Operation and Maintenance Manual

MD6750 Blast Hole Drill

Serial Number D711136 / 2Z71A16 R

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

MD6750 Blast Hole Drill

Operation and Maintenance Manual

SN; 2Z71A16

–Table of Contents–

This manual is divided into major sections covering the various serviceable components and systems of the MD6750 Blast Hole Drill. These sections and their contents are organized as shown below.

Section 1 -INTRODUCTION

Section 2 -OPERATION

Section 3 -LUBRICATION

Section 4 -PREVENTIVE MAINTENANCE

Section 5 -SERVICE PROCEDURES

Section 6 -BRAKES AND COUPLINGS

Section 7 -COMPRESSED AIR SYSTEM

Section 8 -AIR FILTRATION

Section 9 -ENGINEERING DATA

Section 10 -SCHEMATICS

DANGER:

THIS MANUAL PROVIDES INFORMATION AND DATA FOR THE MAINTENANCE AND OPERATION OF THIS MACHINE. ALL ELECTRICAL EQUIPMENT MUST BE SERVICED BY QUALIFIED INDIVIDUALS WHO HAVE BEEN PROPERLY TRAINED TO WORK WITH HIGH VOLTAGE SYSTEMS, AND/OR VARIABLE FREQUENCY AC DRIVES. FAILURE TO COMPLY COULD RESULT IN PERSONAL INJURY OR DEATH.

DANGER:

DO NOT ATTEMPT MECHANICAL OR ELECTRICAL MAINTENANCE ON THIS MACHINE WITHOUT A FULL UNDERSTANDING OF EACH COMPONENT’S OPERATION AND FUNCTION. COMPONENTS UTILIZING ELECTRICAL POWER, AIR PRESSURE, HYDRAULIC PRESSURE AND COMPRESSION OR TENSION SPRINGS FOR OPERATION MUST BE DEACTIVATED AND ISOLATED PRIOR TO DISASSEMBLY.

The FEEDER CABLE must contain a provision for a ground connection, especially whenever 2,300 volts or greater are used. At the substation, the power line must terminate (see paragraph on ground circuits) to a suitable permanent ground. At the machine, the power line must securely terminate through a bolted connection to the machine frame. This provides a constant ground for the machine and its electrical equipment. Failure to provide this adequate ground endangers employees and equipment.

THE NEED FOR A POWER LINE GROUNDING CIRCUIT ADEQUATE FOR THE MACHINE CANNOT BE OVEREMPHASIZED. Without a good grounding system, high voltages exist between the machine and the ground. The portable trail cable and power lines supplying electric energy to the machine must have a ground wire, ample in capacity, running parallel to the main wires over the entire distance from the transformer to the machine. A suitable grounding system must be used at the transformer. Consult your local electrical supplier for details.

DANGER:

DUE TO THE INHERENT DANGERS IN THE OPERATION OF HIGH VOLTAGE ELECTRICAL EQUIPMENT, A SAFE GROUNDING SYSTEM IS REQUIRED THAT INCLUDES GROUND CONDUCTORS IN THE CABLE, A NEUTRAL GROUNDING RESISTOR, AND RELATED RELAYS AND SWITCHGEAR. A GROUND CONTINUITY CHECK SYSTEM IS ALSO RECOMMENDED.

Section 1 Introduction

GENERAL INFORMATION

This manual is designed to assist the owner in the operation of this machine. By following easy to understand step-by-step procedures, the operators and maintenance personnel can perform all tasks in a safe manner. When a systematic and thorough maintenance/service procedure is used for this machine, a minimum of unplanned downtime and more reliable operation will result.

Safe operation of the machine minimizes production delays and costly damage to equipment. Carefully study and follow all recommended procedures in this manual. Safety guidelines are intended to prevent accidents from occurring and are provided in the interest of all mine personnel. Overall safety depends upon the use of good judgment and the alertness of the entire mining crew.

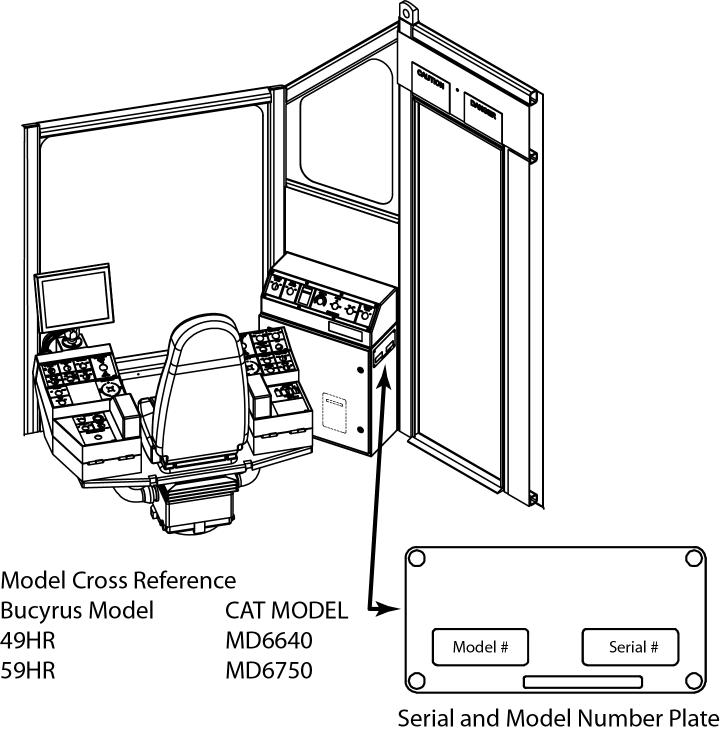

Throughout this manual, the use of the terms “LEFT, RIGHT, FRONT, and REAR” refer to machine locations as viewed by the operator sitting in the operator’s seat in the cab.

THIS MANUAL IS NOT THE PARTS BOOK, and cannot be used as reference material to order parts. A separate, detailed parts book has been supplied for this purpose.

Periodic additions or revisions may be made to this manual. Should you require additional information or factory service assistance, contact your regional service representative or:

Caterpillar Global Mining, LLC

Mining Products Division

3501 S FM 1417

Denison, TX 75020

903-786-9621

The company reserves the right to make changes or add improvements to its machines at any time. This will be without incurred obligations to install such changes on machines sold previously. Due to this ongoing program of product research and development, some procedures, specifications and parts may be altered in a constant effort to improve our machines.

The safety alert symbols displayed here, and throughout this manual, call attention to instructions concerning personal safety. Carefully read and follow these instructions and observe all CAUTION and DANGER placards mounted at various locations on the machine.

Be certain anyone servicing this machine is aware of these SAFETY SYMBOLS and their definition. In the event you question your ability to safely perform any of the enclosed maintenance and operational procedures contact your regional Caterpillar Global Mining service representative or the factory.

The following defines distinctions between safety instructions. In all these definitions the safety alert symbols is used.

NOTE: Denotes required information pertaining to the equipment. A loss of time and assets, or a minor injury can result if the appropriate action is not taken.

CAUTION: Serves as a reminder of safety practices, or directs attention to specific safety practices which could prevent possible injury.

DANGER:Denotes an imminently dangerous hazard which could result in death, bodily injury, or serious damage to equipment if appropriate action is not taken.

DANGER:Denotes an imminently dangerous electrical hazard which can result in death, bodily injury, or serious damage to equipment if appropriate action is not taken.

Operating, maintaining or servicing this machine can be dangerous unless performed properly. Each person must satisfy himself and his employer that he is alert and has the necessary skills, knowledge, tools and equipment for the task at hand. It is critical that all the methods used are safe and correct. Caterpillar Global MiningCustomer Service representatives and/or factory specialists are also available to provide additional information or technical assistance. In addition, the operator must be alert, physically fit, and free from the influence of alcohol, drugs, or any medications that might impair a person’s eyesight, hearing or reaction time.

CAUTION: STORED ENERGY! Components on machine are heavy and removal of pins without proper preparation and precaution can cause serious bodily injury and/or damage to the front-end of the machine.

Safety must always be paramount!

Consult your supervisor when safety is in doubt.

SAFETY PRECAUTIONS

General Precautions:

•The employment of qualified maintenance personnel, through a scheduled maintenance program, is the best way to minimize machine downtime and maximize productivity of equipment.

•Keep hands, feet, and clothing away from rotating parts.

•Wear a hard hat, safety shoes and protective lenses at all times.

•Replace any and all safety and warning placards if they are defaced or removed from the machine.

•Think before you act. Carelessness is one luxury the service man cannot afford.

•Excessive or repeated skin contact with sealants or solvents may cause skin irritation. In case of skin contact refer to the Material Safety Data Sheet (MSDS) for that material and the suggested method of cleanup.

•Inspect safety catches (keepers) on all hoist hooks. Do not take a chance, the load could slip off of the hook if they are not functioning properly.

•If a heavy item begins to fall, let it fall, don’t try to catch it.

•Keep your work area organized and clean. Wipe up oil or spills of any kind immediately. Keep tools and parts off of the ground. Eliminate the possibility of a fall, slipping or tripping.

•Floors, walkways and stairways must be clean and dry. After fluid draining operations be sure all spillage is cleaned up.

•Electrical cords and wet metal floors make a dangerous combination.

•Regularly inspect for any loose bolts or locking devices and properly secure them.

•Use extreme caution while working near any electrical lines or equipment whether it be high or low voltage. Never attempt electrical repairs unless you are qualified.

•Check limit switches for proper operation.

•After servicing, be sure all tools, parts or servicing equipment are removed from the machine and secured in an appropriate storage area.

•Mechanical Brakes are designed for use as static holding brakes only. Use as a motion (dynamic) brake in emergency situations only.

•Use proper interior and exterior lighting.

•Install and maintain proper grounding and ground fault protection systems.

•Perform functional tests of all safety circuits.

•Allow electrical inspection and maintenance to be performed only by a qualified electrician.

•Use extreme caution when working around drilled holes.

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.