Technical Manual

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

Handbook Objectives

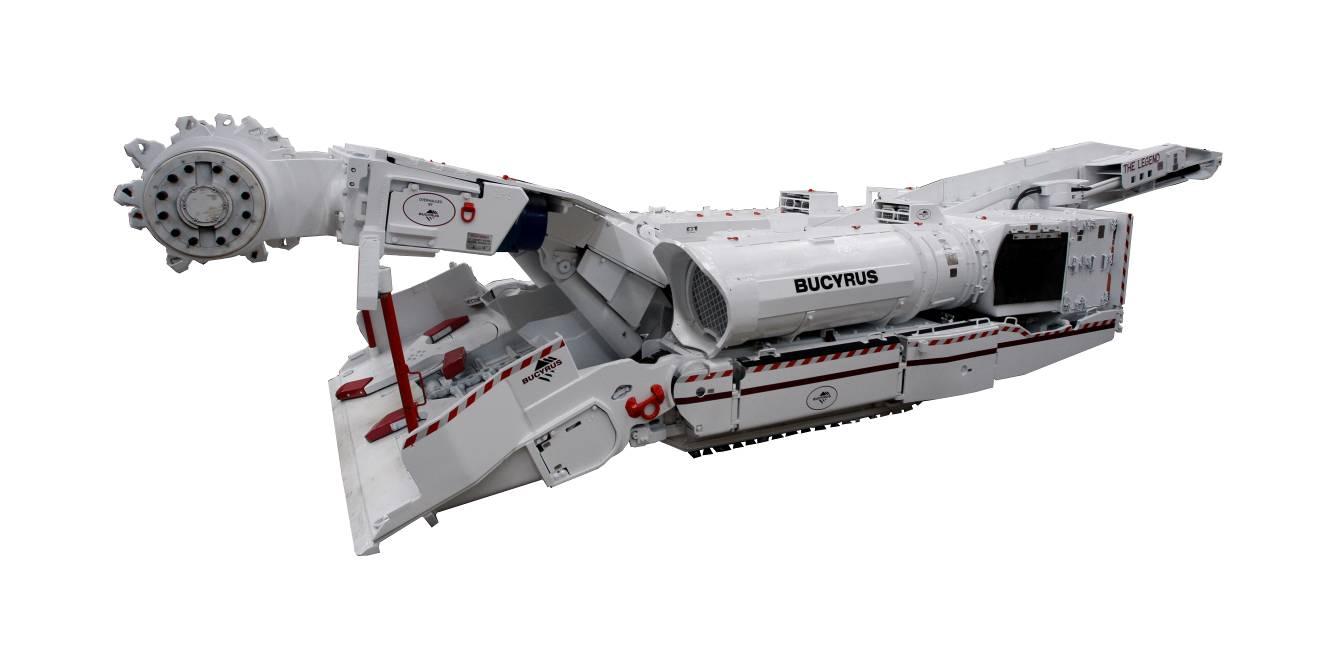

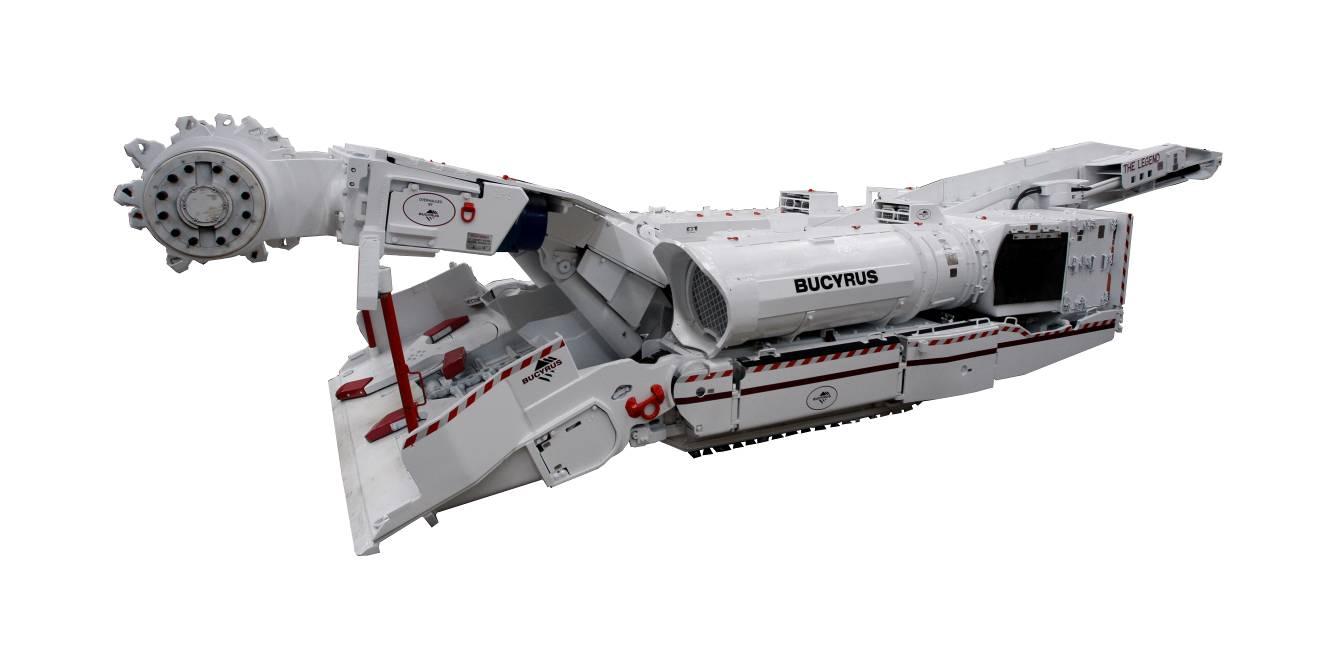

This manual is intended to provide basic operation information on Bucyrus 25M3 series continuous miners. Additional information can be obtained by referring to the Parts Book supplied with your machine, or by contacting your local Bucyrus representative. The illustrations, descriptions and procedures contained in this manual pertain to the machine as it was originally manufactured and delivered to your mine and when the manual was approved for printing.

While this manual attempts to anticipate the most important operations and maintenance needs for this equipment, unforeseen circumstances may arise that have not been addressed in this manual. If any concerns or questions arise, please contact your Bucyrus Australia Service Representative immediately.

Emergency Shutdown

In the event of an emergency, the miner can be shutdown in a number of ways.

1. The electrical power is removed from all drive motors, resulting in all moving parts coming to rest and the tram brakes being applied.

a) By toggling the STOP key on the radio transmitter.

b) By operating either side E/Stops.

c) By operating the handle of the main circuit breaker to the OFF position.

2. Following a 2 second time delay for this function to active, the electrical power is removed from all drive motors resulting in all moving parts coming to rest and the tram brakes being applied.

a) By toggling the [SHIFT] key on the radio transmitter to the OFF position for (2) two seconds.

NOTE: This is not an instantaneous shutdown. There is a 2 second time delay.

Transmitter Stops

Emergency Procedures

Below are generic emergency procedures. Mine site specific procedures are to be followed for all emergencies.

Fire

In the case of fire on or around the miner:

1. Stop all face equipment immediately.

2. Have the power to the face isolated at the D.C.B.

3. If it is safe to do so, retrieve the fire extinguisher from the miner and move to the intake side of the fire zone.

4. If it is not safe, then collect an extinguisher from the nearest location.

5. Attempt to extinguish the fire from the intake side. If unable to extinguish the fire, commence mine fire fighting procedures. ©

6. If able to extinguish the fire:

• Do not attempt to move the miner

• Place a “Danger Tag” on the miner and the D.C.B.

• Advise the Mining Official and the control room immediately.

NOTE: The miner should be equipped with one (1) dry chemical fire extinguisher with a rating of 80 BE. Always check that it is serviceable as part of the miner’s pre-start checks. Report any deficiencies.

General

The Coal Mining Act defines an “emergency situation” as any set of circumstances occurring at a mine which involves the loss of life, or injury to any person, or a real or apparent immediate danger of the loss of life of or injury to any person and which requires a co-ordinated response.

If a person becomes aware of any situation which requires, or may require, prompt first aid and/or emergency assistance, that person should put into effect the emergency procedure at the mine to report the incident.

NOTE: Refer to the mine’s procedures. Do not hang up immediately as you may be required to give further information or receive instructions on dealing with the emergency.

MINIMISE THE USE OF COMMUNICATION SYSTEMS TO LEAVE THE LINES CLEAR FOR EMERGENCY COMMUNICATIONS TRAFFIC.

Troubleshooting

Pumps

There are a number of safety and machine protection interlocks that will stop the machine pumps or prevent it from starting:-

• Transmitter must be logged on

• Machine Emergency Stop is operated

• Electronic Module fault

• Lost radio signal

• Pump overload (4 min.reset)

• Over-temperature (RTD) fault

• Incorrect Transmitter frequency

NOTE: Turning off power to the miner or control circuits will not reset the 4 minute overload reset timers. If power is removed during an overload reset time period, the reset timer will restart at the time remaining when power was removed.

Traction

There are a number of safety and machine protection interlocks that prevent tramming.

• Pumps - these have to be running.

• Earth leakage detected in traction circuit.

• Traction transformer over-temperature (RTD) has tripped.

• Either left or right traction motors have overloaded (Reset time is 4 minutes).

• A shutdown in SCR traction drives electronics.

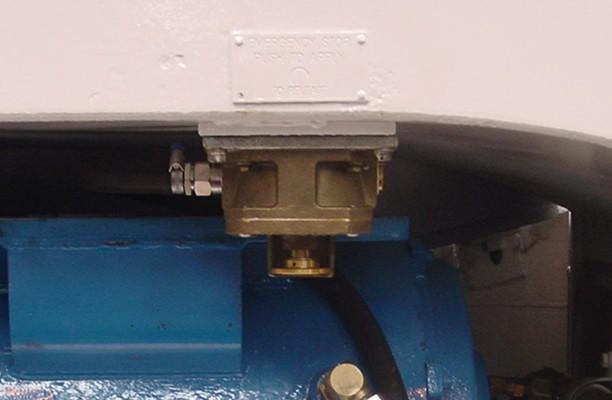

• Deadman pressure - the brake solenoid has not operated or the pressure switch is closed. This has to be energised to allow tramming.

• Traction circuit breakers tripped.

• Traction transformer Overload trip. (Reset time is 4 minutes).

If any of these conditions are not satisfied, a corresponding message will be displayed.

NOTE: Turning off power to the miner or control circuits will not reset the 4 minute overload reset timers. If power is removed during an overload reset time period, the reset timer will restart at the time remaining when power was removed.

©

Cutters

There are a number of safety and machine protection interlocks that prevent the cutters from being started, or stop them if they are already operating:

• Pumps - these have to be running.

• Either left or right cutter motor has overloaded (i.e. the motor current is too high). Reset time is 4 minutes.

• Either left or right cutter motor over-temperature (RTD) has tripped.

• Water spray for cutter head has failed (low flow) or has been turned off.

• Tramming SPEED 2 or SPEED 3 has been selected whilst in reverse.

• Low oil level

• High oil temperature.

• Variation above 50% between current of each cutter motor.

• The machine has to be in mining mode not flit mode.

NOTE: Turning off power to the miner or control circuits will not reset the 4 minute overload reset timers. If power is removed during an overload reset time period, the reset timer will restart at the time remaining when power was removed.

Conveyor

There are a number of safety and machine protection interlocks that prevent the conveyor from being started, or stop it when it has already been started.

• Pumps - these have to be running.

• Gathering Heads reverse has to be stopped, to start the gathering heads in forward.

• Gathering Heads forward has to be stopped, to start the gathering heads in reverse.

• Either left or right gathering head motor is overloaded (i.e. the motor current is too high).

• Either left or right gathering head motor over-temperature (thermistor) has tripped.

• Variation of 50% in motor currents.

• The machine has to be in mining mode not flit mode.

NOTE: Turning off power to the miner or control circuits will not reset the 4 minute overload reset timers. If power is removed during an overload reset time period, the reset timer will restart at the time remaining when power was removed.

Water Troubleshooting Guide

PROBLEM: Lack of water reaching miner - water sprays

IS WATER FROM REEL CONNECTED TO MINER?

NO

CONNECT HOSE AND OPEN WATER VALVE

CORRECT WATER PRESSURE AT MINER? 100 PSI MINIMUM.

YES

I E S WATER PRESSUR AT HOSE REEL

MECHANICAL SKILLS REQUIRED

I SING T FI W AT W

CLEAN FILTER IS WATER FLOW PASSING THROUGH INLET FILTER? CHECK FLOW AT WASH DOWN HOSES

S WATERFLOW PAS HROUGH INLET BAG LTER.CHECK FLO ASHDOWN HOSES?

IS WATER PASSING THROUGH PILOT OPERATED WATER VALVES?

ARE MINER WATER SPRAYS OPERATING

YES YES NO NO NO NO

REPLACE FILTER BAG

MECHANICAL SKILLS REQUIRED

REFER HYDRAULIC SHEET

NOTES TO THE OPERATOR

Notes, Cautions and Warnings

ALL applicable Notes, Cautions and Warnings listed in this Manual are to be included in the support documents following the same format as defined below.

Follow Notes, Cautions and Warnings found in the handout.

NOTE: Indicates a procedure or condition that is essential for the operator to know.

CAUTION: Indicates an action or condition that, if not followed, could cause damage to the vehicle or other equipment.

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.