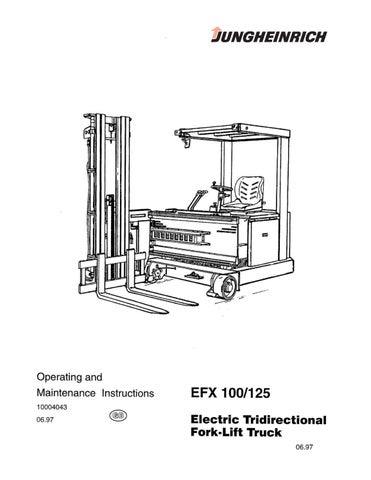

Operating and Maintenance Instructions 10004043 06.97 fiUNGHEINRICH 0 EFX 100/125 Electric Tridirectional Fork-Lift Truck 06.97

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

TABLE OF CONTENTS I. PREFACE 9 II. SAFETY REGULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Ill. NOTES ON SAFETY 15 IV. WARNING LABELS, SIGNS 19 V. OFFICIAL REGULATIONS 25 VI. MANUFACTURER'S REGULATIONS 27 1. 2. 2.1. 2.2. 2.3. 2.4. 2.5. 2.6. 2.7. 2.8. 2.9. 2.10. 2.11. 2.12. 2.13. 2.14. 2.15. 3. 3.1. 3.2. 3.2.1. 3.3. 3.4. 3.4.1. 3.4.2. 3.4.3. 3.4.4. 3.4.5. 10004043 GENERAL TECHNICAL DATA DESCRIPTION ................................................. . Frame Chassis Drive Drive Control ................................................... . Braking System Hydraulic System Swivel/Traverse Unit and Mast Ergonomics and Safety .......................................... . Electrical System Main Components of the Truck (Overall View) Operating and Indicating Instruments .............................. . Positioning Parts and Indicator Instruments of Rail-Guided Trucks (a) .. Positioning Parts and Indicator Instruments for Inductively Guided Trucks (b) Battery Charge Indicator ......................................... . Malfunction Display STARTING ..................................................... . Unloading the Truck using a Crane Commissioning Commissioning without Battery Preparations for Starting ......................................... . Handling ....................................................... . Notes Regarding Driving and Braking Safety Adjusting the Driver's Seat Indications for the use of the restraint belt Adjusting the Steering Wheel Driving and Braking ............................................. . 5 31 35 35 35 35 35 36 36 36 36 37 38 39 40 41 42 42 43 43 44 44 45 46 46 47 48 52 53

TABLE OF CONTENTS

Changing the Driving Direction

Operating Brake

Parking Brake

Engaging of Inductively Guided Trucks ............................. .

Parking the Tridirectional Fork-Lift Truck ........................... .

Towing the Tridirectional Fork-Lift Truck

Lifting Hydraulics Positioning Lever ................................ .

Notes Regarding Safety while Picking up and Setting down the Load

Picking up a Load ............................................... .

Driving with a Load

Setting down the Load

Monitoring Functions for the Lifting Hydraulics and Safety Devices for Rail-Guided and Inductively Guided Trucks ........................ .

Carbon Brush Wear Indicator

Monitoring Functions for Driving and Safety Devices for Inductively Guided Trucks

MAINTENANCE AND INSPECTION

Notes Regarding Maintenance and Inspection ...................... .

Training and Qualification of the Personnel Charged with Service and Maintenance Work Type

and Quantity of Required Operating Material

Work on the Electrical Equipment

Safety Devices

Parameters

Tyres

Brake Fluid

Battery

Notes Regarding Safety when working with Acid Batteries

Battery Care

Loading the Battery

Charge Level Measurement of the Battery using an Acid Siphon

.

3.4.6. 3.4.7. 3.4.8. 3.4.9. 3.4.10. 3.4.11. 3.4.12. 3.4.13. 3.4.14. 3.4.15. 3.4.16. 3.4.17. 3.4.18. 3.4.19. 4. 4.1. 4.1.1. 4.1.2. 4.1.3. 4.1.4. 4.1.5. 4.1.6. 4.1.7. 4.1.8. 4.1.9. 4.1.10. 4.1.11. 4.1.12. 4.2. 4.3. 4.3.1. 4.3.2. 4.3.3. 4.3.4. 4.3.5. 4.3.6. 4.3.7. 4.4. 4.5. 4.5.1.

and Intervals

Spare Parts Disposal of Greases, Oils and Batteries Special Measures ............................................... .

Cleaning

.

Quality

Lifting and Jacking Up

.......................................................

....................................................

Battery ............................. . Cleaning the Battery Surface Changing the Battery Electronics ..................................................... . Electric Motors Visual Check 6 10004043 54 54 54 55 58 58 59 60 61 62 63 64 67 68 69 69 69 69 69 69 70 70 70 70 70 70 71 71 71 72 72 72 73 73 74 74 75 76 76 76

Checking the Acid Level of the

TABLE OF CONTENTS

4.5.2. 4.6. 4.6.1. 4.6.2. 4.6.3. 4.7. 4.8. 4.8.1. 4.8.2. 4.9. 4.10. 4.11. 4.12. 4.13. 4.14. 4.15. 4.16. 4.17. 4.17.1. 4.17.2. 4.17.3. 5. 6. 10004043

Carbon Brushes Lift Chains ..................................................... . Cleaning the Chains Inspecting the Lift Chains ........................................ . Repairing the Chains ............................................ . Changing the Transmission Oil Changing the Hydraulic Oil ....................................... . Changing the Hydraulic Oil Filter Cleaning the Ventilation Filter Brake Fluid ..................................................... . Maintenance of the restraint belt Notes on Lubrication Electrical Circuit Breakers of the truck Settings of the Hydraulic Pressure Limit Valves ..................... . Turning Torques of the Wheel Nuts Oils and Lubricants .............................................. . Maintenance Intervals Lubrication and Maintenance Table ................................ . Lubricating Points on the Add-On Device Lubricating Points of the Fork Carrier .............................. . Lubricating Points on the Mast REPAIRS DRIVER LIST ................................................... . 7 77 77 77 78 79 80 81 82 82 83 84 84 85 85 85 86 87 89 93 94 95 97 99

PREFACE

I. PREFACE

Dear customer, please read these Operating and Maintenance Instructions before starting the truck for the first time to ensure safe and economic utilisation of the truck. These instructions contain all information necessary for the operation and maintenance of the JUNGHEINRICH trucks.

The safety instructions contained in the "Guidelines for Correct and Proper Use of Industrial Trucks" (VDMA) are to be heeded. These instructions are part of the present Operating and Maintenance Instructions. National regulations exceeding the scope of these guidelines remain in force.

All safety requirements stipulated must be met before the truck is started.

Before this truck is used, the Operating and Maintenance Instructions must be made available to and read and understood by all persons operating the truck. The JUNGHEINRICH distributor is always ready to provide further information if questions should arise during perusal of the Operating and Maintenance Instructions.

Only qualified and trained personnel may drive or work with the truck.

Our warranty liability according to our conditions of delivery becomes void if maintenance work is neglected or performed incorrectly.

Only genuine JUNGHEINRICH spare parts should be fitted as replacement parts to maintain quality and reliability.

10004043 9

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL