Technical Manual

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.

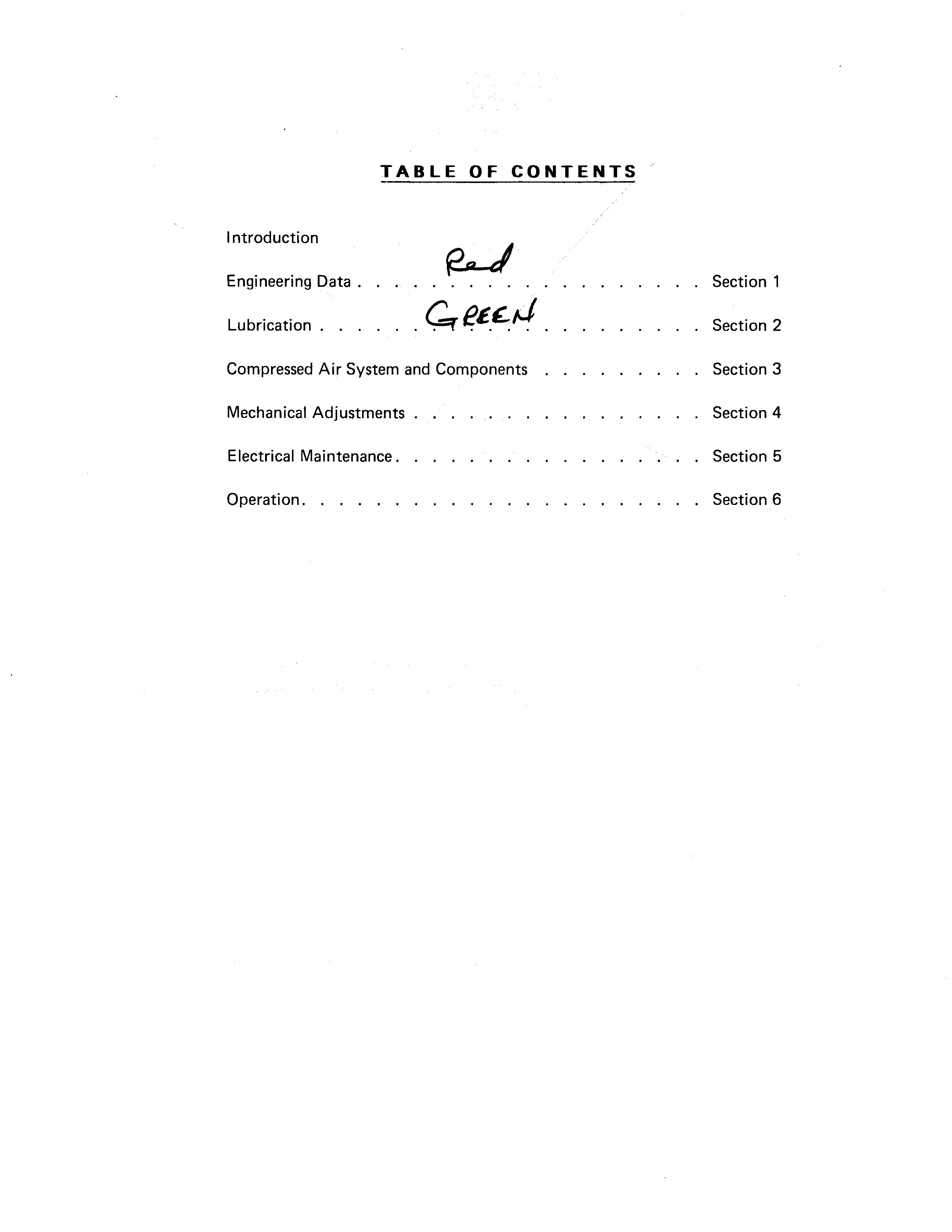

TABLE OF CONTENTS

Introduction

Engineering Data (Red)

Lubrication (Green). ............

Compressed Air System and Components (Yellow) .

Mechanical Adjustments (Orange)

Electrical Maintenance (Blue)

Operation (Gold).

Section 1 ·

Section 2 ·

Section 3

Section 4

Section 5

Section 6

WARNING

DUE TO THE DANGERS INHERENT IN THE OPERATION OF ANY HIGH VOL TAGE ELECTRICAL EQUIPMENT, A SAFE GROUNDING SYSTEM SHOULD INCLUDE GROUND CONDUCTORS IN THE CABLE, A NEUTRAL GROUNDING RESISTOR AND RELATED RELAYS AND SWITCHGEAR. A GROUND CONTINUITY CHECK SYSTEM IS ALSO RECOMMENDED.

In the event you doubt, for any REASON, your ability to safely perform any of the enclosed maintenance and operational procedures as they refer to your machine; please contact Marion Power Shovel Co.; Inc.

READ AND OBSERVE ALL warning signs, they're placed for your health and safety.

This manual has been prepared for the standard production machine. Any deviation due to advanced engineering design, optional equipment or the particular requirements of this machine may not be covered.

Additional information that is required will be furnished as soon as such information is available.

IIiTRODUCTION

The information contained in this manual provides guidance to all persons who care about the operation and maintenance of this machine. Needed data for operation, lubrication, adjustments and other tasks supplied in the various sections permits accurate operation and service. All enclosed specifications agree with the Marion Power Shovel Engineering Department. This information allows for quality maintenance when followed exactly.

This Manual is NOT a Parts Book. Do not use it to Qrder parts. You have been supplied with Q separate, detailed Parts Book. Please read carefully the instructions in the front of it. All parts are listed by group number with items and part numbers for this SPECI FIC machine. Please order the correct parts in exact quantity. Parts ordered by mistake and returned are subject to a Company rehandling charge. RIGHT and LEFT HAND PARTS on the upper frame correspond to the operator's hands atthe controls as he faces the bucket. Please state the correct machine SERIAL NUMBER in any c;onversation or correspondence. Records of each machine are filed by serial number. Given this number, the specific design and original equipment check is accurate and quick.

ADDED INFORMATION, when required, not found in this Manual or the Parts Book may be obtained from Marion Power Shovel Company, Inc. at Marion, Ohio 43302.

SERVICE and LABOR CHARGES are NOT accepted unless previously authorized by the Company in writing.

The operator controls the machine and its usefulness. The crew alone thinks for it. Safety, constantly in mind, prevents accidents. Develop good habits. Everyone has bad habits, but try to erase them quickly. Cleanliness and safety go together. A clean machine is easier to operate, inspect, and maintain.

READ and OBSERVE ALL warning signs, they're placed for your health and safety.

KNOW the location of fire extinguisher.

DO NOT START machine without a FULL tank of air pressure.

DO NOT LEAVE the controls without pushing the button marked "EXCITATION" and turning ALL brake switches to "SET".

DO NOT APPLY swing brakes while machine is rotating, except in emergency.

DO NOT HOLD the bucket/dipper load longer than needed in dumping cycle.

DO NOT SERVICE or lube moving parts.

DO NOT BOARD an operating machine.

PLEASE READ carefully this Manual and Parts Book.

PLEASE LUBE regularly.

PLEASE CREATE A SYSTEMATIC procedure and follow it.

PLEASE WATCH clearance when swinging.

PLEASE OPERATE machine on as near level ground as possible.

PLEASE KEEP safe operating procedures in mind at ALL times.

CAUTION IS THE BY-WORD. Develop a feel for the machine. Try to sense failure before it arrives. Take that extra second to look again at something that seems out of place. A paint chip or bubble may be an early warning. A slight hiss may indicate a growing air leak. It's much easier to tighten a packing nut than shutdown for packing repair.

PROPERLY GROUND the power source.

WATCH AI R system performance.

CHECK boom suspension, hoist and drag ropes for early signs of wear or failure. Kinks cause permanent damage.

CH ECK LI M IT switches for proper operation.

CHECK OVERLOAD and thermal breakers.

MAl NTAI N correct supply of lubricant.

MAINTAIN CLEAR walkways.

LOOK FOR loose bolts and locking devices.

KEEP FLOORS CLEAN and free of oil and grease.

WI PE AWAY excess grease and oil around bearings and gears.

KEEP hands, feet and clothing away from moving parts.

PROMPTLY REPLACE all guards, inspection doors, covers and other safety features after inspection or repair.

NEVE R attempt electrical repair, unless qualified.

HIGH VOLTAGE power lines require using EXTREME CAUTION.

Open pit mining equipment undergoes tremendous shock and stress. Marion's design considers these loads. This machine, built with an apple reserve of power and strength, will meet the demands of its task. Marion's engineers cannot foresee the conditions imposed by abuse, neglect and mismanagement. These factors damage any piece of more than years of continuous operation and normal wear. Care, sound judgement and reason govern the economic need in the operation of PQwer equipment.

Downtime exists, but an ongoing program of inspection and evaluation minimizes it. Awareness of unusual conditions generally warns personnel before breakdown occurs. Normal wear of machinery parts escapes exact definition. Parts do not suddenly expire. Wear takes place at varying degrees over time. Constant checking indicates a wear pattern. An alert maintenance crew checks ALL structural members for evidence of stressed, broken or loose items. Minor cracks occur in steel structures. It's true of ALL machines. This is NOT SERIOUS when weld repaired while SMALL. Cold weather causes faster expansion and brittleness than warm weather. Early detection and quick repair prevents fCjilure. A stretch, bend or defect often shows up in condition of surface paint. A collection of dust along a line may indicate a crack in the metal. Look closely at areas around openings where angles are cut out. Also

check gusset connections and points where thin and heavy metals join. The good crew watches for loose bolts, nuts, cap screws, lock washers and other locking devices. Rod bolts are important too. Signs of scuffed paint, worn or bright spots next to any part indicate movement and becomes second nature to most personnel. Retighten ALL bolts shortly after initial start up. Grease and oil stains often indicate problems. Perhaps just poor housekeeping, but at least something is wrong.

Replacement and maintenance schedules may conform to planned shutdowns. Lack of proper lube, poor adjustments and abuse cause and speed up wear. These facts show up as the MAl N reasons for breakdown. If any part shows wear or distortion beyond expected normal wear, order replacement and quickly install. The cost of parts is nothing when compared to breakdown cost and loss of man hours and production.

Production machines operating 24 hours, 7 days every week deserve an 8 hour inspection and cleaning every 10 days. Cleaning before inspection eliminates dirt and dust falling into machinery parts when inspection plates and covers are removed.

On the upper works, a solvent makes removal of the accumulation of grease around bearings, gears, motors and the like easier. The dirt shield under the drag drum and the trough under the open gears may require a number 3 coal shovel to get the job done.

Start up the machine and dig enough to warm up machinery, open the inspection cover over gears and pinions. Look at gear teeth as machinery slowly goes thru its paces of hoist-lowering and drag-in pay-out. B.roken teeth. are easy to spot, but splayed or an unusual wear pattern takes a closer look.

For a quick check, run a piece of soft wire thru the gear mesh at each side of the pinion. Measure thickness of the two adjacent loops with micrometer. The sum of the two loops indicates backlash. Comparing them gives an indication of misalignment. If excessive backlash is suspected, measure with a dial indicator. There just isn't enough room between the gear guard and the pinion to use a feeler gauge.

Slowly rotate the upper works several times in each direction. Look at condition of roller circle, rail, gear and swing pinion. Sound here may indicate a flat or chipped roller or even suggest burrs or damaged teeth on the rotating pinion.

While hoist operates, check condition of point sheaves groove and bearings. Test hold down bolts on boom point end plate. While operating drag, check fairlead sheaves, grooves and bearings. Look at fairlead swivel, Test ALL hold down bolts with impact wrench. Check rope guides for wear. Look at hoist and drag ropes for broken wires. While on boom point and gantry, may as well check auto-lube system for loose, broken or damaged fittings or lines. Note condition of injector. Properly lube ALL points, it's important.

Lower bucket/dipper to ground and shut down machine. I nspect bucket/dipper for cracks and breaks. Do not permit tooth base exposure. Teeth may be reversed. Remove bucket/ dipper from service and rebuild in shop before breakdown. Check main rotating gear hold down bolts. Use impact wrench if needed. Test ALL hold down bolts on rotating frame. Especially swing gear case, motor mounting, machinery pedestal and base bolts. Check also motor generator and air compressor mount and base bolts. Tighten rod bolts on bearing housing.

Examine and readjust, if needed, hoist and drag brakes and drag clutch. Look at the condition of brake and clutch lining. Remove inspection plate from swing gear case. Look at condition of gears. Use pry bar to detect any side motion of shaft indicating worn bearings. Examine condition of rotating brakes and their adjustment. Adjust, if needed. I nspect air compressor "v" belt tension, replace if needed. Fill the anti-freezer but don't drink that stuff. Check auto-lube system for loose or broken fittings or injectors.

Check center journal thrust washer and bearing. Secure ALL guards and safety features in place. DISCONNECT POWER SOURCE with machine shut down so electrical crew may adequately clean and inspect motor generators and electrical cabinets. NOTE any discolored electrical parts, it's a sign of overheating. In humid areas, look for fungus and mildew. Dry compressed air at LOW pressure works well for dust removal. Clean corrosion from parts, joints and connections. Retighten, where needed, any loose connections and terminals. Use of proper tool here eliminates broken terminals and terminal blocks. Replace missing or damaged tags and labels. Bundle loose wiring. Fasten ALL components and wiring in cabinets. Check the cable armor tight in the fixture. Look closely where wires and cables pass thru openings and grommets. Insulation damage generally occurs here. Replace grommets if needed. Arcing of motors and generators causes discolored commutators. Look at brushes and brush holder condition. Correct brush spring tension where needed. Collector rings need cleaning and checking also. Use a hand grease gun at each injector. Fill ALL grease lines and purge EACH bearing with MPG. Remember to replace ALL plugs, covers and inspection plates.

This may seem like a lot of running around checking, looking, inspecting, cleaning and then greasing; but this is the machine that makes the payroll possible. Keeping it running is very important.

Passing equipment condition reports along the line is important also. Wear patterns show up at varying degrees in time. Recording and checking these reports at a future date allows comparison and planned shutdowns. Planned repairs, part orders and crews for a scheduled shutdown eliminates idle downtime.

SECTION 1

ENGINEERING DATA INDEX

Bronze Sleeve Bushings

Flange Bushing

Straight Sleeve Bushing

Bushing Life

Bronze Bushing Replacement

Running Clearance for Bronze Bushings

Installation of Oil and Grease Seals.

Split Seals

Gear Case Seal

I nstallation of Vee Type Grease Seals

Surface Preparation.

Adhesive Removal

Adhesive Application

Cured Spline Disassembly

Involute Spline Assemblies Permanent Fit with Adhesive

Installing Anti-Friction Bearings on Shaft Installation of Shrink Fit Pinions

(Sect. 1- Eng. Data cont.)

(Sect. 1- Eng. Data cont.)

Care of Wire Rope cont.: Handling and Installation of Strand Boom Pendants

Common Precautions

Coils Reels The Right Way to Recoil.

The Wrong Way to Uncoil Wire Rope

• Thank you very much for reading the preview of the manual.

• You can download the complete manual from: www.heydownloads.com by clicking the link below

• Please note: If there is no response to CLICKING the link, please download this PDF first and then click on it.