Technical Manual

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

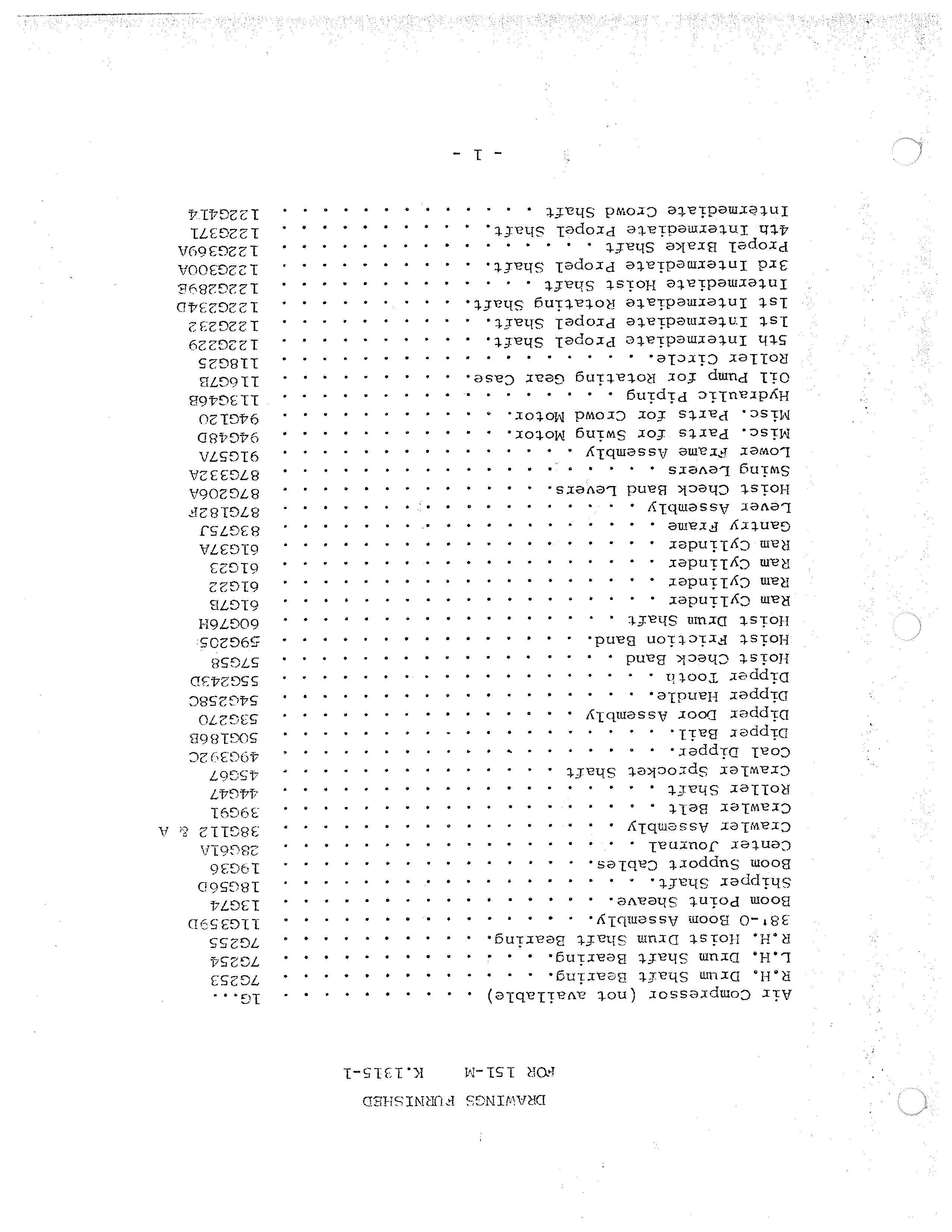

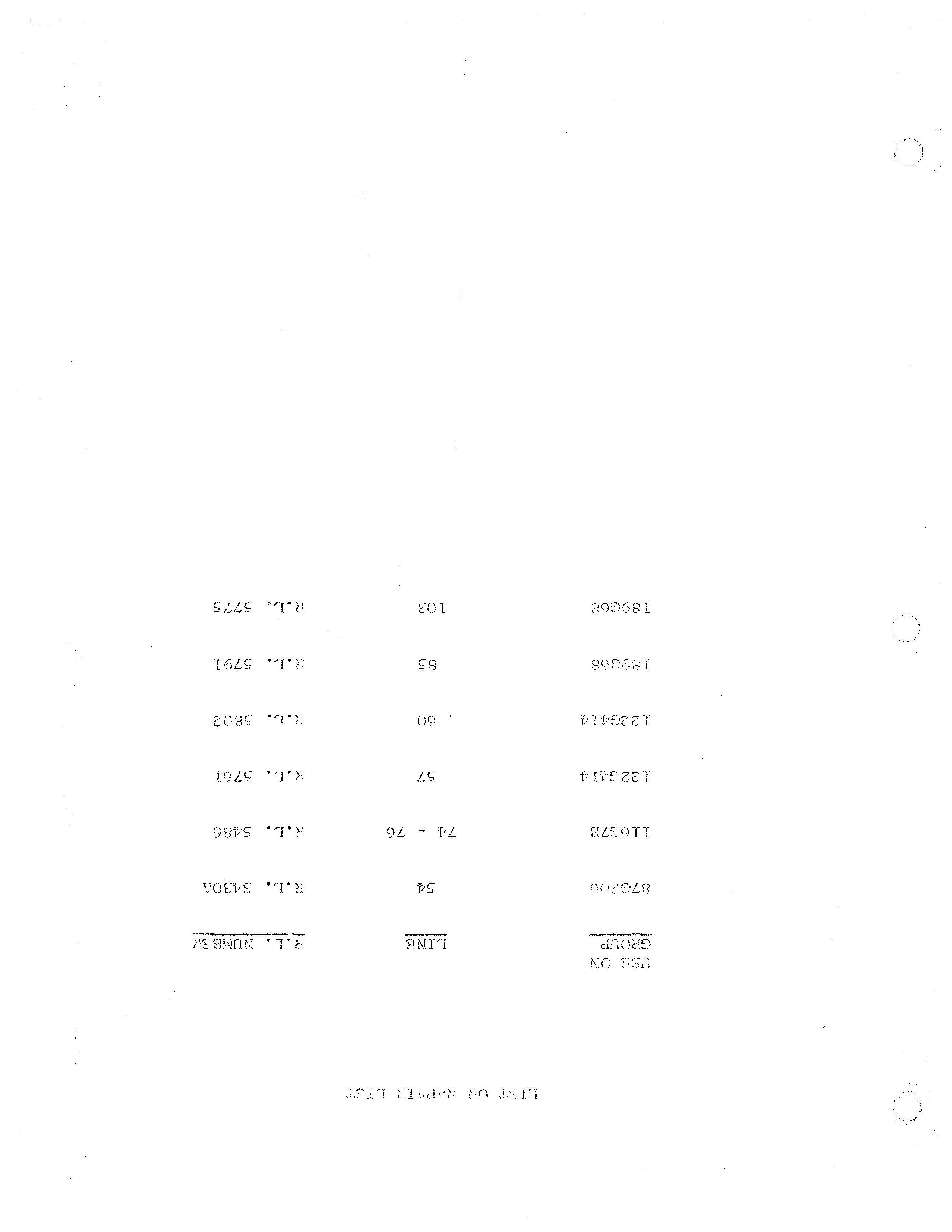

DRAVJINGS FURNISHED

FOR 151-M K.1315-1

Air Compressor (not available)

R.H. Drum Shaft Bearing •••..

L.H. Drum Shaft Bearing ••••

R.H. Hoist Drum Shaft Bearing.

38 1 -0 Boom Assembly.

Boom Point Sheave .•

Shipper Shaft ....•

Boom Support Cables.

Center Journal ..•••

Crawler Assembly.

Crawler Belt ••.

Roller Shaft •.•

Crawler Sprocket Shaft

Coal Dipper ..•

Dipper Bail.

Dipper Door Assembly

Dipper Handle. • .

Dipper Tooth ....

Hoist Check Band • •

Hoist Friction Band.

Hoist Drum Shaft

Ram Cylinder

Ram Cylinder . .

Ram Cylinder

Ram Cylinder

Gantry Frame .

Lever Assembly .

. .

Hoist Check Band Levers.

. . .

Swing Levers •.•••••.•.

Lower Frame Assembly ••

Misc. Parts £or Swing Motor •..•..

Misc. Parts for Crowd Motor.

Hydraulic Piping ••••• Oil Pump for Rotating Gear Case. Roller Circle ...•.•.•.

5th Intermediate Propel Shaft .••

1st Intermediate Propel Shaft •.

1st Intermediate Rotating Shaft •• Intermediate Hoist Shaft •..•••.

3rd Intermediate Propel Shaft ••

Propel Brake Shaft •••...

4th Intermediate Propel Shaft.

Crowd Shaft ••.

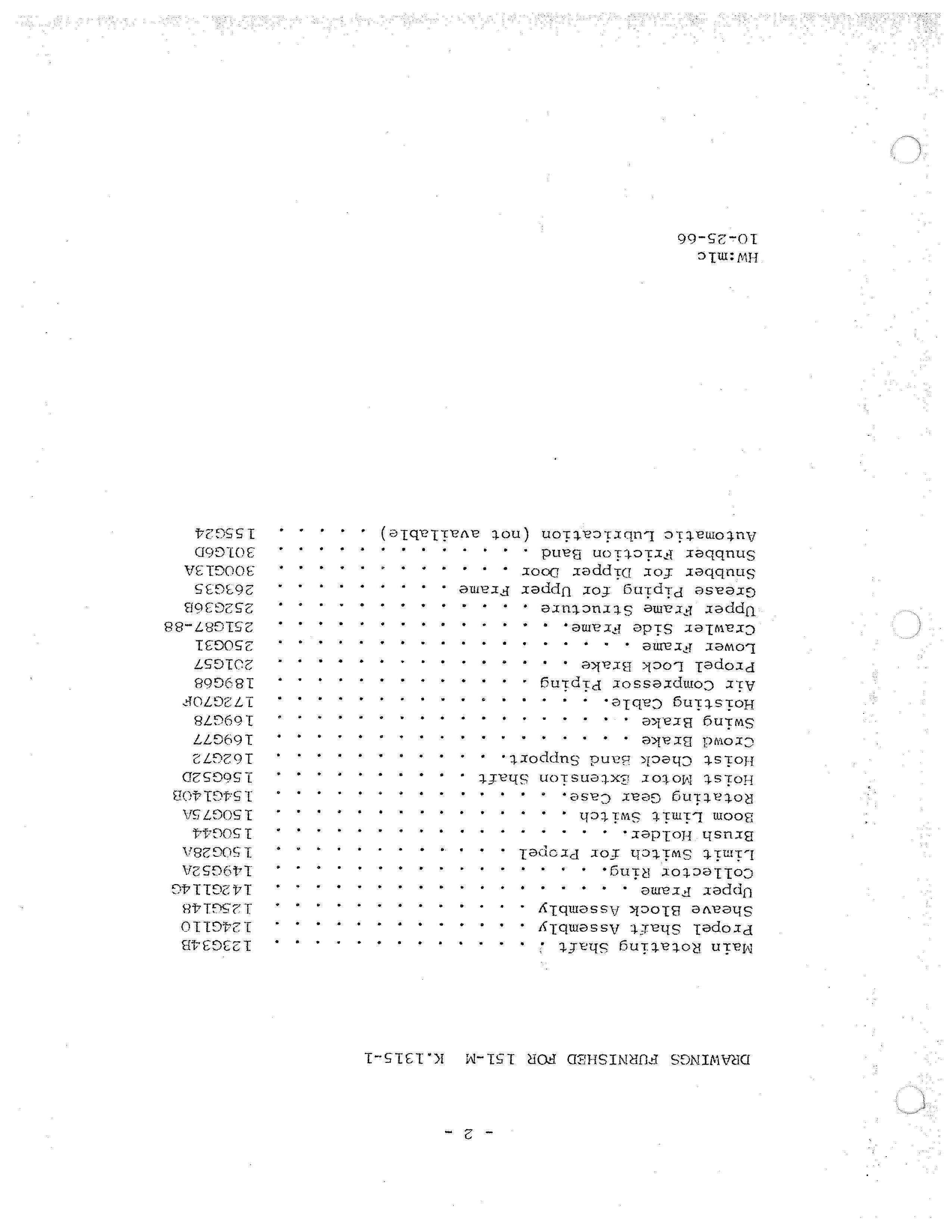

DRAWINGS FURNISHED FOR 151-M K.1315-1

Main Rotating Shaft : Propel Sha.ft Assembly

Sheave Block Assembly.

Upper Frame . • • . . •

Collector Ring •...

Limit Switch for Propel.

Brush Holder ....

Boom Limit Switch ••

Rotating Gear Case •..

Hoist Motor G:xtension Shaft .

Hoist Check ~and Support.

Crowd Brake

Swing Brake .•...

Hoisting Cable .....

Air Compressor Piping.

Propel Lock Brake.

Lower Frame •.•..

Crawler Side Frame •••.

Upper Frame Structure

Grease Piping for Upper Frame

Snubber for Dipper Door

Snubber Friction Band •...

Automatic Lubrication (not available)

GENERAL LUBRICATION

SELECTION No part of the care df your Marion machine is more OF LUBRICANTS important than proper lubrication. WITHOUT PROPER LUBRICATION, the air compressor, anti-friction bearings, finished shafts, gears and other important parts of this precision-built piece of machinery can be quickly ruined.

The lubrication specification in this manual covers the lubrication requirements of the machine when operating within an ambient temperature range from -20 degrees to 110 degrees F. If this machine is to be operated at temperatures below -20 degrees F. or greater than 110 degrees F., contact the Marion Power Shovel Company, Inc., Marion, Ohio, for special lubrication recommendations. Give full particulars concerning your condition of operation.

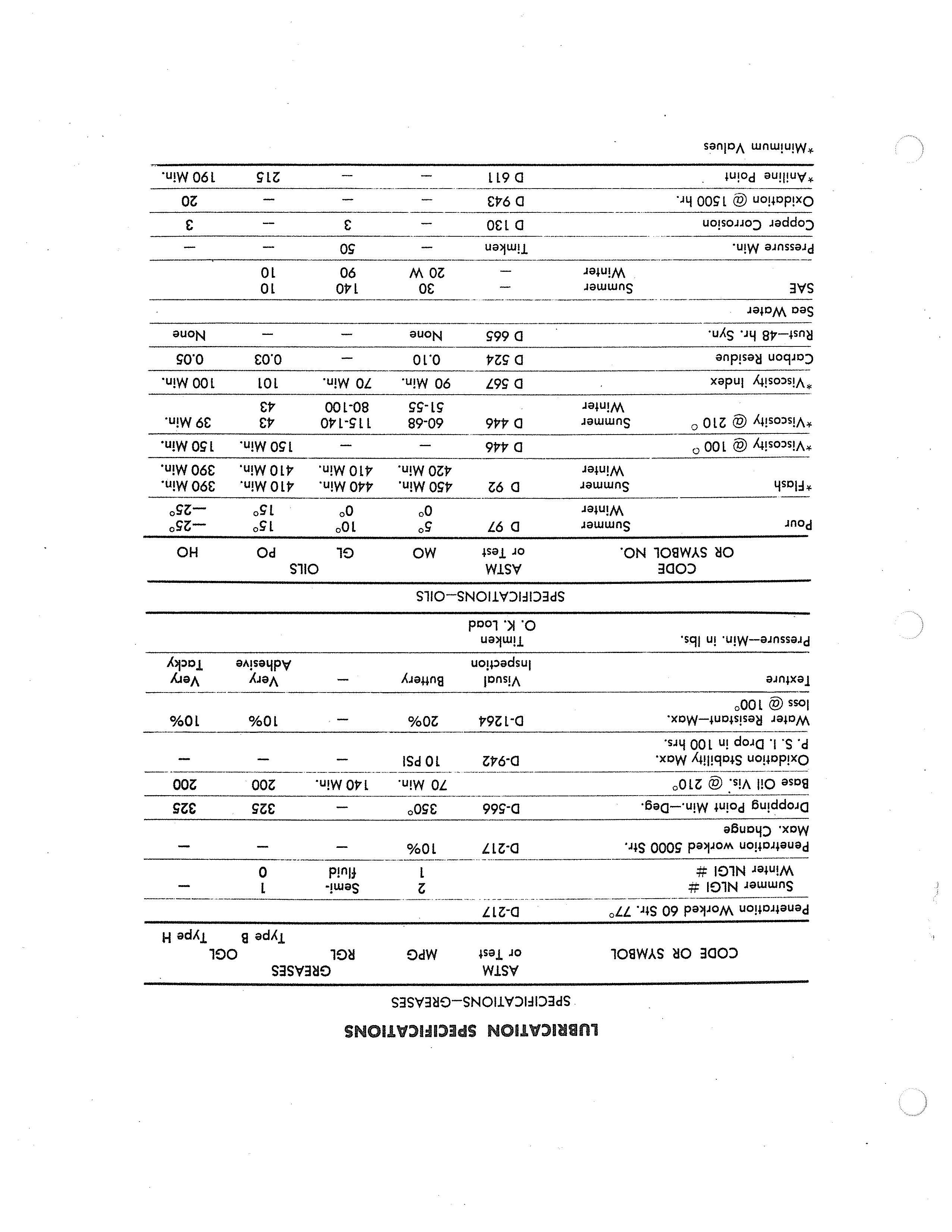

For above reasons, the lubricants recommended for this machine have been selected according to the ASTM specification standards. These standards have been compiled through the cooperation of major petroleum suppliers in order that the consumer can be supplied with the exact lubricant to fit specific requirements regardless of the source of supply.

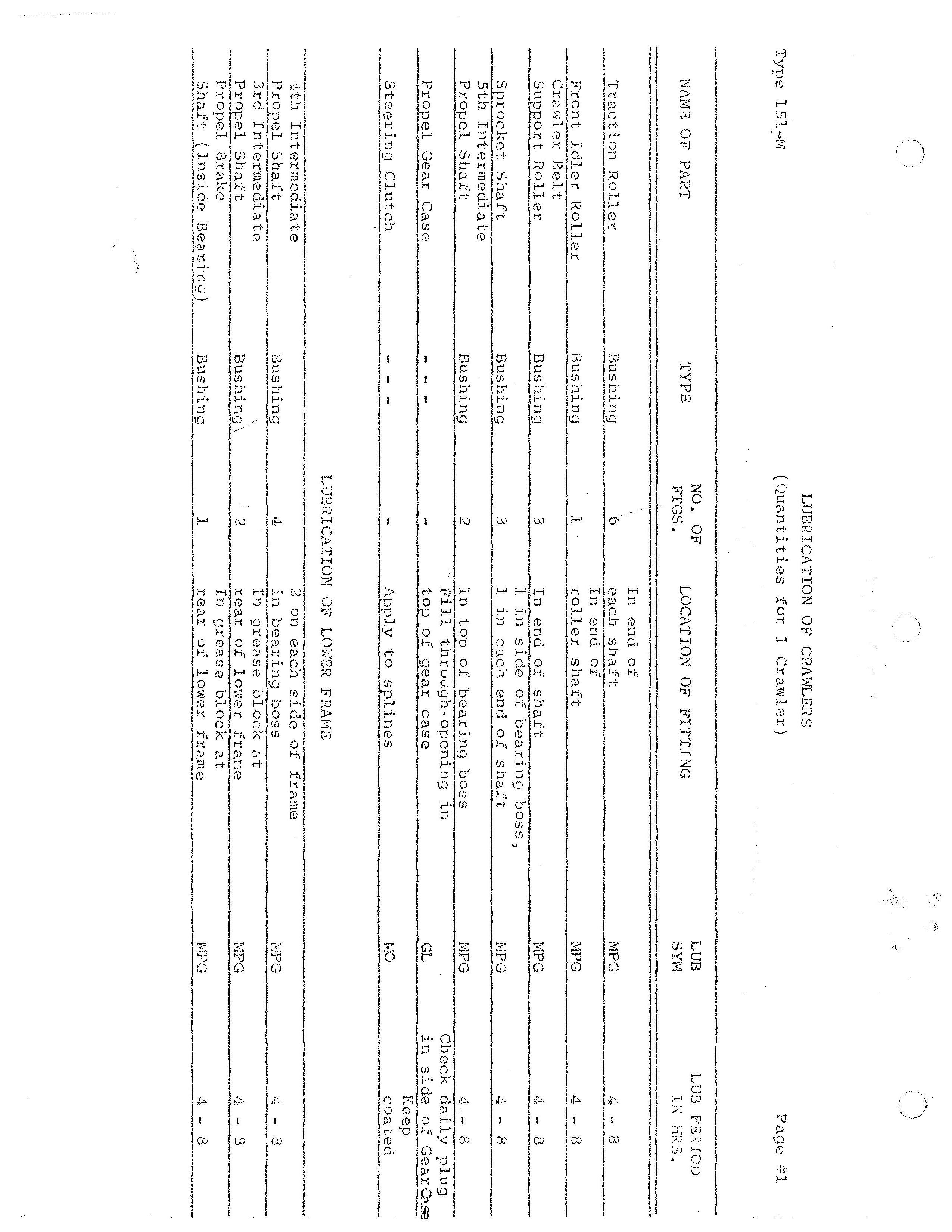

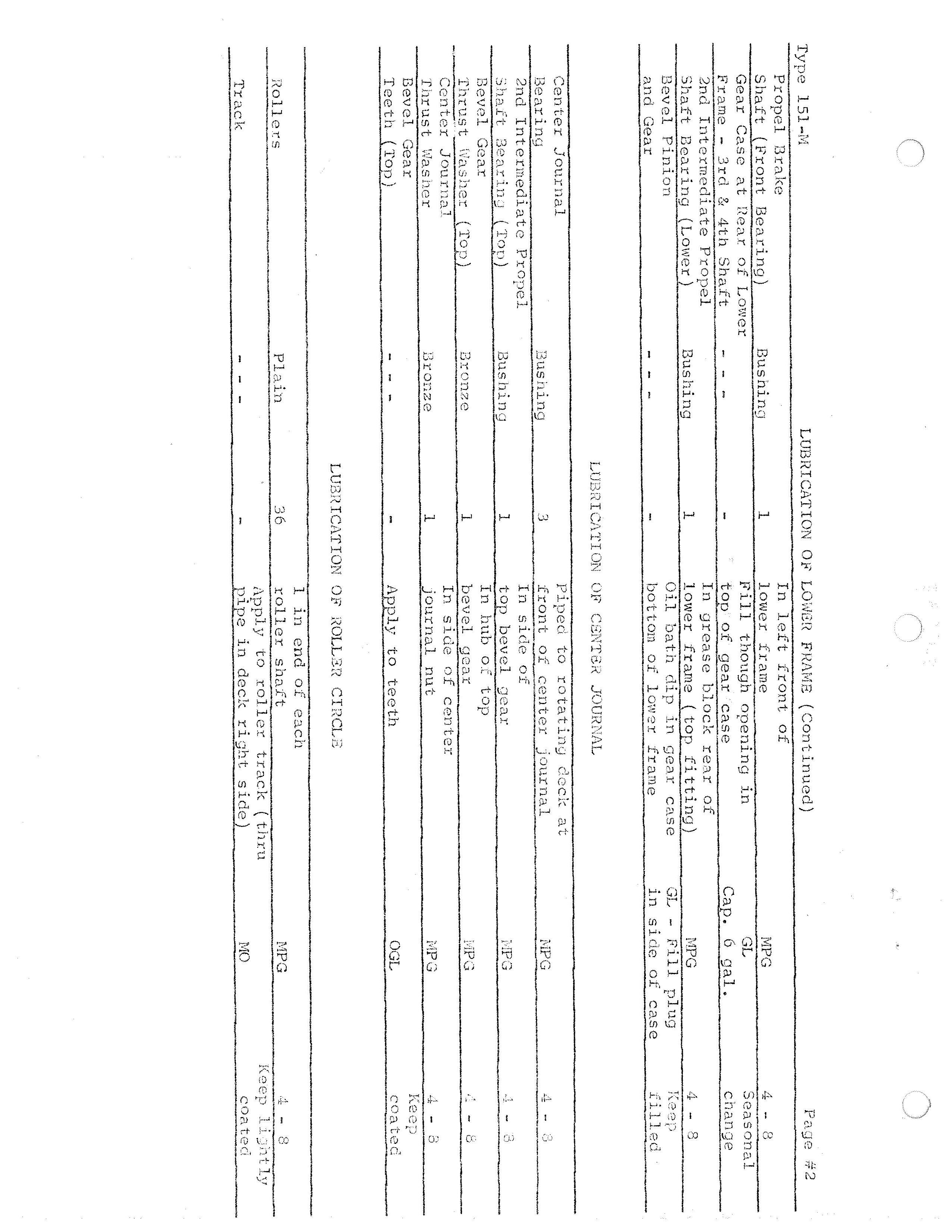

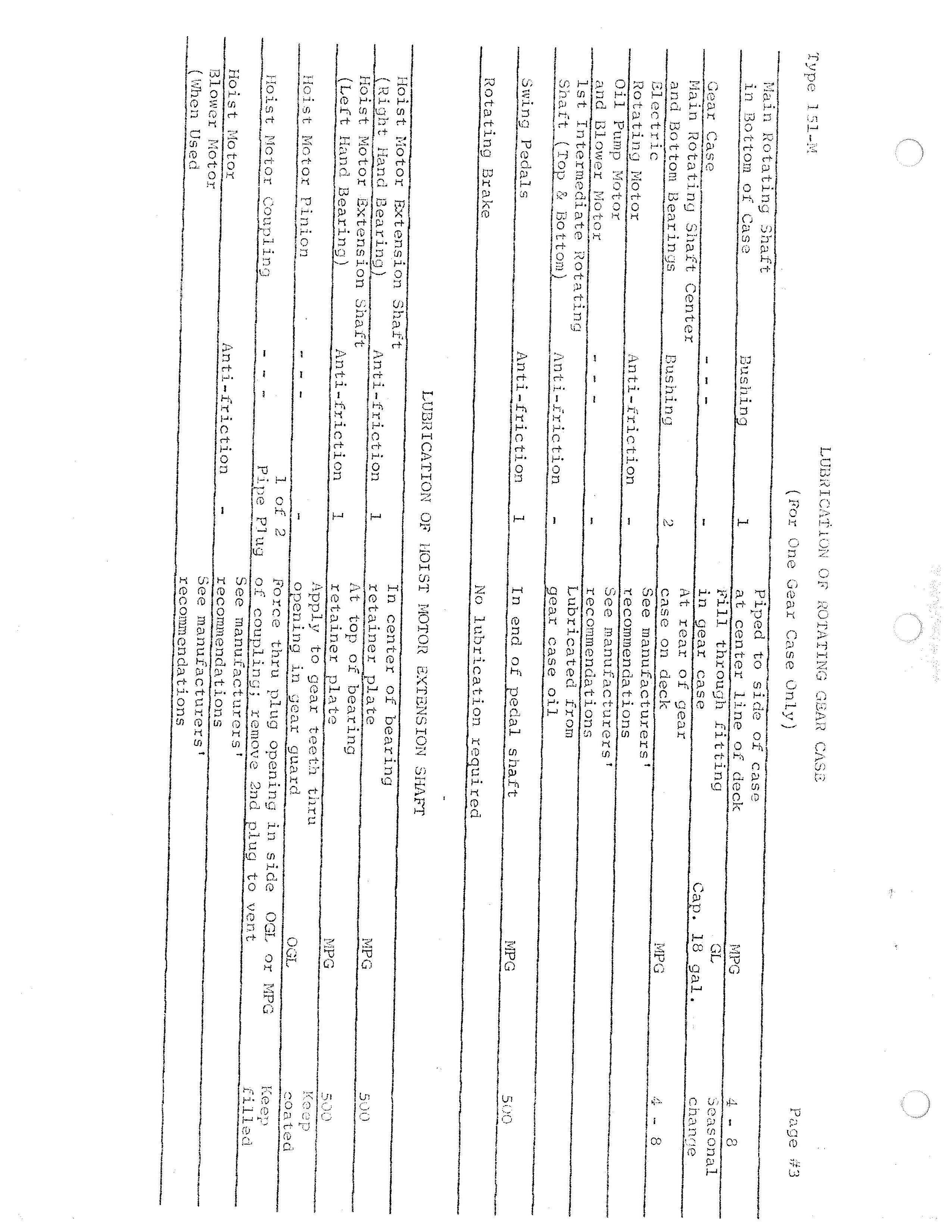

LUBRICATION FITTINGS

This machine is fitted with two types of lubrication fittings. The button head fitting for plain or bronze bushed bearings and hydraulic push-on fittings for anti-friction bearings. This way the operator can easily distinguish between anti-friction and plain bearings if he wishes to use different kinds of lubricant or to determine the frequency of lubrication.

LUBRICATION OF ANTIFRICTION BEARINGS

All roller and ball bearings on the machine should be kept about 1/3 to 1/2 fu11 of the lubricant recommended in the Lubrication Instructions. Add only enough lubricant to maintain this level. These are oil-tight bearings and the lubricant level will usually remain constant over a long period of time. Therefore, only very small quantities need be added. Unless otherwise specified, we recommend a small amount of lubricant every 500 hours which will usually maintain the desired level in the bearing of about 1/3 to 1/2 full at al 1 t i mes .

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.