Media-ID: EM027759-05

Doc. -No: Harvey_04_01_00

Date: December/2019

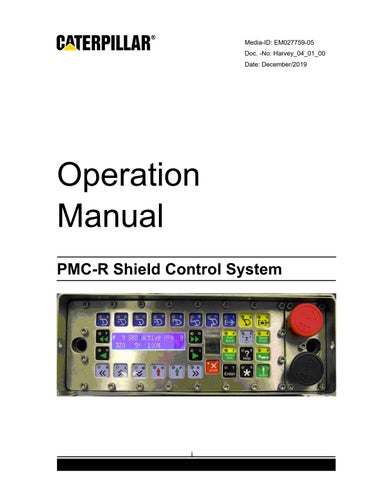

Operation Manual

PMC-R Shield Control System

i

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

Program changes:

Added push restriction on shearer in gate area.

New parameters: Configuration > Conveyor push:

•

Added gate push distance behind prime.

New parameters: SRB Face Automation: •

Operating manual changes from media number EM027759-04. Took out several blank pages

Min Max Default

Shear

Restriction OFF ON ON

Shr Psh Rstrct HG Dist 1 10 5

Shr Psh Rstrct TG Dist 1 10 5 • Shr Psh Rstrc HG Zone 10 30 20

Shr Psh Rstrc TG Zone 10 30 20

Push

•

•

•

HG Push Dist

OFF ON OFF

HG Push Distance 2 15 4

TG Push Dist Enable OFF ON OFF

TG Push Distance 2 15 4

Enable

•

•

•

ii

Table of Contents Description 1 Display 2 Display Categories 2 Default Display 2 Active Display 2 Master Display 3 Slave Display 3 Input Display 3 Keys 4 General Key Concepts 4 Audible Feedback 4 Timeout 4 Stuck Key Error 4 Multiple Key Error 4 Keyboard Modes 4 Idle Mode 4 Master Mode 5 Group Function Mode 5 Data Entry Mode 5 Help Mode 5 Specific Key Information 5 Hot keys 5 Single Select Keys 6 Man-In-Place Function Keys 7 In-Shield Automatic Keys 8 Group Select Keys 9 Group Function Keys 9 Number keys 10 Menu Navigation Keys 10 Other Keys 11 Menu Control 12 Navigation 12 iii

Freeze Display Feature 13 Go-Back Feature 13 Parameter Changing 14 Local / Global Parameters 15 Parameter Locking 15 Safety Features 16 Local Lockout Button 16 Quickstop Button 16 Pressure Dump Feature 16 Resetting the System 17 Conveyor Prestart 17 Umbrella Lock 18 Controlling the Umbrella Lock 18 Maintenance Lock 19 Controlling the Maintenance Lock 20 Active Maintenance Lock Displays 20 Stop Key 21 Flashing lights 22 Shearer Signaling 23 Single Shield Control 24 Remote Control 24 Autosequence 25 Overview 25 Start Options 25 Prewarning / Active Display 25 Restrictions 26 Umbrella Lock interaction 26 Detailed Operating Logic 26 Autosequence Chart 27 List of Steps 27 Errors 35 Parameter Summary 36 Lite Set 38 Group Auto Functions 39 iv

Batch Advance 39 Prewarning / Active Display 41 Operating Logic & Modes 41 Enable / Disable Options 42 Restrictions 42 Errors 42 Parameter Summary 42 Wedge Advance 42 Operator Display & Keystrokes 42 Prewarning / Active Display 43 Operating Logic 43 Enable / Disable Options 44 Restrictions 44 Errors 44 Parameter Summary 44 Batch Pullback 44 Operator Display & Keystrokes 44 Prewarning / Active Display 45 Operating Logic 46 Enable / Disable Options 48 Restrictions 48 Errors 48 Parameter Summary 48 Bankpush 49 Operator Display & Keystrokes 49 Prewarning / Active Display 50 Operating Logic 50 Enable / Disable Options 51 Restrictions 51 Errors 51 Parameter Summary 51 Conveyor Push 52 Operator Display & Keystrokes 52 Prewarning / Active Display 53 v

Operating Logic 53 AutoDrag 57 Enable / Disable Options 57 Restrictions 57 Errors 57 Parameter Summary 58 Bank Watersprays 59 Operator Display & Keystrokes 59 High-Pressure Cleanout 62 Prewarning / Active Display 62 Operating Logic 62 Enable / Disable Options 63 Restrictions 63 Errors 63 Parameter Summary 63 Water Curtain 63 Operator Display & Keystrokes 64 Prewarning / Active Display 64 Operating Logic 64 Enable / Disable Options 66 Restrictions 66 Errors 66 Parameter Summary 66 Atomizer Sprays 67 Keystroke Details 68 Shearer Running Batch (SRB) 68 Shearer Position 68 Primepoint 69 Mining Cycle Overview 70 Bidirectional 70 Operator Display & Keystrokes 70 Newstart 70 Restart 71 Entering a Manual Position 72 vi

Stopping SRB 72 Prewarning / Active Display 73 Setting up the Safety Zones 74 Shearer Safety Zone 74 Manual Safety Zone 75 Conveyor Push Distance Behind Advanced Shields 76 Delayed or Reverse Pushing 77 SRB Gate Operation 77 Leaving the Gate End 77 Entering the Gate End 78 Bidirectional Cutting Cycle 79 Bidirectional Cutting Cycle Beginning at Headgate 80 Bidirectional Cutting Cycle Beginning at Tailgate 82 Push Distance Behind Prime 85 Restrictions 86 Parameter Summary 87 Filter Station 88 Operator Display & Keystrokes 89 Man in place function of filter station valves 89 Manually triggering sequences 90 Calibration 90 Prewarning / Active Display 90 Operating Logic 91 Emulsion Filter Auto Backflush 91 Manual Backflush Control 91 Enable / Disable Options 92 Restrictions 92 Errors 92 Filter Station Parameters 92 Filter Station Connections 94 Sensor Connections 94 Solenoid Connections 95 Diagnostics 95 Personnel Proximity detection 95 vii

Entering and exiting a PPD equpped face. 96 Walking off of the face 96 Miner PPD tag lost on face shields 96 Neighbor/remote functions and PPD 97 Autosequence (ASQ) and PPD 97 SRB and PPD 97 Batching shields and PPD 97 Faulted PPD reader operation 97 PPD tag programming 98 PPD tag low battery station 98 Move-mode without PPD 98 PPD modes 98 Parameter Summary 98 Errors 99 Clearing Errors 100 Error List 100 PMC-R System Components 103 PMC-R Single Control Unit (SCU) 103 Driver Board 104 Brass Bar 104 Isolation Adapter 105 SKK24 Hose Cable 105 SKK28 Hose Cable 106 Pressure Sensor 107 Reed Rod 108 Configuration Drawings 109 Shield Layout (Face) 109 Shield Layout (Gate) 110 Headgate Area 111 Group Layouts 112 Left Hand Face Configuration 113 Right Hand Face Configuration 114 Display Glossary 115 viii

ix

DESCRIPTION

The PMC-R Shield Control Unit is an advanced digital shield control system. It is based on patented state-of-the-art electronics and contains multiple sub-processors, a dual line display, color coded keys, and a built-in infrared receiver. The PMC-R is capable of operating in a network of hundreds of units and utilizes modern software concepts to maximize the effectiveness of the computing and communications hardware. The PMC-R is housed in a stainless steel watertight enclosure that will hold up to most underground situations.

The keys are color coded to match the type of purpose they serve.

1

Keys Left or Right

Select Keys Left or Right Man-in-place Keys (Blue) 8 Total Number Keys 0 thru 9

© Caterpillar Menu Navigation Keys Single Select

Group

DISPLAY

The PMC-R Display is a backlit LCD display with 2 lines of 22 characters each.

Display Categories

The following display categories exist:

Default Display: no keys pressed; no shield function is occurring

Active Display: shield function (such as Bankpush) is active

Master Display: operator has selected another shield for manual operation

Slave Display: this shield is selected for manual operation

Input Display: operator is entering numerical values

Default Display

The Default Display is shown when the PMC-R is not operating any other function.

#129 317 105>I 100% 180

"#129" is the shield number.

"317" is the leg pressure in bar.

"105>" is the Shearer Position & Direction.

"I" indicates "Infrared" shearer tracking is in use. An "S" would indicate serial tracking. An "M" would indicate manual shearer tracking.

"100%" is the Ram Stroke in percent.

"180" is the Leg Pressure to your right in bar.

An "i" preceding any sensor reading indicates the sensor is being ignored because it is turned Off under the Sensor Status section of the menu.

Any invalid value will be displayed as "~~~" instead of a number.

Active Display

The Active Display is shown when the shield is executing a function. The details vary depending on the function which is active. Generally, functions will leave the bottom line of the default display and display status information on the top line with the name of the function surrounded by “!”. For example, this shows an active ASQ function in the Warning state: ! ASQ ! * WARNING *

317 105>I 100% ~~~ © Caterpillar

2

Note also that the last value on the bottom line is invalid causing it to be displayed as “~~~”.

Master Display

When an operator uses the PMC-R on one shield to control another shield manually, the shield where the operator is pressing keys is called the Master and the Master Display will be shown. Although most hydraulic functions can be activated using the dark blue “man-in-place function keys” there may be other hydraulic functions available. These are called Auxiliary Functions and are shown in the display where they are controlled using the N & P arrow keys.

For example, the Canopy Spray line allows the operator to control the canopy spray function by pressing and holding the P-key (the arrow below the “ON” text).

8: Canopy Spray

From the Master Display, available Auxiliary Functions are accessed by using the Menu Navigation keys to scroll up or down.

Slave Display

The Slave Display is shown on a shield that has been selected from another shield. # 3 ! Slave ! - # 1

317 105>I 100% ~~~

The top line indicates that the shield is being operated as a slave unit. It shows that this is shield #3 and it is being controlled by shield #1.

The bottom line continues to show the default display of sensor values and shearer position.

Input Display

When an operator is entering a numerical value the display is in Input Mode and will show the name of the value being entered and a question mark, similar to this:

Abort Dist

Input Mode terminates when the Enter key is pressed or, if no keys are pressed, after a several second timeout.

ON

?

3 © Caterpillar

KEYS

General Key Concepts

Audible Feedback

When any key is pressed there is audible feedback. If it is a valid keystroke, there will be a single short beep. If it is an invalid keystroke, there will be an "error beep" which is 3 consecutive short beeps.

Timeout

When no key has been pressed for the 4s, the display will timeout and revert to the Default Display Mode and any manual actions will be canceled (e.g., Master Mode, menu scrolling).

Stuck Key Error

If a key is held for more than 60s continuously, the key will be considered "stuck", an error sound will occur, and an error will be posted.

(err: "KEYBOARD ERROR stuck key")

Multiple Key Error

If an invalid combination or sequence of keys is pressed an error sound will occur and an error will be posted.

(err: "KEYBOARD ERROR bad key combination")

Keyboard Modes

Beep and Error-Beep

Don’t wait too long!

Don’t hold keys too long!

Don't press too many keys at once!

Some PMC-R keys have only one function (e.g., the Stop key). But most keys have multiple functions (e.g., the 2-key is also the Positive Set key). The keyboard mode determines what the multi-function keys do when they are pressed.

Idle Mode

When nothing else is going on.

©

Idle Mode is the normal mode when no keys are being pressed. When Menu Keys have been used to view different displays, the keyboard is still in the Idle Mode until an actual action has been taken. When any other mode times out, the Idle Mode is entered and the Default Display is shown. In Idle Mode, the man-in-place keys are shortcuts to various menu displays. 4

Caterpillar

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL

CLICK HERE TO DOWNLOAD THE COMPLETE MANUAL