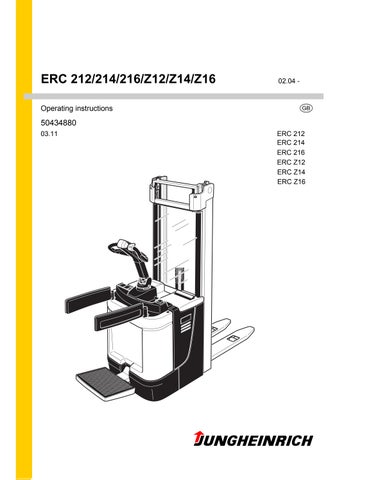

02.0403.11 50434880 ERC 212/214/216/Z12/Z14/Z16 Operating instructions G ERC 214 ERC 216 ERC Z12 ERC 212 ERC Z14 ERC Z16

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

2

Declaration of Conformity

Jungheinrich AG, Am Stadtrand 35, D-22047 Hamburg Manufacturer or his authorized representative in the Community

TypeOptionSerial No.Year of construction

ERC 212

ERC Z12

ERC 214

ERC Z14

ERC 216

ERC Z16

Additional information

Authorised signatory

Date

G EU Declaration of Conformity

The signatories hereby certify that the specified powered industrial truck conforms to the EU Directive 2006/42/EC (Machine Directive) and 2004/108/EEC (ElectroMagnetic Compatibility, EMC) including their amendments as translated into national legislation of the member countries. The signatories are individually empowered in each case to compile the technical documentation.

3

4

Foreword

Notes on the operating instructions

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide sufficient instruction for the safe operation of the industrial truck. The information is provided clearly and concisely. The chapters are arranged by letter and the pages are numbered continuously.

The operator manual details different industrial truck models. When operating and servicing the industrial truck, make sure that the particular section applies to your truck model.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to alter the design, equipment and technical features of the system. No guarantee of particular features of the truck should therefore be assumed from the present operating instructions.

Safety notices and text mark-ups

Safety instructions and important explanations are indicated by the following graphics:

DANGER!

Indicates an extremely hazardous situation. Failure to comply with this instruction will result in severe irreparable injury and even death.

WARNING!

Indicates an extremely hazardous situation. Failure to comply with this instruction may result in severe irreparable injury and even death.

CAUTION!

Indicates a hazardous situation. Failure to comply with this instruction may result in slight to medium injury.

NOTE

Indicates a material hazard. Failure to comply with this instruction may result in material damage.

Used before notices and explanations.

t Indicates standard equipment

o Indicates optional equipment

Copyright Copyright of these operating instructions remains with JUNGHEINRICH AG.

5

Z

Jungheinrich Aktiengesellschaft

Am Stadtrand 35 22047 Hamburg - Germany

Tel: +49 (0) 40/6948-0

www.jungheinrich.com

6

7 Table of Contents ACorrect Use and Application...................................................11 1General................. ...........11 2Correct application.............. ...........11 3Approved application conditions..............................................................11 4Proprietor responsibilities..... ...........12 5Adding attachments and/or accessories........... ...........12 BTruck Description....................................................................13 1Application...............................................................................................13 1.1Truck models and rated capacity............... .............13 2Assemblies and Functional Description...................................................14 2.1Assembly Overview.............. ...........14 2.2Functional Description........ ...........15 3Technical Specifications..........................................................................17 3.1Performance data........ ...........17 3.2Dimensions..............................................................................................18 3.3Weights............ ...........20 3.4Tyre type............... ...........20 3.5EN norms.................................................................................................21 3.6Conditions of use.................... ........22 3.7Electrical requirements....... ...........22 4Identification points and data plates........................................................23 4.1Data plate........ ...........24 4.2Truck load chart.......................................................................................25 4.3Capacity, wheel arm lift...........................................................................26 4.4Plate, order, inventory and service nos. .............26 CTransport and Commissioning................................................27 1Lifting by crane........................................................................................27 2Transport................ ...........28 3Using the Truck for the First Time...........................................................29 DBattery - Servicing, Recharging, Replacement.......................31 1Safety Regulations Governing the Handling of Lead-Acid Batteries.......31 2Battery types........... ...........32 3Exposing the battery................................................................................33 4Charging the battery.... ...........35

8 4.1Charging the battery with an on-board charger.......................................37 5Battery removal and installation......... ...........42 5.1Changing the battery from the top, trucks without wheel arm lift.............43 5.2Changing the battery from the top, trucks with wheel arm lift..................44 5.3Removing the battery from the side............. ...........45 EOperation............ ......................................47 1Safety Regulations for the Operation of the Forklift Truck.......................47 2Displays and Controls..............................................................................48 2.1Battery discharge indicator. ...........51 3Starting up the truck................................................................................52 3.1Checks and operations to be performed before starting daily operation.52 3.2Preparing the truck for operation............. ........53 3.3Parking the truck securely.......................................................................55 3.4Battery discharge monitor... ...........55 4Industrial Truck Operation..... ...........57 4.1Safety regulations for truck operation......................................................57 4.2Emergency Disconnect, Travel, Steering, Braking....... ...........59 4.3Lifting, transporting and depositing loads................................................64 4.4Switch Matrix / Safety Switch Height.......................................................67 5Troubleshooting............. ...........68 5.1Truck does not start.................................................................................68 5.2Load cannot be lifted.......... ...........68 6Operating the truck without its own drive system......... ...........69 7Load handler emergency lowering..........................................................71 8Optional equipment.............. ...........72 8.1CanCode keypad.....................................................................................72 8.2Parameter................................................................................................ 78 8.3CANDIS display instrument.. ...........80 FIndustrial Truck Maintenance..................................................83 1Operational Safety and Environmental Protection...................................83 2Maintenance Safety Regulations............... .............83 3Servicing and Inspection........ ........87 4Maintenance checklist.............................................................................88 5Lubricants and Lubrication Schedule................. ........91 5.1Handling consumables safely ..................................................................91 5.2Lubrication Schedule............ ...........93 5.3Consumables.......... ...........94 6Maintenance and repairs.........................................................................95 6.1Preparing the truck for maintenance and repairs......... ...........95 6.2Removing the front panel..... ...........96 6.3Checking the hydraulic oil level...............................................................97 6.4Check the gear oil level........ ...........98 6.5Tightening the wheel nuts........................................................................99 6.6Checking electrical fuses.........................................................................100 6.7Restoring the truck to service after maintenance and repairs.................101 7Safety tests to be performed at intervals and after unusual incidents.....102 8Decommissioning the industrial truck............... ...........103

9 8.1Prior to decommissioning........................................................................103 8.2Action to be taken during decommissioning................. ...........104 8.3Restoring the truck to service after decommissioning.............................105 9Final de-commissioning, disposal............................................................105 10Human vibration measurement.. .............106

10

ACorrect Use and Application

1General

The industrial truck described in the present operating instructions is designed for lifting, lowering and transporting load units.

It must be used, operated and serviced in accordance with the present instructions. Any other type of use is beyond the scope of application and can result in damage to personnel, the industrial truck or property.

2Correct application

NOTE

The maximum load and load distance are indicated on the load chart and must not be exceeded.

The load must rest on the load handler or be lifted by an attachment approved by the manufacturer.

The load must rest on the back of the fork carriage and centrally between the forks.

raised load (>500 mm).

l load units.

3Approved application conditions

and commercial environments. range +5°C to +40°C. rfaces with sufficient capacity. visible and approved by the proprietor. to a maximum of 15 %. at an angle. Transporting loads downhill.

ZSpecial equipment and authorisation are required if the truck is to be used in extreme conditions.

The truck is not author ised for use in areas at risk of explosion.

11

4Proprietor responsibilities

For the purposes of the present operating in any natural or legal person who either uses the industrial truck himself, or on whose behalf it is used. In special cases (e.g. leas ing or renting) the proprietor is considered the person who, in accordance with existing contractual agreements between the owner and user of the industrial truck, is charged with operational duties. The proprietor must ensure that the industrial truck is used only for the purpose for which it is intended and that there is no danger to life and limb of the user and third parties. Furthermore, accident prevention regulations, safety regulations and operating, servicing and repair guidelines must be followed. The proprietor must ensure that all users have read and understood these operating instructions.

NOTE

Failure to comply with the operating instructions shall invalidate the warranty. The same applies if improper work is carried out on the truck by the customer or third parties without the permission of the manufacturer.

5Adding attachments and/or accessories

Adding accessories

The mounting or installation of additional equipment which affects or enhances the performance of the forklift truck requires the written permission of the manufacturer. Local authority approval may also need to be obtained. Local authority approval does not however constitute the

12

BTruck Description

1Application

The industrial truck is an electric pallet truck with a folding platform. It is designed for lifting and transporting goods on level floors. Wheel arm lift (ERCZ12/Z14/Z16 only) increases the ground clearance when transporting goods on uneven surfaces. Loads can be stacked or unstacked up to 5.35m high and transported over long distances. The rated capacity of the truck is shown on the data plate or the data capacity plate Qmax. Due to its high travel speed the ERC 214/216 has side restraints.

1.1Truck models and rated capacity

The rated capacity depends on the model. The rated capacity can be derived from the model name.

ERC 212 / Z121200

ERC 214 / Z141400

ERC 216 / Z161600

The rated capacity does not generally match the permissible capacity. The capacity can be found on the load chart attached to the rack.

13

TypeCapacityMotor output

kg2,0

kW

kg2,0

kW

kg2,0

kW

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL