Edition: December 2002

Revision: April 2004

Publication No. SM3E-1S50U3

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any form, or by any means, electronic, mechanical, recording or otherwise, without the prior written permission of Nissan Motor Company Ltd., Tokyo, Japan.

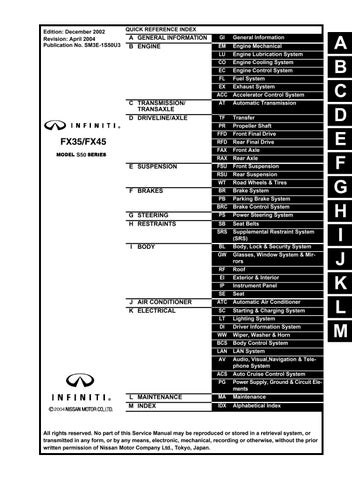

A B C D E F G H I J K M L QUICK REFERENCE INDEX A GENERAL INFORMATION GI General Information B ENGINE EM Engine Mechanical LU Engine Lubrication System CO Engine Cooling System EC Engine Control System FL Fuel System EX Exhaust System ACC Accelerator Control System C TRANSMISSION/ TRANSAXLE AT Automatic Transmission D DRIVELINE/AXLE TF Transfer PR Propeller Shaft FFD Front Final Drive RFD Rear Final Drive FAX Front Axle RAX Rear Axle E SUSPENSION FSU Front Suspension RSU Rear Suspension WT Road Wheels & Tires F BRAKES BR Brake System PB Parking Brake System BRC Brake Control System G STEERING PS Power Steering System H RESTRAINTS SB Seat Belts SRS Supplemental Restraint System (SRS) I BODY BL Body, Lock & Security System GW Glasses, Window System & Mirrors RF Roof EI Exterior & Interior IP Instrument Panel SE Seat J AIR CONDITIONER ATC Automatic Air Conditioner K ELECTRICAL SC Starting & Charging System LT Lighting System DI Driver Information System WW Wiper, Washer & Horn BCS Body Control System LAN LAN System AV Audio, Visual,Navigation & Telephone System ACS Auto Cruise Control System PG Power Supply, Ground & Circuit Elements L MAINTENANCE MA Maintenance M INDEX IDX Alphabetical Index

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

This manual contains maintenance and repair procedure for the 2003 INFINITI FX35/FX45.

In order to assure your safety and the efficient functioning of the vehicle, this manual should be read thoroughly. It is especially important that the PRECAUTIONS in the GI section be completely understood before starting any repair task.

All information in this manual is based on the latest product information at the time of publication. The right is reserved to make changes in specifications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the technician and the efficient functioning of the vehicle. The service methods in this Service Manual are described in such a manner that the service may be performed safely and accurately. Service varies with the procedures used, the skills of the technician and the tools and parts available. Accordingly, anyone using service procedures, tools or parts which are not specifically recommended by NISSAN must first be completely satisfied that neither personal safety nor the vehicle’s safety will be jeopardized by the service method selected.

PLEASE HELP MAKE THIS SERVICE MANUAL BETTER!

Your comments are important to INFINITI and will help us to improve our Service Manuals

Use this form to report any issues or comments you may have regarding our Service Manuals

Please print this form and type or write your comments below. Mail or fax to:

Nissan North America, Inc.

Technical Service Information

39001 Sunrise Drive, P O Box 9200 Farmington Hills, MI USA 48331

FAX: (248) 488-3910

SERVICE MANUAL: Model: Year:

PUBLICATION NO. (Refer to Quick Reference Index ):

Please describe any Service Manual issues or problems in detail:

Page number(s) Note: Please include a copy of each page, marked with your comments

Are the trouble diagnosis procedures logical and easy to use? (circle your answer) YES NO

If no, what page number(s)? Note: Please include a copy of each page, marked with your comments

Please describe the issue or problem in detail:

Is the organization of the manual clear and easy to follow? (circle your answer) YES NO

Please comment:

What information should be included in INFINITI Service Manuals to better support you in servicing or repairing customer vehicles?

DATE: YOUR NAME: POSITION:

DEALER: DEALER NO : ADDRESS:

CITY: STATE/PROV /COUNTRY: ZIP/POSTAL CODE:

R I N F I N I T I

INCHTOMETRICCONVERSIONTABLE

(Rounded-offforautomotiveuse) inches mm inches mm .100 2.54 .610 15.49 .110 2.79 .620 15.75 .120 3.05 .630 16.00 .130 3.30 .640 16.26 .140 3.56 .650 16.51 .150 3.81 .660 16.76 .160 4.06 .670 17.02 .170 4.32 .680 17.27 .180 4.57 .690 17.53 .190 4.83 .700 17.78 .200 5.08 .710 18.03 .210 5.33 .720 18.29 .220 5.59 .730 18.54 .230 5.84 .740 18.80 .240 6.10 .750 19.05 .250 6.35 .760 19.30 .260 6.60 .770 19.56 .270 6.86 .780 19.81 .280 7.11 .790 20.07 .290 7.37 .800 20.32 .300 7.62 .810 20.57 .310 7.87 .820 20.83 .320 8.13 .830 21.08 .330 8.38 .840 21.34 .340 8.64 .850 21.59 .350 8.89 .860 21.84 .360 9.14 .870 22.10 .370 9.40 .880 22.35 .380 9.65 .890 22.61 .390 9.91 .900 22.86 .400 10.16 .910 23.11 .410 10.41 .920 23.37 .420 10.67 .930 23.62 .430 10.92 .940 23.88 .440 11.18 .950 24.13 .450 11.43 .960 24.38 .460 11.68 .970 24.64 .470 11.94 .980 24.89 .480 12.19 .990 25.15 .490 12.45 1.000 25.40 .500 12.70 2.000 50.80 .510 12.95 3.000 76.20 .520 13.21 4.000 101.60 .530 13.46 5.000 127.00 .540 13.72 6.000 152.40 .550 13.97 7.000 177.80 .560 14.22 8.000 203.20 .570 14.48 9.000 228.60 .580 14.73 10.000 254.00 .590 14.99 20.000 508.00 .600 15.24

(Rounded-offforautomotiveuse) mm inches mm inches 1 .0394 51 2.008 2 .079 52 2.047 3 .118 53 2.087 4 .157 54 2.126 5 .197 55 2.165 6 .236 56 2.205 7 .276 57 2.244 8 .315 58 2.283 9 .354 59 2.323 10 .394 60 2.362 11 .433 61 2.402 12 .472 62 2.441 13 .512 63 2.480 14 .551 64 2.520 15 .591 65 2.559 16 .630 66 2.598 17 .669 67 2.638 18 .709 68 2.677 19 .748 69 2.717 20 .787 70 2.756 21 .827 71 2.795 22 .866 72 2.835 23 .906 73 2.874 24 .945 74 2.913 25 .984 75 2.953 26 1.024 76 2.992 27 1.063 77 3.031 28 1.102 78 3.071 29 1.142 79 3.110 30 1.181 80 3.150 31 1.220 81 3.189 32 1.260 82 3.228 33 1.299 83 3.268 34 1.339 84 3.307 35 1.378 85 3.346 36 1.417 86 3.386 37 1.457 87 3.425 38 1.496 88 3.465 39 1.535 89 3.504 40 1.575 90 3.543 41 1.614 91 3.583 42 1.654 92 3.622 43 1.693 93 3.661 44 1.732 94 3.701 45 1.772 95 3.740 46 1.811 96 3.780 47 1.850 97 3.819 48 1.890 98 3.858 49 1.929 99 3.898 50 1.969 100 3.937

METRICTOINCHCONVERSIONTABLE

QUICK REFERENCE CHART FX35/FX45

ENGINE TUNE-UP DATA (VQ35DE)

QUICK REFERENCE CHART FX35/FX45 PFP:00000

ELS0003W Engine model VQ35DE Firing order 1-2-3-4-5-6 Idle speed A/T (In “P” or “N” position) rpm 650±50 Ignition timing (BTDC at idle speed) A/T (In “P” or “N” position) 15°± 5 ° CO% at idle 0.7 - 9.9 % and engine runs smoothly Drive Belt Deflection adjustment Unit: mm (in)Tension adjustment Unit: N (kg, lb) Used belt New belt Used belt New belt LimitAfter adjustmentLimit After adjustment Alternator and air conditioner compressor belt 7 (0.28) 4 - 5 (0.16 - 0.20) 3.5 - 4.5 (0.138 - 0.177) 294 (30, 66) 730 - 818 (74.5 - 83.5, 164 - 184) 838 - 926 (85.5 - 94.5, 188 - 208) Power steering oil pump belt 12 (0.47) 9 - 10 (0.35 - 0.39) 8 - 9 (0.31 - 0.35) 196 (20, 44) 348 - 436 (35.5 - 44.5, 78 - 98) 470 - 559 (48 - 57, 106 - 126) Applied pushing force98N (10kg, 22lb) — Radiater cap relief pressure kPa (kg/cm2 , psi) 78 - 98 (0.8 - 1.0, 11 - 14) Standard Limit59 (0.6, 9) Cooling system leakage testing pressure kPa (kg/cm2 , psi) 157(1.6, 23) Compression pressure kPa (kg/cm2 , psi)/rpm 1,275 (13.0, 185) /300 Standard Minimum981 (10.0, 142)/300 Spark plugStandard typePLFR5A - 11 Hot typePLFR4A - 11 Cold typePLFR6A - 11 2003

QUICK REFERENCE CHART FX35/FX45

ENGINE TUNE-UP DATA (VK45DE)

Tensions of drive beltsAuto adjustment by auto tensioner

FRONT WHEEL ALIGNMENT (Unladen* )

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

ELS0003X

Engine model VK45DE Firing order 1-8-7-3-6-5-4-2 Idle speed A/T (In “P” or “N” position)rpm 650±50 Ignition timing (BTDC at idle speed) 12 °±5°

CO% at idle 0.7 - 9.9 % and engine runs smoothly

78-98

Standard

157(1.6,

kPa (kg/cm2

Compression pressure 1,320 (13.5, 191) /300 Standard kPa (kg/cm2 , psi)/rpm Minimum 1,130 (11.5, 164)/300 Spark plugStandard typePLFR5A -

Hot typePLFR4A

Cold typePLFR6A - 11 CamberDegree minute (Decimal degree)Minimum– 1° 29′ ( – 1.48 ° ) Nominal– 0° 44′ ( – 0.73 ° ) Maximum 0 ° 01′ ( 0.02° ) Left and right difference45′ ( 0.75° ) or less CasterDegree minute (Decimal degree)Minimum3° 02′ ( 3.03° ) Nominal3° 47′ ( 3.78° ) Maximum4° 32′ ( 4.53° ) Left and right difference45′ ( 0.75° ) or less Kingpin inclinationDegree minute (Decimal degree)Minimum12° 20′ ( 12.33° ) Nominal13° 05′ ( 13.08° ) Maximum13° 50′ ( 13.83° ) Total toe-inDistance (A – B)Minimum0.6 mm ( 0.024 in ) Nominal1.6 mm ( 0.063 in ) Maximum2.6 mm ( 0.102 in ) Angle

Degree minute (Degree) Minimum–Nominal6′ ( 0.1° ) Maximum–Wheel turning angle (Full turn)InsideMInimum32 ° 00′ ( 32.0 ° ) Degree minute (Decimal degree)Nominal35 ° 00′ ( 35.0 ° ) Maximum36 ° 00′ ( 36.0 ° ) Outside Nominal30 ° 00′ ( 30.0 ° ) Degree minute (Decimal degree) 2003

Radiater cap relief pressure

(0.8-1.0 , 11-14 )

kPa (kg/cm2 , psi) Cooling system leakage testing pressure

23)

, psi)

11

- 11

(left plus right)

QUICK REFERENCE CHART FX35/FX45

REAR WHEEL ALIGNMENT (Unladen*)

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

* : Under force of 490 N( 50 kg, 110 lb ) with engine running.

ELS0003Y

BRAKE ELS0003Z

ELS00040 Camber Degree minute (Decimal degree) Minimum– 1° 18′ ( – 1.30° ) Nominal– 0 ° 48′ ( – 0.80° ) Maximum– 0 ° 18′ ( – 0.30° ) Total toe-in Distance ( A – B )Minimum2.4 mm ( 0.094 in ) Nominal4.7 mm ( 0.185 in ) Maximum7.0 mm ( 0.276 in ) Angle (left plus

) Degree minute (Degree) Minimum 0° 05 ′ ( 0.08° ) Nominal 0° 10 ′ ( 0.17° ) Maximum 0° 15 ′ ( 0.25° ) Front brakePad wear limit2.0 ( 0.079 ) Rotor repair limit26.0 mm ( 1.024 in ) Rear brakePad wear limit2.0 mm ( 0.079 in ) Rotor repair limit14.0 mm ( 0.551 in ) Pedal free height161.5 - 171.5 mm ( 6.358 - 6.752 in ) Pedal depressed height*90 mm ( 3.54 in ) UNIT LiterUS measure Fuel tank 9023 - 3/4 gal Coolant ( With reservoir tank ) VQ35DE8.69 - 1/8 qt VK45DE10.010 - 5/8 qt Engine(VQ35DE) Drain and refill With oil filter change4.75 qt Without oil filter change4.44 - 5/8 qt Dry engine (Overhaul)5.45 - 3/4 qt Engine(VK45DE) Drain and refill With oil filter change6.67qt Without oil filter change6.06 - 3/8 qt Dry engine (Overhaul)7.78 - 1/8 qt TransmissionA/T10.310 - 7/8 qt Transfer 1.252 - 5/8 pt Differential carrier Front0.651 - 3/8 pt Rear1.43 pt Power steering system1.01 - 1/8 qt Air conditioning system Compressor oil0.186.0 fl oz Refrigerant0.55 kg1.21 lb 2003

REFILL CAPACITIES

right

TEST VALUE AND TEST LIMIT (GST ONLY — NOT APPLICABLE TO CONSULT-II)

The following is the information specified in Mode 6 of SAE J1979. The test value is a parameter used to determine whether a system/circuit diagnostic test is “OK” or “NG” while being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the

maximum or minimum value and is compared with the test value being monitored. These data (test value and test limit) are specified by Test ID (TID) and Component ID (CID) and can be displayed on the GST screen.

SRT item

CATALYST

EVAP SYSTEM

Self-diagnostic test item

Three way catalyst function (Bank 1)

Three way catalyst function (Bank 2)

HO2S

HO2S HTR

Heated oxygen sensor 1 (Bank 1)

Heated oxygen sensor 1 (Bank 2)

Heated oxygen sensor 2 (Bank 1)

Heated oxygen sensor 2 (Bank 2)

Heated oxygen sensor 1 heater (Bank 1)

Heated oxygen sensor 1 heater (Bank 2)

Heated oxygen sensor 2 heater (Bank 1)

Heated oxygen sensor 2 heater (Bank 2)

Test limit Conversion DTC

Test value (GST display)

Attachment No.35 TID CID P0420 01H 01H Max. 1/128 P0420 02H 81H Min. 1 P0430 03H 02H Max. 1/128 P0430 04H 82H Min. 1 EVAP control system (Small leak) P0442 05H 03H Max. 1/128mm2 EVAP control system purge flow monitoring P0441 06H 83H Min. 20mV EVAP control system (Very small leak) P0456 07H 03H Max. 1/128mm2 P0133 09H 04H Max. 16ms P1143 0AH 84H Min. 10mV P1144 0BH 04H Max. 10mV P0132 0CH 04H Max. 10mV P0134 0DH 04H Max. 1s P0153 11H 05H Max. 16ms P1163 12H 85H Min. 10mV P1164 13H 05H Max. 10mV P0152 14H 05H Max. 10mV P0154 15H 05H Max. 1s P0139 19H 86H Min. 10mV/500ms P1147 1AH 86H Min. 10mV P1146 1BH 06H Max. 10mV P0138 1CH 06H Max. 10mV P0159 21H 87H Min. 10mV/500ms P1167 22H 87H Min. 10mV P1166 23H 07H Max. 10mV P0158 24H 07H Max. 10mV P0032 29H 08H Max. 20mV P0031 2AH 88H Min. 20mV P0052 2BH 09H Max. 20mV P0051 2CH 89H Min. 20mV P0038 2DH 0AH Max. 20mV P0037 2EH 8AH Min. 20mV P0058 2FH 0BH Max. 20mV P0057 30H 8BH Min. 20mV

ACC-1 ACCELERATOR

SYSTEM B ENGINE CONTENTS C D E F G H I J K L M SECTION ACC A ACC Revision; 2004 April 2003 FX ACCELERATOR CONTROL SYSTEM ACCELERATOR CONTROL SYSTEM ......................2 Removal and Installation ..........................................2 REMOVAL .............................................................2 INSTALLATION .....................................................2 INSPECTION AFTER INSTALLATION .................2

CONTROL

REMOVAL

1.Disconnect accelerator pedal position sensor harness connector.

2.Loosen nuts, and remove accelerator pedal assembly.

CAUTION:

● Do not disassemble the accelerator pedal assembly. Do not remove the accelerator pedal position sensor from the accelerator pedal assembly.

● Avoid impact from dropping etc. during handling.

● Be careful to keep the accelerator pedal assembly away from water.

INSTALLATION

Install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

● Check that the accelerator pedal moves smoothly within the whole operation range.

● Check that the accelerator pedal securely returns to the original position.

● For the electrical inspection of the accelerator pedal position sensor, refer to EC-1247, "DTC P2138 APP SENSOR"

CAUTION:

When the harness connector of the accelerator pedal position sensor is disconnected, perform ″Accelerator Pedal Released Position Learning″. Refer to EC-703, "Accelerator Pedal Released Position Learning" .

ACC-2

Revision; 2004 April 2003 FX ACCELERATOR CONTROL SYSTEM PFP:18005 Removal and Installation ABS005ZA

ACCELERATOR CONTROL SYSTEM

SBIA0332E

1.Accelerator pedal assembly

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

AUTO CRUISE CONTROL SYSTEM

ACS-1

K ELECTRICAL CONTENTS C D E F G H I J L M SECTION ACS A B ACS Revision; 2004 April 2003 FX AUTO CRUISE CONTROL SYSTEM ASCD AUTOMATIC SPEED CONTROL DEVICE (ASCD).....3 Description ...............................................................3 ICC PRECAUTIONS ..........................................................4 Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER” ..................................................................4 Precautions for ICC System Service ........................4 Wiring Diagrams and Trouble Diagnosis ..................4 PREPARATION ...........................................................5 Special Service Tools ...............................................5 DESCRIPTION ............................................................6 Outline ......................................................................6 VEHICLE-TO-VEHICLE DISTANCE CONTROL MODE ...................................................................6 CONVENTIONAL (FIXED SPEED) CRUISE CONTROL MODE .................................................6 BRAKE ASSIST (WITH PREVIEW FUNCTION).....6 System Diagram .......................................................6 Components Description ..........................................7 CAN Communication ................................................7 CAN COMMUNICATION UNIT FOR 2WD MODEL .................................................................7 CAN COMMUNICATION UNIT FOR AWD MODELS ......................................................................11 Switch Operation ....................................................16 ICC System Display ...............................................16 ACTION TEST ..........................................................17 ICC System Running Test ......................................17 VEHICLE-TO-VEHICLE DISTANCE CONTROL MODE .................................................................17 CONVENTIONAL (FIXED SPEED) CRUISE CONTROL MODE ...............................................18 LASER BEAM AIMING ADJUSTMENT ...................20 Outline ....................................................................20 Preparation .............................................................20 Outline of Adjustment Procedure ...........................20 Setting the ICC Target Board ..................................20 ADJUSTING HEIGHT OF THE TARGET ............20 ADJUSTING THE RIGHT-LEFT POSITION OF THE TARGET ......................................................21 SETTING THE TARGET .....................................21 Aiming Adjustment ..................................................22 CHECK AFTER THE ADJUSTMENT ..................25 ELECTRICAL UNITS LOCATION ............................26 Component Parts and Harness Connector Location...26 WIRING DIAGRAM ...................................................27 Schematic ...............................................................27 Wiring Diagram — ICC — ......................................28 TERMINALS AND REFERENCE VALUE .................35 Terminals and Reference Value for ICC Unit ..........35 Terminals and Reference Value for ICC Sensor .....36 TROUBLE DIAGNOSIS — GENERAL DESCRIPTION ..........................................................................37 Work Flow ...............................................................37 CONSULT-II Function .............................................38 DESCRIPTION ....................................................38 CONSULT-II INSPECTION PROCEDURE ..........38 WORK SUPPORT ...............................................39 SELF-DIAGNOSTIC RESULTS ...........................39 DATA MONITOR .................................................40 ACTIVE TEST .....................................................41 Self-Diagnostic Function .........................................43 WITH CONSULT-II ..............................................43 WITHOUT CONSULT-II .......................................43 SELF-DIAGNOSIS BY ICC SYSTEM DISPLAY WILL NOT RUN. ..................................................44 TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS ........................................................................47 Diagnostic Trouble Code (DTC) Chart ...................47 DTC 11 CONTROL UNIT .......................................48 DTC 20 CAN COMM CIRCUIT ...............................48 DTC 31 POWER SUPPLY CIR 1, DTC 34 POWER SUPPLY CIR 2 .......................................................49 DTC 41 VHCL SPEED SE CIRC ............................49 DTC 43 VDC/TCS/ABS CIRC ................................50 DTC 45 BRAKE SW/STOP L SW ...........................50

Symptom 3: The ICC System Cannot Be Operated by the CANCEL Switch, ACCEL/RES Switch, or DISTANCE Switch.. ................................................68

Symptom 4: The ICC System Is Not Cancelled When the Gear Is in Other Than ‘D’

Symptom 6: Driving Force Is Hunting

Symptom 7: The ICC System Frequently Cannot Detect the Vehicle Ahead/The Detection Zone Is Short

Symptom 8: The System Does Not Detect the Vehicle

ACS-2 Revision; 2004 April 2003 FX

.............................52

PRESS

CIRCUIT ..............................53

......................54

CIRCUIT ...........................55

65 PRESSURE CONTROL ............................56 DTC 74 LASER BEAM OFF CNTR ........................56 DTC 90 STOP LAMP RLY FIX ...............................57 DTC 92 ECM CIRCUIT ...........................................61 DTC 96 NP RANGE ...............................................62 DTC 97 AT CIRCUIT ..............................................63 DTC 98 GEAR POSITION ......................................63 DTC 102 RADAR STAIN ........................................64 DTC 103 LASER SENSOR FAIL ............................65 DTC 104 LASER AIMING INCMP ..........................65 DTC 107 LASER COMM FAIL ................................65 DTC 109 LASER HIGH TEMP ...............................65 TROUBLE DIAGNOSIS FOR SYMPTOMS ..............66 Symptom Chart .......................................................66

1: ON/OFF Switch Does Not Switch ON*1 , ON/OFF Switch Does Not Switch OFF*2 ..............67

2: The ICC System Cannot Be Set (ON/ OFF Switch Turns On/Off). .....................................67

DTC 46 OPERATION SW CIRC

DTC 61

SEN

DTC 62 BOOSTER SOL/V CIRCUIT

DTC 63 RELEASE SW

DTC

Symptom

Symptom

......................69

........................69 Symptom 5: Chime Does Not Sound

.....................70

Ahead at

.......................................................70 ELECTRICAL COMPONENT INSPECTION .............72 ICC Steering Switch ................................................72 ICC Brake Switch and Stop Lamp Switch ...............72 Booster Solenoid .....................................................72 Release Switch .......................................................73 REMOVAL AND INSTALLATION ..............................74 ICC Unit ..................................................................74 ICC Sensor .............................................................74 ICC Steering Switch ................................................74

.......................................................................70

All

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

[ASCD] AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Description

Regarding the information for ASCD system, refer to EC-657, "AUTOMATIC SPEED CONTROL DEVICE (ASCD)" (VQ35DE), EC-1329, "AUTOMATIC SPEED CONTROL DEVICE (ASCD)" (VK45DE).

ACS-3 [ASCD] C D E F G H I J L M A B ACS Revision; 2004 April 2003 FX

PFP:18930

AKS007XN

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

AKS007IE

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted. Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag Module, see the SRS section.

● Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

Precautions for ICC System Service

● Do not look straight into the laser beam discharger when adjusting laser beam aiming.

AKS006Y8

● Turn the ON/OFF switch OFF in conditions similar to driving, suchlike Free rollers or Chassis dynamometer.

● Do not use the ICC sensor removing from vehicle, disassemble, or remodel the sensor.

● Erase DTC when replacing parts of ICC system, then check the operation of ICC system after adjusting laser beam aiming if necessary.

Wiring Diagrams and Trouble Diagnosis

When you read wiring diagrams, refer to the followings:

● Refer to GI-15, "How to Read Wiring Diagrams" in GI section

● Refer to PG-3, "POWER SUPPLY ROUTING CIRCUIT" for power distribution circuit in PG section

When you perform trouble diagnosis, refer to the followings:

● Refer to GI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES" in GI section

● Refer to GI-27, "How to Perform Efficient Diagnosis for an Electrical Incident" in GI section

AKS006Y9

ACS-4 [ICC] PRECAUTIONS Revision; 2004 April 2003 FX [ICC] PRECAUTIONS PFP:00001

PREPARATION

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number (Kent-Moore No.)

Tool name Description

KV99110100 (J-45718) ICC target board Laser beam aiming adjustment

PREPARATION ACS-5 [ICC] C D E F G H I J L M A B ACS Revision; 2004 April 2003 FX

PFP:00002

AKS006YA

PKIA0358J

DESCRIPTION

Outline

The Intelligent Cruise Control (ICC) system automatically maintains a selected distance from the vehicle ahead according to that vehicle's speed, or at the set speed, if the road ahead is clear.

The ICC function has two cruise control modes and brake assist (with preview function).

VEHICLE-TO-VEHICLE DISTANCE CONTROL MODE

Vehicle-to-vehicle distance control mode, the same speed as other vehicles can be maintained without the constant need to adjust the operating speed as with a normal cruise control system.

The system is intended to enhance the operation of the vehicle when following another vehicle in the same lane and direction.

If the distance sensor detects a slower moving vehicle ahead, the system will reduce speed so that the vehicle ahead can be followed at the selected distance.

The system automatically controls the throttle and applies the brakes (up to 25% of vehicle braking power) if necessary.

The detection range of the sensor is approximately 390 ft (120 m) ahead.

CONVENTIONAL (FIXED SPEED) CRUISE CONTROL MODE

Conventional (fixed speed) cruise control mode is cruising at preset speeds.

BRAKE ASSIST (WITH PREVIEW FUNCTION)

When the force applied to brake pedal exceeds a certain level, the Brake Assist is activated and generates a greater braking force than that of a conventional brake booster even with light pedal force.

When the Preview Function identifies the need to apply the sudden brake by sensing the vehicle ahead in the same lane and the distance and relative speed from it, it applies the brake pre-pressure before driver depress the brake pedal and improves brake response by reducing its free play.

Refer to Owner's Manual for Intelligent Cruise Control System operating instructions.

System Diagram

ACS-6 [ICC]

Revision; 2004 April 2003 FX

DESCRIPTION

PFP:00000

AKS006YB

AKS006YC SKIA5972E

Components Description AKS006YD

Component

ICC unit

Vehicleto-vehicle distance control mode

Conventional (fixed speed) cruise control mode

Brake assist (with preview brake)

Description

××× Operates throttle control actuator and brake booster based on that sensor signals and CAN communication data, then controls vehicle distance.

ICC sensor ×× Irradiate laser beam, and receives reflected laser beam to measure distance from preceding vehicle.

ECM

ABS actuator and electric unit (control unit)

Brake pressure sensor

Brake booster

×× Transmits throttle position signal and ICC steering switch signal to ICC unit.

××× Transmits wheel speed signal to ICC unit.

×× Detects fluid pressure in master cylinder.

×× Adjusts brake fluid pressure, based on command from ICC unit.

BCM × Transmit front wiper request signal to ICC unit.

TCM ×× Transmits gear position signal and output shaft revolution signal to ICC unit.

CAN Communication

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle multiplex communication line with high data communication speed and excellent error detection ability. Many electric control units are equipped onto a vehicle, and each control unit shares information and links with other control units during operation (not independent). In CAN communication, control units are connected with 2 communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring. Each control unit transmits/receives data but selectively reads required data only.

CAN COMMUNICATION UNIT FOR 2WD MODEL System

Diagram

DESCRIPTION ACS-7 [ICC] C D E F G H I J L M A B ACS Revision; 2004 April 2003 FX

AKS00815

SKIA6173E

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

DESCRIPTION

Input/output Signal Chart

SignalsECMTCM

Display control unit

Low tire pressure warning control unit

ICC unit

Intelligent Key unit BCM

Steeri ng angle sensor

Unified meter and A/C amp.

ICC sensor

T: Transmit R: Receive

ABS actuator and electric unit (control unit)

Engine speed signalTRRRRR

Engine status signalTR

Engine coolant temperature signal TRRR

A/T self-diagnosis signalRT

Accelerator pedal position signal TRRR

Closed throttle position signal TR R

Wide open throttle position signal TR

Battery voltage signalTR

Driver seat control unit

IPDM E/R

Key switch signalTR

Ignition switch signalTRR

P range signalTRRR

Stop lamp switch signalRT

ABS operation signalRRT

TCS operation signalRRT

VDC operation signalRRT

Fuel consumption monitor signal TRR

Input shaft revolution signal RTR

ACS-8 [ICC]

Revision; 2004 April 2003 FX

A/C compressor request signal T R A/C relay status signalR T A/C compressor feedback signal TR Blower fan motor switch signal RT A/C control signal TR RT Cooling fan speed signalR T Position light request signal RTRR Low beam request signalTR Low beam status signalR T

Output shaft revolution signal RTR A/C switch signalRT

SignalsECMTCM

High beam request signal

High beam status signalR

Front fog light request signal

Day time running light request signal

Turn LED burnout status signal

Vehicle speed signal

Sleep wake up signal

Low tire pressure warning control unit

ICC unit

Intelligent Key unit BCM

Steeri ng angle sensor

Unified meter and A/C amp.

ICC sensor

Driver seat control unit

ABS actuator and electric unit (control unit) E/R

IPDM

Door switch signalRRTRRR

Turn indicator signalTR

Key fob ID signalTR

Key fob door unlock signal

Oil pressure switch signal

Buzzer output signal

Fuel level sensor signalRT

Fuel level low warning signal

ICC operation signalRT

Front wiper request signal

Front wiper stop position signal

Rear window defogger switch signal TR

Rear window defogger control signal RRRT

Hood switch signalRT

Theft warning horn request signal TR

Horn chirp signalTR

Steering angle sensor signal TR

Tire pressure signalTR

DESCRIPTION ACS-9 [ICC] C D E F G H I J L M A B ACS Revision; 2004 April 2003 FX

TRR

T

TR

TR

RT

RRT RRRRRRTRR

TRRR TR

TR

RT TR

TR TR TR

RT

RTR

RT

Display control unit

SignalsECMTCM

Low tire pressure warning control unit

Tire pressure data signalRT

ICC unit

Intelligent Key unit BCM

Steeri ng angle sensor

Unified meter and A/C amp.

ICC sensor

Driver seat control unit

IPDM

ABS actuator and electric unit (control unit) E/R

ABS warning lamp signalRRT

VDC OFF indicator lamp signal RRT

SLIP indicator lamp signal

Brake warning lamp signal RT

System setting signalTRR

Distance to empty signalRT

Hand brake switch signalRT

Door lock/unlock request signal TR

Door lock/unlock status signal RT

Starter permission signalTR

Back door open request signal

Power window open request signal

Alarm request signalTR

Key warning signalTR

ICC sensor signalRT

ICC warning lamp signalTR

ICC system display signal

Current gear position signal TRR

Steering switch signalTR

ASCD operation signalTR

ASCD OD cancel request TR

ICC OD cancel requestRRT

A/T CHECK indicator lamp signal

A/T position indicator lamp signal

ACS-10 [ICC]

Revision; 2004 April 2003 FX

DESCRIPTION

RT

TR

TR

TR

TR

TR

RT

A/T shift schedule change demand signal R T Manual mode signalRT Not manual mode signalRT Manual mode shift up signal

Display control unit

Display control unit

Low tire pressure warning control unit

ICC unit

Intelligent Key unit BCM

Steeri ng angle sensor

Unified meter and A/C amp.

Manual mode shift down signal RT

Manual mode indicator signal TRR

Ignition knob switch signal TR

CAN COMMUNICATION UNIT FOR AWD MODELS

System Diagram

ICC sensor

ABS actuator and electric unit (control unit)

Driver seat control unit SKIA6176E

IPDM E/R

DESCRIPTION ACS-11 [ICC] C D E F G H I J L M A B ACS Revision; 2004 April 2003 FX

SignalsECMTCM

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL