Technical Manual

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

DUE TO THE DANGERS INHERENT IN THE OPERATION OF' ANY HIGH VOLT AGE ELECTRICAL EQUIPMENT, A SAFE GROUNDING SYSTEM SHOULD BE USED. SUCH SYSTEM SHOULD INCLUDE GROUND CONDUCTORS IN THE CABLE, A NEUTRAL GROUNDING RESISTOH AND RELATED RELAYS AND SWITCHGEAH. A GROUND CONTINUITY CHECK SYSTEM IS ALSO RECOMMENDED.

READ AND OBSERVE ALL warning signs, they're placed for your health and safety.

In the event you doubt, for any REASON, your ability to safely perform any of the enclosed maintenance and operational procedures as they refer to your machine, please contact Marion Power Shovel Company, fnc.

ThLS manual has been prepared for the standard production machine. Any deviation due to advanced engineering design, optional equipment or the particular requirements of this machine may not be covered.

Additional information that is required will be furnished as soon as such information is available.

T ABLE OF CONTENTS

General Information

Air System and Components

Lubrication

Engineering Data

Mechanical Adjustments

Operation

Electrical ::Ylaintenance

SECTION I

GENERAL INFORMATION

INTRODUCTION

This manual is provided for the guidance of all persons who operate, lubricate, adjust or maintain the Marion 8050 Walking Dragline. The information was prepared with the purpose in mind of furnishing accurately and concisely all the data neces sary to the operation and servicing of this machine.

All information, nleasurements, and specifications herein are in accord with the Marion Power Shovel Engineering Department and should be strictly adhered to in all work on this machine.

PARTS BOOK

THIS MANUAL IS NOT A PARTS BOOK AND SHOULD NOT BE USED IN ORDERING PARTS.

You have been furnished detailed Parts Books which list all parts by group numbers with items and part numbers for your specific machine.

Read carefully the instructions Ln the front of the Parts Book for ordering parts.

SERIAL NUMBER OF MACHINE

Be sure that the serial number of the machine is given in any letters, telegrams, orders or other communications. Records for each individual machine are filed by serial number and if this number is available, the design and original equipment can be quickly and accurately checked.

RIGHT AND LEFT HAND PARTS

On the upper frame, right hand (R. H. ) and left hand (L. H. ) correspond to the operator's right and left hands when he is facing the bucket while at the operator's controls.

ORDEHJNG PARTS

The Parts Book covering this machine gives complete information on how to order parts. Order carefully 51) that the right parts in the right quantities can be furni shed. \Vrong parts. ordered by mistake. which are returned to the company are subject to a rehandling charge.

FUHTHER INFORMATION

If further information is required which is not foundln the Manual or in the Parts Books. conlnlunicate with the Marion Power Shovel Company. Inc .• at 1',larion. Ohio.

CHAHGE FOR SERVICE. LABOR. ETC.

No charges for service or labor are accepted unless the work has been previously authorized by the company in writing.

STANDARD WARRANTY

lVlarion Power Shovel Conlpany. Inc. guarantees the equipment manufactured by it to be free from defects 1r1 material and workmanf;hip under normal use and service. its obligation under this warranty being limited to making good at its factory any part or parts thereof manufactured by it which shall. within six (6) months after delivery to Buyer. be returned to it. with transportation charges prep<Jid. v\/l1ich its examination shall disclose to its sa ti sfaction to have been thus defective. this warranty being expressly in lieu of all warranties. express or implied. and of all other obligations or liabilities on Marion Power Shovel Company's part.

Marion Power Shovel Company. Inc. shall not be held responsible or liable in any event for special or consequential damages. arising from any cause whatsoever. and Buyer agrees to indemnify and save Marion Power Shovel Company. Inc. harmless therefrom.

Marion Power Shovel Company. Inc. no guaranty 01' warranty. express or implied. as to adequancy. fitnesE;, quality. or perfornlance of any luachiner,y, equipment, apparatus or accessories not rrlanufactured ,lt its own factory. vrhich are subject only to such guaranty as may be made by the respf'ctive nlanufacturers thereof.

The company reserves the right to improve or change the design of its products and specifications thereof and the company shall incur no liability thereby or any obligations to install such improvements on products previously sold.

SAFETY PRECAUTIONS

of this machine depends entirely on the man The operator is its brains. He must think safely.

Neatness and safety go hand in hand. Good housekeeping habits should be developed.

1. Keep the floor clean and free from oil and grease.

2. Keep the walkways clean, clear, and free from obstructions.

3. Prevent the accumulation of grease and oil around bearings and gears. Grease and oil collect and hold grit and dirt which work into finely machined parts.

4. A clean machine is easier to operate - easier to inspect - easier to service.

5. Keep hands and clothing away from moving parts.

6. Replace guards, inspection plates, access covers, etc., promptly after reason for removal is accomplished.

Strip mining equipment is subject to tremendous stresses arid shock loads. These stresses are thoroughly studied and considered in the design and building of Marion equipment.

This machine is built with an ample reserve of power and strength and is well fitted to meet the demands of its task.

Page 5 Section 1 8050 BI005699

Care, sound judgnlent and reason are an economic necessity in the operation of power equipment. IX)

1. Carefully read this Manual and Parb Book.

2. Lubricate regularly. Establish a systematic procedure and stick to it.

3. When lubricating, check all bolts. nuts, lock nuts and cotter pins.

4. Keep loose objects in tool box or in suitable enclosure or cabinet.

5. Always t>eplace guards.

6. Always watch your clearance when swinging.

1.

DON'T Service or lubricate parts that are moving. Leave the load sw-;pended in air.

DON'T APPLY SWING BIlAKF:S W IIILE NI/\Cl-JIN I': IS noTATING, EXCEPT IN EMERGENCY.

PREVENTIVE MAINTENANCE

Open pit n1ining machinery is required to operate in the most adverse conditions of any industrial machines.

Conditions are rarely ideal. It is always too hot, too cold, too dry or too wet. The air is a1 ways saturated with fine abrasive dust. High production schedules tax both men and rnachines.

Downtirne and delays are intolerable. Downtin1c can not be e[inlinated, but it cem be kept to a rninimum by a progress i ve and con scientiou s progranl of preventive l1laintenance'.

Aside from regular lubrication, proper and accurate adjustments, the personnel should be aware of any deviation from the normal, which could be evidence of iDlpendin,g breakdown or components failure.

The Dlaintenancc people should inspect, during their rounds, all structural members for evidence of stressed, broken or loo:-;e parts. Evidence of a member stretching, bending, or deflecting can often be determined by the conditions of the surface paint. Stressed parts will show wrinkles or \\'aves in the paint or check marks.

Breaks or chips in the surface or a collection or dust along a line may indicate a crack in the metal. Pay particular attention to those areas around openings where corners or angles are cut out, at the ends of gussets or at brace connections and at transitional points where heavy cmel thin parts join.

Stress in a rnonolithic structure nlay travel eli stance from the damaged area and manifest itself at a remote point in some seemingly unrelated plac e.

The rnaintenance people should check all bolts, nuts, cap screws and rod bolts. Lock washers and other locking devices must be in place.

Be sure that bolted and assembled parts are tight. Evidence of movement may be detected by signs of scuffed paint, worn or bright spots adjacent to the part. Often a slight movement of parts that can't be seen with the eye can felt with the finger tip when the 1nachine is working.

Grease or oil stains that are unaccountable, or out of place arc often evidence of a fault.

If any part or parts shows wear or distortion beyond that expected frorn nonnal wear, replacement part should be made available at once and promptl,y installed. The of prompt replacernent of parts is negligible conlparcd to the cost of breakdo\vn - loss of production ancl man hours.

SECTION 2

AIR SYSTEM AND COMPONENTS

INTRODUCTION

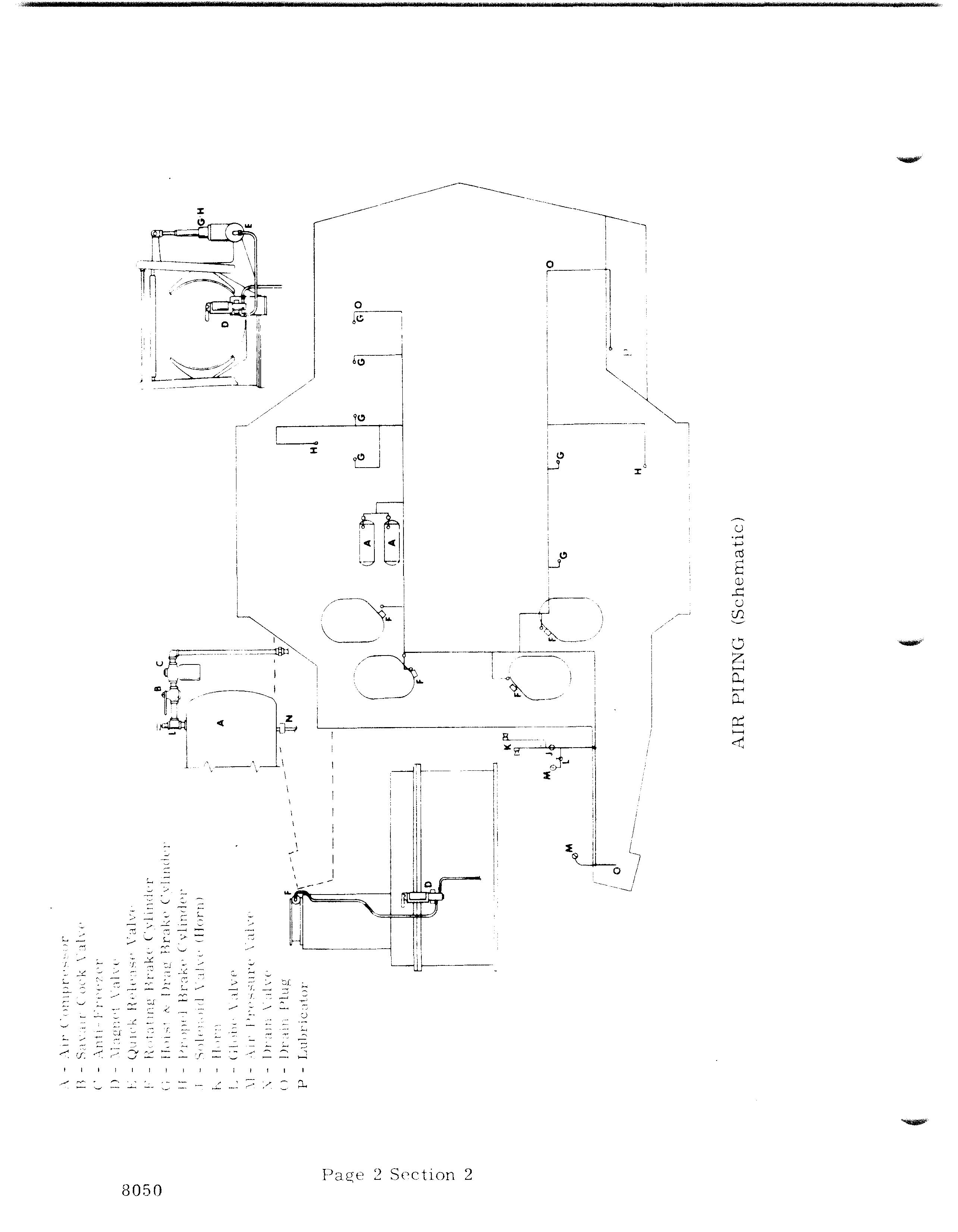

The hoist, drag, propel and swing brakes of the 8050 walking dragline are released by compressed air. Compressed air is also used to actuate the automatic lubrication system.

The Marion air control system is simple in operation and, with reasonable care and maintenance, will have a long trouble free life.

The system can best be explained by a brief description of its components and their functions in the system. Fig. 1 shows a schematic view of the complete system used on the machine.

The operator must be constantly aware of the air pressure gauge reading. If at any time the pressure drops below the operating differential. 90 psi to 120 psi, the operator should shut down the machine and investigate the cause.

Do not operate the machine without full tank pressure.

AIR COMPRESSOR

The air compressor that supplies the system is located on the rotai ing frame at the right of the center ,journal.

The compressor is a complete unit that includes a storage tank, electric motor and a two stage air compressor with a pressure switch. Read the m.anual that is attached to the unit.

Check the oil level in the compressor crank case daily. Keep the oil level to the full mark on the dip stick. Drain and flush the crank case every 500 hours of operation. Refill with oil specified on the chart "Oil Specifications" in the lubrication section.

The air cleaner located at the air compressor intake is an oil bath type cleaner. The cleaner should be disassembled

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.