Technical Manual

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

SAFETY PRECAUTIONS AND PRESTART CHECKS

Safe operation of a rotary blast hole drill promotes personal safety and minimizes delays and costly damage to equipment. Carefully study and follow all recommended procedures in this manual. Safety guidelines are intended to help prevent accidents from occurring and are provided in the interest of all mine personnel. Overall safety depends upon a good sense of judgment and alertness on the part of the entire mining crew.

SPECIFIC SAFETY RULES

The following is a list of some important safety rules relating to prestart and operation of the 49RIII drill. The safety instructions given in this manual cover normal daily operations of the machine. Additional precautions may be necessary to cover unusual circumstances. Be constantly alert for any potentially dangerous conditions and take action as necessary to correct the conditions immediately.

Wear hard hat, safety shoes and safety glasses at all times.

When operating or performing maintenance functions, wear snug fitting clothing. Loose clothing can be caught on controls or in moving parts. Remove all jewelry.

Keep the operator's cab, ladders, walkways and steps free of materials which cause slippery conditions or obstacles which create tripping hazards.

Use proper interior and exterior lighting.

Do not allow unauthorized personnel on board the machine while in operation.

• Do not begin operation until all personnel are clear of the machine or in a safe position on the machine.

Use audible signals to warn of machine movements. Asignal horn button is provided for this purpose.

Do not propel until the travel route has been cleared of obstructions.

Ensure that all personnel are clear of the machine when propelling.

Do not propel the machine on a slope greater than specified in the stability limits shown on the STABILITY CHART at the end of this section.

Do not leave the rotary gearbox suspended in the air when leaving the machine unattended.

Always wear approved rubber gloves, and use insulated hooks or tongs when handling trail cable.

Install and maintain proper grounding and ground fault protection systems.

Allow electrical inspection and maintenance to be performed only by a qualified electrician.

Prevent trail cable from being dragged on the ground for long distances or at high speeds.

Limit the amount of cable being dragged by the machine. Pulling too much cable will damage both the cable and the machine.

Use extreme caution when working around blast holes.

OPERATION NEAR ELECTRICAL TRANSMISSION LINES

Permission to reproduce the following material has been granted by the Construction Industry Manufacturers Association (CIMA). CIMA assumes no responsibility for the accuracy of this reproduction.

CAUTION: THE FOLLOWING PRECAUTIONS SHALL BE COMPLIED WITH WHENEVER OPERATING NEAR ELECTRICAL TRANSMISSION LINES.

Working in the vicinity of electrical power lines presents a very serious hazard and special precautions must be taken. For purposes of this manual you are considered to be working in the vicinity of power lines when the machine, in any position, can reach to within the minimum distance specified by local, state and federal regulations.

Safe operating practices require that you maintain the maximum possible distance from the lines and never violate the minimum clearances.

Be certain to comply with all local, state and federal regulations regarding working in the vicinity of power lines.

Before working in the vicinity of power lines, always take the following precautions:

1. Always contact the owners of the power lines or the nearest utility before beginning work.

2. You and the electric utility representative must jointly determine what specific precautions must be taken to insure safety.

3. It is the responsibility of the user and the electric utility to see that the necessary precautions are taken.

4. Consider all lines to be power lines and treat all power lines as energized even though it is known that the power is shut off and the line is visibly grounded.

5. Slow down the operating cycle. Reaction time may be too slow and distances may be misjudged.

6. Caution all ground personnel to stand clear of the machine at all times.

7. Use a signal person to guide the machine into close quarters. The sole responsibility of the signal person is to observe the approach of the machine to the power line. The signal person must be in direct communication with the operator and the operator must pay close attention to the signals.

CAUTION:

DEATH OR SERIOUS INJURY GOULD RESULT SHOULD ANY PART OF THE DRILL COME WITHIN THE MINIMUM DISTANCE SPECIFIED OF AN ENERGIZED POWER LINE.

PRESTART CHECKS

Before starting the drill, inspect it to ensure it is ready to be put into operation. Failure to make such a routine check could result in unnecessary downtime. For example, an undetected oil leak could result in a dry gear case, which would lead eventually to excessive gear wear or destruction, seized bearings, or other mechanical problems. A few minutes spent inspecting the machine often results in considerable savings in time and machine efficiency. This inspection should be performed before each shift.

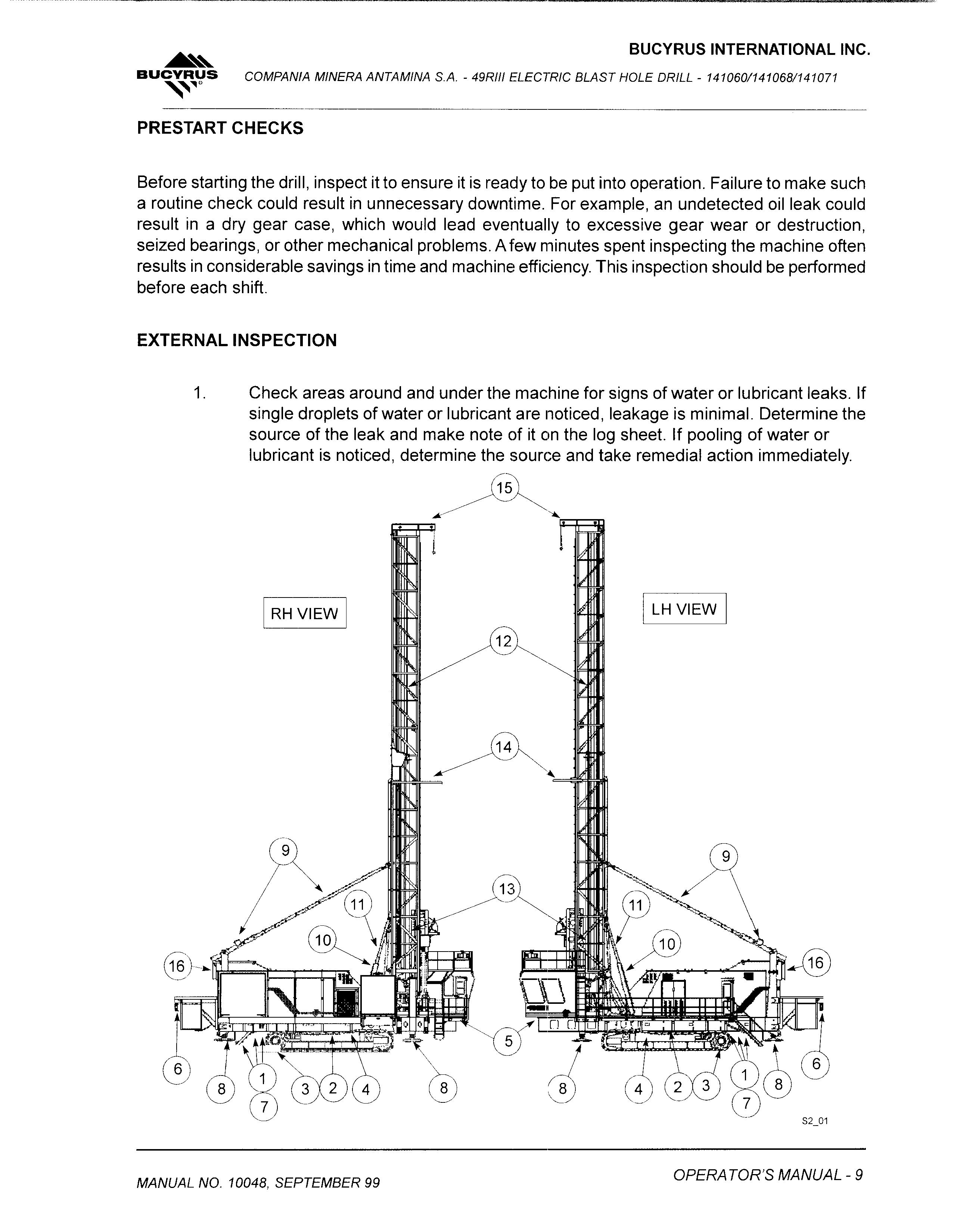

EXTERNAL INSPECTION

1. Check areas around and under the machine for signs of water or lubricant leaks. If single droplets of water or lubricant are noticed, leakage is minimal. Determine the source of the leak and make note of it on the log sheet. If pooling of water or lubricant is noticed, determine the source and take remedial action immediately.

2. Inspect the crawler belts for broken or cracked pads, missing lock pins, loose track pins, and proper crawler belt tension.

3. Check the drive tumbler gearcase, hydraulic motor and hoses for leaks. Check the lubricant level in the drive tumbler gearcase.

4. Inspect the crawler frames for cracks and dirt or ice buildup. Check the rollers and tumblers for proper lubrication, free operation, and dirt or ice buildup. Check axle attachment pins and bolts.

5. Check the dust curtains for tears. Be sure that the curtains are not frozen to the ground or covered with cuttings.

6. Inspect the trail cable for proper placement out of the line of travel of the drill. Inspect the insulation for cuts or abrasion. sure the cable is kept out of water and away from sharp rocks. Have an electrician inspect the strain relief device and the condition of the cable where it enters the machine.

CAUTION: THE MACHINE TRAIL CABLE GARRIES A LETHAL VOLTAGE. HANDLE THE CABLE IN AN APPROVED MANNER WITH APPROVED RUBBER GLOVES AND INSULATED HOOKS OR TONGS.

7. Inspect the underside of the machine for cracks, loose hoses or wires, dirt or ice accumulation, or other deterioration or damage. If loose wires are noted, do not touch them but notify an electrician immediately.

8. Inspect the leveling jack spuds for proper lubricant covering. Inspect the leveling jack pads for cracks, broken or missing pins, or excessive dirt accumulation.

9. Inspect the mast braces and locking pins. Replace missing or defective components immediately. Verify that all adjusting bolts are properly adjusted. Check all hoses and cylinders for leaking.

ACAUTION: USE A SAFETY BELT AND LANYARD TO PROTECT AGAINST FALLS WHEN CLIMBING ON THE MAST BRACES OR WORKING ON THE HOUSE ROOF.

10. Inspect the mast hinge pins for loose or keepers or bolts. Replace missing or damaged parts immediately. Check the pins for sufficient lubrication and lubricate if necessary.

Inspect the mast hoist cylinders for loose or missing pins or keepers, oil leaks, damaged hoses or structural damage. Hepair or replace any missing or damaged components immediately.

Inspect the mast structure for bent or broken chords or plates, loose or broken parts, proper rack lubrication or excessive rack wear. Inspect ladders, handrails and platforms for broken or missing parts. Repair or replace broken or missing parts immediately.

Check the main air flex hose, lubrication lines, and electric lines running from the mast to the rotary drive/pulldown unit for interference with the mast or excessive wear or leaks.

Check the safety restraint cables on the mast. Be certain that the cables and supports are in good repair with no cracks, missing or loose hardware or any damage that could affect their effectiveness.

Every 160 hours inspect the upper auxiliary winchsheaves. All pins, keepers and hardware should be secured.

Check the machinery house air filtering fan duct to see that it is clear of obstructions.

ONBOARD INSPECTION

1. Inspect the air compressor lubrication lines for leaks. Correct any leaks found immediately.

2. Check the condition of the air compressor intake filter. Replace the filter cartridge if the red flag is visible in the service indicator. Empty the dust hopper and clean the pre-cleaner element. Inspect the and ductwork for damage or leaks. Repair or replace leaking components.

3. Check the oil level in the hydraulic tank. Fill the tank to the proper level as described on the instruction plate on the tank.

4. Check hydraulic system for leaks. Correct all leaks immediately and clean up all oil spills immediately.

5. If the machine is equipped with a bit lubricator for the main air system, check that the lubricator is full.

6. Inspect the automatic lubrication central pumping stations for proper operation. Check the supply of lubricant and or refill drums as necessary.

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.