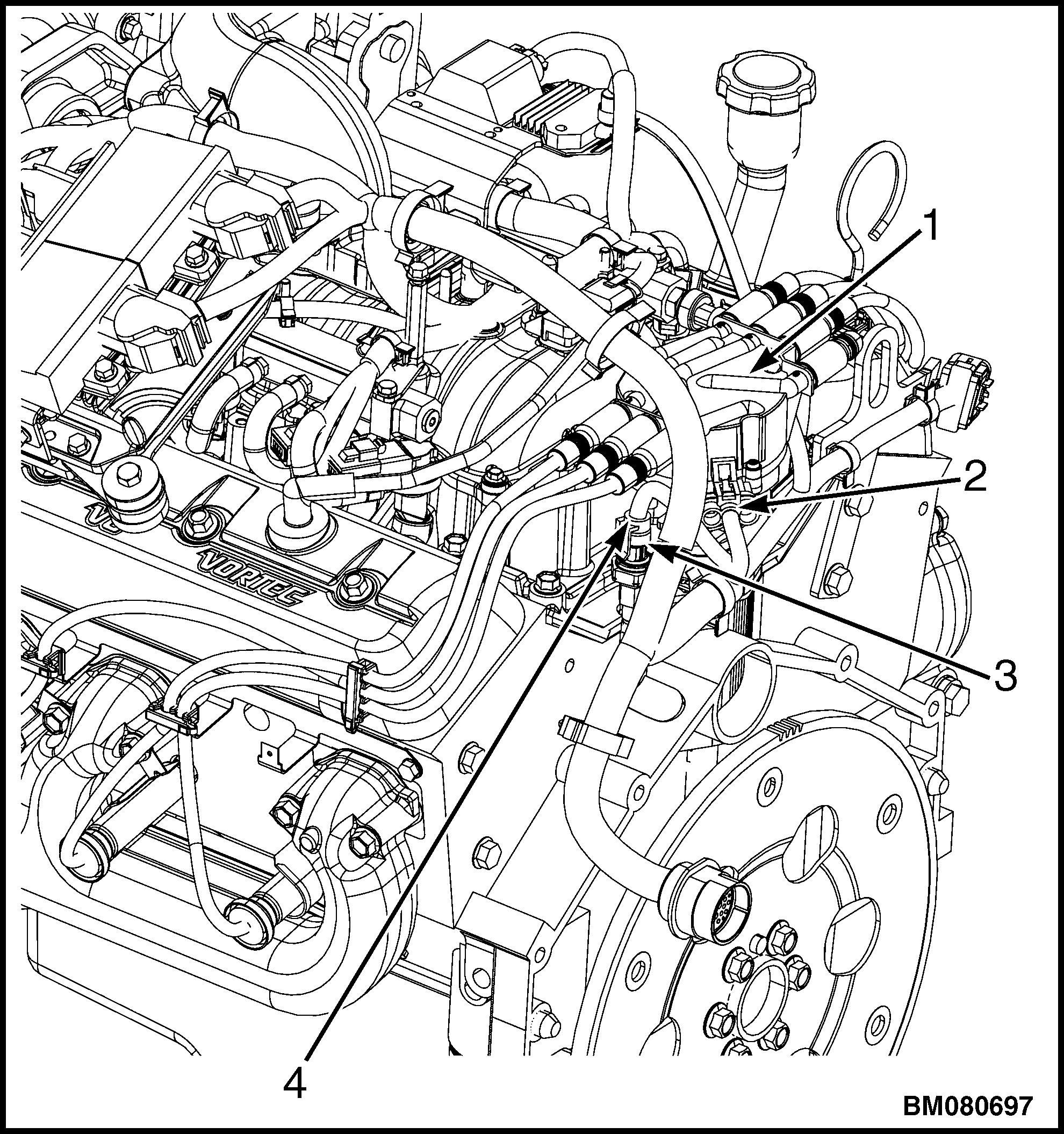

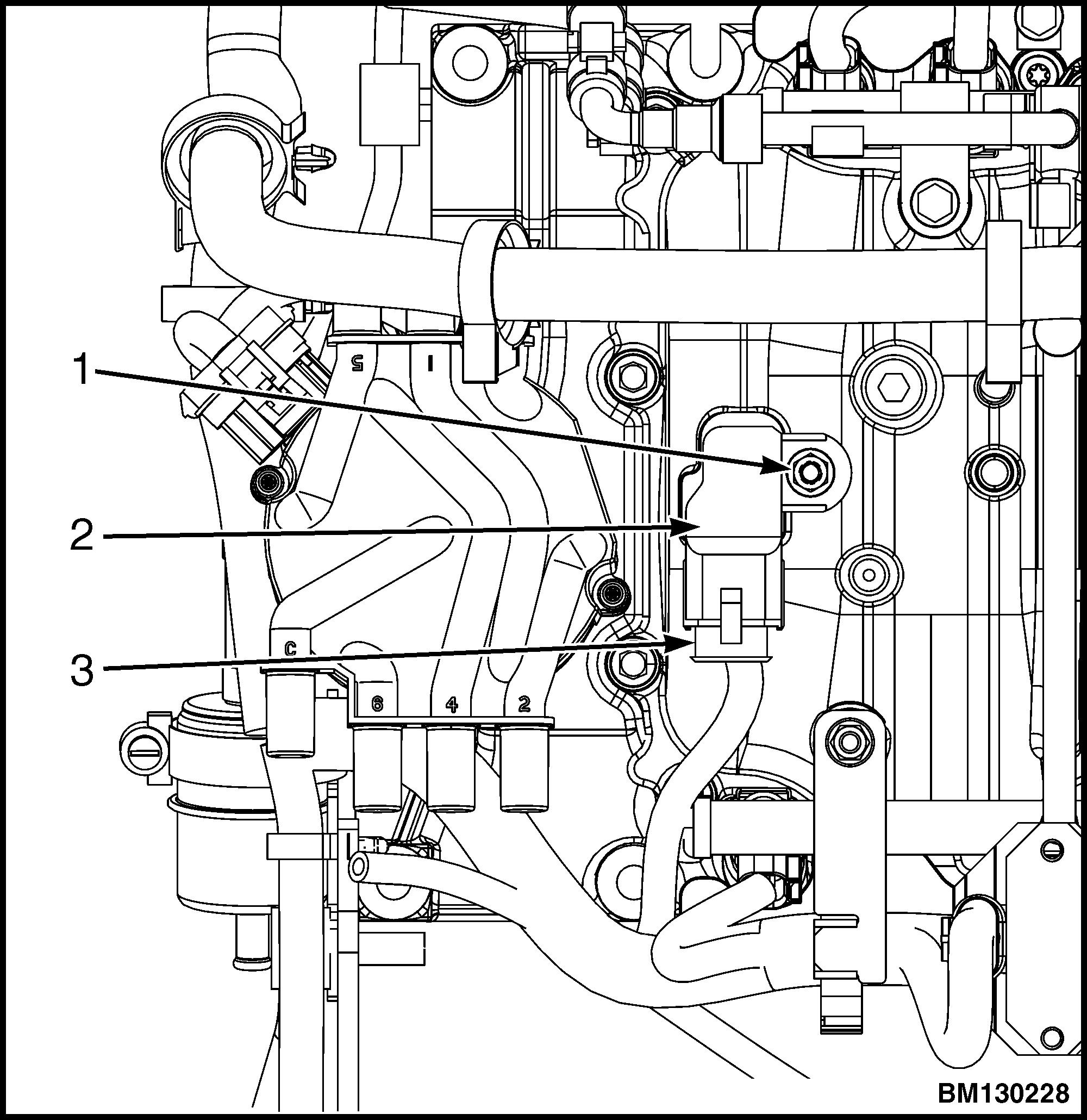

2. Disconnect the electrical connector for the oil pressure sensor. See Figure 41.

1.DISTRIBUTOR

2.CAMSHAFT POSITION SENSOR

3.OIL PRESSURE SENSOR

4.ELECTRICAL CONNECTOR, OIL PRESSURE SENSOR

Figure 41. Camshaft and Oil Pressure Sensors

3. Remove the oil pressure sensor.

Install

1. Install new oil pressure sensor onto engine. Tighten sensor to 20 N•m (177 lbf in).

2. Connect the electrical connector for the oil pressure sensor. See Figure 41.

3. Connect the battery; install floor plate and floor mat for lift truck models

• GLP60-70VX (GC/GLC135-155VX) (C878, D878, E878, F878

• GLP60-70VX (GLP135-155VX, GP155VXS) (G878)

• GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909)

• GLP80VX, GLP80VX9, GLP90VX (C909)

• GLP80VX, GLP80VX9, GLP90VX (D909)

Connect the battery and lower the hood for lift truck models

• GC/GLC/GDC135-155CA (B879)

• GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879)

• GC070-120LJ/MJ (D818)

• GLC40-55VX; GLC55SVX; (GC/ GLC080-120VX; GC/GLC080-100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818)

• GDP60-70CA (GP/GLC/GDP135-155CA (B878)

• GLP/GDP3.5-5.5LJ/MJ (GP/GLP/ GDP70-120LJ/MJ) (E813)

• GLP40VX5/VX6; GLP45SVX5, GLP45VX6, GLP50-55VX (GP/GLP080-120VX ) (F813, G813, H813, J813, K813)

Manifold Absolute Pressure (MAP)/ Manifold Air Temperature (MAT) Sensor

Remove

1. Remove the floor mat and floor plate; disconnect the battery for lift truck models

• GLP60-70VX (GC/GLC135-155VX) (C878, D878, E878, F878)

• GLP60-70VX (GLP135-155VX, GP155VXS) (G878)

• GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909)

• GLP80VX, GLP80VX9, GLP90VX (C909)

• GLP80VX, GLP80VX9, GLP90VX (D909)

Raise the hood and disconnect the battery for lift truck models

• GC/GLC/GDC135-155CA (B879)

• GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879)

• GC070-120LJ/MJ (D818)

• GLC40-55VX; GLC55SVX; (GC/ GLC080-120VX; GC/GLC080-100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818)

• GDP60-70CA (GP/GLC/GDP135-155CA (B878)

• GLP/GDP3.5-5.5LJ/MJ (GP/GLP/ GDP70-120LJ/MJ) (E813)

• GLP40VX5/VX6; GLP45SVX5, GLP45VX6, GLP50-55VX (GP/GLP080-120VX ) (F813, G813, H813, J813, K813)

2. Disconnect the electrical connector from the MAP/MAT sensor. See Figure 42.

3. Remove the nut and MAP/MAT sensor from the intake manifold.

1.RETAINING NUT

2.MAP/MAT SENSOR

3.ELECTRICAL CONNECTOR

Figure 42. MAP/MAT Sensor

Install

1. Place the MAP/MAT sensor in position on the intake manifold and install the retaining nut. Tighten retaining nut to 6 N•m (53 lbf in).

2. Connect the electrical connector to the MAP/MAT sensor. See Figure 42. Verify that the connector clicks/locks into place.

3. Connect the battery; install floor plate and floor mat for lift truck models

• GLP60-70VX (GC/GLC135-155VX) (C878, D878, E878, F878)

• GLP60-70VX (GLP135-155VX, GP155VXS) (G878)

• GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909)

• GLP80VX, GLP80VX9, GLP90VX (C909)

• GLP80VX, GLP80VX9, GLP90VX (D909)

Connect the battery and lower the hood for lift truck models

• GC/GLC/GDC135-155CA (B879)

• GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879)

• GC070-120LJ/MJ (D818)

• GLC40-55VX; GLC55SVX; (GC/ GLC080-120VX; GC/GLC080-100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818)

• GDP60-70CA (GP/GLC/GDP135-155CA (B878)

• GLP/GDP3.5-5.5LJ/MJ (GP/GLP/ GDP70-120LJ/MJ) (E813)

• GLP40VX5/VX6; GLP45SVX5, GLP45VX6, GLP50-55VX (GP/GLP080-120VX ) (F813, G813, H813, J813, K813)

Engine Coolant Temperature (ECT) Sensor

Remove

1. Remove the floor mat and floor plate; disconnect the battery for lift truck models

• GLP60-70VX (GC/GLC135-155VX) (C878, D878, E878, F878)

• GLP60-70VX (GLP135-155VX, GP155VXS) (G878)

• GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909)

• GLP80VX, GLP80VX9, GLP90VX (C909)

• GLP80VX, GLP80VX9, GLP90VX (D909)

Raise the hood and disconnect the battery for lift truck models

• GC/GLC/GDC135-155CA (B879)

• GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879)

• GC070-120LJ/MJ (D818)

• GLC40-55VX; GLC55SVX; (GC/ GLC080-120VX; GC/GLC080-100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818)

• GDP60-70CA (GP/GLC/GDP135-155CA (B878)

• GLP/GDP3.5-5.5LJ/MJ (GP/GLP/ GDP70-120LJ/MJ) (E813)

• GLP40VX5/VX6; GLP45SVX5, GLP45VX6, GLP50-55VX (GP/GLP080-120VX ) (F813, G813, H813, J813, K813)

2. Disconnect the electrical connector from the ECT sensor.

See Figure 43 for lift trucks built before January, 2010.

See Figure 44 for lift trucks built after January, 2010.

3. Remove the ECT sensor.

See Figure 43 for lift trucks built before January, 2010.

See Figure 44 for lift trucks built after January, 2010.

1.ELECTRICAL CONNECTOR

2.ECT SENSOR

3.INTAKE MANIFOLD

Figure 43. ECT Sensor for Lift Trucks Built Before January, 2010

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE

1.ELECTRICAL CONNECTOR

2.ECT SENSOR

3.INTAKE MANIFOLD

Figure 44. ECT Sensor for Lift Trucks Built After January, 2010

Install

1. Install the new ECT sensor. Tighten the sensor to 20 N•m (14.75 lbf ft).

See Figure 43 for lift trucks built before January, 2010.

See Figure 44 for lift trucks built after January, 2010.

2. Connect the electrical connector to the ECT sensor.

See Figure 43 for lift trucks built before January, 2010.

See Figure 44 for lift trucks built after January, 2010.

3. Connect the battery; install floor plate and floor mat for lift truck models

• GLP60-70VX (GC/GLC135-155VX) (C878, D878, E878, F878)

• GLP60-70VX (GLP135-155VX, GP155VXS) (G878)

• GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909)

• GLP80VX, GLP80VX9, GLP90VX (C909)

• GLP80VX, GLP80VX9, GLP90VX (D909)

Connect the battery and lower the hood for lift truck models

• GC/GLC/GDC135-155CA (B879)

• GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879)

• GC070-120LJ/MJ (D818)

• GLC40-55VX; GLC55SVX; (GC/ GLC080-120VX; GC/GLC080-100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818)

• GDP60-70CA (GP/GLC/GDP135-155CA (B878)

• GLP/GDP3.5-5.5LJ/MJ (GP/GLP/ GDP70-120LJ/MJ) (E813)

• GLP40VX5/VX6; GLP45SVX5, GLP45VX6, GLP50-55VX (GP/GLP080-120VX ) (F813, G813, H813, J813, K813)

Air Flow Restriction Switch

NOTE: The air flow restriction switch is an optional feature on these lift trucks and is a part of the Electronic Monitoring package option.

Remove

1. Remove the floor mat and floor plate; disconnect the battery for lift truck models

• GLP60-70VX (GC/GLC135-155VX) (C878, D878, E878, F878)

• GLP60-70VX (GLP135-155VX, GP155VXS) (G878)

• GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909)

• GLP80VX, GLP80VX9, GLP90VX (C909)

• GLP80VX, GLP80VX9, GLP90VX (D909)

Raise the hood and disconnect the battery for lift truck models

• GC/GLC/GDC135-155CA (B879)

• GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879)

• GC070-120LJ/MJ (D818)

• GLC40-55VX; GLC55SVX; (GC/ GLC080-120VX; GC/GLC080-100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818)

• GDP60-70CA (GP/GLC/GDP135-155CA (B878)

• GLP/GDP3.5-5.5LJ/MJ (GP/GLP/ GDP70-120LJ/MJ) (E813)

• GLP40VX5/VX6; GLP45SVX5, GLP45VX6, GLP50-55VX (GP/GLP080-120VX ) (F813, G813, H813, J813, K813)

2. Disconnect the air flow restriction switch electrical connection. See Figure 45.

3. Remove air filter restriction switch from air cleaner.

NOTE: AIR CLEANER HOSE NOT SHOWN FOR CLARITY. SWITCH NOT SHOWN, BUT ITEM #4 POINTS TO ITS LOCATION.

1.ECT SENSOR

2.AIR FLOW RESTRICTION ELECTRICAL CONNECTOR

3.AIR CLEANER

4.AIR FLOW RESTRICTION SWITCH

Figure 45. Air Flow Restriction Switch

Install

1. Install new air flow restriction switch into air cleaner.

2. Connect the air flow restriction switch electrical connection. See Figure 45.

3. Connect the battery; install floor plate and floor mat for lift truck models

• GLP60-70VX (GC/GLC135-155VX) (C878, D878, E878, F878)

• GLP60-70VX (GLP135-155VX, GP155VXS) (G878)

• GLP80VX, GLP80VX9, GLP90VX (GLP170VX, GLP175VX36, GLP190VX) (A909, B909)

• GLP80VX, GLP80VX9, GLP90VX (C909)

• GLP80VX, GLP80VX9, GLP90VX (D909)

Connect the battery and lower the hood for lift truck models

• GC/GLC/GDC135-155CA (B879)

• GLC/GDC60VX, GLC/GDC70VX (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879)

• GC070-120LJ/MJ (D818)

• GLC40-55VX; GLC55SVX; (GC/ GLC080-120VX; GC/GLC080-100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818)

• GDP60-70CA (GP/GLC/GDP135-155CA (B878)

• GLP/GDP3.5-5.5LJ/MJ (GP/GLP/ GDP70-120LJ/MJ) (E813)

• GLP40VX5/VX6; GLP45SVX5, GLP45VX6, GLP50-55VX (GP/GLP080-120VX ) (F813, G813, H813, J813, K813)

Application

Specifications and Special Tools

Table 1. Ignition System Specifications for GM 4.3L Engines

Firing Order 1-6-5-4-3-2

Spark Plug Wire Resistance 1,000 ohms per ft

Spark Plug Torque 15 N•m (11 lbf ft)

Spark Plug Specifications, GFI LPG Fuel System

B879

C879, D879

R44LTS

C878, D878

E813

F813, G813, H813

D879, E879, F879

E818, F818

R44LTS

D878, E878 AC R44LTS

G813, H813, J813, K813

F878, G878

R44LTS

R44LTS

in.

in.

in.

Table 2. Ignition System Specifications for GM 5.7L Engine Application

Spark Plug Wire Resistance 1225 Ohms per ft. (± 245 Ohms per ft.)

Spark Plug Torque 15 N•m (11 lbf ft)

Spark Plug Specifications

Table 3. Fastener Tightening Specifications

Table 4. Special Tools

Illustration

Tool Number/Description

OTC Part No. 7230 Spark Tester

OTC Part No. KMJ35616A Connector Test Adapter Kit

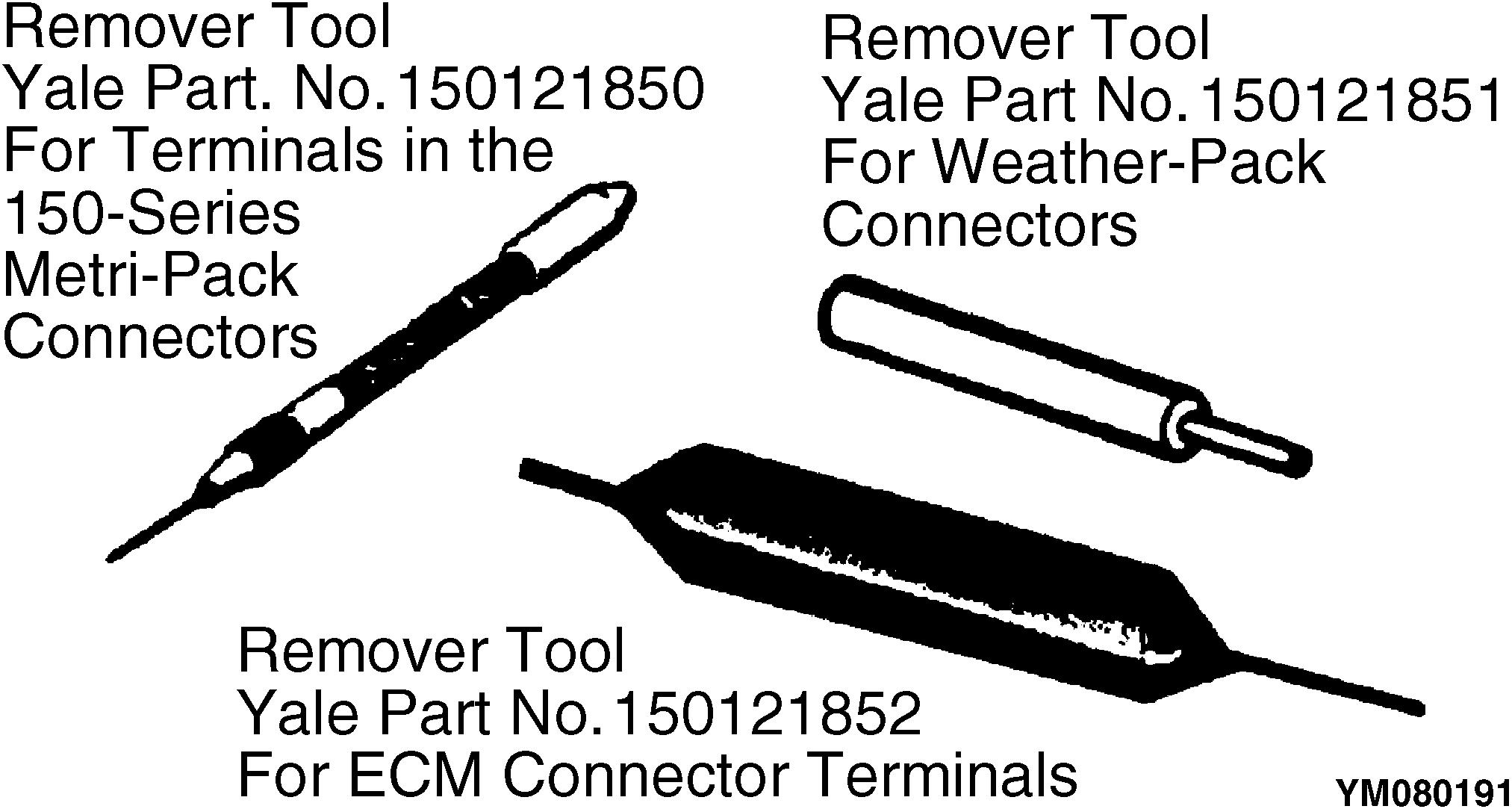

Tool Kit for Terminal Repair Terminals cannot be removed from their connectors nor repaired without special tools. This kit has the special removal and installation tools and crimping tools required to make repairs in Micro-Pack, Metri-Pack, and Weather-Pack connectors. This repair kit does not have the terminals nor the connectors.

DIAGNOSTIC TROUBLESHOOTING MANUAL