• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

Important note

Any type of duplication or excerpt from this document, also in electronic form, is not subject to the revision service of Manitowoc Crane Group Germany GmbH.

© Copyright reserved by Manitowoc Crane Group Germany GmbH

The passing on or duplication of this document as well as the utilisation and disclosure of its contents are prohibited unless expressly permitted. Infringement will incur liability for compensation. All rights pertaining to registration of patent or utility model are reserved.

Validity

Fall-back guard strut of the luffing jib

This additional page applies to all GMK7450 as of serial number 8031, except 8033, that are equipped with luffing jibs.

Reasons for the additional information

As opposed to the information in the lattice extension operating manual, the fall-back guard strut is:

–no longer hoisted during unrigging and rigging, –fastened with a tightening belt during transport. The risk of accidents during unrigging and rigging is reduced.

SRisk of damage to the fall-back guard strut

The fall-back guard strut can be damaged if it: –is not securely fastened during transport, –is hoisted during unrigging and rigging.

To avoid damage, fasten the fall-back guard strut and rig as described in the following:

When riggingCreate a joint between the luffing control arm and the fall-back guard strut

• Remove the pin from bore (6). Insert it into bore (5) and secure it.

• Join the stand (1) and the fall-back guard strut (3) with the pin (2).

• Remove the tightening belt from the strut(4).

When unriggingLoosen the joint between the luffing control arm and the fall-back guard strut

• Remove the pin from bore (5). Insert it into bore (6) and secure it.

• Secure the fall-back guard strut with a tightening belt at the strut (4); à During transport

• Pull the pin (2) out of the bore and set the stand (1) down.

• Insert the pin (2) into the bore on the fallback guard strut (3) and secure it.

During transport

The following information applies regardless of the means of transport.

SRisk of damage to the fall-back guard strut

The fall-back guard strut can be damaged if it is not securely fastened during transport. It may not move backwards or forwards, or laterally.

To avoid damage, fasten the fall-back guard strut as described in the following:

• Place the tightening belt (2): –from left side of the strut (1) –in front of the roll (3) completely around the fall-back guard strut, once, –to the right side of the strut.

• Tighten the tightening belt.

• Make sure that the pin is inside the bore (4) and is secured.

Validity

Slinging points

These additional pages apply to all GMK 7450 as of serial number 8001, that are equipped with luffing jibs.

Reasons for the additional information

The foot section of the luffing jib is frequently lifted with the short intermediate section attached together with the rear pendant link. The lattice extension operating manual is supplemented in the slinging points section by the following.

When lifting

GRisk of accidents if used improperly! Attach the boom sections to these slinging points only, as they will then automatically have the right centre of gravity. Use only the supplied lifting gear of sufficient lifting capacity.

• Only use the following slinging points.

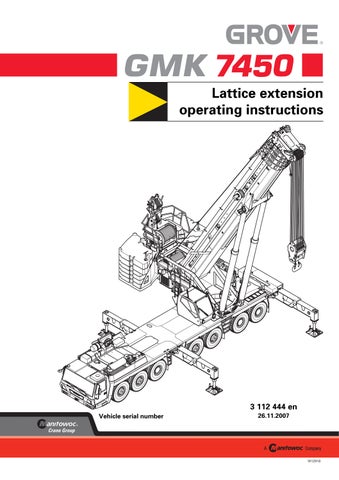

These operating instructions consist of the following chapters:

1Important information

2Additional operating and display elements

3Transport measurements, weights and allocation of the lattice extension sections

4Boom extension

5Luffing jib

6Heavy load lattice extension

7Rigging winch (additional equipment)

8Malfunctions

9Index

1.1 About these operating instructions

Important information

1.1 About these operating instructions

HAll the lattice extensions described in these operating instructions can be obtained as additional equipment.

Validity of these Operating Instructions

These operating instructions only apply to lattice extensions which were delivered by Deutsche GROVE GmbH.

In addition, for the operation of the truck crane with a lattice extension described in these operating instructions, all details in the included Operating instructions for the GMK7450 for which the lattice extension was delivered, are applicable.

Prerequisites for assembly and operation

The lattice extensions described in these operating instructions may only be operated together with a GROVE truck crane GMK7450 whose serial number is identical with the serial number that is marked on the lattice extensions.

Safety instructions

The operation of GMK7450 with one of the lattice extensions described in these operating instructions is subject to:

–the basic safety instructions to be found in the subsequent section Basic safety instructions and

–the safety instructions contained in the supplied operating instructions of GMK7450.

Reference to other operating instructions

Cross references to other operating or maintenance instructions are shown as follows:

à GMK7450 operating instructions, Part 1 Superstructure – Rigging work

The number for the chapter on Rigging work is found in front on the second page of the operating instructions indicated. or

à GMK7450 operating instructions – Safe load indicator

You will find the respective page in the index.

1.2 Basic safety instructions

1.2.1 Warnings and symbols

The following definitions and symbols are used in the operating instructions to highlight particularly important information:

GThis symbol indicates hazards related to the operation described which may cause personal injury. The type of danger (e.g. danger of fatal or nonfatal injury, or risk of crushing) is normally specified in the warning sign.

SThis symbol indicates dangers which could put objects at risk, e.g. damage to the truck crane, the load or the environment.

BThis symbol alerts you to situations where you are in danger of receiving an electric shock.

OThis symbol reminds you that you are working with substances which pose a risk to the environment. Take particular care. Further information on handling substances that pose a risk to the environment; à Maintenance manual, chapter Safety and environmental protection

The vertical line to the left of the warning text indicates the following: This text, regardless of its length, relates to the warning symbol.

HThe hand with the pointing finger indicates passages that contain additional instructions and tips regarding truck crane operation.

sThis symbol indicates that the topic is continued on the next page. Turn to the next page.

1.3

Intended use

The truck crane GMK7450 is constructed in accordance with the latest technology and the recognized safety regulations. Nevertheless, personal injury to the operator or a third party as well as damage to the crane and other property may occur during use.

The truck crane may only be modified with the consent of the manufacturer.

The truck crane GMK7450 may only be used when in excellent working condition and for its intended purpose, and with due attention to safe operation and any possible hazards. Malfunctions that may affect the safe operation of the unit are to be corrected immediately.

The GMK7450 truck crane may only be operated at temperatures of between –25 and +40 °C if it is not equipped with the relevant special equipment.

The GMK7450 truck crane may only be used to vertically lift loads in the authorized rigging modes using a hook block that is reeved to the hoist rope. The weight and centre of distribution of the loads must be known. Any other use of the crane is not considered to represent intended use.

The manufacturer is not liable for damage resulting from the improper or unauthorized use of the truck crane GMK7450. The user shall take full responsibility for any such use.

Only use the rigging winch (special equipment) to do the following:

–Pull the rope of the hoisting gear to the head when rigging the boom extension and the luffing jib.

–Pull the rope of the hoisting gear over the luffing control arm to the upper hook block when rigging the luffing jib.

Intended use also entails

–Observing the complete crane documentation consisting of the operating instructions, the lifting capacity table, the outrigger pressure table and the safety manual

–Observing the inspection and maintenance requirements specified in the Maintenance manual.

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.